Full-automatic boxing machine

A cartoning machine, fully automatic technology, applied in packaging and other directions, can solve problems such as low degree of automation, increased labor intensity and production cost, and inability to form easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

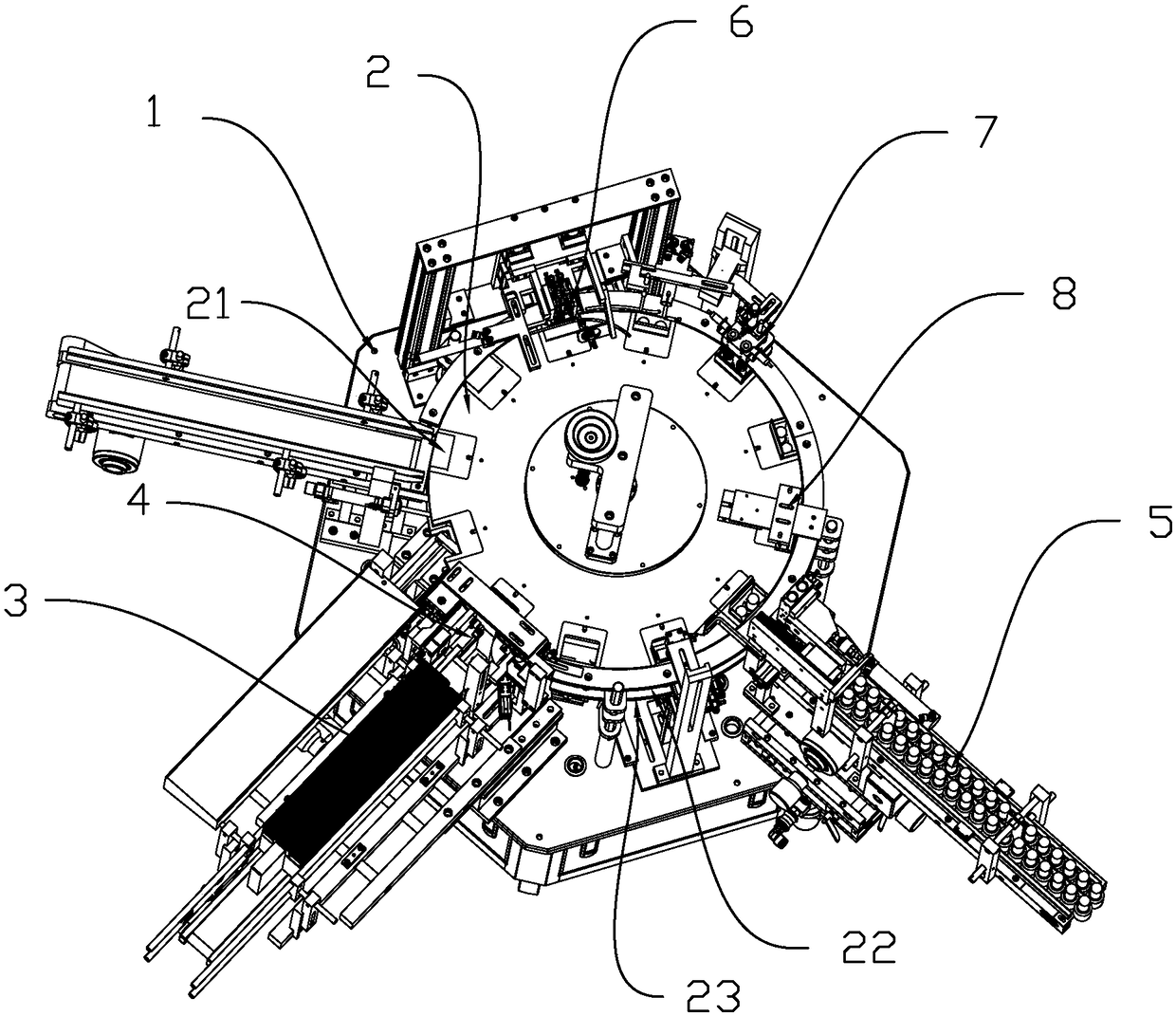

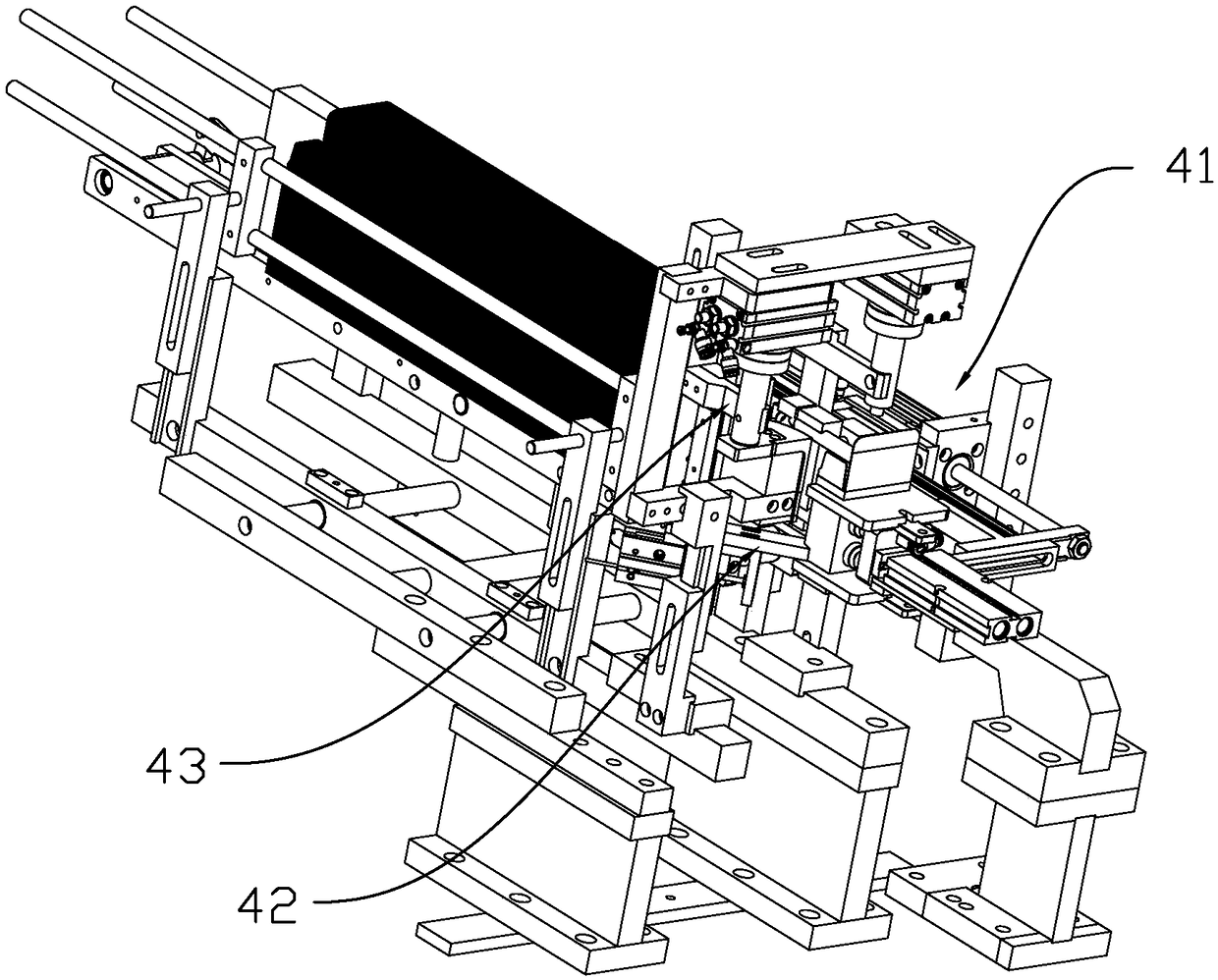

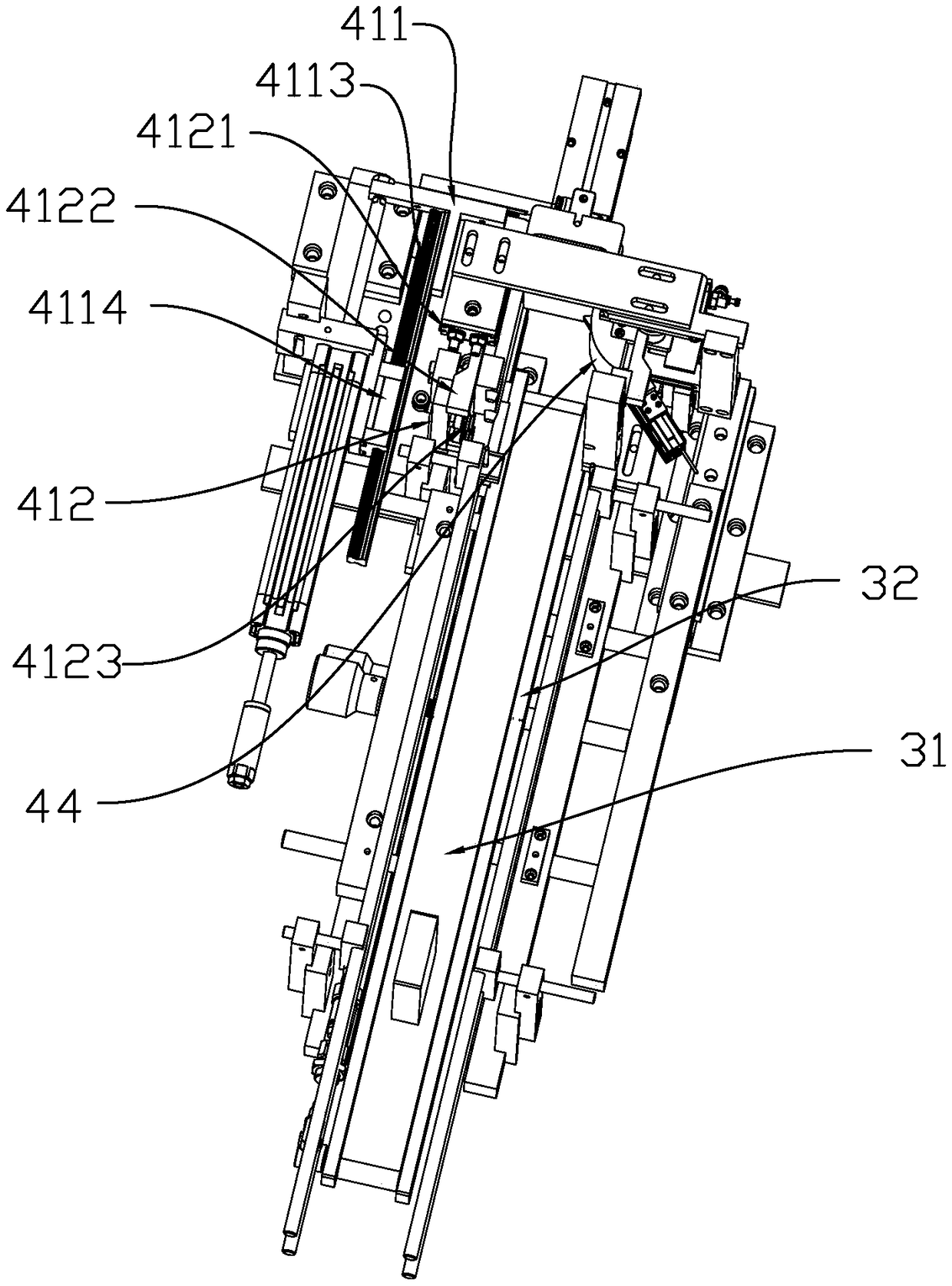

[0043] Specific embodiments of the present invention such as Figure 1-17 As shown, a fully automatic cartoning machine includes a frame 1, a turntable 2, a green sheet conveying device 3, a green sheet forming device 4, a box loading device 5 and a box sealing device 6, and the turntable 2 is provided with a The box body clamping cavity 21 evenly distributed in the circumferential direction, the embryo conveying device 3 includes a embryo conveying belt 31 and embryo limit rods 32 arranged on the corresponding two sides of the embryo conveying belt 31, the embryo forming device 4 includes a suction cup assembly 41, a push rod assembly 42 and a limit assembly 43. The suction cup assembly 41 includes a rear side suction cup mechanism 411 and a front side suction cup mechanism 412. The rear side suction cup mechanism 411 includes a first driving member 4111 and a first driving member 4111 Linked first suction cup 4112, the first driving member 4111 is an air cylinder or oil cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com