Design method of tunnel mechanized construction power distribution scheme based on drilling and blasting method

A design method and technology of drill-and-blast method, applied in electrical components, circuit devices, AC network circuits, etc., can solve the problem of low load efficiency, failure to consider reactive power loss of electrical equipment and transmission lines, and inability to accurately grasp holes. The capacity of the internal mobile transformer and the selection of the specifications of the low-voltage transmission wire of the mobile frequency are solved to achieve the effect of reducing energy consumption, avoiding facility reactive power loss and resource waste, and selecting reasonable parameter values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific implementation examples.

[0030] A design method of power distribution scheme for tunnel mechanized construction based on drill and blast method, the method steps are as follows:

[0031] S1. Combined with the design of the project construction organization, through on-site inspections, understand the situation and supply of the temporary high-voltage end power supply, and determine the type, quantity, and rated voltage U of the electrical equipment n and rated power P n , according to the power distribution control and the location of the low-voltage power supply main box and distribution box, plan the power supply line direction and line design and layout scheme, and calculate the rated power P of all electrical equipment in each power supply line during the peak period of power consumption n the sum of P e ;

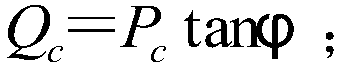

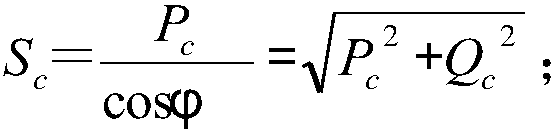

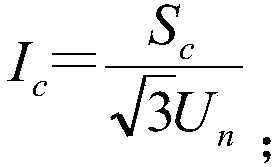

[0032] S2. Calculate the load active power P of each power supply line s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com