Explosion-proof low-noise permanent magnet coupler

A permanent magnet coupler, low noise technology, applied in the direction of permanent magnet clutch/brake, electric brake/clutch, asynchronous induction clutch/brake, etc. Safety production in explosive places, etc., to achieve the effect of saving power consumption, satisfying heat dissipation and noise reduction, and having a compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

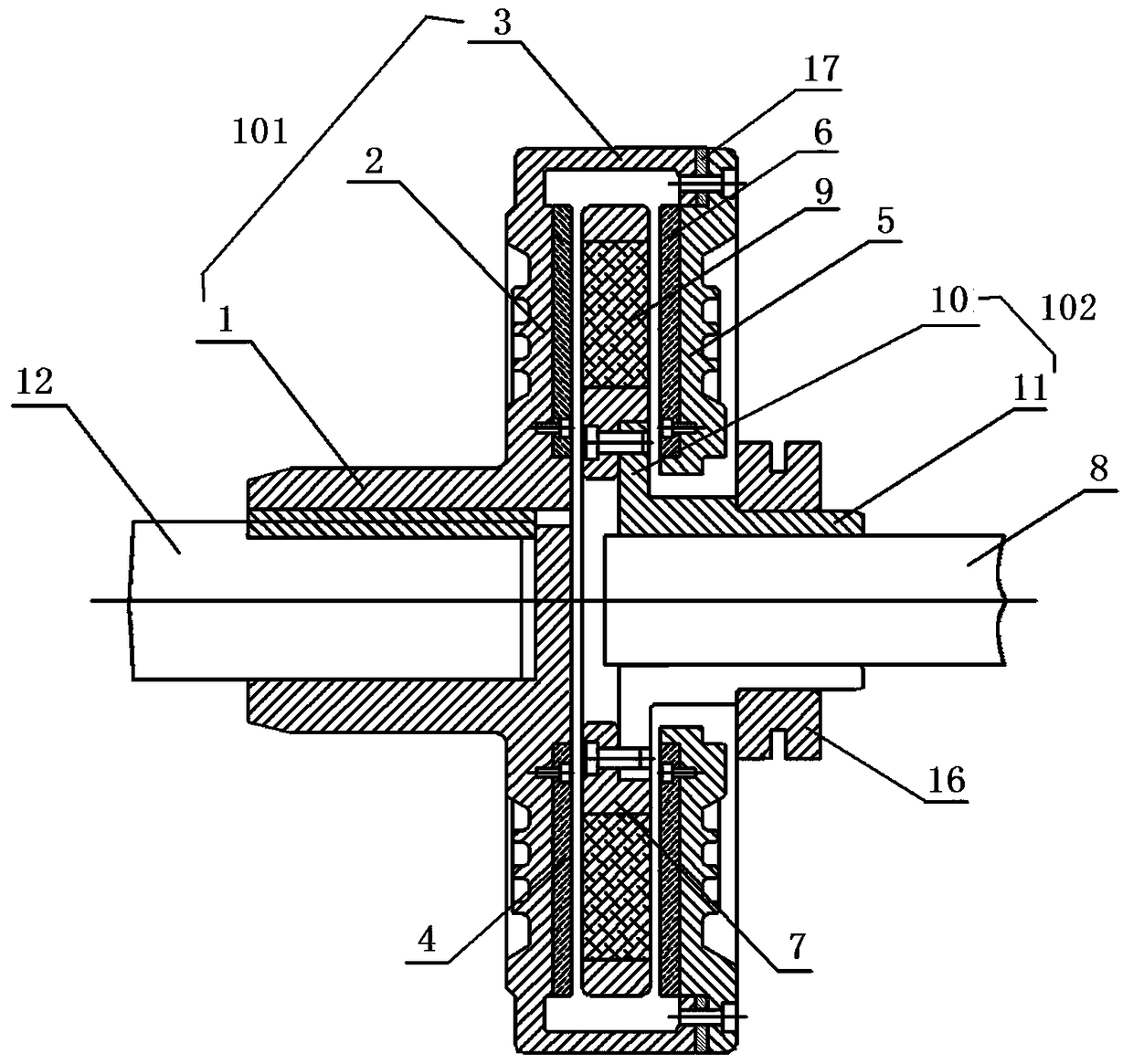

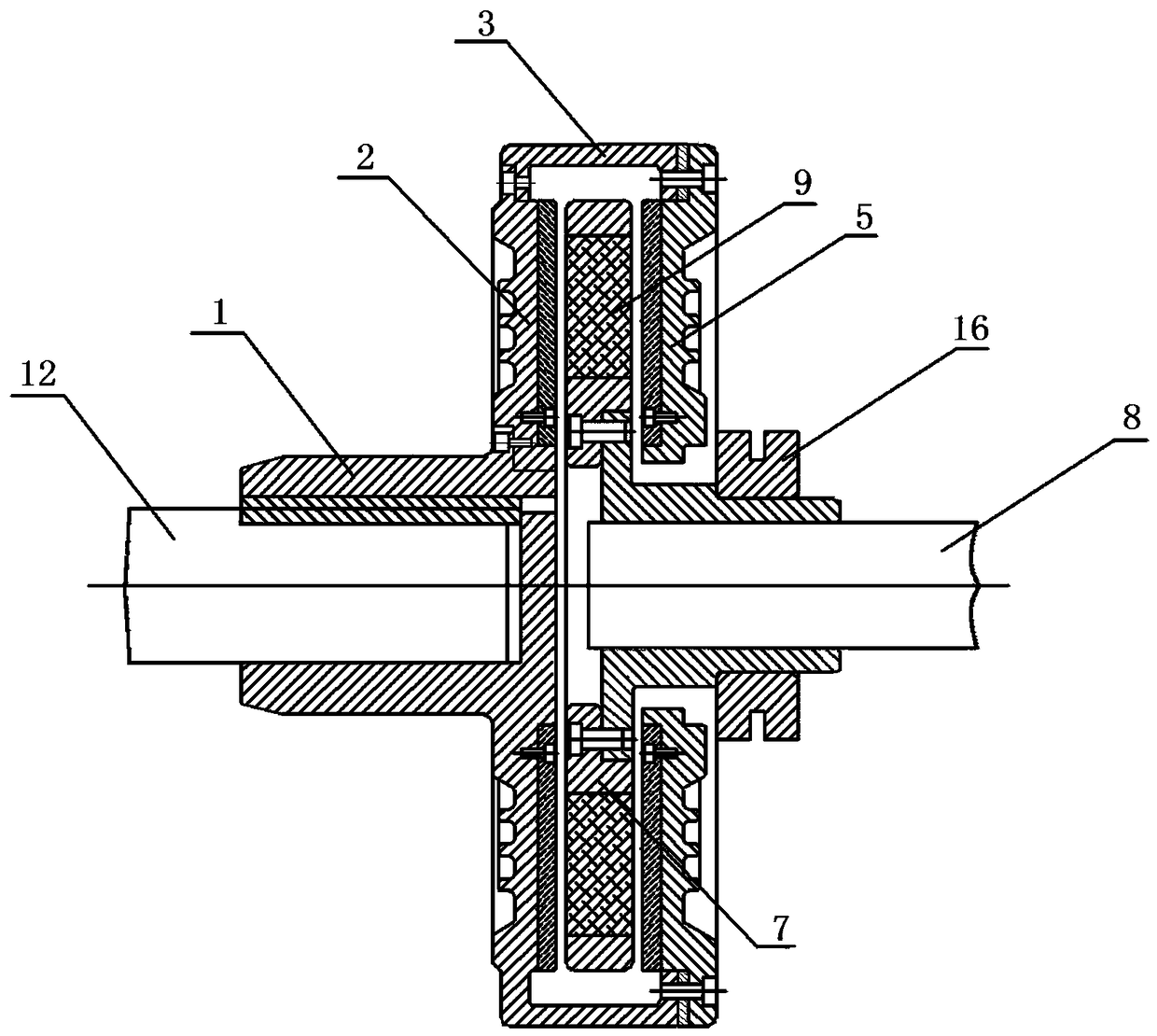

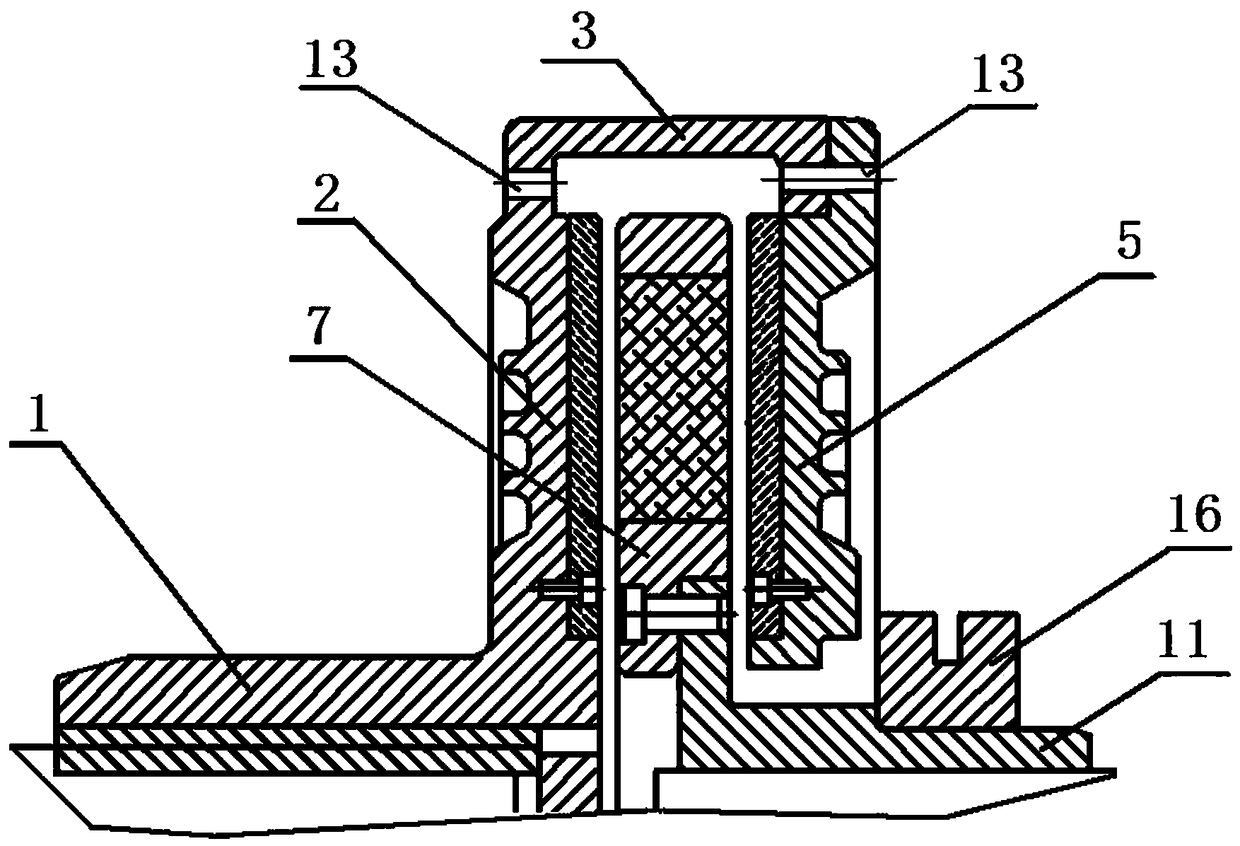

[0032] See figure 1 , is a structural schematic diagram of Embodiment 1 of an explosion-proof low-noise permanent magnetic coupler of the present invention, including a driving hub 101, which includes an integrated structure composed of three parts: a shaft sleeve body 1, a steel disc body 2 and an outer circular sleeve body 3, and the steel disc The inner side of the body 2 is connected to the conductor disc 1 4, and the inner side of the steel disc 1 at the load end is connected with the conductor disc 2 6. A semi-enclosed space opening to the axial direction is formed between them, which has an explosion-proof effect.

[0033] The load hub 102 includes a flange 10 for connecting the magnetic rotor disc 7, and a sleeve 11 matching the load shaft 8, the sleeve 11 is connected with the load shaft 8 through a locking disc 16; the magnetic rotor di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com