Rotor structure of a drive motor

A technology of rotor structure and driving motor, applied in the direction of magnetic circuit shape/pattern/structure, electromechanical device, electrical components, etc., can solve the problems of increasing direct-axis reactance, affecting motor performance, lack of increase, etc., to improve the salient pole rate , Improve magnet utilization, efficiency and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

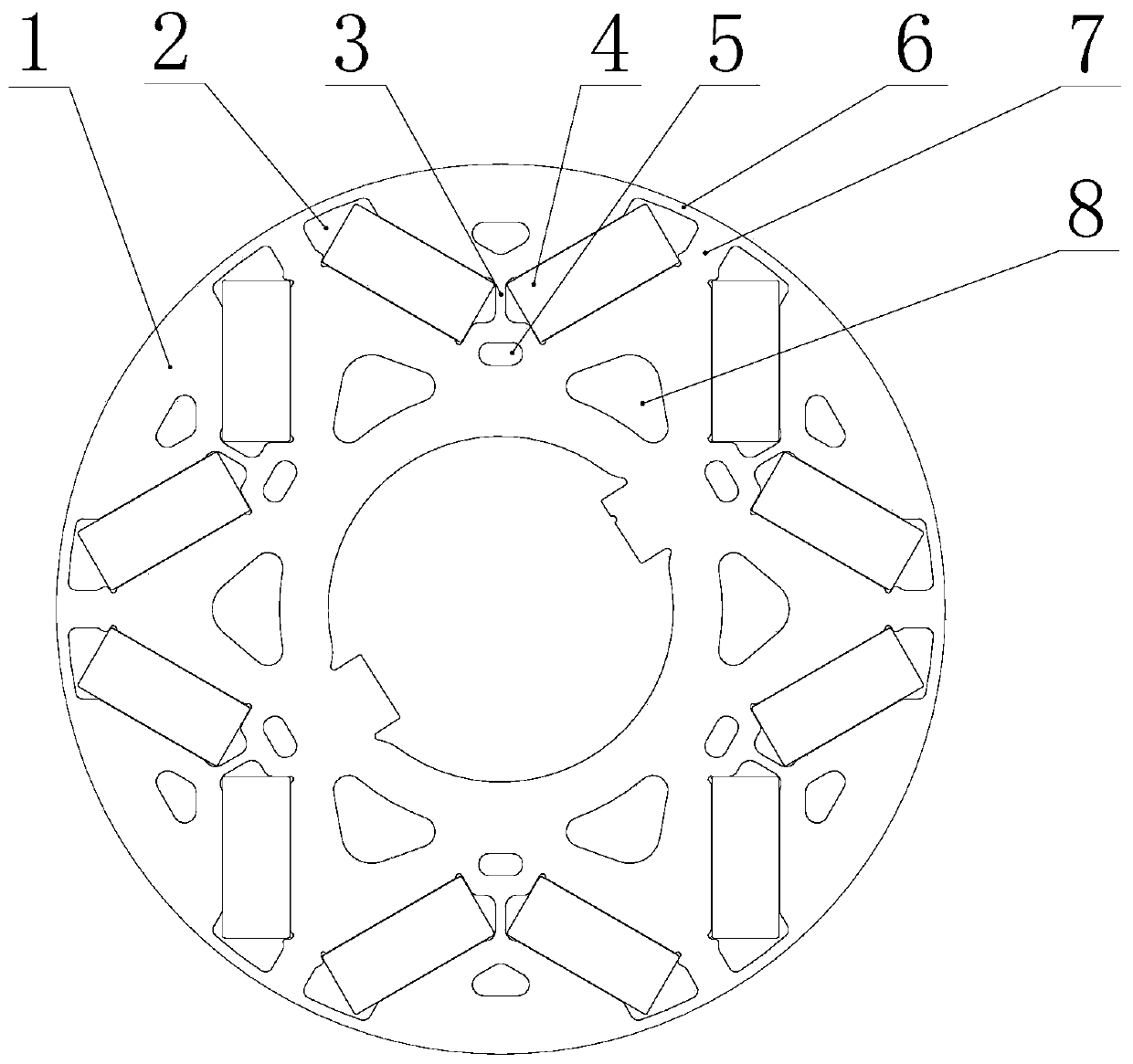

[0018] refer to figure 1 , the embodiment of the present invention provides a rotor structure for driving a motor, including a rotor punch 1, six V-shaped grooves 2 arranged in a circular array on the rotor punch 1, and a straight shaft is arranged in the middle of each V-shaped groove 2 Reinforcing rib 3, a rectangular magnetic steel 4 is inlaid on both sides of each V-shaped groove 2, an unloading hole 5 is opened under the straight axis reinforcing rib 3, and the outer ring of the rotor punch 1 is connected to each V-shaped groove 2. Magnetic isolation bridges 6 are provided at both ends of the groove 2, and an intersecting rib 7 is formed between two adjacent V-shaped grooves.

[0019] A first lightening hole 8 is opened between the two adjacent V-shaped groove groups; a second lightening hole is opened above the straight-axis reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com