Three-box modeling process for medium thin-wall frame castings

A molding process and casting technology, which is applied in the field of three-box molding process, can solve problems such as complex processes, and achieve the effects of simplifying the process, reducing the number of box turnovers, and reducing the turnover of heavy sand boxes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

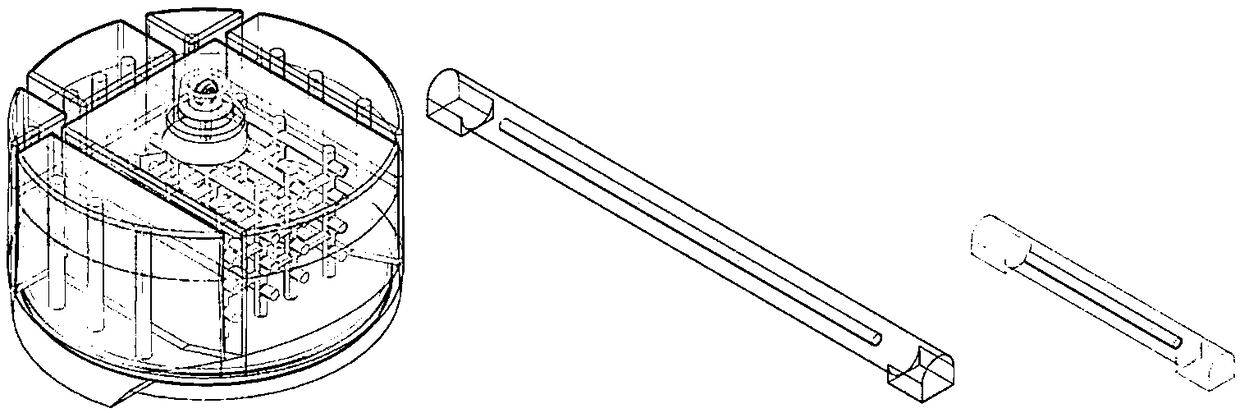

[0021] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

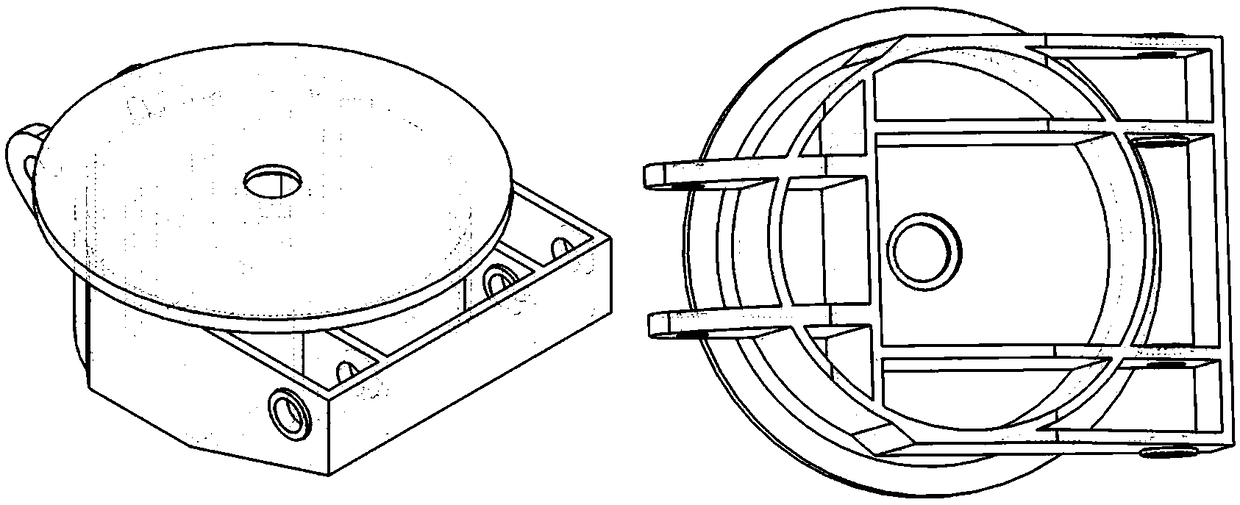

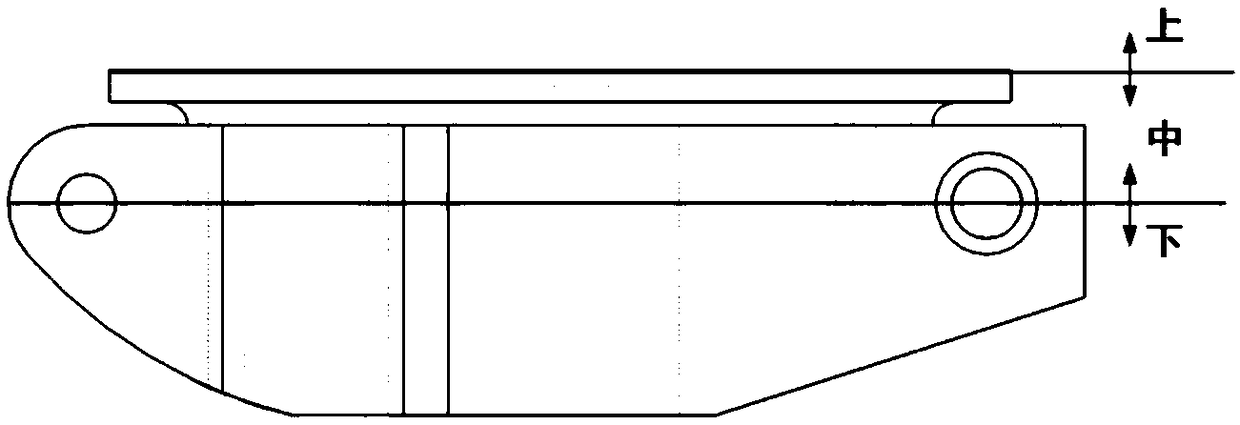

[0022] The casting example adopted by the present invention is a medium-sized complex thin-walled aluminum alloy casting, and the material is ZL114A, such as figure 1 As shown, its outline size is 1150mm×1375mm×440mm, and the main wall thickness is about 30mm. The size of the upper flask is 1570mm×1520mm×165mm, the size of the middle flask is 1570mm×1520mm×192mm, and the size of the lower flask is 1570mm×1520mm×430mm.

[0023] A three-box molding process for medium-sized thin-walled frame castings of the present invention comprises the following steps:

[0024] Step 1: Lower box molding: take the plane formed by the boss of the casting and the axes of the through holes on both sides as a partin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com