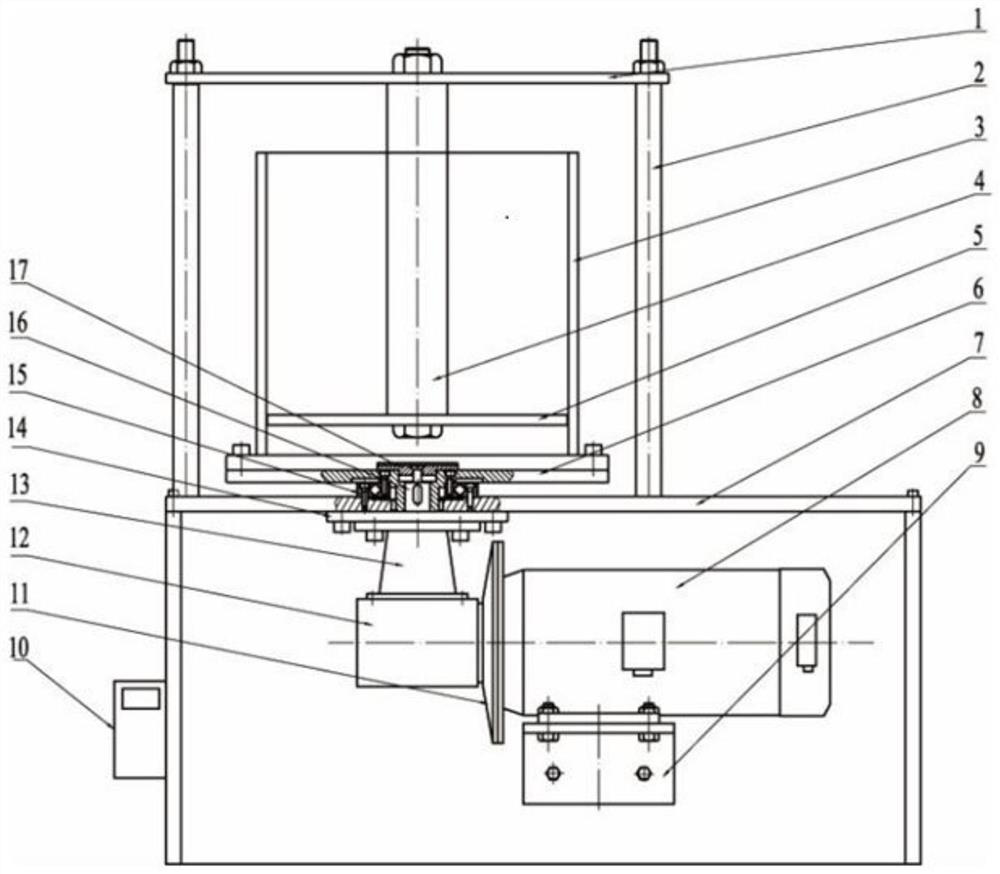

A Particle Annular Couette Shear Flow Experimental Device

An experimental device and shear flow technology, applied in the direction of measurement device, flow characteristics, indirect flow characteristics measurement, etc., can solve the problems of poor reliability of simulation results and only have reference significance, and achieve rich particle flow characteristics and precise velocity control , the effect of high experimental precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

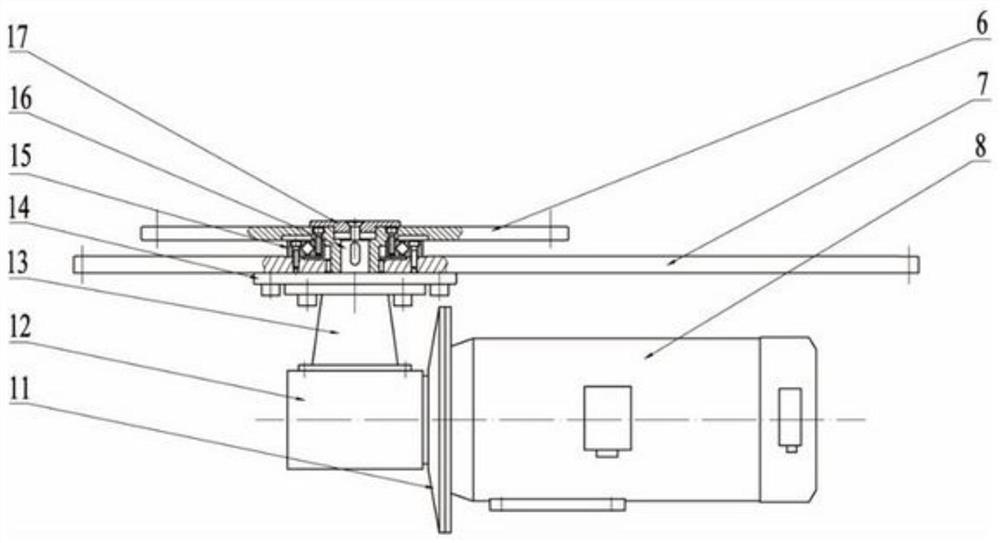

Method used

Image

Examples

Embodiment 1

[0026] A transparent glass ball with a diameter of Φ1mm is selected as the particle medium, and a thin layer of black coating is sprayed on a part of the particle surface as a tracer particle. During the experiment, the tracer particles are closely arranged on the surface of the granular medium along the radial direction of the outer cylinder 3, and the frequency conversion motor 8 and the high-speed camera are started to shoot the flow process of the tracer particles with the granular medium. The experimental results are shown in Figure 5, as can be seen, as As shown in Figure 5(a), the tracer particles are closely arranged on the surface of the granular medium along the radial direction of the outer cylinder 3 at the initial moment, and as time increases, as shown in Figure 5(b), the tracer particles form a line on the surface of the granular medium The curved arc curve, the tracer particles at the end of the curve can be regarded as the position of the boundary of the shear ...

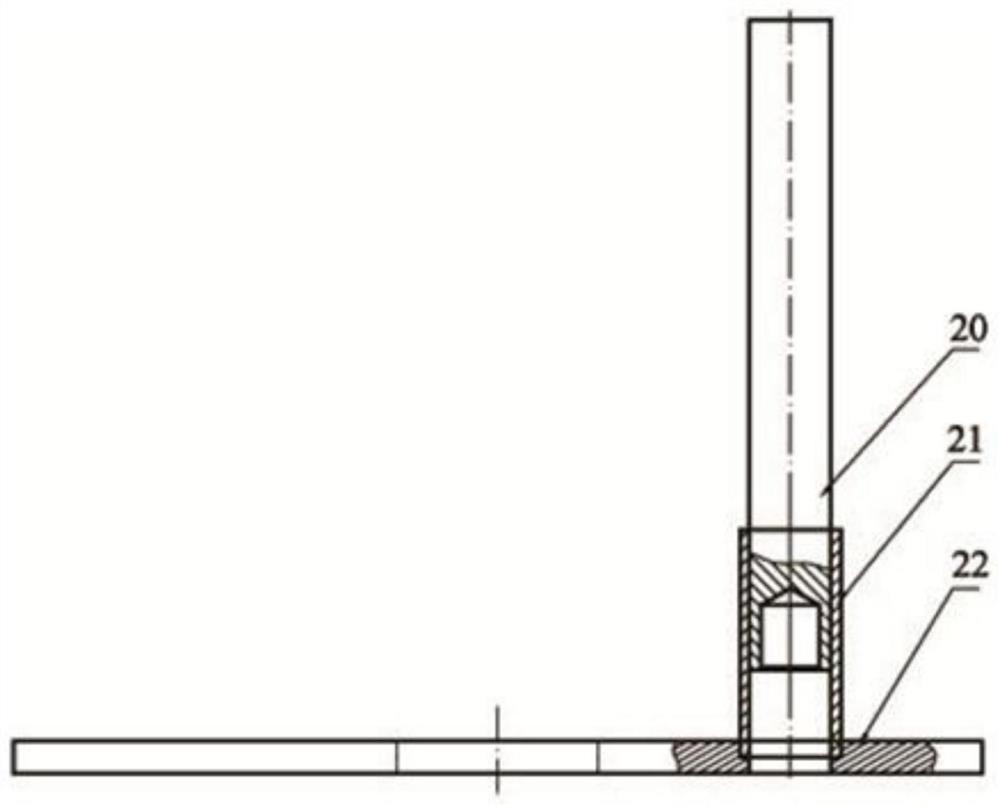

Embodiment 2

[0028] A transparent glass ball with a diameter of Φ1mm is selected as the particle medium, and a black hollow iron ball with a diameter of Φ25mm and a wall thickness of 1mm is used as the tracer particle. The surface of the hollow iron ball has a through hole with a diameter of Φ4mm, which is used to drop steel balls to change Hollow iron ball weight. During the experiment, the hollow iron ball was pressed into the granular medium through the positioning device, the guide cylinder 21 was installed at the through hole 23, and the pressing rod 20 was inserted into the guide cylinder 21 to press the hollow iron ball into the outer shell. In the granular medium in cylinder 3. Start the frequency conversion motor 8 and the high-speed camera to photograph the process of the hollow iron ball floating on the surface of the particle flow. The experimental results are as follows: Figure 6 As shown, it can be seen that the hollow iron ball has just floated up from the inside of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com