Iron comprising an ironing surface, a heating plate and a vaporisation chamber

A technology for heating the soleplate and the evaporation chamber, which is applied in the direction of hand irons, textiles and papermaking, washing devices, etc., can solve the problems of complicated and expensive manufacturing, and does not allow the wetting of fabrics, and achieves the effect of avoiding overheating and improving ironing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

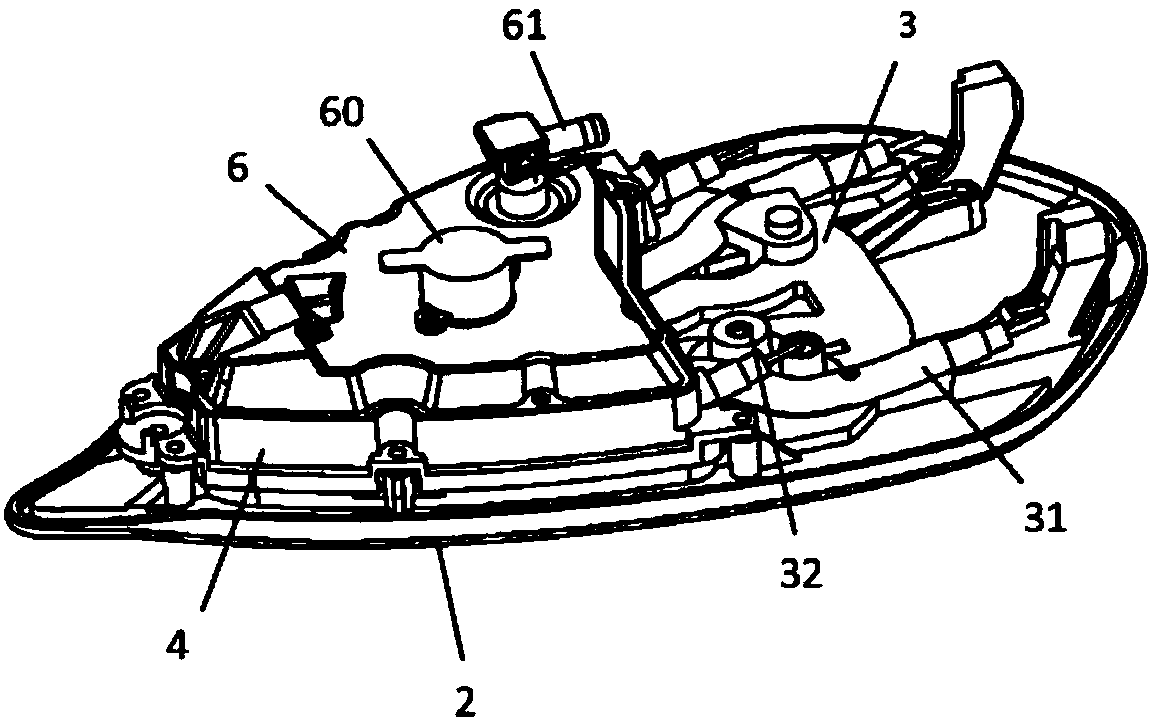

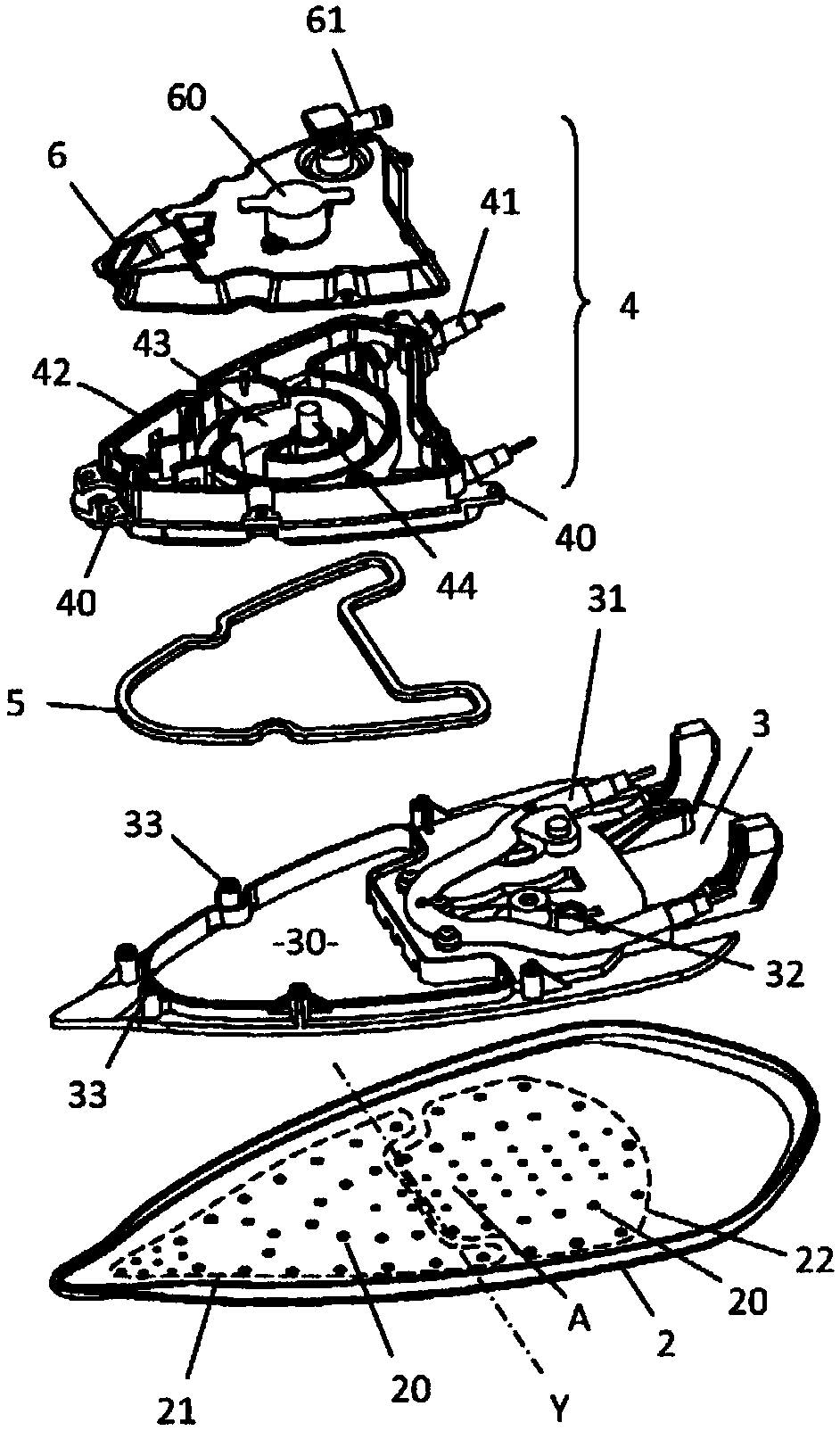

[0071] Only elements necessary for an understanding of the invention are shown. In order to facilitate the reading of the drawings, the same elements in different drawings use the same symbols.

[0072] It is worth noting that in this document the terms "horizontal", "vertical", "lower", "upper", "front", "rear" are used to describe irons This iron is in use with the plate placed on a horizontal surface.

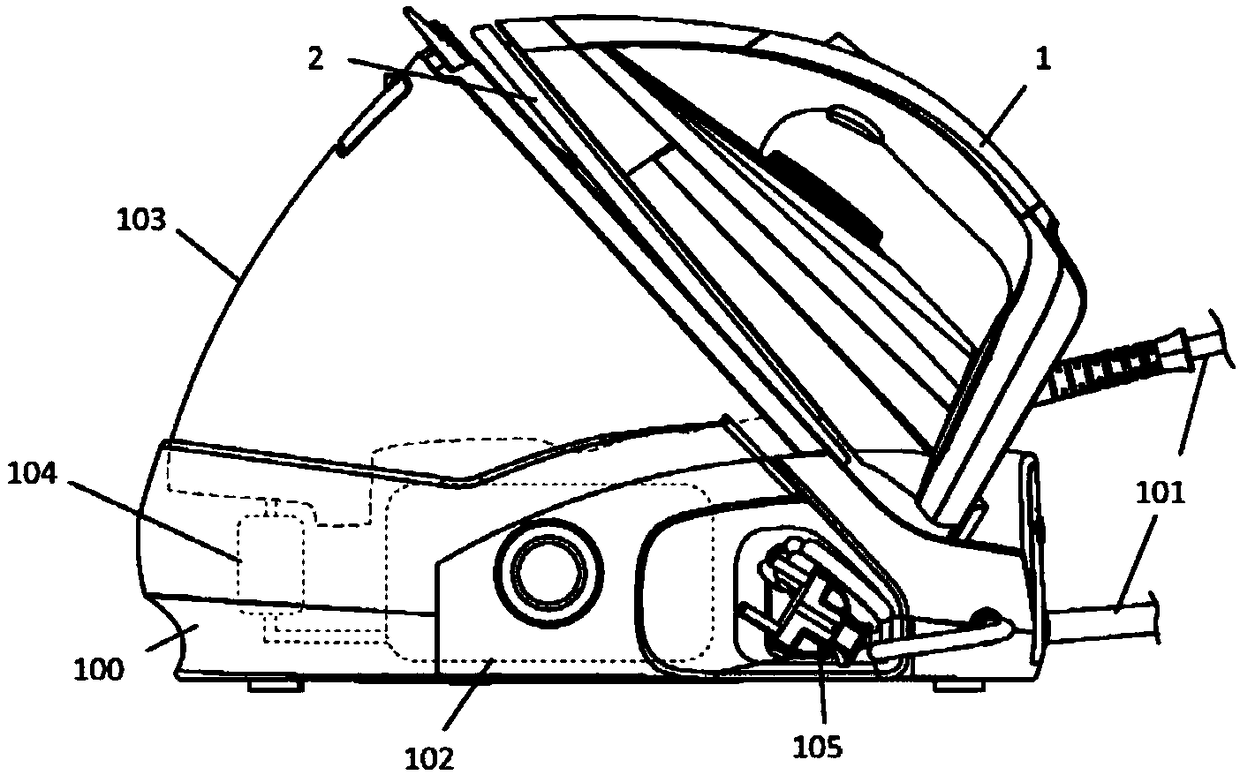

[0073] figure 1 Shown is an ironing appliance comprising a steam generating base 100 connected to each other by a conduit 101 and an iron 1 comprising a housing realized in plastic material with an integrated grip handle.

[0074] The base 100 comprises an inclined plane against which the iron 1 can rest during the non-operating phase of ironing, and which comprises, in a known manner, means for generating approximately 4 to 6 A tank 102 of steam at a pressure of bar, said tank 102 being supplied with water from a container 103 by means of a pump 104 .

[0075] The base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com