Aluminum wheel rim low-pressure casting mold with heat conduction system

A technology of low-pressure casting and heat conduction, which is applied in the field of low-pressure casting molds for aluminum alloy wheel rims, can solve problems such as the inability to guarantee the continuous and periodic production of the casting process, and achieve the effect of continuous and periodic casting production and the improvement of material strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

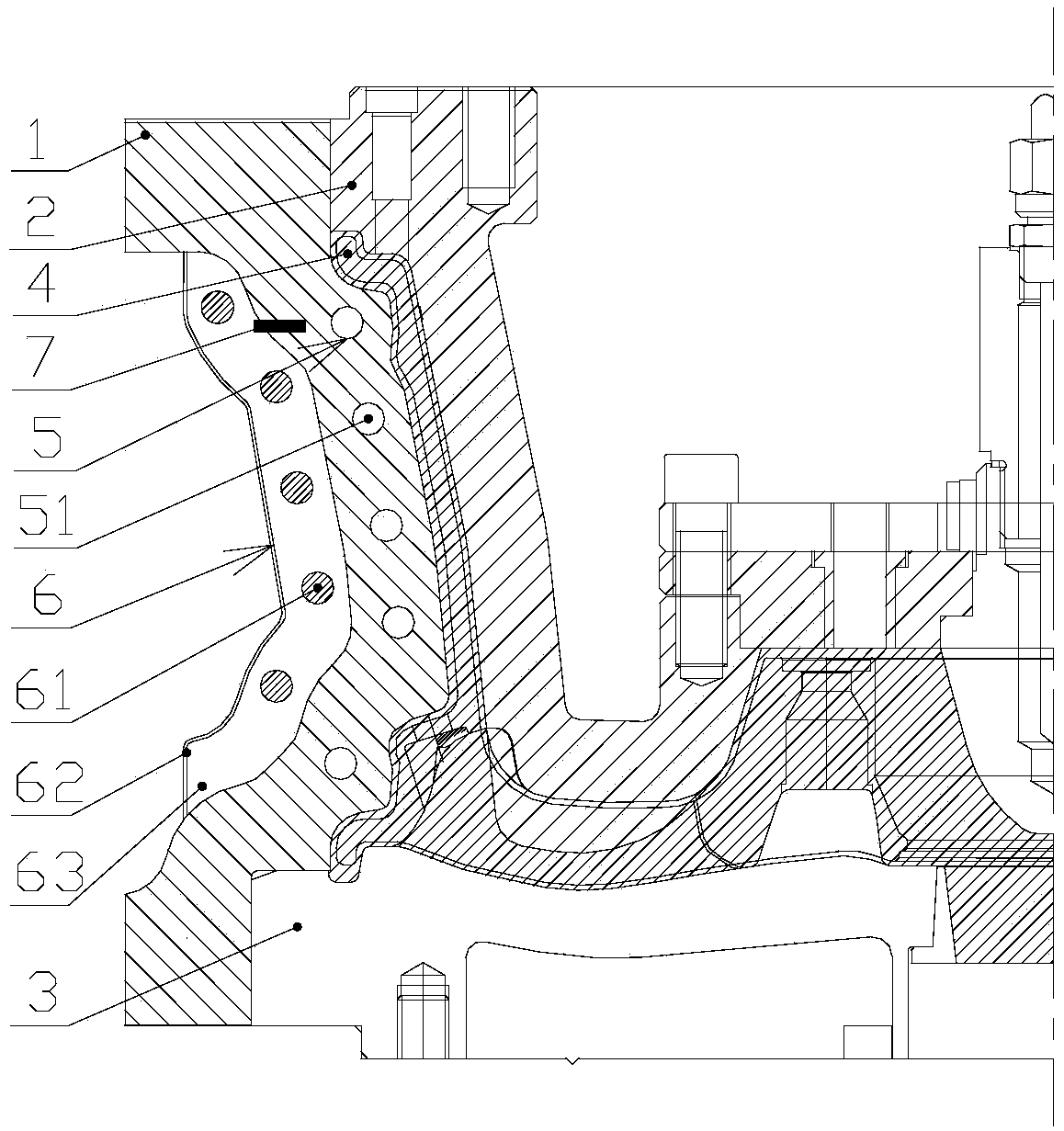

[0024] refer to figure 1 , figure 1 It is a schematic diagram of the half-section structure of Embodiment 1 of the aluminum wheel rim low-pressure casting mold of the present invention, including a side mold 1, a fixed mold 2 and a bottom mold 3, figure 1 Only the structure of one side mold is shown, and the structures of the other three side molds are the same as this side mold. After the four side molds 1 are closed, they form a thin-walled rim cavity 4 with the fixed mold 2 and the bottom mold 3 . The mold wall of the side mold 1 is provided with a heat export system 5 and a temperature sensor 7 for measuring the temperature of the mold wall of the side mold, and the outer surface of the side mold 1 is provided with a heat introduction system 6 .

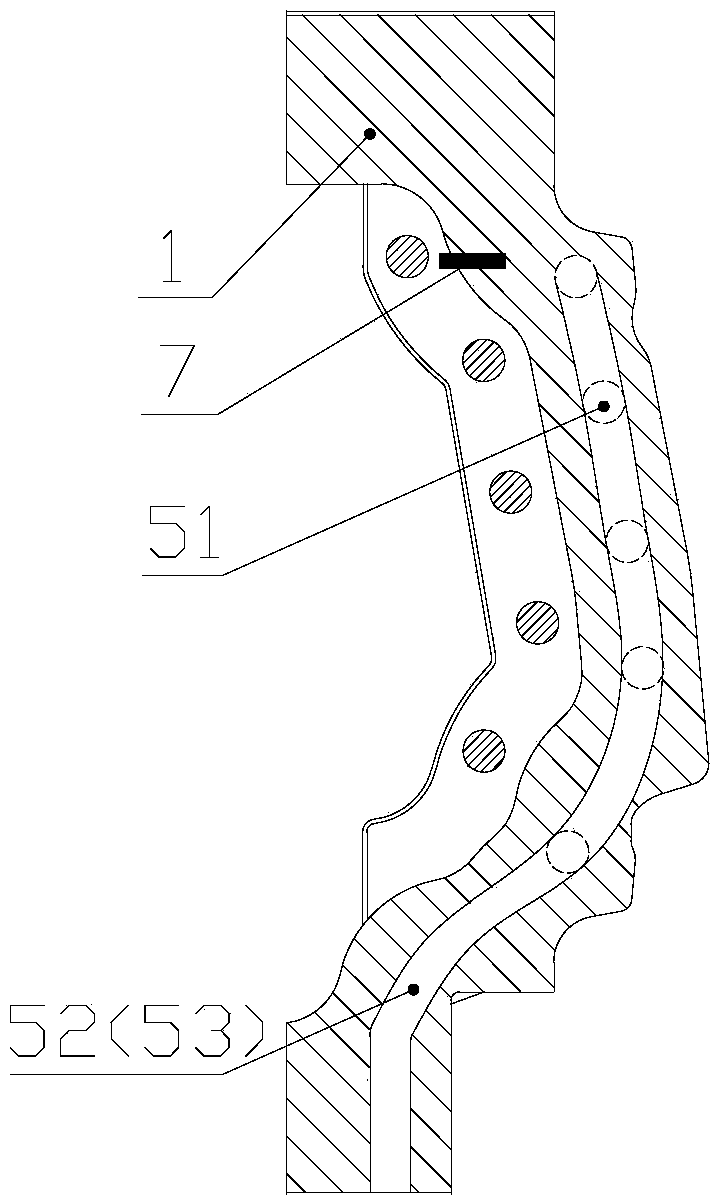

[0025] In this embodiment, the heat removal system 5 includes a general inlet tunnel 51 , a total outlet tunnel 52 , and several fan-shaped tunnels 51 surrounding the cavity. The fan-shaped annular channel channels 51 are arran...

Embodiment 1

[0028] Example 1 works like this:

[0029] When the alloy fills the thin-walled rim cavity 4, the heat export system 5 is started, that is, cold oil is introduced into the general inlet channel 52, and the cold oil flows into each inlet of the fan annular channel 51 through the general inlet channel 52, and flows through the fan annular channel The tunnels 51 then converge from each outlet to the general outlet pipeline 53, and flow out of the mold through the total outlet pipeline 53. During the flow of the cold oil in the mold wall, the latent heat of alloy crystallization and crystallization heat are quickly transferred out. When the temperature of the side mold part shown by the temperature sensor 7 reaches 430° C., stop feeding the cold oil, and the heat derivation system 5 stops working, and stops the heat exchange.

[0030] When entering the next casting cycle, start the heat introduction system 6 60-80 seconds before the mold opening command, that is, the electric heat...

Embodiment approach 2

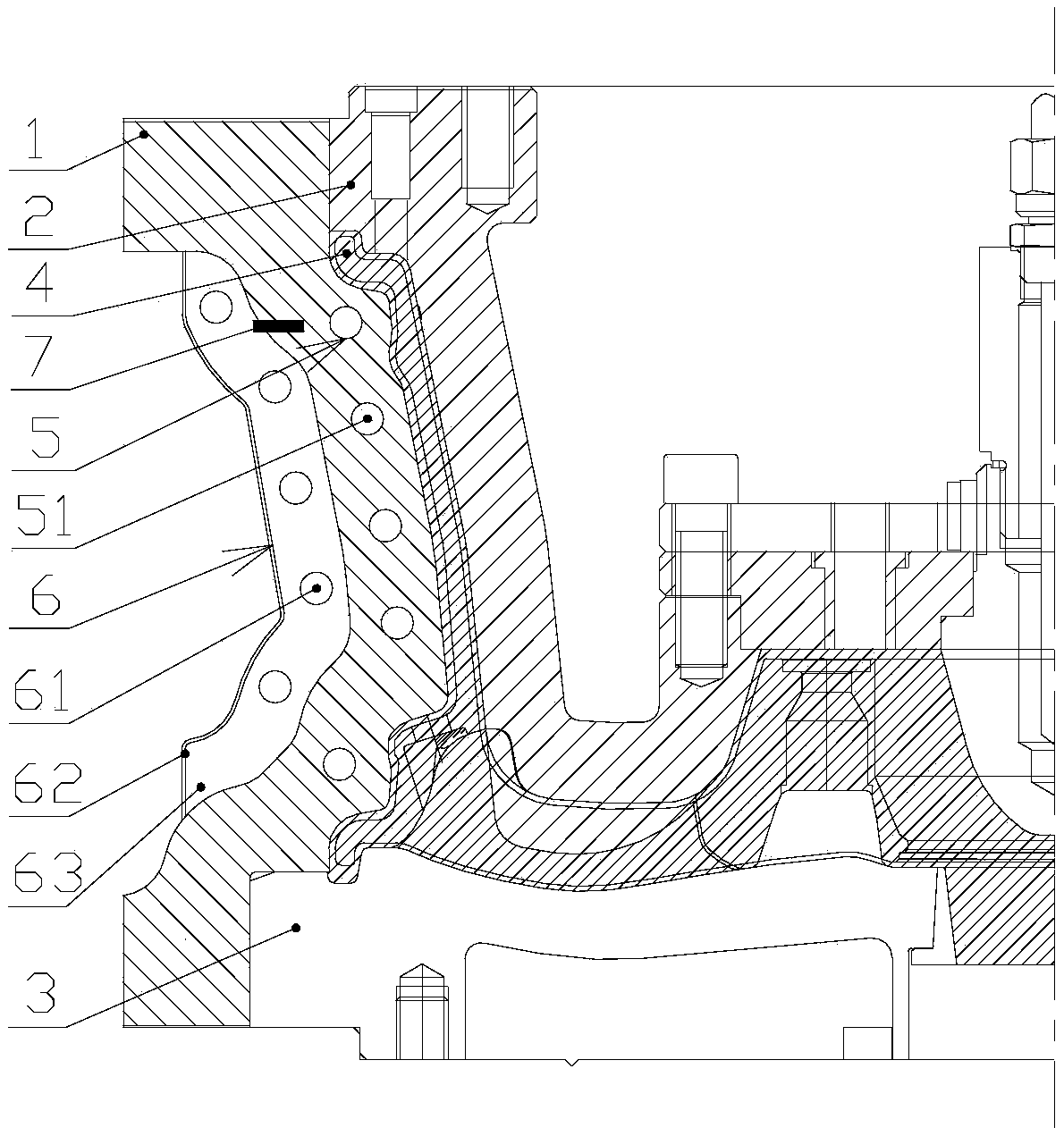

[0032] refer to image 3 and Figure 4 Embodiment 2 is basically the same as Embodiment 1, except that the heating device is a total inlet pipe 64, a total outlet pipe 65 arranged in the heat transfer oil, and a plurality of fan-shaped circular pipes 61 surrounding the cavity; Described fan annular pipe 61 is arranged at intervals from top to bottom, and its inlet end is communicated with through total inlet pipe 64, and outlet end is communicated through total outlet pipe 65; All are closed, and the other ends extend to the outside of the mold through the heat insulating layer 62 and communicate with the space outside the mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com