Single-stage high-power-factor and low-output-ripple Flyback/Sepic LED driving circuit

A high power factor, driving circuit technology, applied in the direction of DC power input conversion to DC power output, high-efficiency power electronic conversion, output power conversion device, etc., can solve the problem of reducing output low-frequency ripple, loss, and reducing LED service life and other problems, to achieve the effect of eliminating power frequency current ripple, reducing system cost, and strong ripple removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

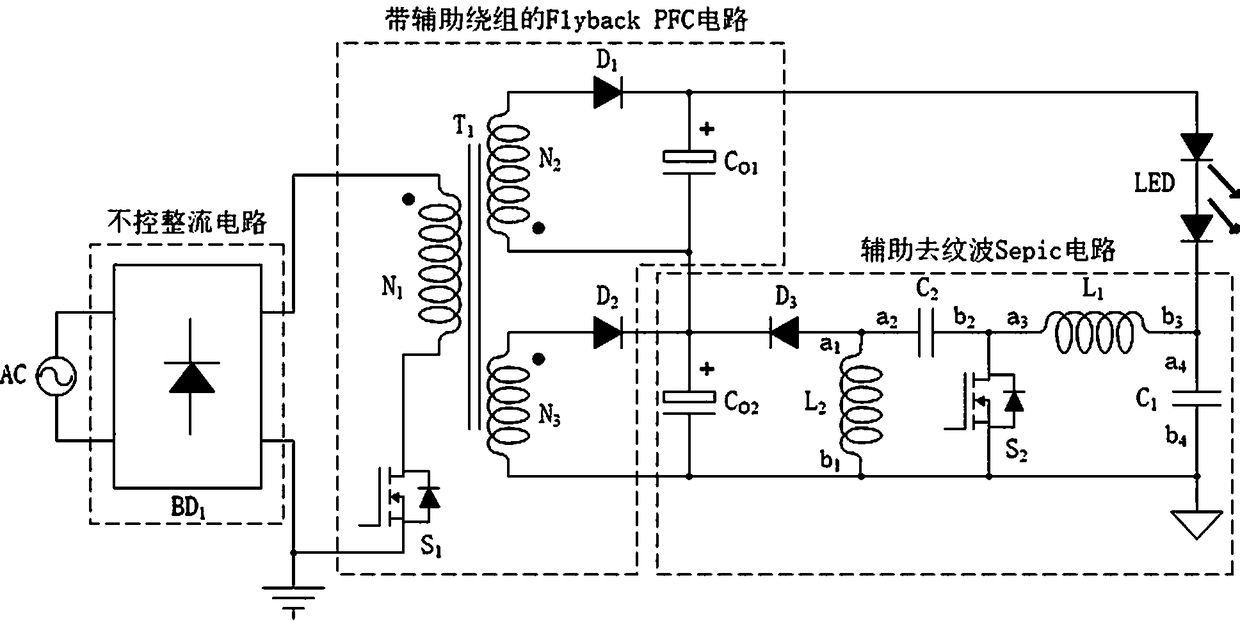

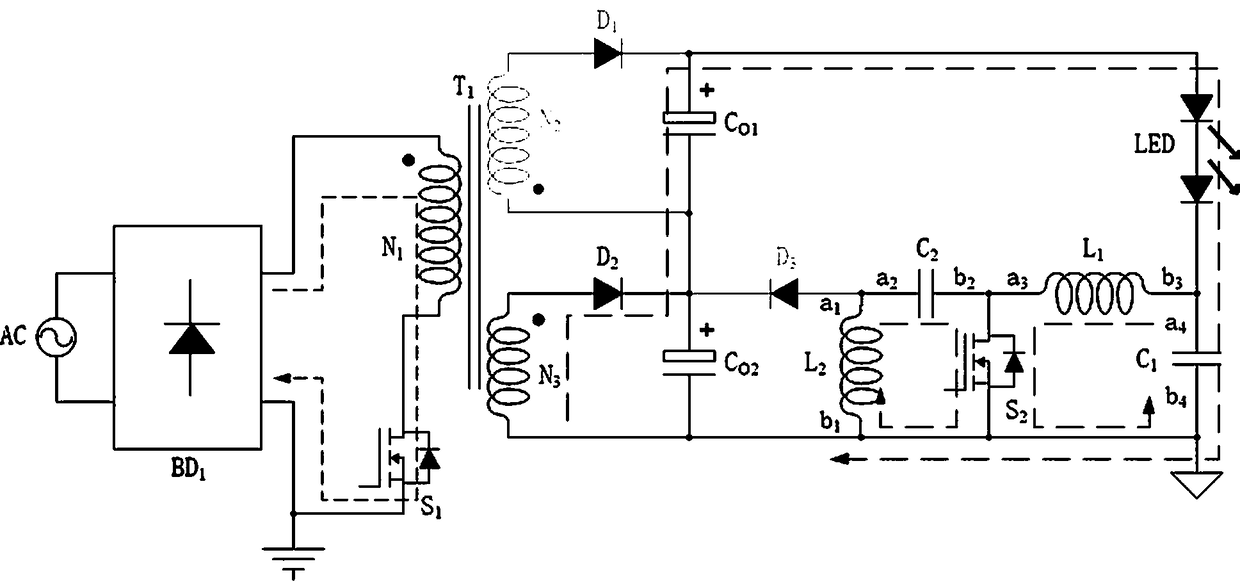

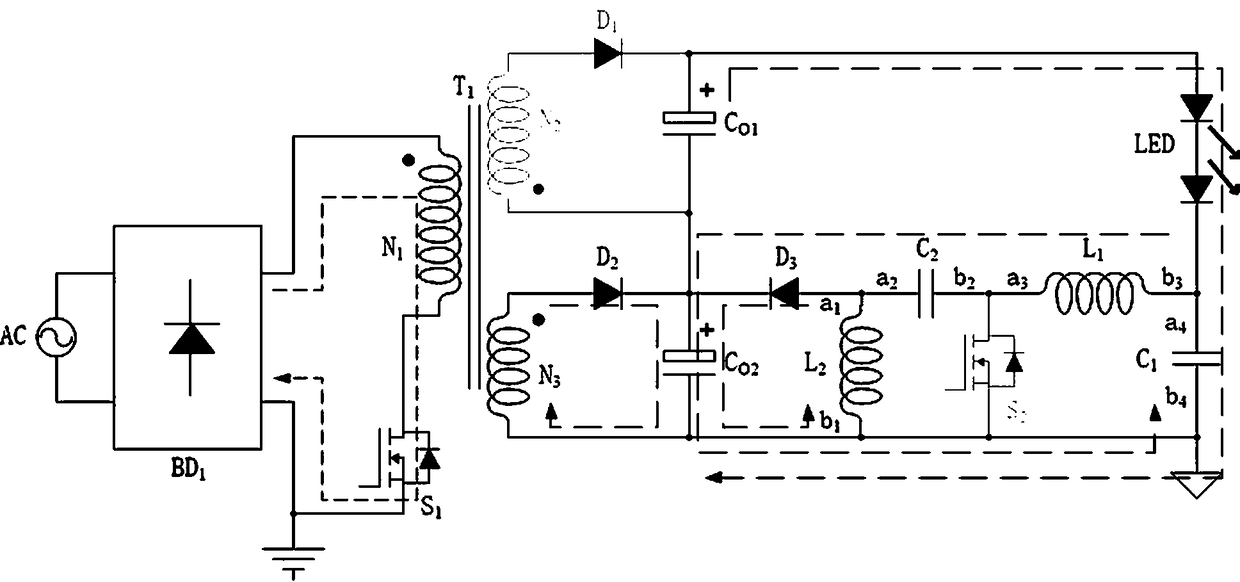

[0025] The present invention provides a single-stage high power factor and low output ripple Flyback / Sepic LED drive circuit, such as figure 1 As shown, including: input AC power supply, diode rectifier bridge BD 1 , Flyback PFC circuit with auxiliary winding and auxiliary de-ripple Sepic circuit; Flyback PFC circuit with auxiliary winding includes: high frequency transformer T 1 , the first power MOS switch tube S 1 , the first power diode D 1 , the second power diode D 2 and the first electrolytic capacitor C o1 ; The auxiliary ripple removal Sepic circuit includes: the second power MOS switch tube S 2 , the third power diode D 3 , the first high frequency capacitor C 1 , the second high frequency capacitor C 2 , the second electrolytic capacitor C o2 , the first high frequency inductance L 1 and the second high frequency indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com