Physical compensator generating, equipment, medium and system based on 3D printing

A 3D printing and compensator technology, applied in radiation therapy, X-ray/γ-ray/particle irradiation therapy, treatment, etc., can solve the problem of high precision cutting machine and material performance, phantom model stays in the theoretical stage, precision Failure to meet clinical requirements and other issues, to meet the quality control needs of clinical treatment, meet high-precision personalized clinical needs, and avoid medical accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

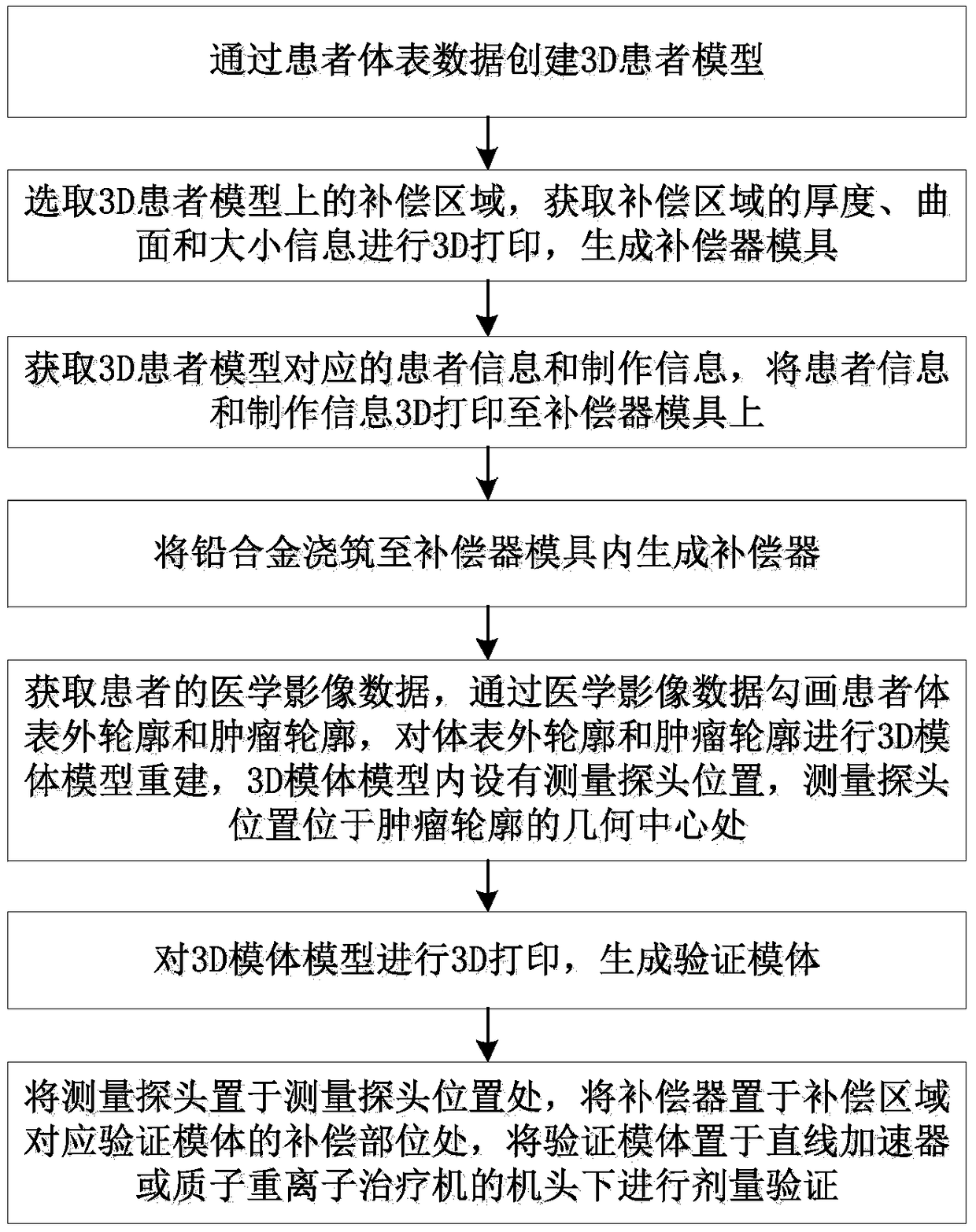

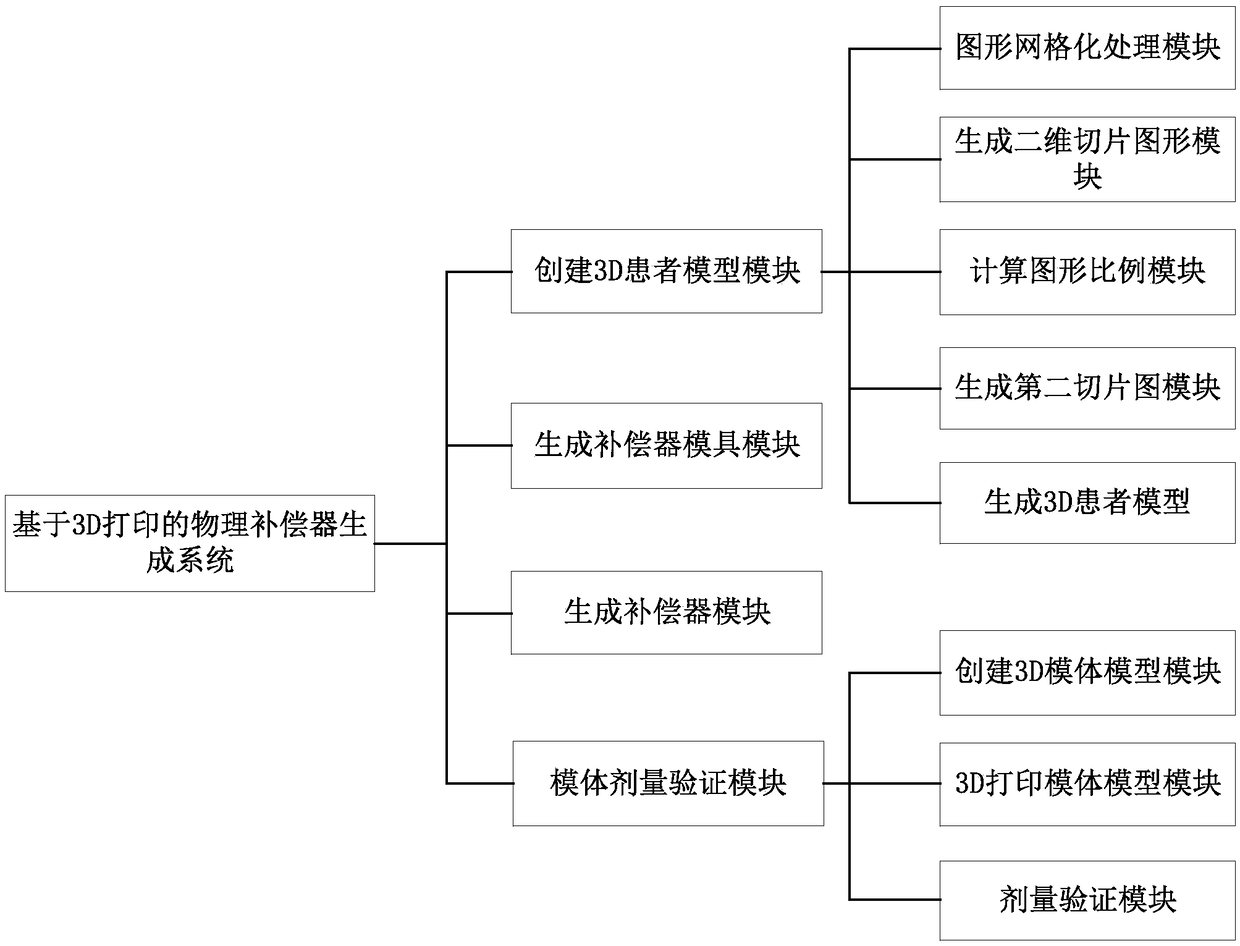

[0045] 3D printing-based physical compensator generation methods, such as figure 1 shown, including the following steps:

[0046] Creating a 3D patient model, creating a 3D patient model through the patient's body surface data; preferably, the step of creating a 3D patient model includes obtaining the patient's body surface data scanned by a 3D scanner to create a 3D patient model; the step of creating a 3D patient model also includes obtaining the medical information of the patient Image data, such as: CT, MRI, PET-CT image data of the patient, reconstruct the body surface contour of the patient through the medical image data, and smooth the body sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com