Rectangular large flange and tube plate seal face machining device and use method

A technology of processing device and large flange, applied in feeding device, metal processing equipment, metal processing machine parts, etc., can solve the problem of large size of tube sheet and flange cover, inability to process square flange sealing surface, dimensional tolerance, shape and position Tolerance and surface roughness have high requirements and other issues to achieve the effect of ensuring machining accuracy, easy transformation, and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

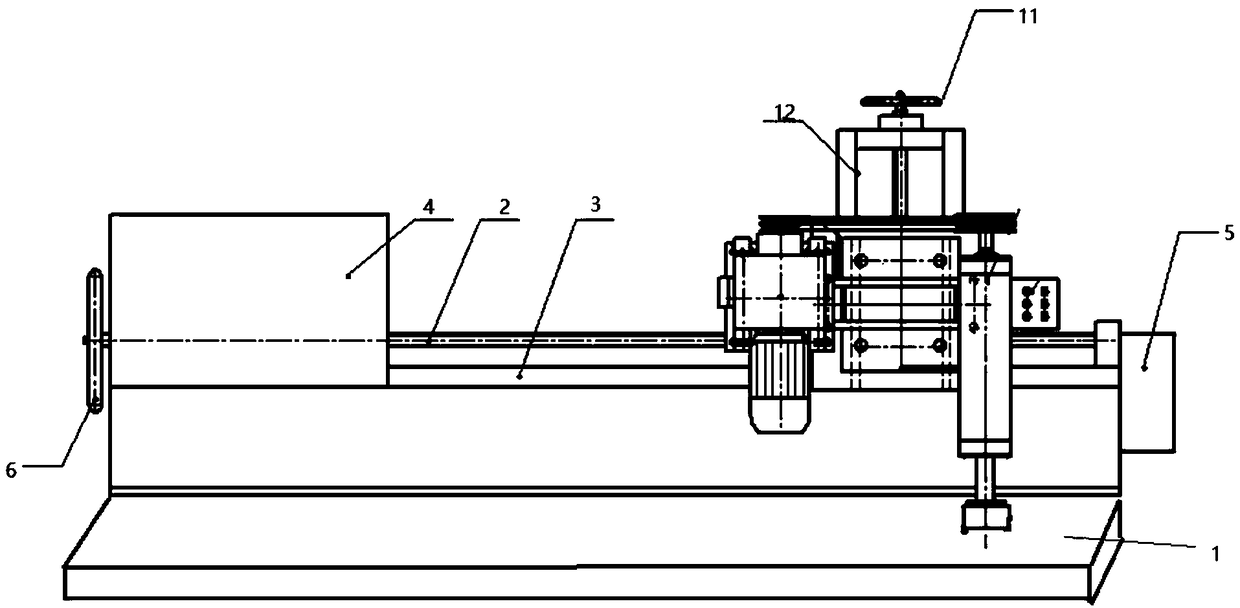

[0035] Such as figure 1 Shown is a preferred embodiment of a rectangular large flange and tube sheet sealing surface processing device of the present invention, including a milling mechanism, a vertical height adjustment mechanism, a horizontal milling feed mechanism and a platform 1; the milling mechanism is used for milling workpieces; the vertical The height adjustment mechanism is connected with the milling mechanism to adjust the vertical height of the cutter head of the milling mechanism; the horizontal milling feed mechanism is connected with the vertical height adjustment mechanism and is configured to regulate the horizontal milling feed speed of the milling mechanism and the vertical height adjustment mechanism; the platform is It is configured to fix the workpiece to be processed and adjust the position of the workpiece to be processed.

[0036] In the present invention, the workpiece is fixed on the platform, and the vertical stroke of the vertical height adjustmen...

Embodiment 2

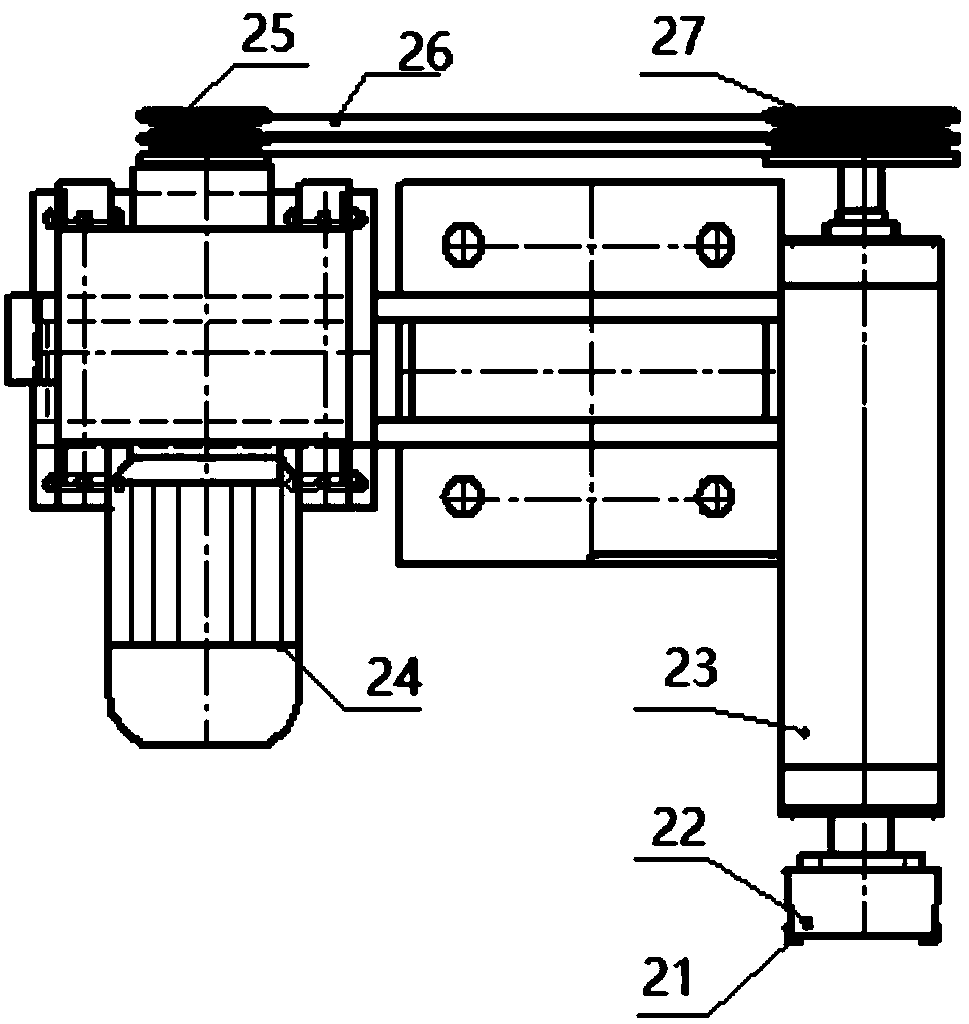

[0043] figure 2 Shown is a schematic diagram of the milling mechanism of another preferred embodiment of the present invention.

[0044]At present, there are two main types of speed change for the spindle drive of lathes: one is the spindle motor with gear shifting, the purpose is to reduce the spindle speed and increase the transmission ratio to meet the needs of cutting; the other is the spindle motor through the synchronous toothed belt or V Driven main shaft, this type of driving method does not require mechanical shifting, and the gear and clutch are omitted in the main shaft box, which simplifies the main transmission system and improves the reliability of the transmission chain.

[0045] Considering that the processing of the rectangular and large-sized tube plate sealing surface generally has a small center distance and a large transmission ratio, and the milling process is required to be as smooth as possible without vibration, this embodiment uses a V-belt to drive ...

Embodiment 3

[0048] image 3 It is a schematic diagram of the platform of another preferred embodiment of the present invention.

[0049] In this embodiment, the platform 1 includes a working platform and an adjustment mechanism; the working platform is connected to the adjustment mechanism, and a T-shaped groove, a compression bolt and a nut are arranged on the surface, and the workpiece to be processed is fixed by the T-shaped groove, the compression bolt and the nut; the adjustment The mechanism includes a screw mandrel and a screw nut. Based on the relative positions of the screw mandrel and the screw nut, the center line of the workpiece to be processed on the working platform is adjusted to be on the same straight line as the horizontal feed direction of the cutter head chuck 22 of the milling mechanism. image 3 Among them, the left part is the front view of platform 14, and the right part is the left view of platform 1.

[0050] In order to better configure the positional relation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com