FBG (fiber bragg grating) stay cable force monitoring sensor based on frequency method, and sensing method

A technology for monitoring sensors and cable force sensors, which is applied in the field of fiber grating type cable force monitoring sensors, can solve the problems of cable structures that have not been considered for installation, can no longer remove anchors, cannot be installed or replaced, and achieve electromagnetic resistance Strong interference ability, convenient installation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

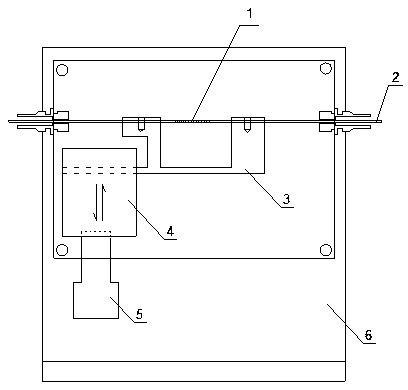

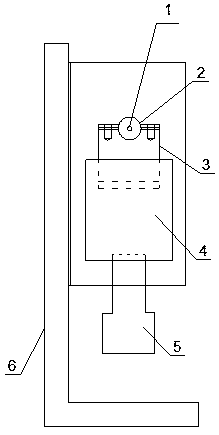

[0028] The basic technical idea of the present invention is to install the fiber grating type cable force sensor on the surface of the cable through a special base to capture the vibration signal of the cable, monitor and analyze the vibration characteristics and force of the cable, and equip it with special visualization application software to form a Set of long-term online monitoring system.

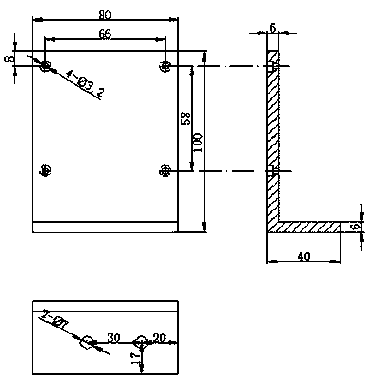

[0029] (1) Installation of the cable force meter: the optical fiber grating type cable force sensor is installed at the midpoint of the length direction of the cable body, and the special base is L-shaped. First, the cable force sensor is fixed to the installation base by 4 M3 screws. There are two 7mm diameter mounting holes on the lower side, which can be used to lock the sensor as a whole, and then the long side of the base is directly pasted on the surface of the cable body with solid glue. The overrange of the accelerometer is easy to cause damage, so the limit screw must be lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com