Novel waste plastic granulation waste gas treatment device

A waste gas treatment device and waste plastic technology, which is applied in the direction of combination device, dispersed particle separation, electrostatic effect separation, etc., can solve the problems that the spray system and valves cannot be automatically opened or closed, and the filter cannot realize the full treatment of waste gas, etc. Achieve the effect of avoiding dangerous situations, reducing harmful substances and improving the degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

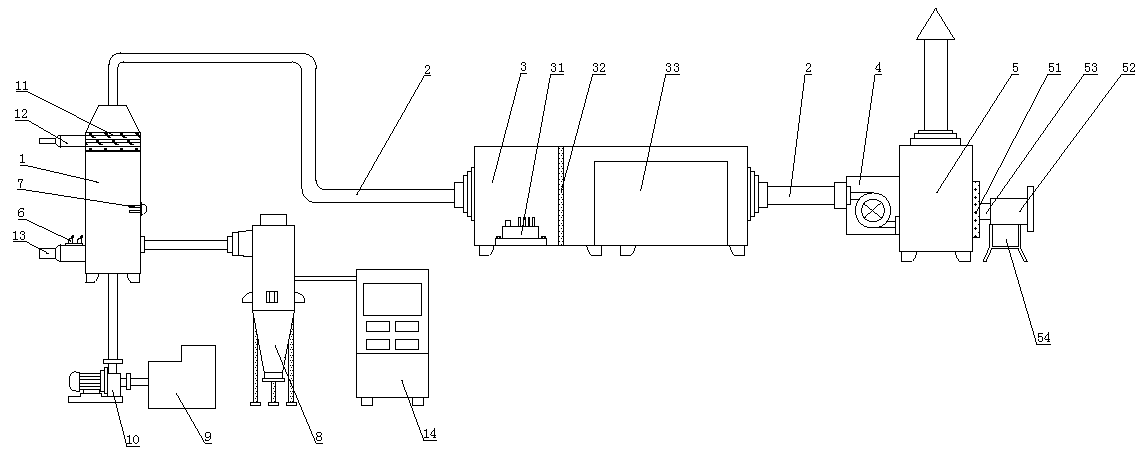

[0011] like figure 1 As shown, a new type of waste plastic granulation exhaust gas treatment device includes a spray tower 1, the spray tower 1 communicates with the filter 3, the explosion-proof fan 4, and the air outlet chamber 5 through the gas pipeline 2, and the spray tower 1 The air inlet 13 is provided with a fire damper 6, a temperature sensor 7 is installed inside the spray tower 1, one side of the spray tower 1 is connected to the cyclone vacuum cleaner 8 through the gas pipeline 2, and an oil-water separation box is arranged under the spray tower 1 9. The oil-water separation box 9 is connected to the bottom of the spray tower 1 through the circulating water pump 10. The upper part of the spray tower 1 is provided with a spray layer 11, and the other side of the spray tower 1 is provided with a through hole, and the water delivery pipe 12 Pass through the through hole to communicate with the spray layer 11; the top of the spray tower 1 is connected to one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com