Downhole pressurization auxiliary rock breaking tool

A tool and rock-breaking technology, which is applied in the field of underground pressurized auxiliary rock-breaking tools, can solve the problems of harmful impact, difficult manufacturing, complex structure, etc., achieve stable pulse, improve service life and reliability, and solve complex structures. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

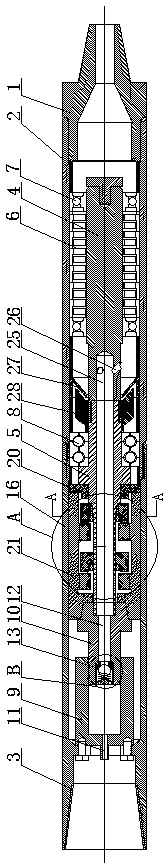

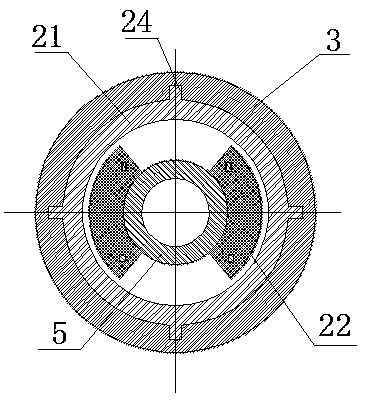

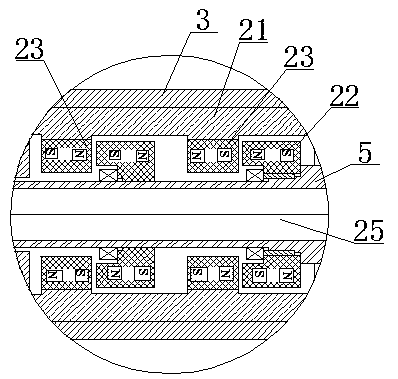

[0020] The downhole pressurized auxiliary rock-breaking tool includes a conversion joint 1, an upper casing 2, a lower casing 3, a turbine main shaft 4, a rotating shaft 5 and a hydraulic cylinder, and the upper casing 2 and the lower casing 3 are screwed to each other, and the upper One end of the housing 2 is threaded with a conversion joint 1; the turbine main shaft 4 is installed through the turbine assembly 6 and the symmetrically arranged central bearing 7 in the upper housing 2; the turbine assembly 6 includes a turbine rotor and a turbine stator; The lower casing 3 is equipped with a rotating shaft 5 through a thrust bearing 8, and the turbine main shaft 4 and the rotating shaft 5 are threadedly connected. The rotating shaft 5 is provided with a central through hole 25. 4 There are a plurality of distribution holes 26 uniformly distributed in the radial direction on the circumference, and the distribution holes 26 communicate with the central through hole 25 of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com