Multifunctional high-efficiency automobile part stamping forming machine

A technology of auto parts and stamping forming, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as low production efficiency, manpower consumption, waste of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

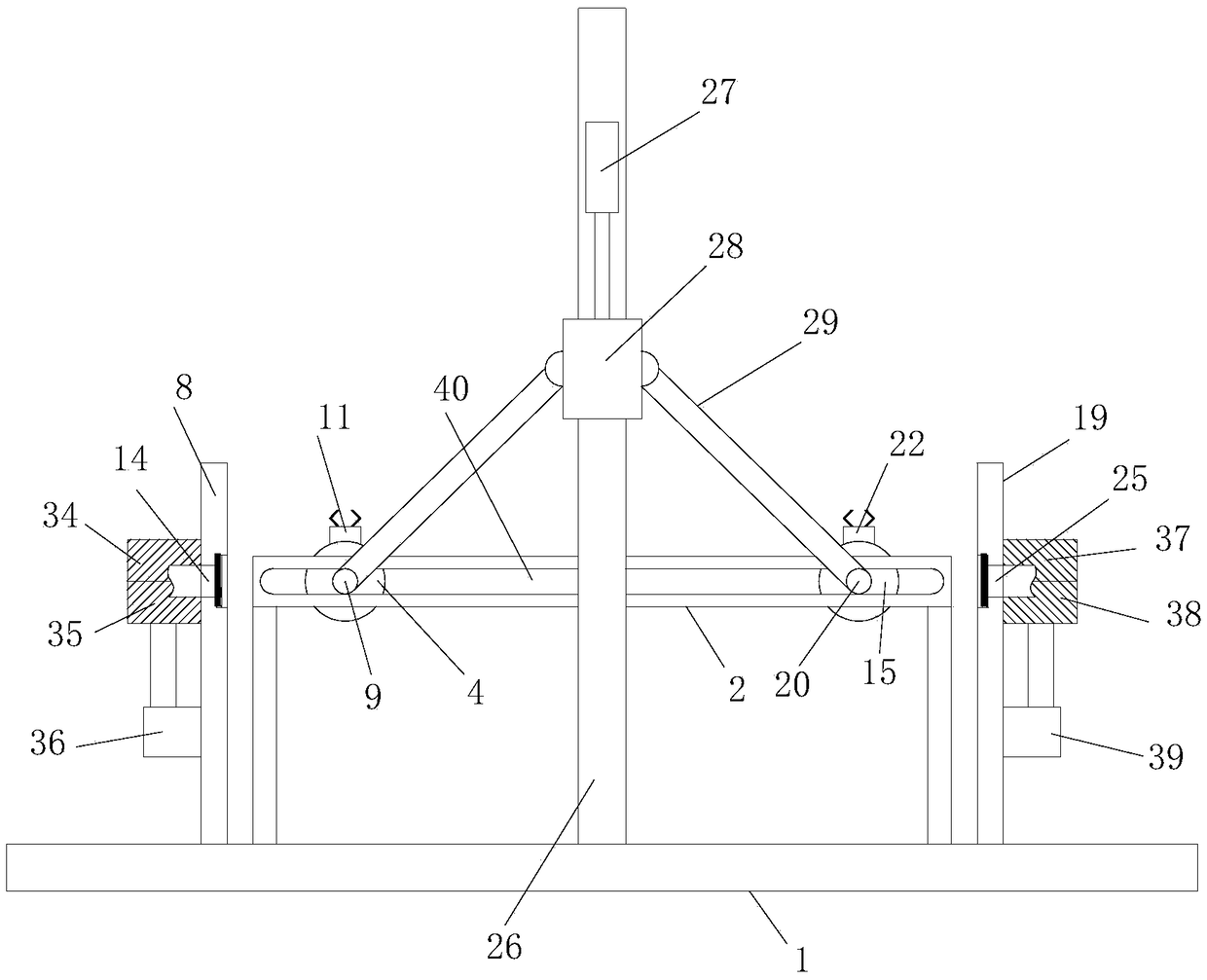

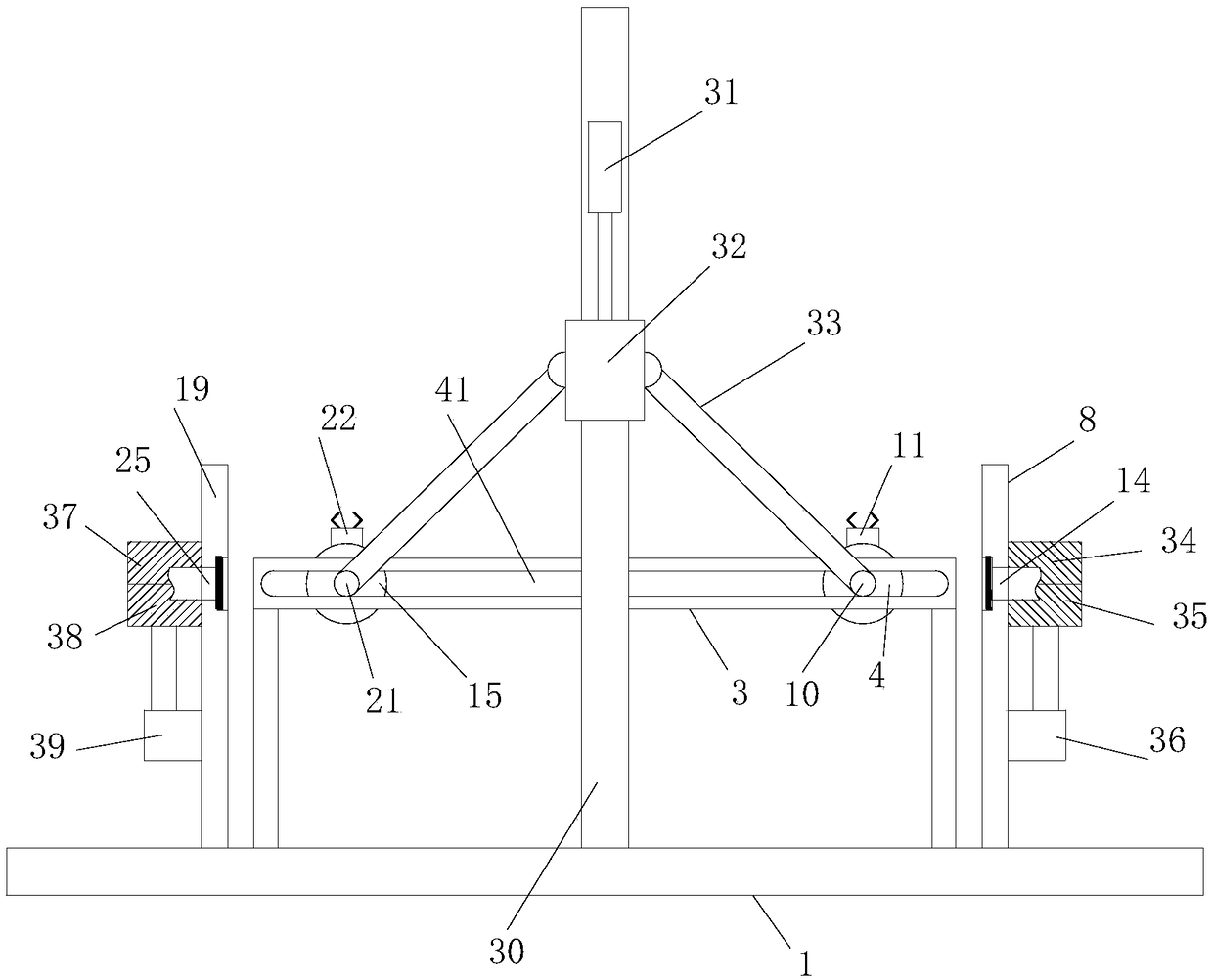

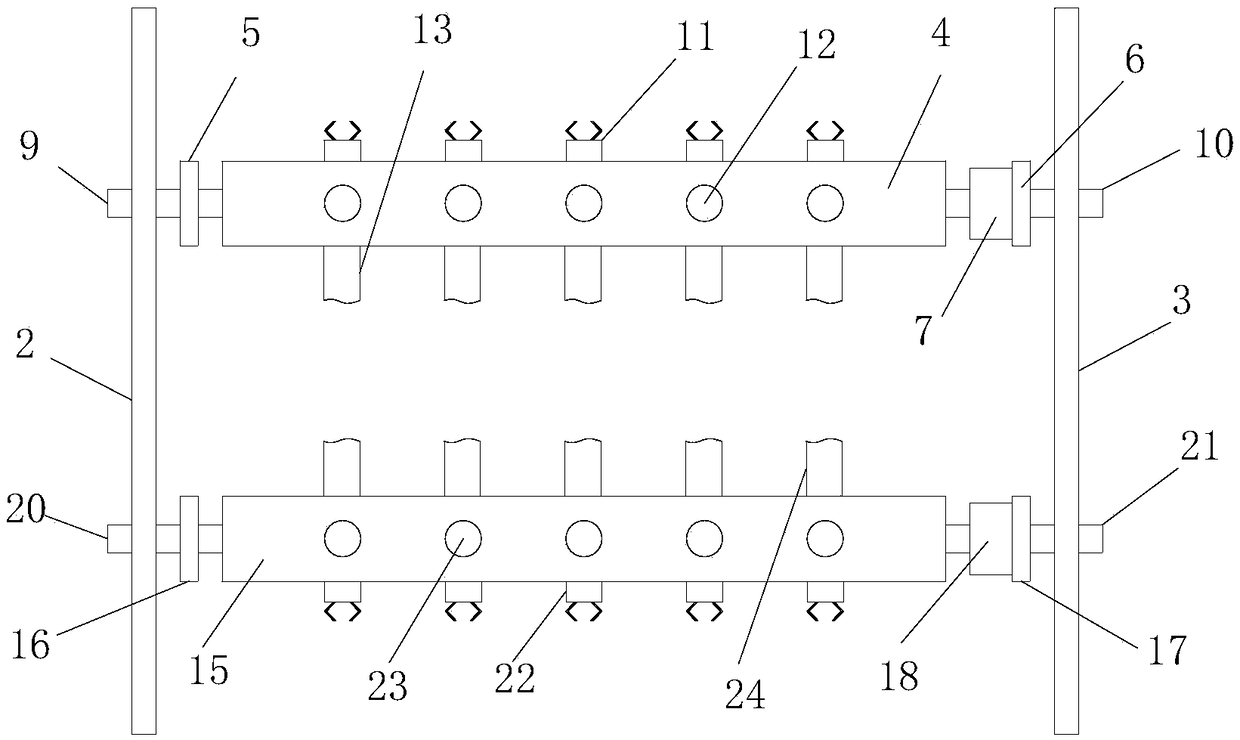

[0020] Such as Figure 1-Figure 3 as shown, figure 1 It is a structural schematic diagram of a multi-functional high-efficiency auto parts stamping machine proposed by the present invention; figure 2 It is the right side view of a multi-functional and high-efficiency auto parts stamping machine proposed by the present invention; image 3 It is a structural schematic diagram of the first stamping and forming assembly and the second stamping and forming assembly in a multifunctional and high-efficiency auto parts stamping and forming machine proposed by the present invention.

[0021] refer to Figure 1-Figure 3 , a multifunctional high-efficiency auto parts stamping machine proposed by the present invention, a base 1, a first mounting plate 2, a second mounting plate 3, a first stamping assembly, a second stamping assembly, a first power unit and Second power unit; where:

[0022] The first mounting plate 2 and the second mounting plate 3 are relatively arranged above the ba...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap