Marine hose status monitoring system

A technology for monitoring systems and ships, applied to pipeline systems, hoses, ship accessories, etc., can solve problems such as damage and inability to grasp deformation, and achieve the effect of avoiding fatal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the state monitoring system of the marine hose of this invention is demonstrated based on embodiment shown in a drawing.

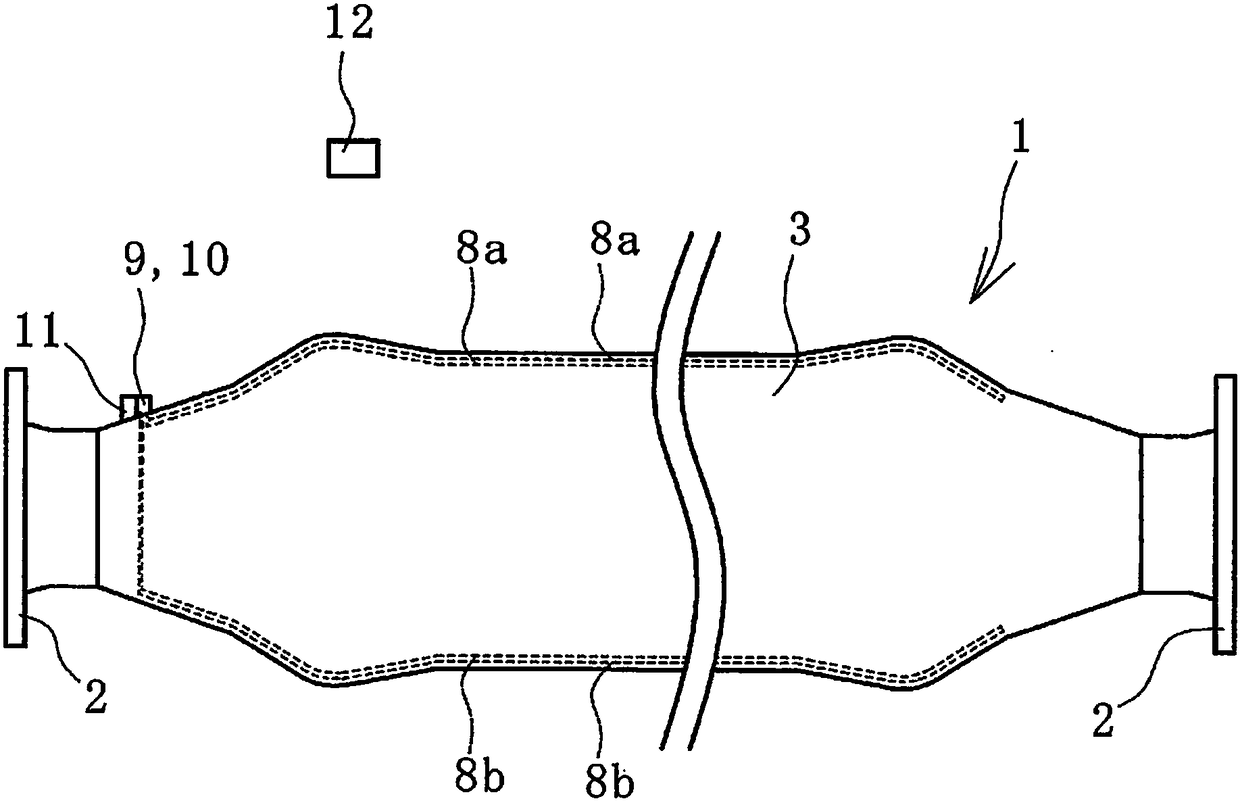

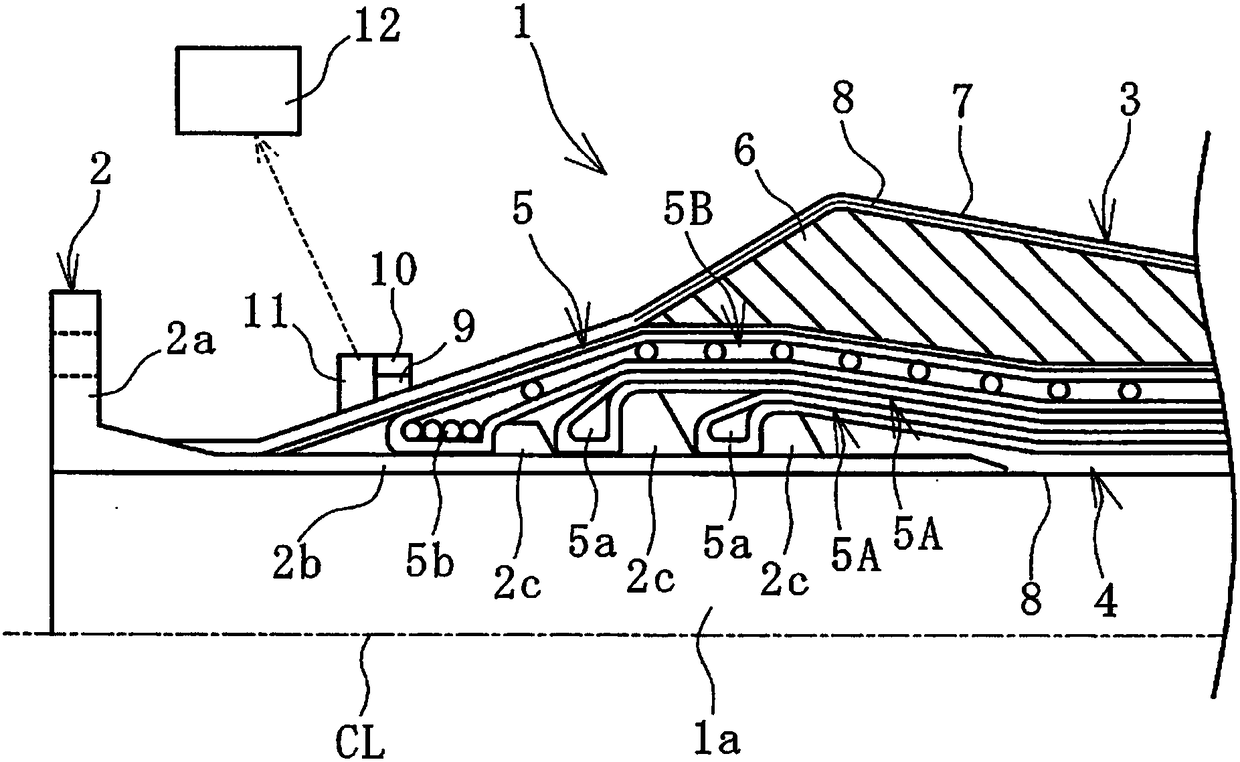

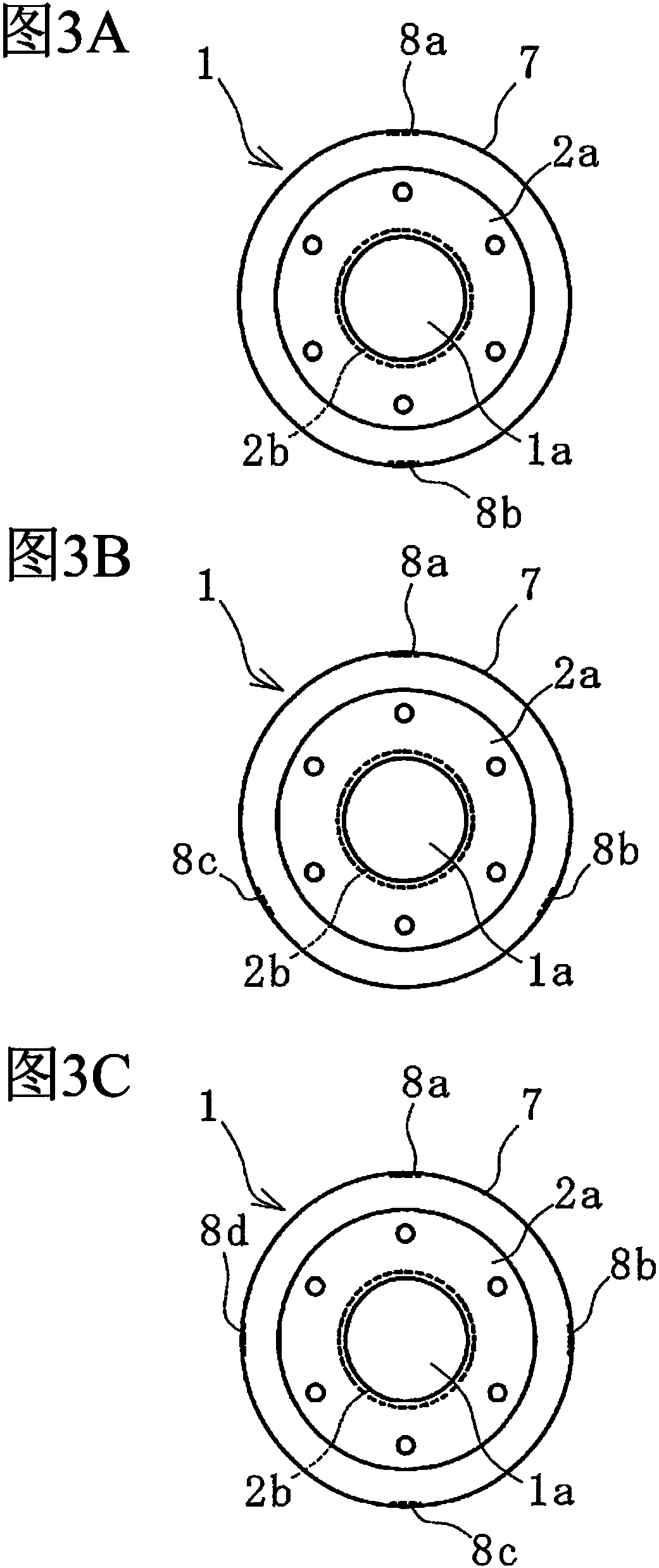

[0027] Figure 1 ~ Figure 3 The exemplified marine hose state monitoring system (hereinafter referred to as a monitoring system) of the present invention includes a specific embodiment of the marine hose 1 , a resistance sensing mechanism 9 for sensing a resistance value, and a storage unit 10 . The marine hose 1 has a hose main body 3 and connecting metal fittings 2 respectively connected to both longitudinal ends of the hose main body 3 .

[0028] The hose main body 3 has: an inner surface layer 4; a reinforcement layer 5 (a main reinforcement layer 5A and a main body wire layer 5B) arranged on the outer peripheral side of the inner surface layer 4; and an outer surface layer 7 arranged on the reinforcement layer 5 the outer peripheral side. Other required members are appropriately provided on the hose main body 3 . Since the marin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com