Nano dual-phase composite permanent magnet particles and preparation method thereof

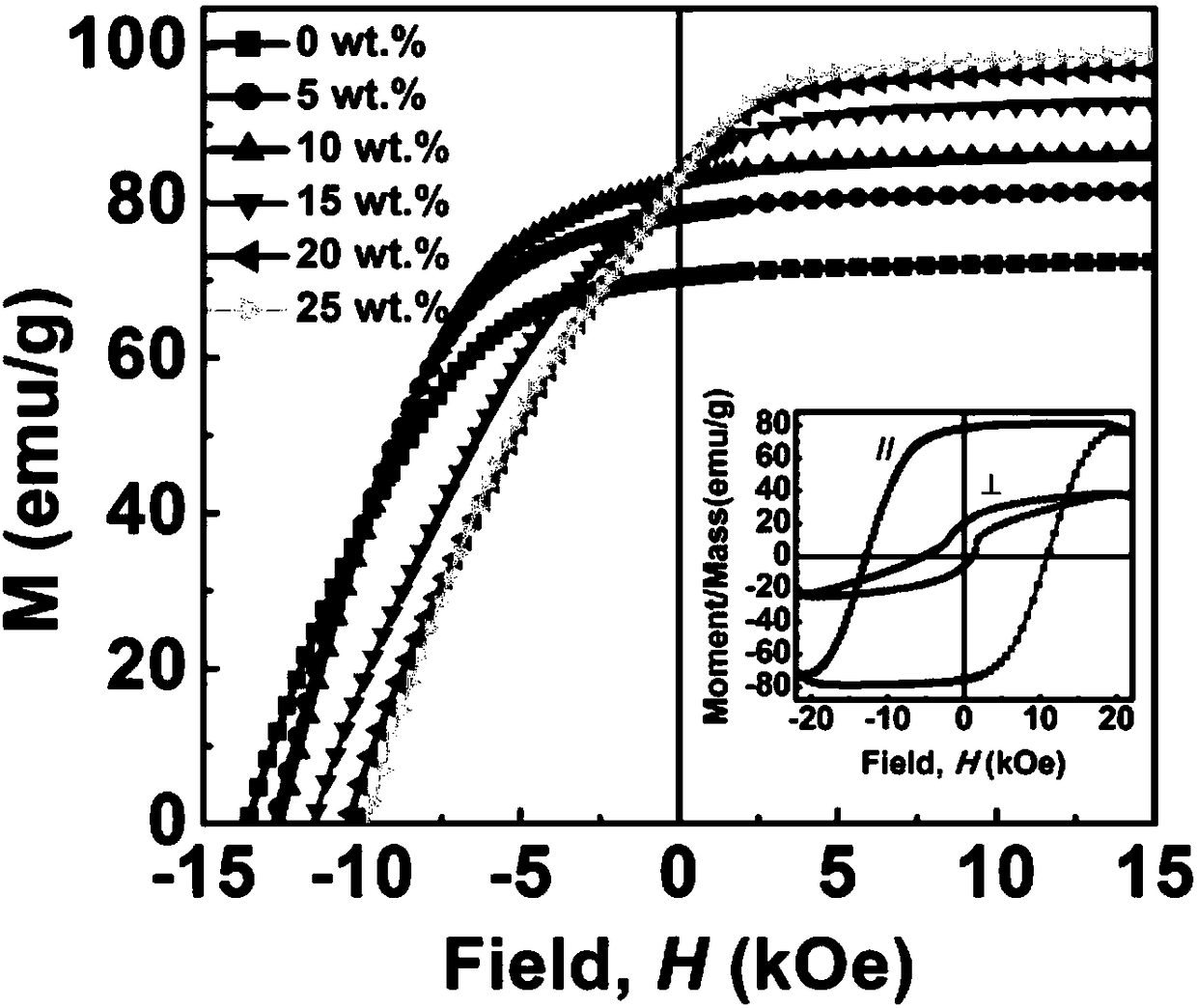

A nano and permanent magnet technology, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problem of simultaneous control of nanoscale continuity of difficult-to-deposit particles, low theoretical saturation magnetization of soft magnetic phase Co, and double Remanent magnetism and magnetic energy product improvement of phase composite materials, etc., to avoid hysteresis curve collapse, low cost, and improve the effect of magnetic energy product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] An aspect of the embodiments of the present invention provides a method for preparing nano-two-phase composite permanent magnet particles, which includes:

[0021] Uniformly disperse the hard magnetic phase powder in the solvent to form a hard magnetic phase powder dispersion;

[0022] In a protective atmosphere, the hard magnetic phase powder dispersion is adjusted to alkaline with alkaline substances, and at least a reducing agent and a soft magnetic phase precursor material are added, and after mixing and reaction, nanometer two-phase composite permanent magnetic particles are obtained .

[0023] As one of the preferred solutions, the preparation method includes: pretreating the hard magnetic phase powder with an acid solution, and then uniformly dispersing the hard magnetic phase powder in a solvent to form the hard magnetic phase powder dispersion. Pretreatment of the hard magnetic phase powder with acid can remove the oxide layer on the surface of the hard magnet...

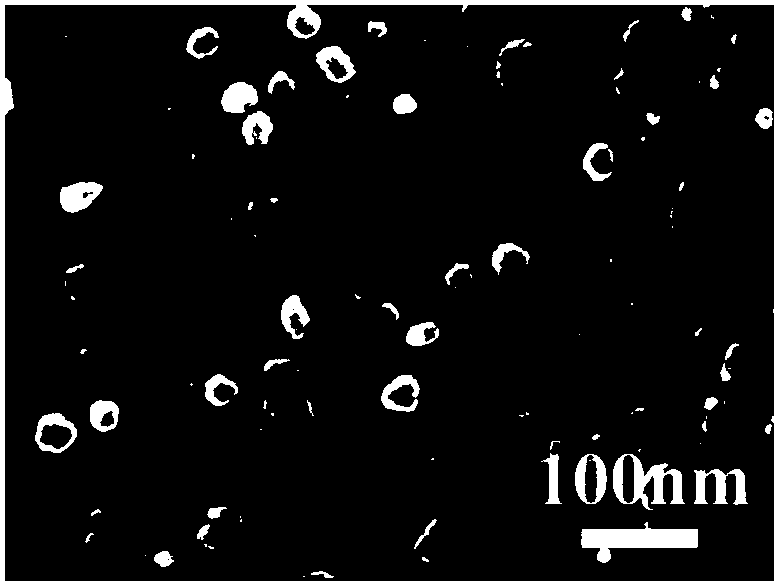

Embodiment 1

[0062] (1) Take 0.12g SmCo 5 Disperse in 60ml of absolute ethanol, add 0.5ml of dilute hydrochloric acid, react in a water bath at 60°C for 10 minutes, remove the acid solution after the reaction, pass in Ar gas as a protective gas, and use mechanical stirring and ultrasonic dispersion;

[0063] (2) SmCo pretreated with hydrochloric acid 5 Disperse in 60ml of absolute ethanol, add 1g of PVP as a dispersant, dissolve 0.4g of NaOH in 20ml of absolute ethanol and add it dropwise to SmCo with a syringe 5 dispersion, then 3ml N 2 h 4 ·H 2 O was added dropwise to SmCo with a peristaltic pump at a rate of 0.15ml / min. 5 In the dispersion, at the same time 0.0143g FeCl 2 4H 2 O dissolved in 20ml absolute ethanol and 0.0092g CoCl 2 ·6H 2 O was dissolved in 20ml absolute ethanol and added dropwise to the SmCo with a syringe 5 In the dispersion liquid, react in a water bath at 60°C for 30 minutes, pass Ar gas as a protective gas, and disperse with mechanical stirring and ultrason...

Embodiment 2

[0067] (1) Take 0.12g SmCo 5 Disperse in 60ml of absolute ethanol, add 0.5ml of dilute hydrochloric acid, react in a water bath at 60°C for 10 minutes, remove the acid solution after the reaction, pass in Ar gas as a protective gas, and use mechanical stirring and ultrasonic dispersion;

[0068] (2) SmCo pretreated with hydrochloric acid 5 Disperse in 60ml of absolute ethanol, add 1g of PVP as a dispersant, dissolve 0.4g of NaOH in 20ml of absolute ethanol and add it dropwise to SmCo with a syringe 5 dispersion, then 3ml N 2 h 4 ·H 2 O was added dropwise to SmCo with a peristaltic pump at a rate of 0.15ml / min. 5 In the dispersion liquid, at the same time 0.0303g FeCl 2 4H 2 O dissolved in 20ml absolute ethanol and 0.0195g CoCl 2 ·6H 2 O was dissolved in 20ml absolute ethanol and added dropwise to the SmCo with a syringe 5 In the dispersion liquid, react in a water bath at 60°C for 30 minutes, pass Ar gas as a protective gas, and disperse with mechanical stirring and u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com