3D printing system and method

A 3D printing and component technology, applied in the field of 3D printing systems, can solve problems such as easy defects in products, and achieve the effect of improving forming efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

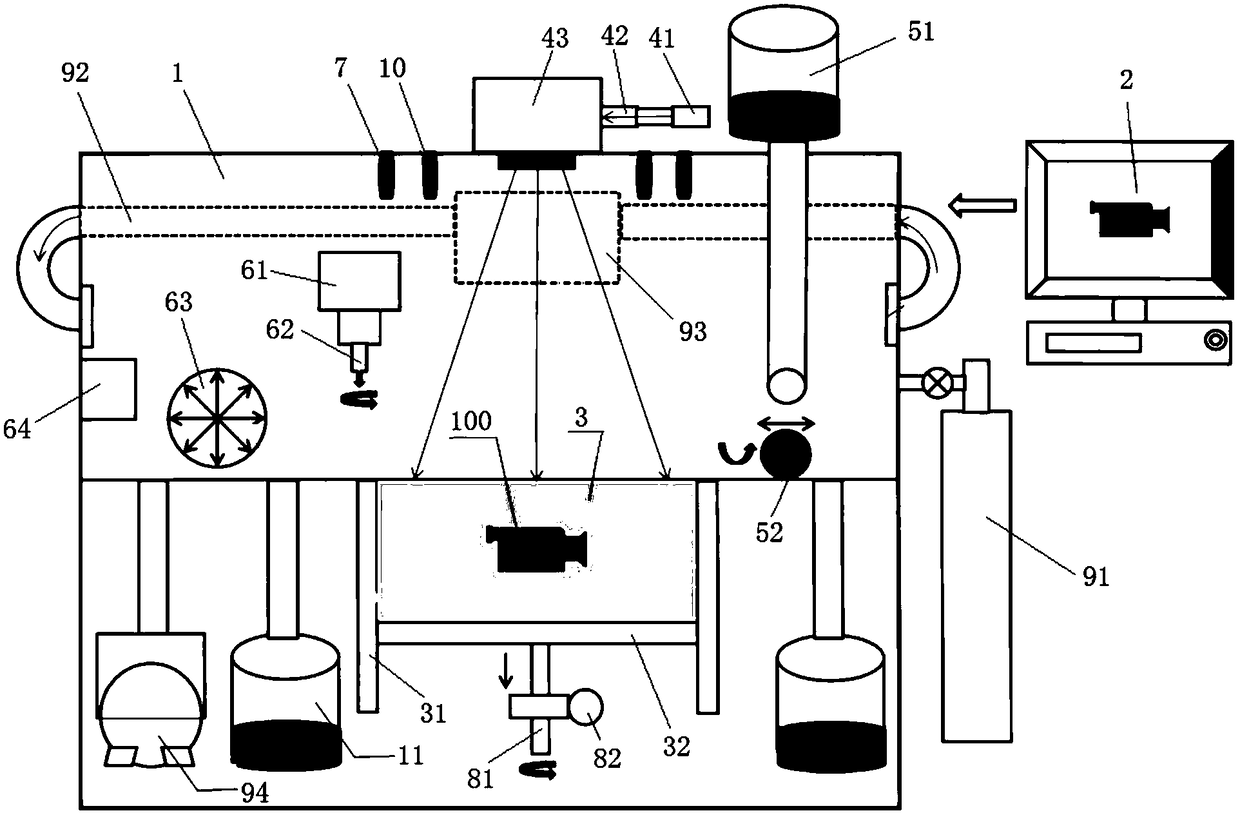

[0027] Such as figure 1 As shown, the present invention provides a preferred embodiment of a 3D printing system.

[0028] Specifically, a 3D printing system, the 3D printing system includes a sealed cavity 1, a processor 2, a powder cylinder 3, a laser component, a powder spreading component and a milling component, and the powder cylinder 3, a powder spreading component and a milling component Located inside the sealed chamber 1, the processor 2 and the laser assembly are arranged outside the sealed chamber 1, the laser assembly includes a laser 41, a dynamic focusing unit 42 and a vibrating mirror 43, and the laser 41 emits laser light , and the spot size is adjusted by the dynamic focusing unit 42 , and then irradiated onto the vibrating mirror 43 , and the vibrating mirror 43 reflects the laser light to the inside of the sealed cavity...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap