N (The cyclohexyl thio), phthalimide's manufacturing method and installation

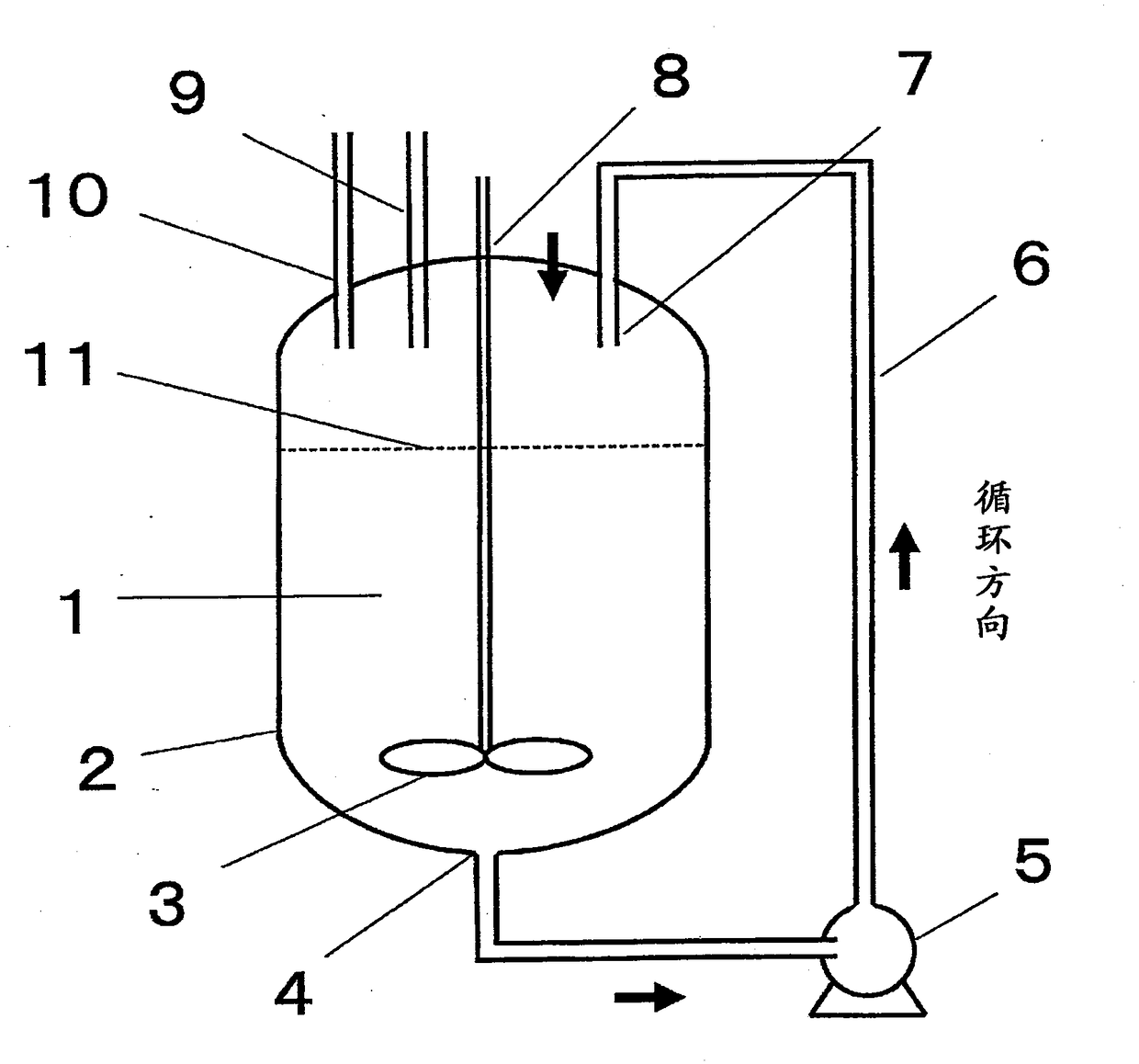

A technology of phthalimide and cyclohexylthio, which is applied in chemical instruments and methods, chemical/physical/physical-chemical stationary reactors, chemical/physical/physical-chemical processes, etc., can solve the problem of reaction yield Not necessarily satisfactory, insufficient raw material contact, etc., to achieve the effects of reducing reaction by-products, improving purity, and improving reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Hereinafter, the present invention will be described in more detail with reference to examples.

reference example 1

[0058] 3m made of glass-lined glass in the stirring tank type 3 In the reactor, the mixed solvent 1250Kg (toluene is 14% by weight, density 0.781Kg / L, 1600L), cooled to -20°C with refrigerant. While stirring, 303Kg of chlorine (molecular weight: 70.9, 4.27Kg moles) was blown into it at a liquid temperature of -20 to -10°C over 2.0 hours to chlorinate dicyclohexyl disulfide to obtain cyclohexylsulfenyl chloride. The solution is 2460Kg (the molecular weight is 150.7, the content of cyclohexylsulfenyl chloride is 1120Kg, and the mole is 7.43Kg).

reference example 2

[0060] As a solvent for the synthesis of cyclohexylsulfenyl chloride, 1340Kg of a mixed solvent of vinyl chloride (boiling point 83°C) / cyclohexane (20% by weight of vinyl chloride, density of 0.839Kg / L, 1600L) was used. Reference Example 1 was operated in the same manner to obtain a solution of 2550 Kg (7.43 Kg moles) of cyclohexylsulfenyl chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com