Ship water inlet passage and manufacturing and installation method

A technology of water inlet channel and manufacturing method, which is applied in the direction of ship propulsion, ship parts, propulsion parts, etc., can solve the problems of increasing the workload of the berth and prolonging the construction period of the berth, so as to improve the integrity of the sections, shorten the construction period, and ensure The effect of margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

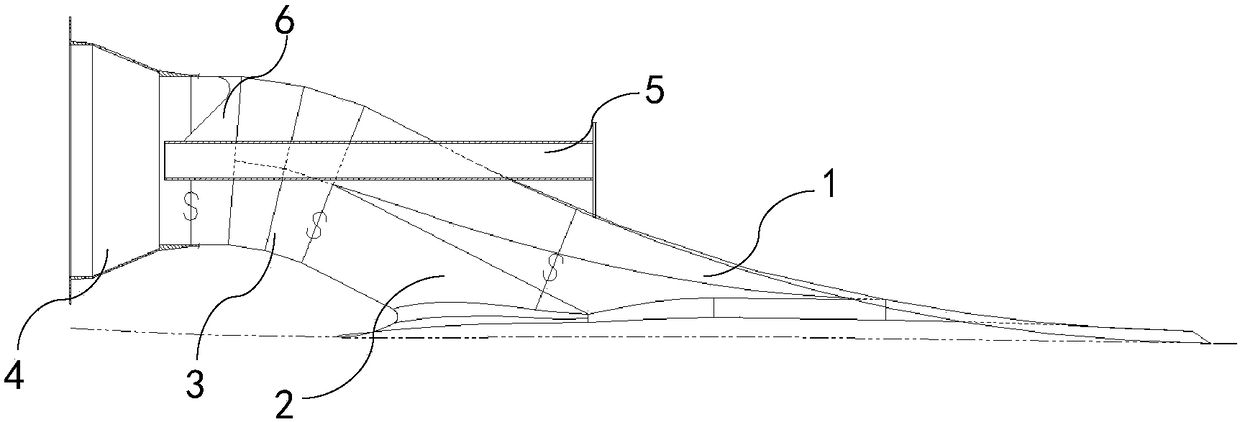

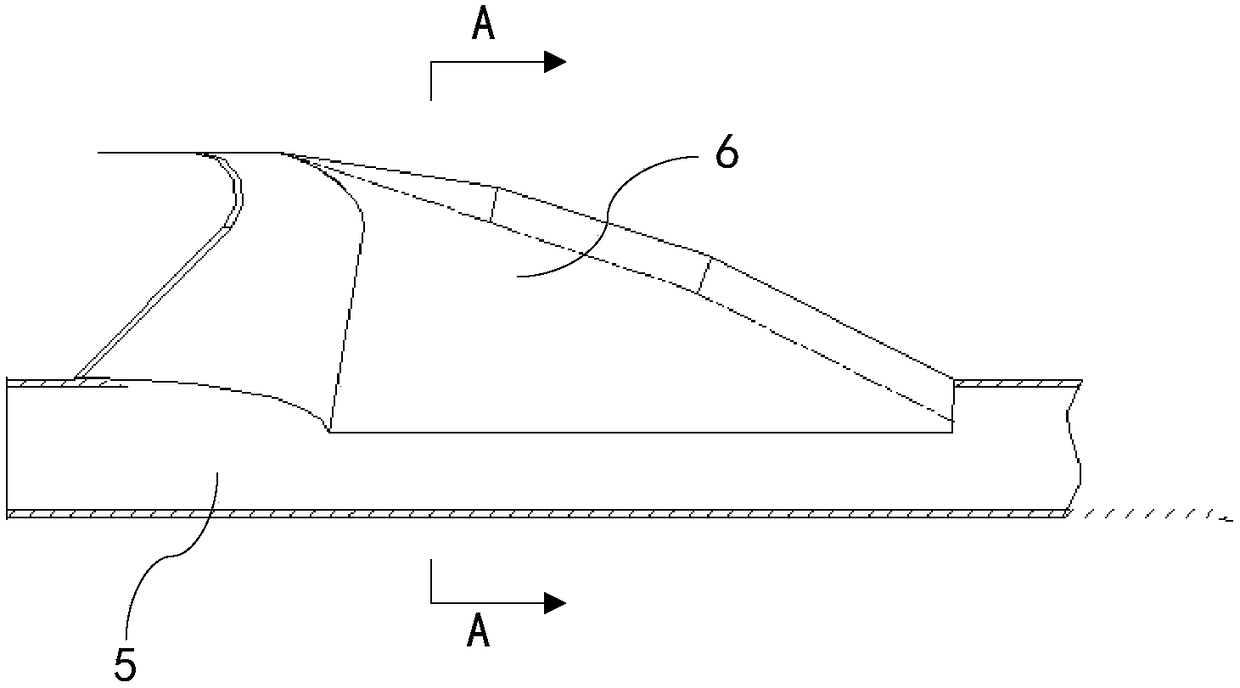

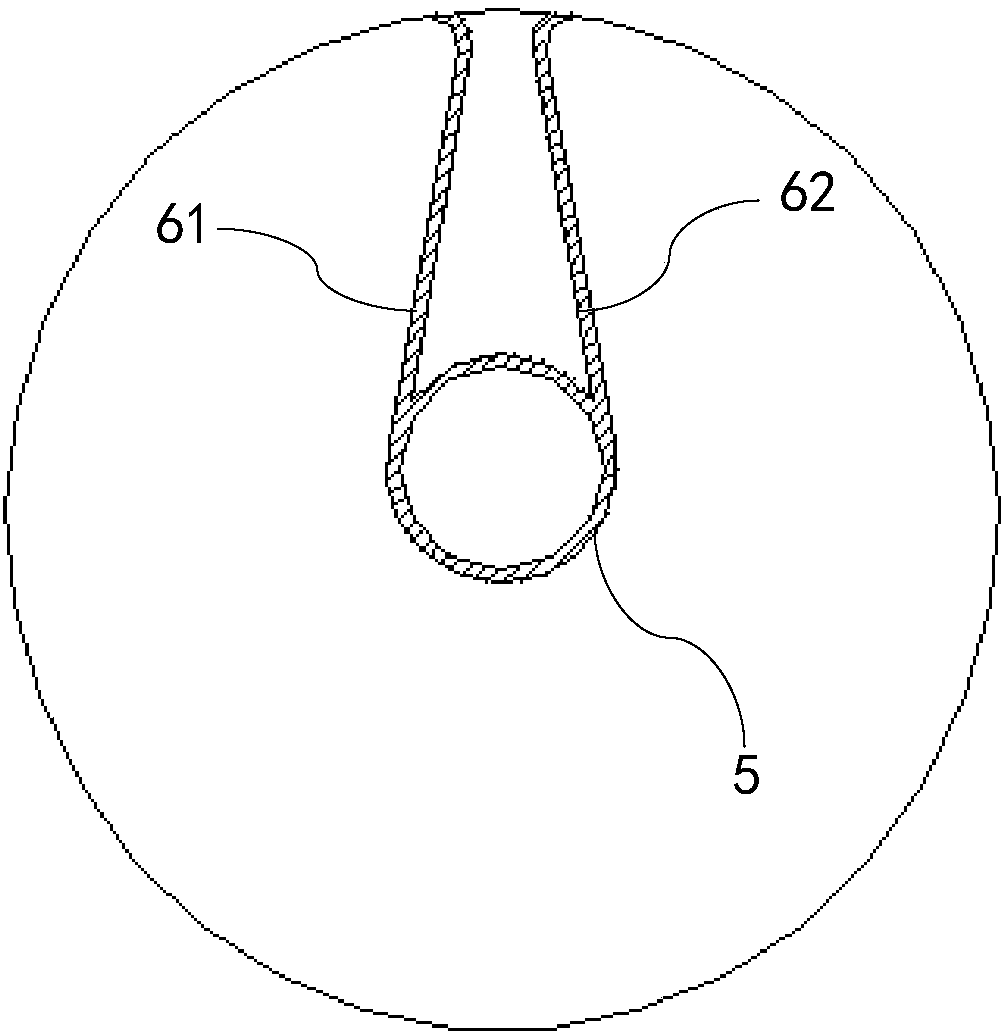

[0028] Please refer to the attached Figure 1-9 , a ship water inlet channel provided by the present invention, which includes a water inlet channel first zone part 1, a water inlet channel second zone part 2, and a curved cylindrical elbow part connected in sequence along the water flow direction 3 and the spout part 4; it also includes a stern shaft protection tube 5 parallel to the horizontal plane passing through the second area part 2 of the water inlet channel and connecting the stern shaft protection tube 5 and the elbow part 3 Anti-resonance sheet 6 on the top of the inner surface.

[0029] Based on the above technical features, by dividing the ship’s water inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com