Yarn carrier and three-dimensional braiding machine

A technology of yarn carrier and yarn storage, which is applied in the field of three-dimensional weaving, can solve the problems that cannot meet the development needs of weaving technology, achieve the effects of reducing friction fluffing and friction breaking, convenient processing, and lower precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

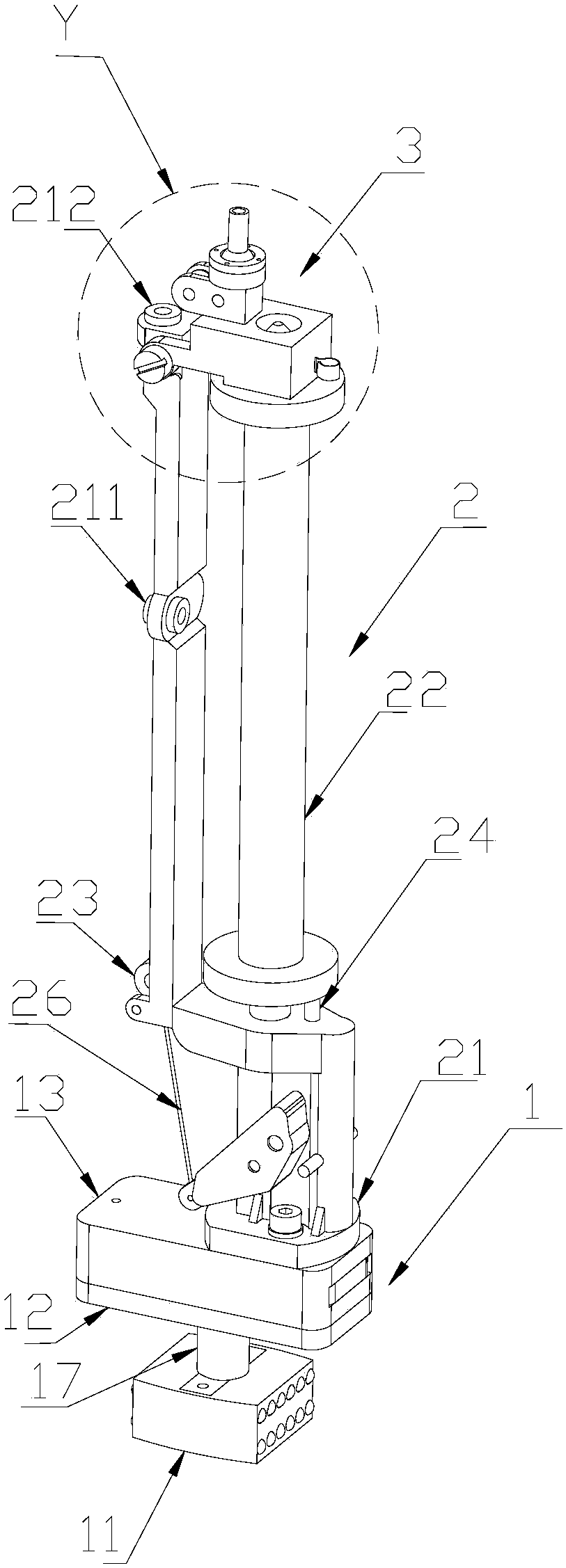

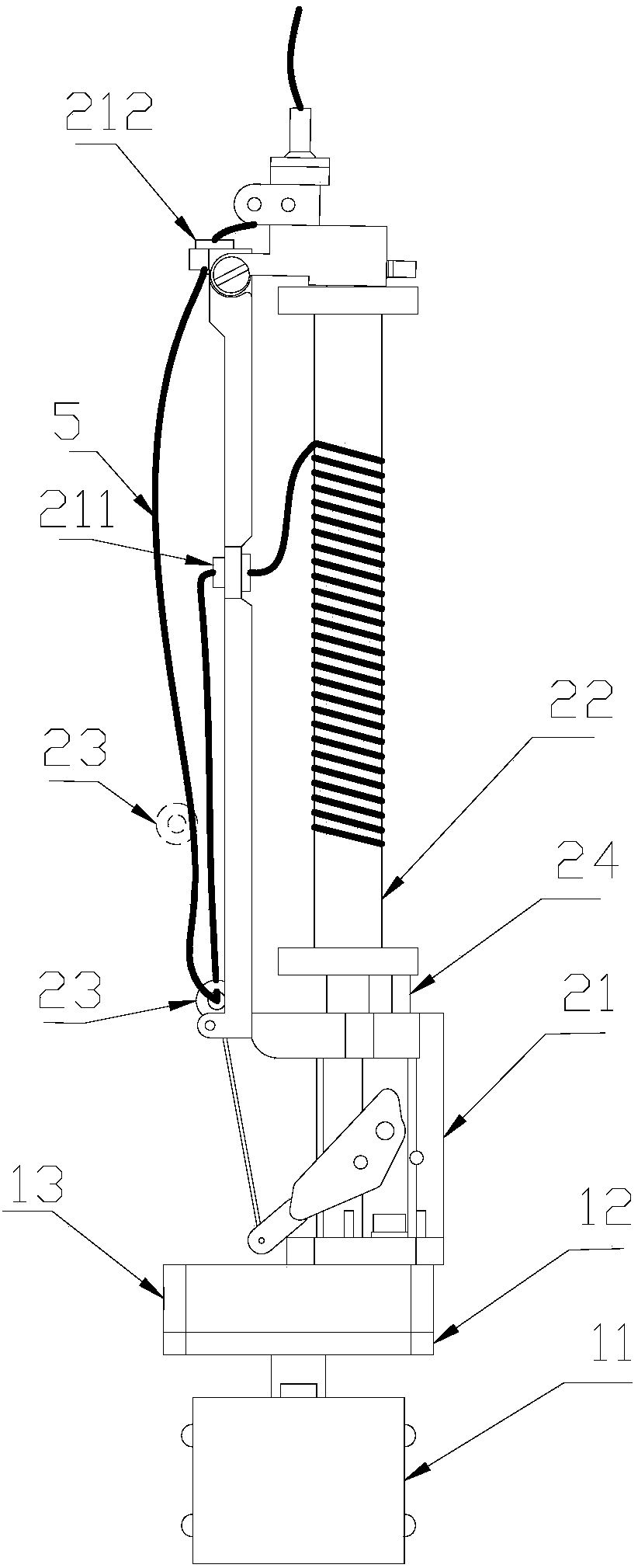

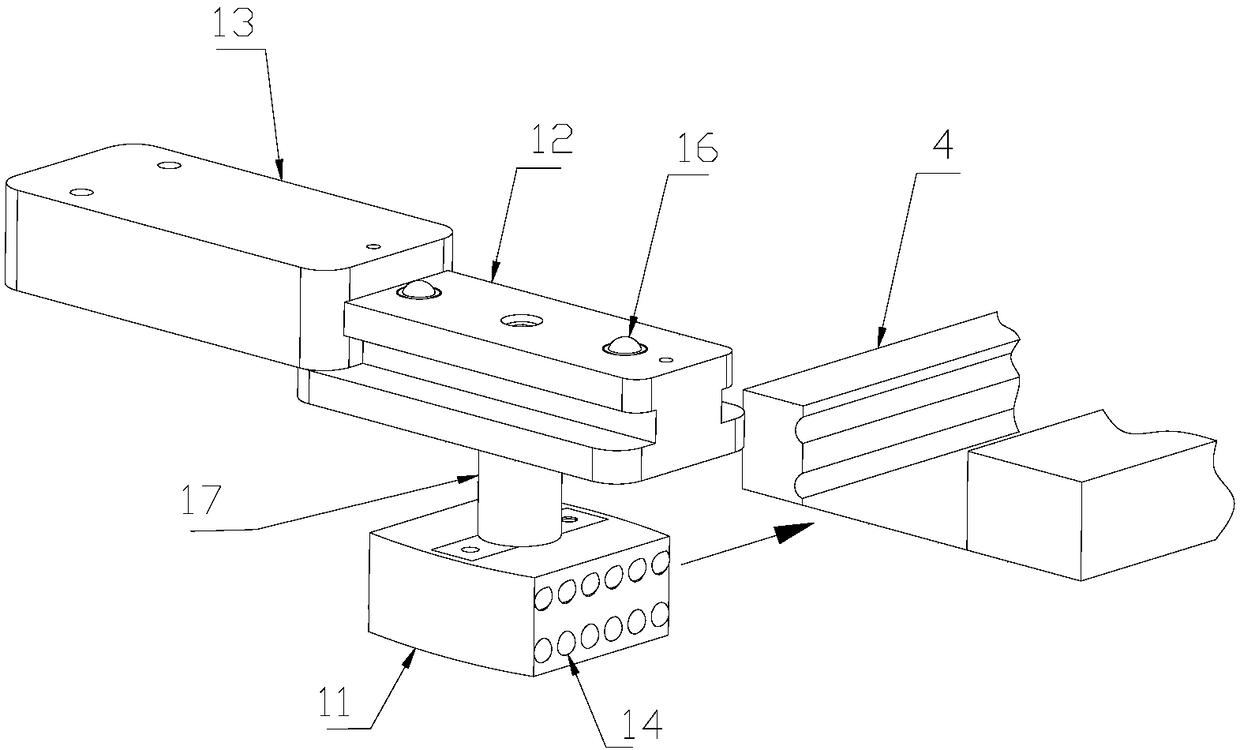

[0034] Such as figure 1 and image 3 As shown, a yarn carrier includes a detachable base 1, a yarn carrier body 2 and a living hinge 3 arranged on the upper end of the yarn carrier body 2, the base 1 is installed on the guide rail 4 of the knitting machine body, It can slide along the guide rail 4 to make the whole yarn carrier move, and the base 1 is detachably connected to the main body 2 of the yarn carrier so that the main body 2 of the yarn carrier can be detached from the base 1 . In order to reduce the friction between the base 1 and the guide rail 4, a plurality of rolling elements 14 are arranged on the outer surface of the base 1, and the rolling elements 14 are in rolling contact with the guide rail 4 to convert sliding friction into rolling friction and reduce the friction during the weaving process. fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com