Automatic chemical tablet material transporting, gathering and distributing device

An automatic transportation and material technology, applied in transportation and packaging, conveyor control devices, conveyors, etc., can solve the problems of lagging process production automation, high personnel costs, environmental hazards to the occupational health of workers, and achieve the elimination of pungent gases and micro-particle hot dust harmful emissions, solve the effect of manual material collection, reduce staff and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

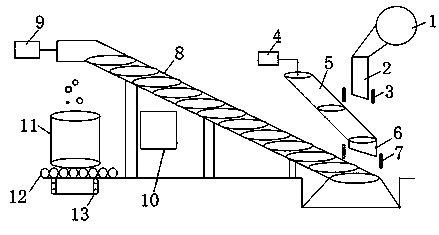

[0015] Refer to attached figure 1 , an automatic transport and distribution device for chemical tablet materials, including a disc feeder 1, a hopper A2, a beam feeder A3, a screw feeder 5, a hopper B6, a beam grating B7, and a chain conveyor bucket 8 , material collection barrel 11 and weighing conveying roller table 12, disc feeder 1 is provided with discharge hopper A2, discharge hopper A2 is provided with opposite beam grating A3, screw feeder 5 is provided with feed hopper and discharge hopper B6, The discharge hopper A2 of the disc feeder 1 is matched with the feed hopper of the screw feeder 5, and the discharge hopper B6 of the screw feeder 5 is provided with an anti-radiation grating B7, and the chain conveyor 8 is arranged obliquely. The lower end of the conveyor bucket 8 is the receiving end, the higher end of the chain conveyor bucket is the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com