Coordination control method for material conveying and discharging of electric spraying vehicle

A technology of coordinated control and feeding, applied in the direction of electric components, controlling mechanical energy, electrical components, etc., can solve the problems of the feeding board running too fast, the discharge board overflowing or lacking material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

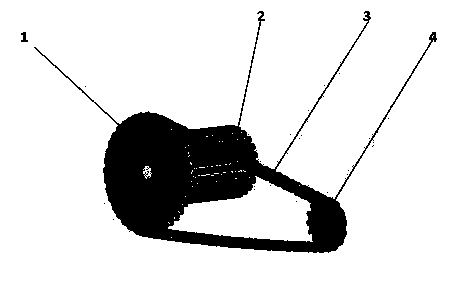

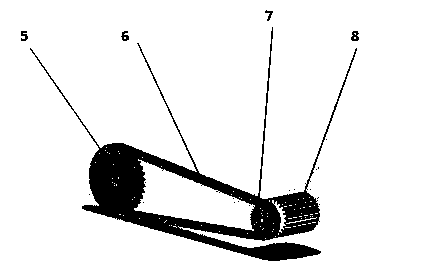

[0021] figure 1 for the vehicle model, figure 2 It is the transmission mechanism of the discharging motor, image 3 It is the transmission mechanism of the conveying motor, Figure 4 It is the structure diagram of one side of the spreader, Figure 5 Schematic diagram of the interior structure of the car. The feeding motor (8) drives the feeding plate gear (5) to rotate through the feeding motor gear (7) and the feeding chain (6), thereby making the feeding plate (15) rotate, and the feed falls into the discharge box (12) , the discharge motor (2) drives the discharge plate gear (4) through the discharge motor gear (1) and the discharge chain (3), so that the discharge plate (11) runs, and the feed is sprinkled into the feeding pool.

[0022] The specific derivation process is as follows:

[0023] Measured: The angular velocity of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com