Numerical modeling method of rock mass mechanics considering macroscopic and microscopic defect coupling

A technology of numerical modeling and rock mass mechanics, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of not considering the influence of rock mass mechanical properties, etc., and achieve the effect of data reliability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

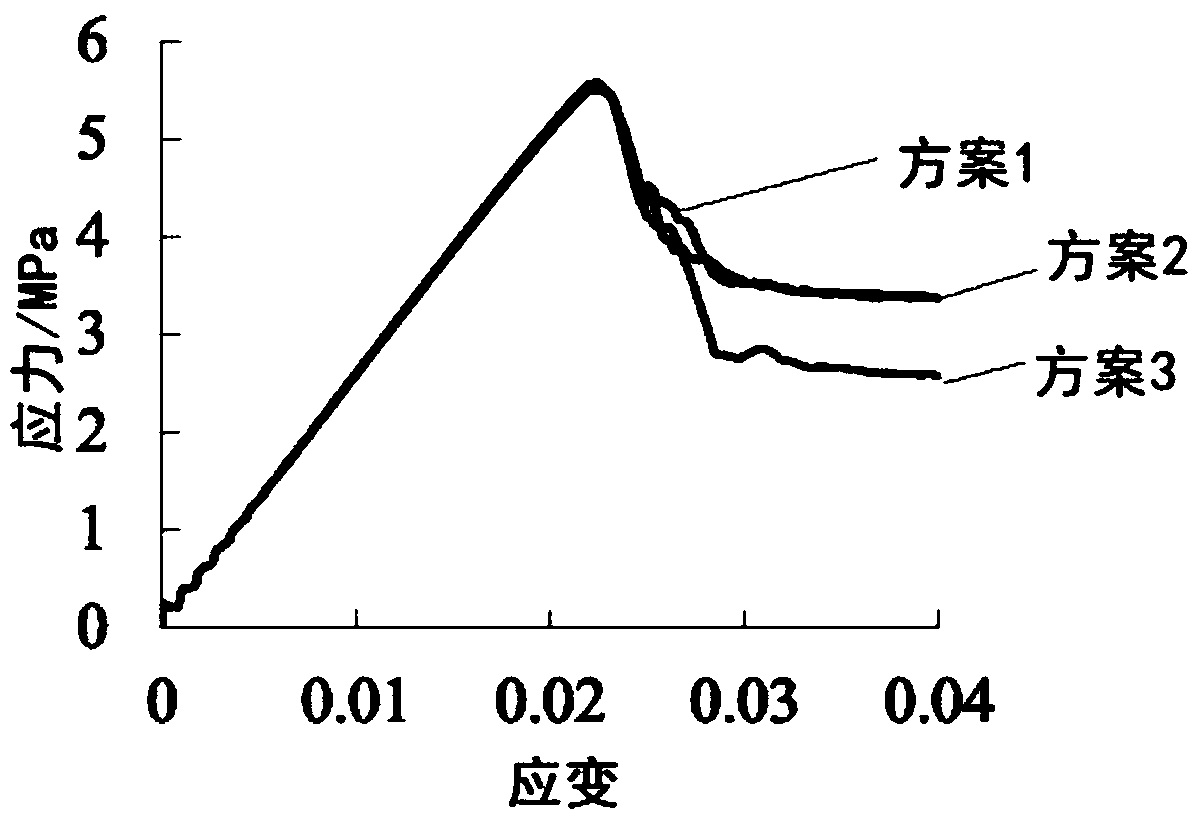

[0040] This embodiment considers a numerical modeling method of rock mechanics coupled with macroscopic and microscopic defects, and the method includes the following steps:

[0041] The first step is to generate a numerical calculation model:

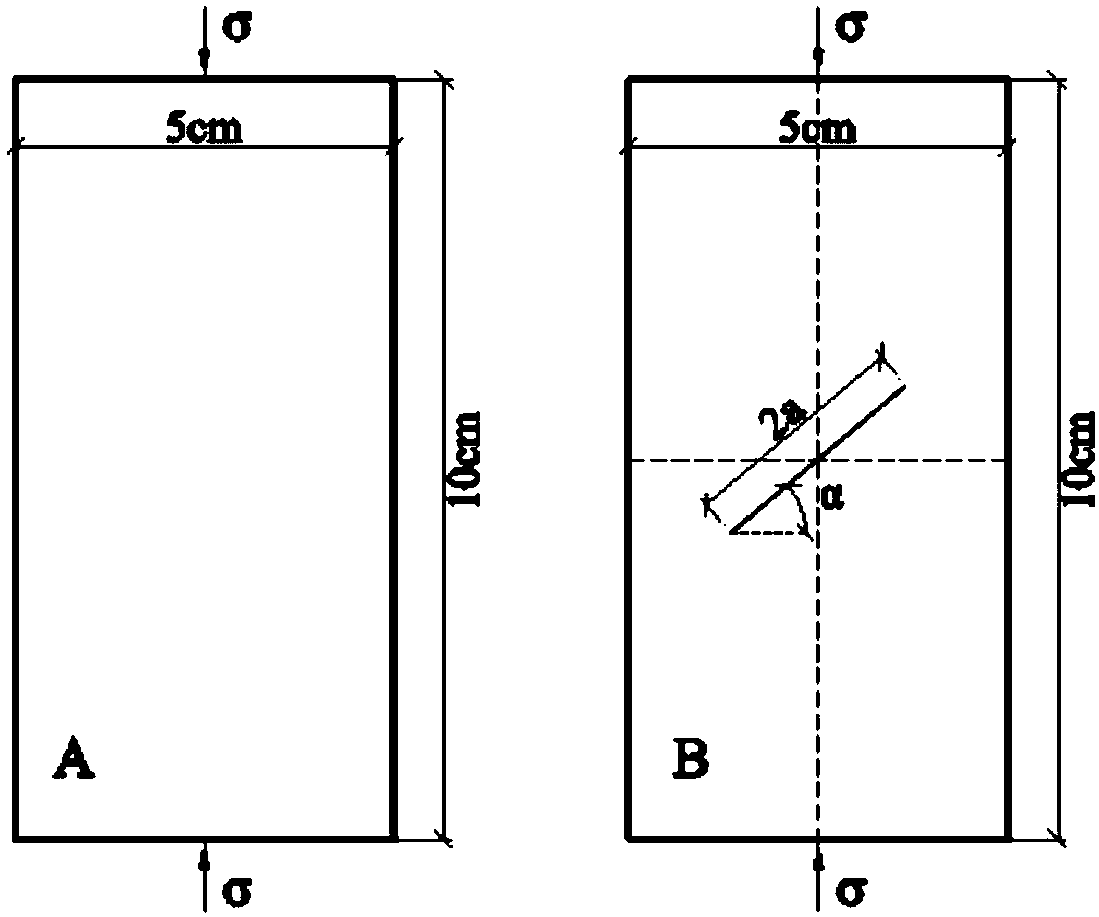

[0042] Using FLAC 3D The program performs numerical modeling, assuming that the plane size of the calculation model is: height 10cm, width 5cm, and the thickness of the model is 0.5mm, such as figure 1 As shown, it can speed up the calculation speed and reduce the number of elements in the calculation model; the calculation model is divided into ultra-fine meshes by using three-node triangular elements, the grid elements are cubes, and the side length of the mesh elements is 0.5mm, which can better The line-like propagation characteristics of new cracks when the model is damaged can be simulated accurately. In this embodiment, the calculation model is divided into 23256 nodes and 45910 grid units.

[0043] The boundary conditions of...

Embodiment 2

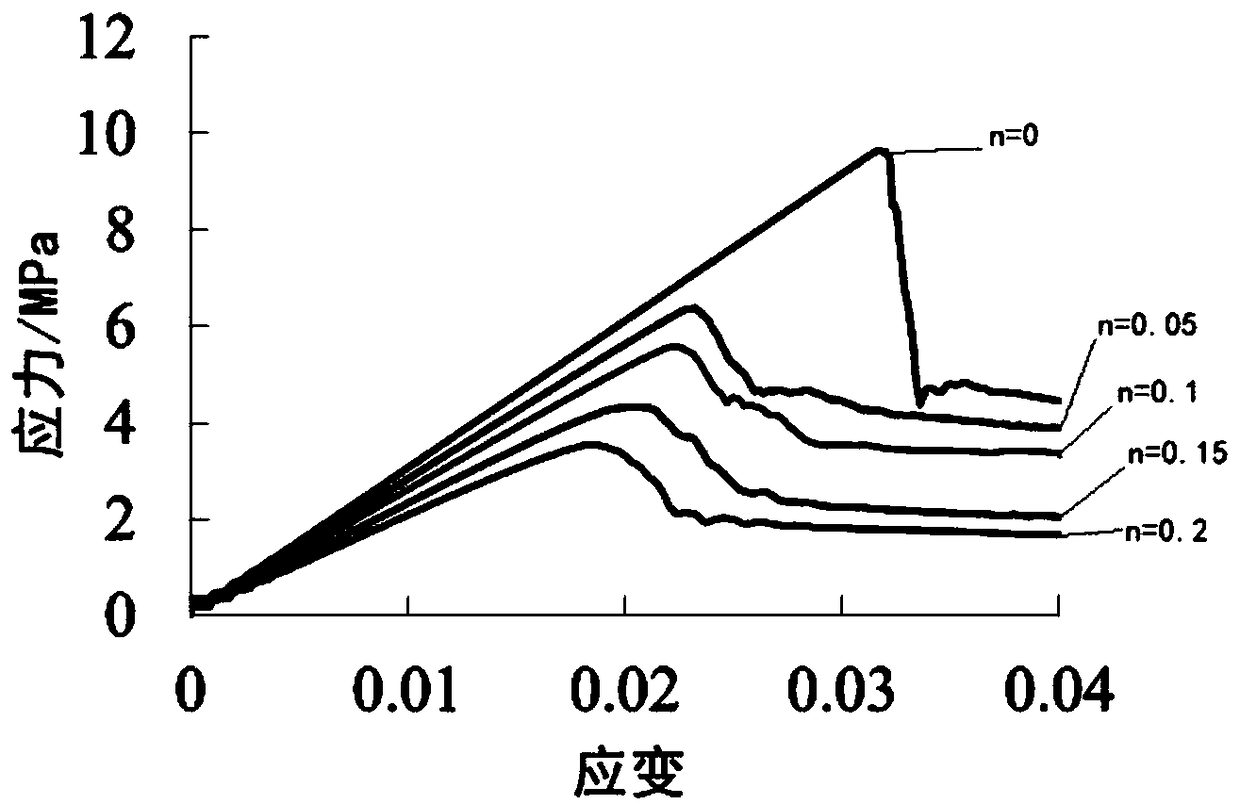

[0058] In this embodiment, the numerical modeling method of rock mass mechanics considering the coupling of macro and micro defects is applied to the stability problem of the fractured slope. When the cracks penetrate, the failure of the slope usually occurs along the through cracks. But in actual engineering, most of the cracks are non-penetrating, so the failure of the slope will appear as a complex interaction between non-penetrating cracks and rock bridges. Rock slopes contain two types of defects of different sizes, macroscopic and mesoscopic.

[0059] In rock slopes, the existence forms of macroscopic defects, that is, cracks in slopes, are more complicated. According to its penetration, it can be divided into penetrating fissures and non-penetrating fissures; according to whether it is filled, it can be divided into filled fissures and non-filled fissures. In this embodiment, a non-penetrating rock slope with filling joints with a length of 2a and a dip angle of α is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com