Direct liquid-injecting-type poultry egg multi-functional integrated pickling room and processing method

A multi-functional, poultry egg technology, applied in the field of poultry egg processing, can solve the problems of high egg damage rate, low volume ratio of pickling containers, high economic cost of pickling equipment, etc., to increase volume ratio, improve pickling quality, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

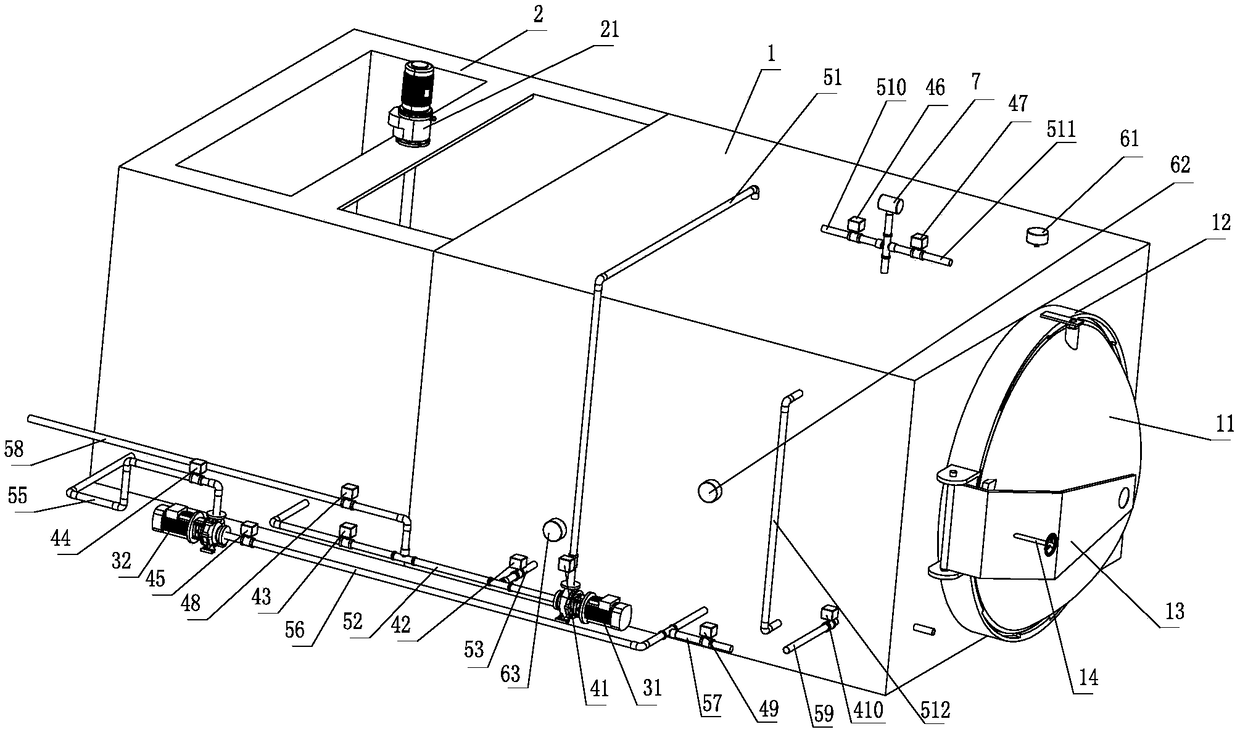

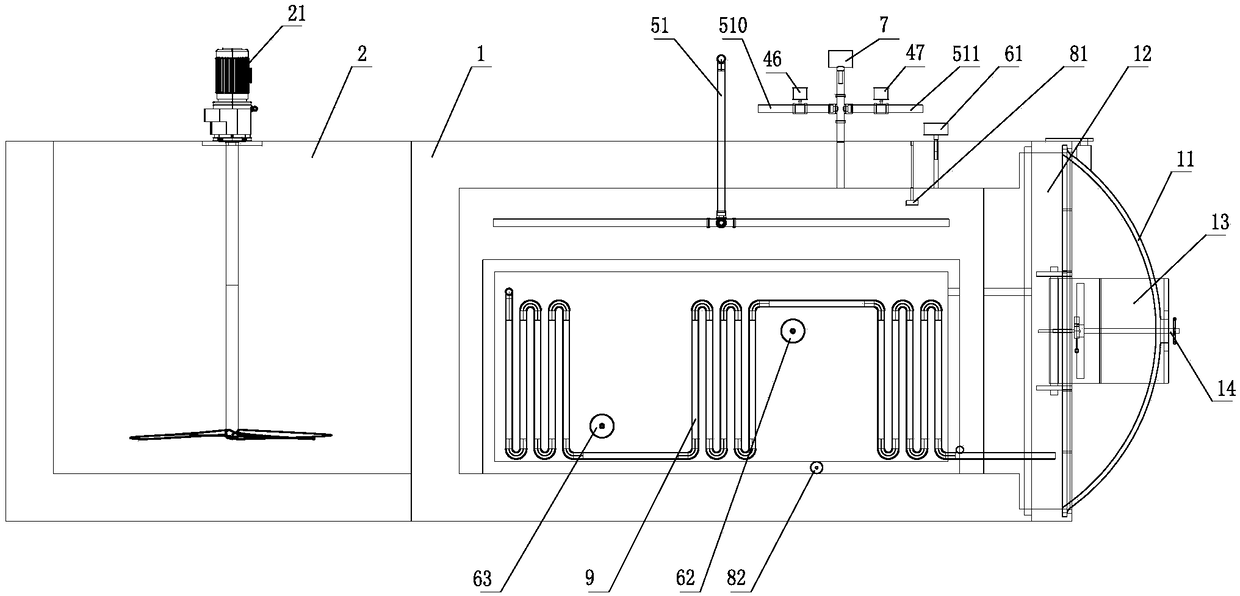

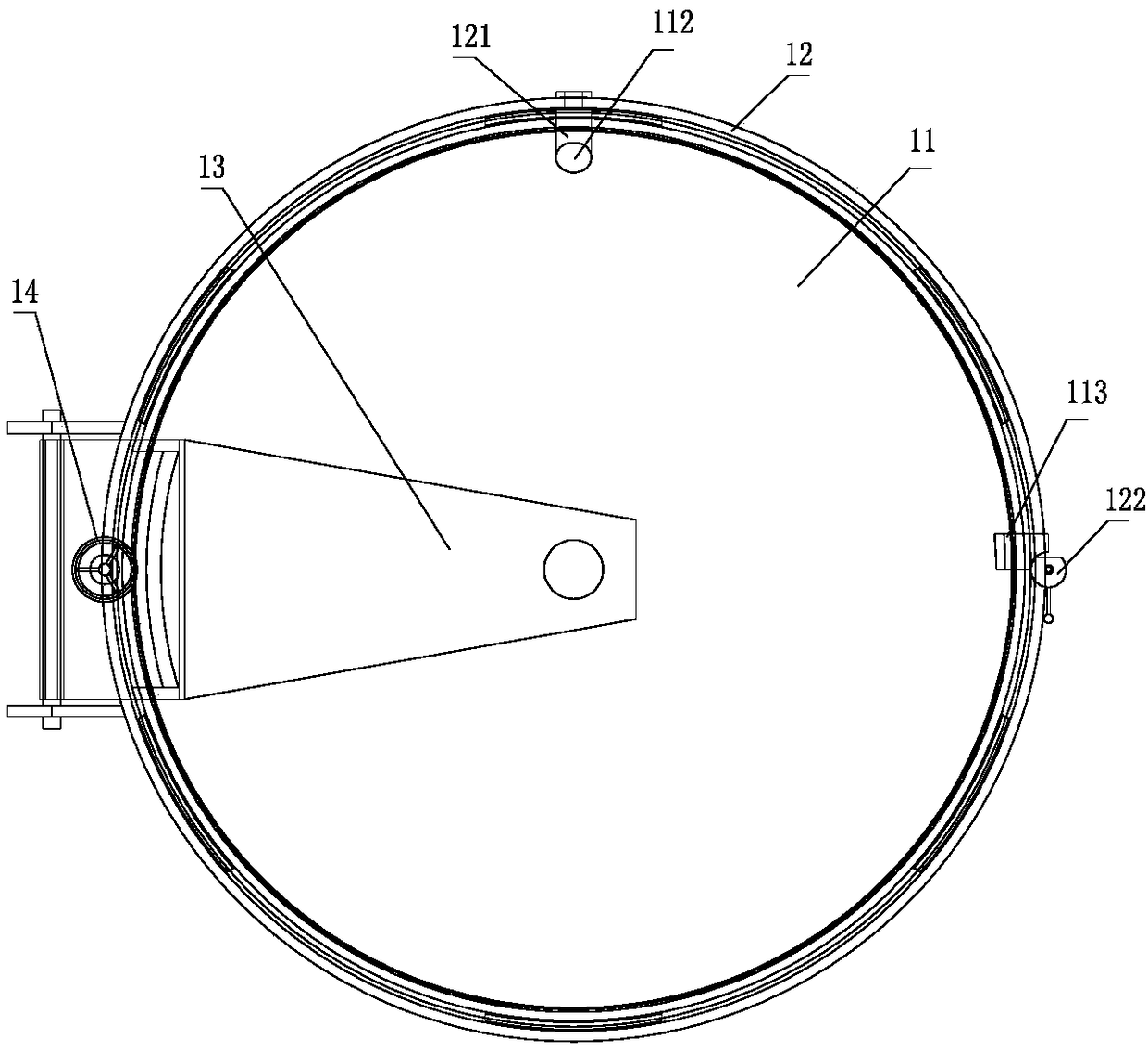

[0039] Such as figure 1 As shown, a kind of direct liquid injection type poultry and egg multifunctional integrated pickling room of the present invention comprises a pickling room body 1, a gate 11 arranged on one side of the curing room body 1 for poultry eggs to enter and exit, and a door 11 arranged on a pickling room body 1. The stirring tank 2 on the other side of the curing room body 1 is provided with a first liquid pump 31 and a second liquid pump 32 beside the curing room body 1 .

[0040] The liquid outlet of the first liquid pump 31 communicates with the top of the interior of the pickling room body 1 through the first solenoid valve 41 and the liquid inlet pipe 51. The liquid inlet of the first liquid pump 31 is divided into two paths, and one path passes through the second solenoid valve. 42 and the internal circulation liquid ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com