Stud connection-based steel-concrete composite beam calculation model analysis method

A technology of calculation model and analysis method, which is applied in the field of simplified analysis of stud shear connectors and calculation model analysis of steel-concrete composite beams based on stud connections, can solve problems such as limiting the promotion of steel-concrete composite structural beams, To achieve the effect of convenient quantitative analysis, strong practicability, and intuitive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

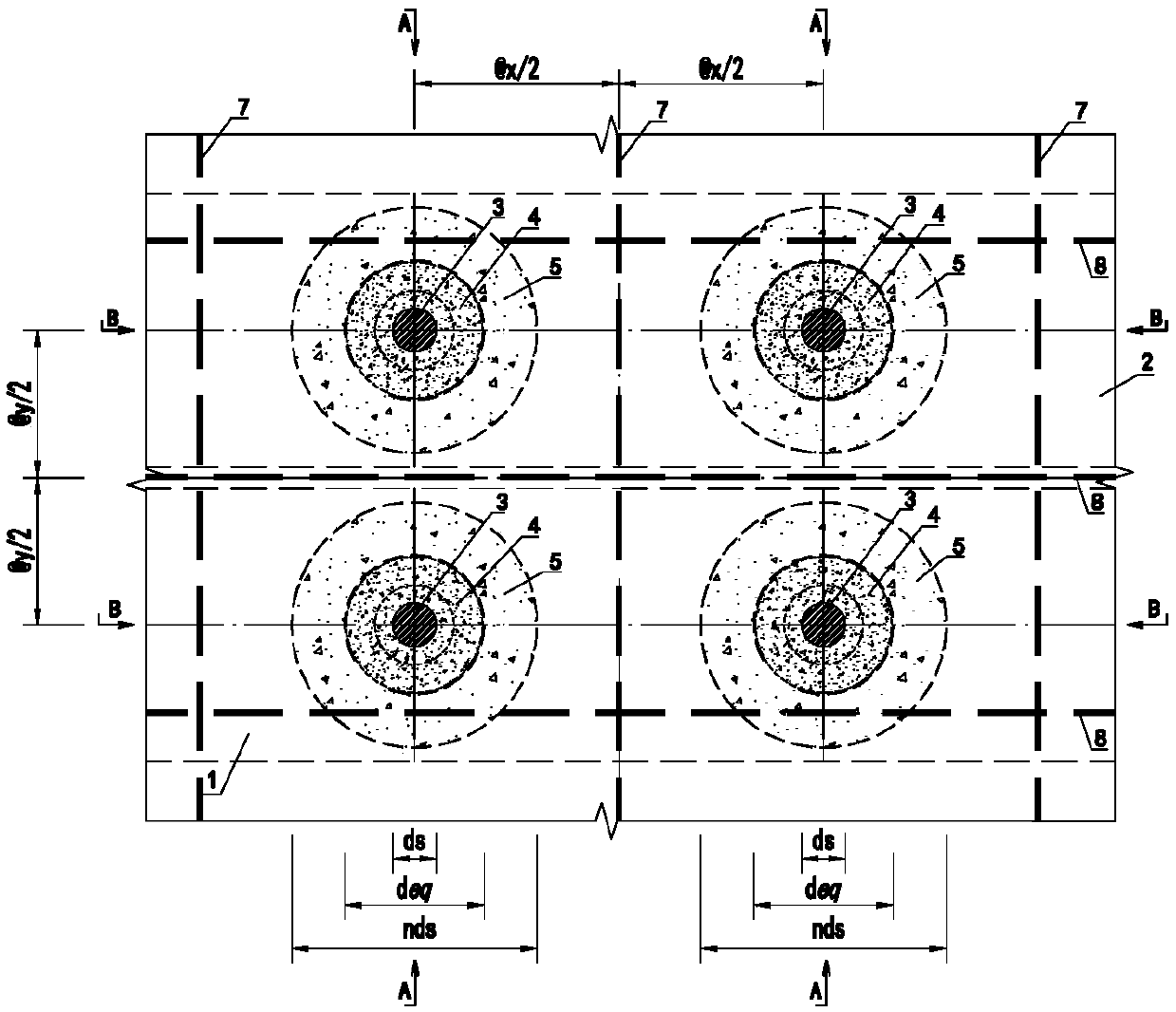

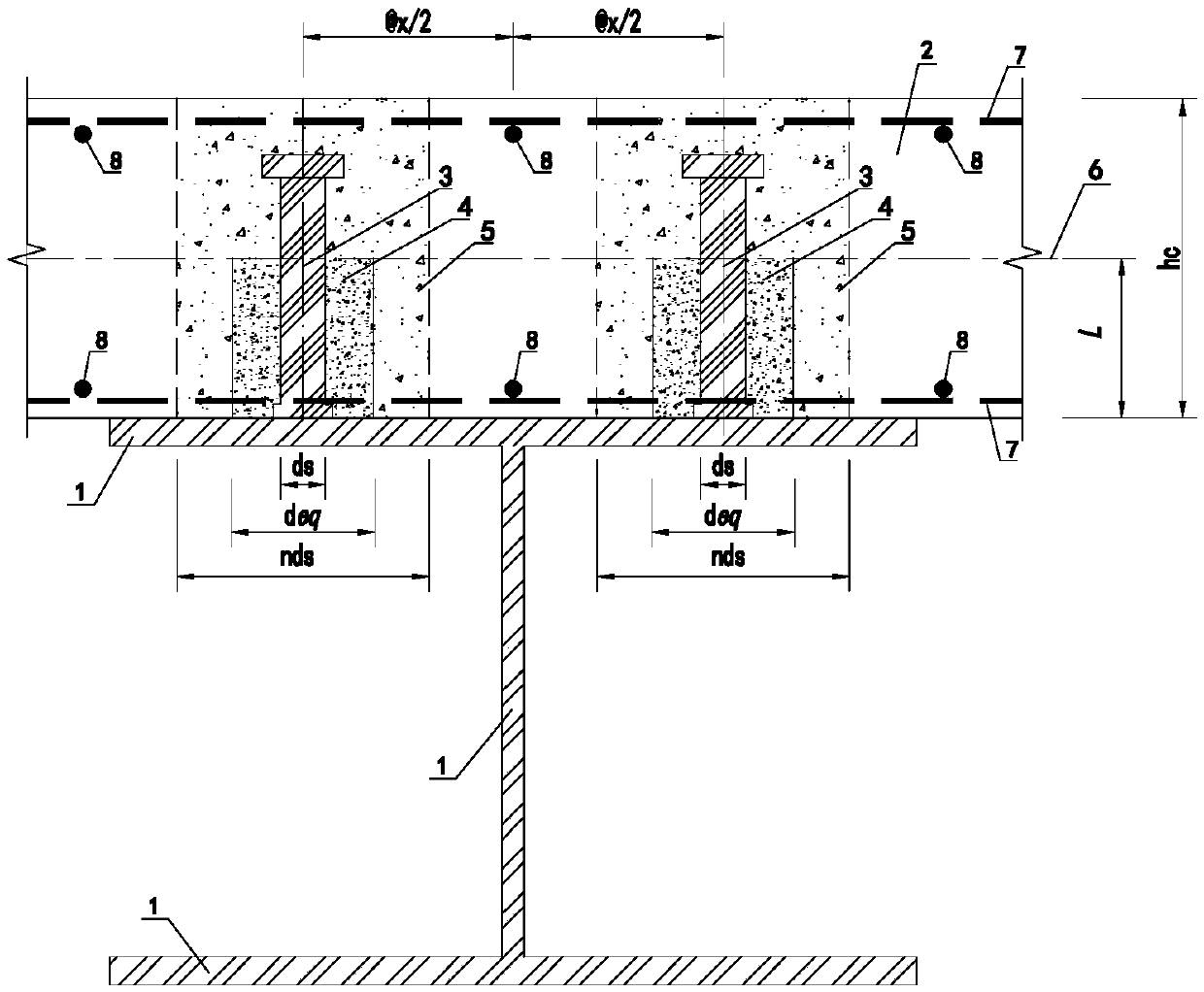

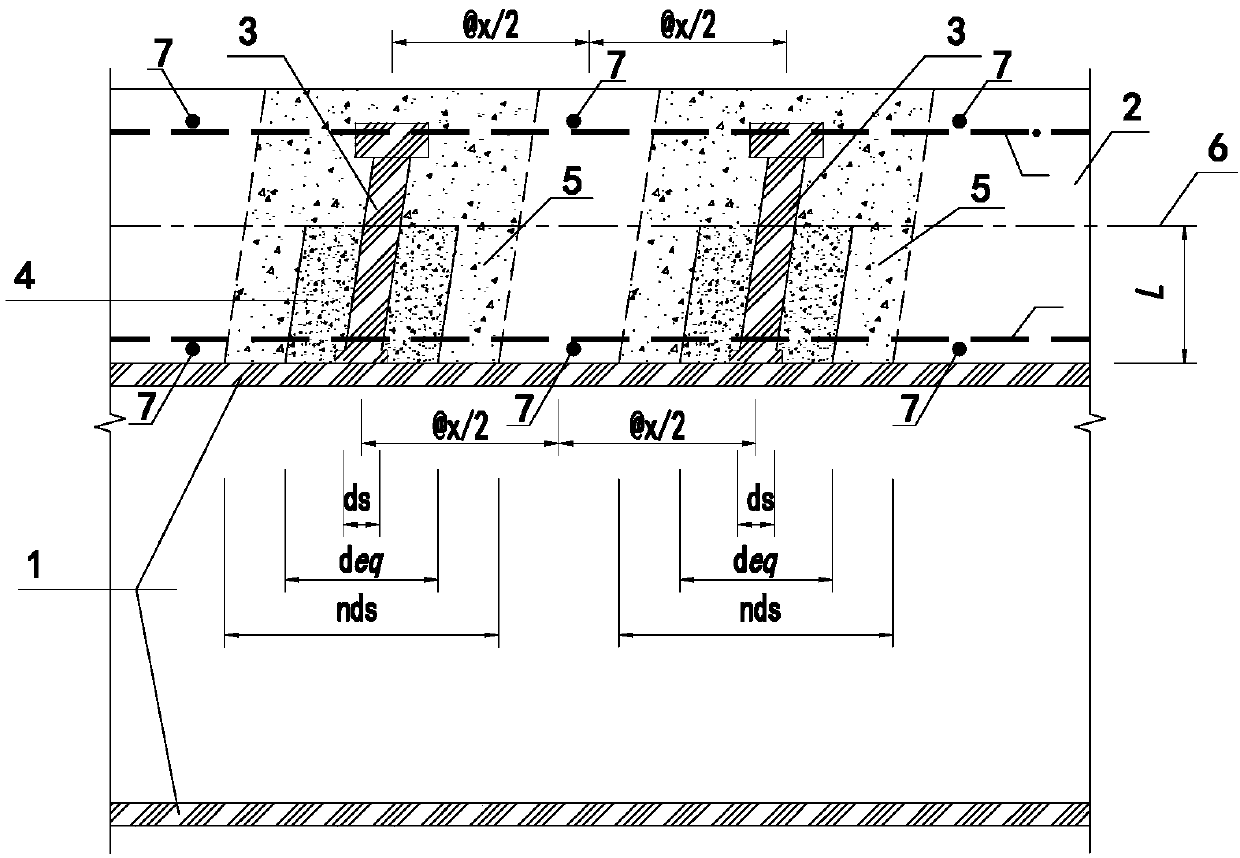

[0143] Example 2, please refer to Figure 6 , Figure 7 and Figure 9 , the parameters of the flange plate of the reinforced concrete slab in the "box" simply supported composite beam are: slab thickness 120mm, width 800mm, C40concrete f ck =26.8N / mm 2 ,E c =3.25x10 4 N / mm 2 , the steel is Q235B, f s =235N / mm 2 ,E s =2.06x10 5 N / mm 2 ;

[0144] Among them, SCBB-1, the diameter d of the stud is used s =16@100, according to the equivalent diameter d in Table 1 eq = 23, the finite element analysis model is established in the MIDAS general finite element program, and its mid-span load-deflection (P-f) curve is as follows Figure 9 .

[0145] The span height of the composite beam is L / h=4.0 / 0.54=7.4, and the shear connection nf=0.55. Since there is no original data, the difference between the simulated value and the experimental value cannot be known, but according to literature and papers, the deflection-span ratio is 1 / When the stiffness is less than 500, the nume...

Embodiment 3

[0147] Embodiment three, please refer to Figure 6 , Figure 7 and Figure 10 , take the value according to the typical steel-concrete composite beam bridge section in actual engineering, the steel-concrete flange plate thickness is 200mm, the flange plate stem rib thickness is 250mm, the flange plate width is 3200mm, C50concrete ck =32.4N / mm 2 ,E c =3.45x10 4 N / mm 2 , the steel is Q345C, f s =345N / mm 2 ,E s =2.06x10 5 N / mm 2 ;

[0148] Among them, SCBB-1, the diameter d of the stud is used s =22@150, arranged in 3 rows, take the equivalent diameter d according to Table 1 eq = 48, the finite element analysis model is established in the MIDAS general finite element program, and the mid-span load-deflection (P-f) curve of the bridge mid-girder is as follows Figure 10 .

[0149] Composite beam span height L / h = 39.25 / 1.7 = 23, shear connection degree nf = 4.3, the difference between the simulated value and the experimental value is unknown, but according to the lit...

Embodiment 4

[0165]Embodiment 4, in order to further study the relationship between the stress characteristics and section characteristics of the composite beam mid-span load-deflection (P-f) curve from linear to nonlinear deformation, the "I-shaped" simply supported combination in Embodiment 1 Numerical simulations of the whole process were carried out for two types of composite beams (the neutral axis of the composite section is in the concrete) and the "box-shaped" simply supported composite beam in Example 2 (the neutral axis of the composite section is in the steel beam) Calculation and analysis (considering the core 3d concrete contribution, according to the diameter d of studs in 120 thick slabs in Table 1 s Take 16mm, the corresponding equivalent diameter d eq =23), mainly researching different height-span ratios (h / L 0 ) of the composite beam at the end of the simply supported beam at 0.1L, the maximum shear force of the studs and the change law of the shear stiffness of the stud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com