Constant-head multidirectional seepage test device for bituminous mixture

A technology of asphalt mixture and testing device, which is applied in the direction of measuring device, analysis material, permeability/surface area analysis, etc. It can solve the problem of inability to test lateral seepage, inability to achieve constant high water head pressure, and difficulty in realizing pure lateral water flow in asphalt pavement Seepage and pure vertical seepage test and horizontal-vertical coupling seepage test and other issues, to achieve good consistency and ensure the effect of unity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

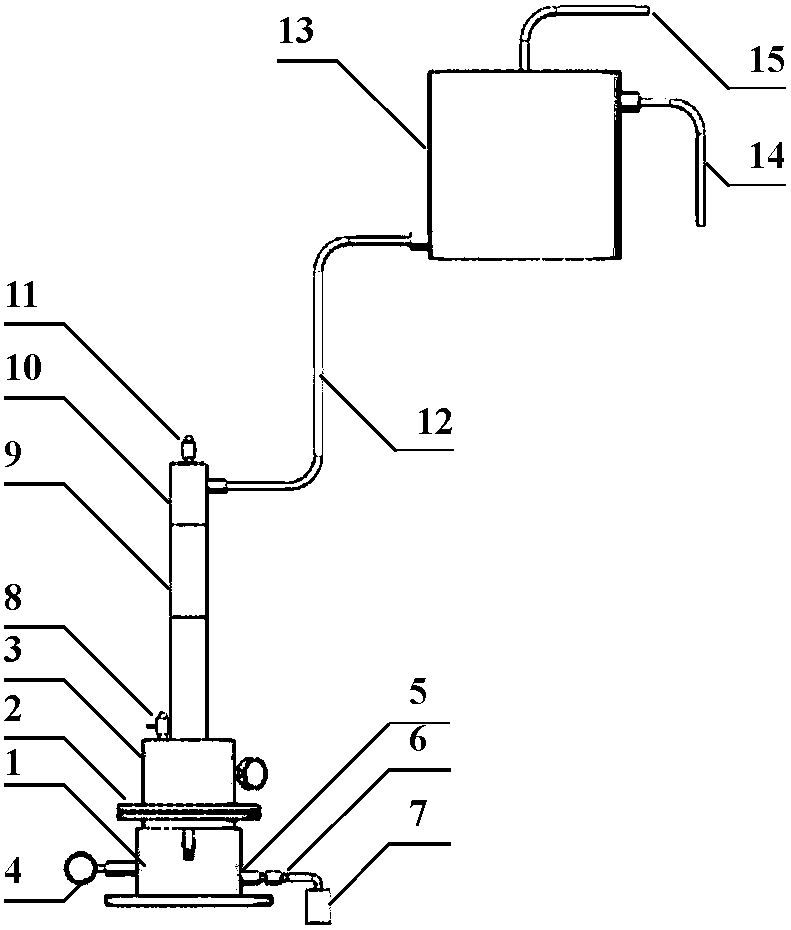

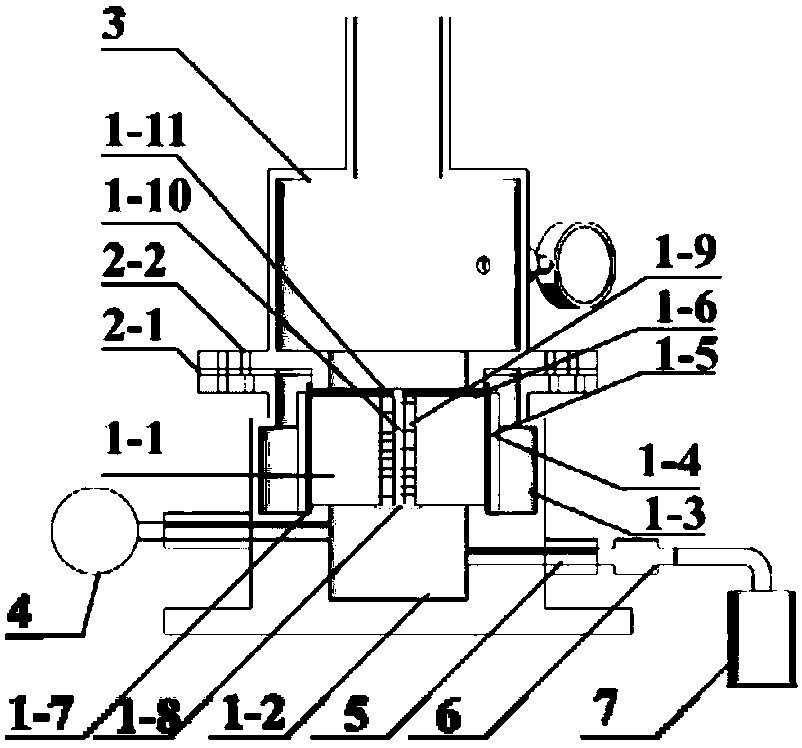

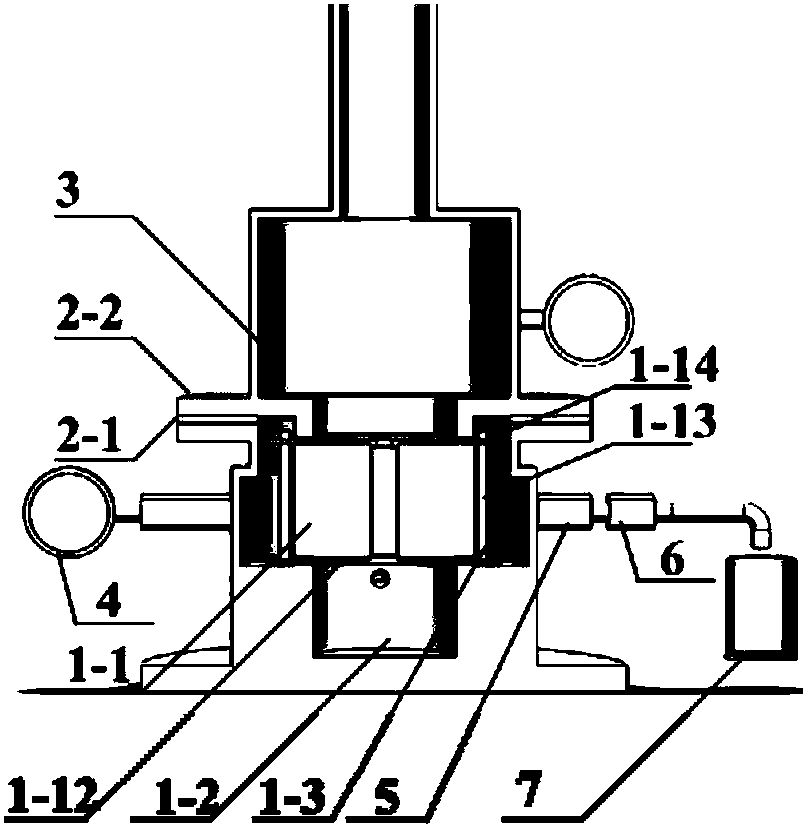

[0017] Specific implementation mode one: combine Figure 1 to Figure 5 To illustrate this embodiment, a multi-directional seepage test device for asphalt mixture with constant water head described in this embodiment includes a lower chamber 1 of the seepage mechanism, a connecting piece 2 for the upper and lower chambers of the seepage mechanism, an upper chamber 3 of the seepage mechanism, and a seepage outlet 5 , cut-off valve 6, measuring cylinder 7, connecting sleeve 9, end sleeve 10, water tank connecting pipe 12, constant water head supply water tank 13, constant pressure drain pipe 14 and water supply pipe 15, the lower cavity 1 of the seepage mechanism passes through the seepage mechanism The upper and lower chamber connectors 2 are connected to the upper chamber 3 of the seepage mechanism, the seepage outlet 5 of the lower chamber 1 of the seepage mechanism is connected to the measuring cylinder 7 through the water cut-off valve 6, and the lower end of the connecting p...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1 to Figure 5 To illustrate this embodiment, a multi-directional seepage test device for asphalt mixture with constant water head described in this embodiment further includes a hydraulic pressure gauge 4 installed on the lower cavity 1 of the seepage mechanism. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 5 To illustrate this embodiment, a multi-directional seepage test device for asphalt mixture with constant water head described in this embodiment also includes an exhaust valve 8 for the upper cavity of the seepage mechanism, and the exhaust valve 8 for the upper cavity of the seepage mechanism is installed in the upper cavity of the seepage mechanism on the upper surface of body 3. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com