Full-automatic double-shaft tightening machine for flange bolt

A fully automatic, screwing machine technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problem of no variable pitch function, achieve the effect of reducing labor intensity, good versatility, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing.

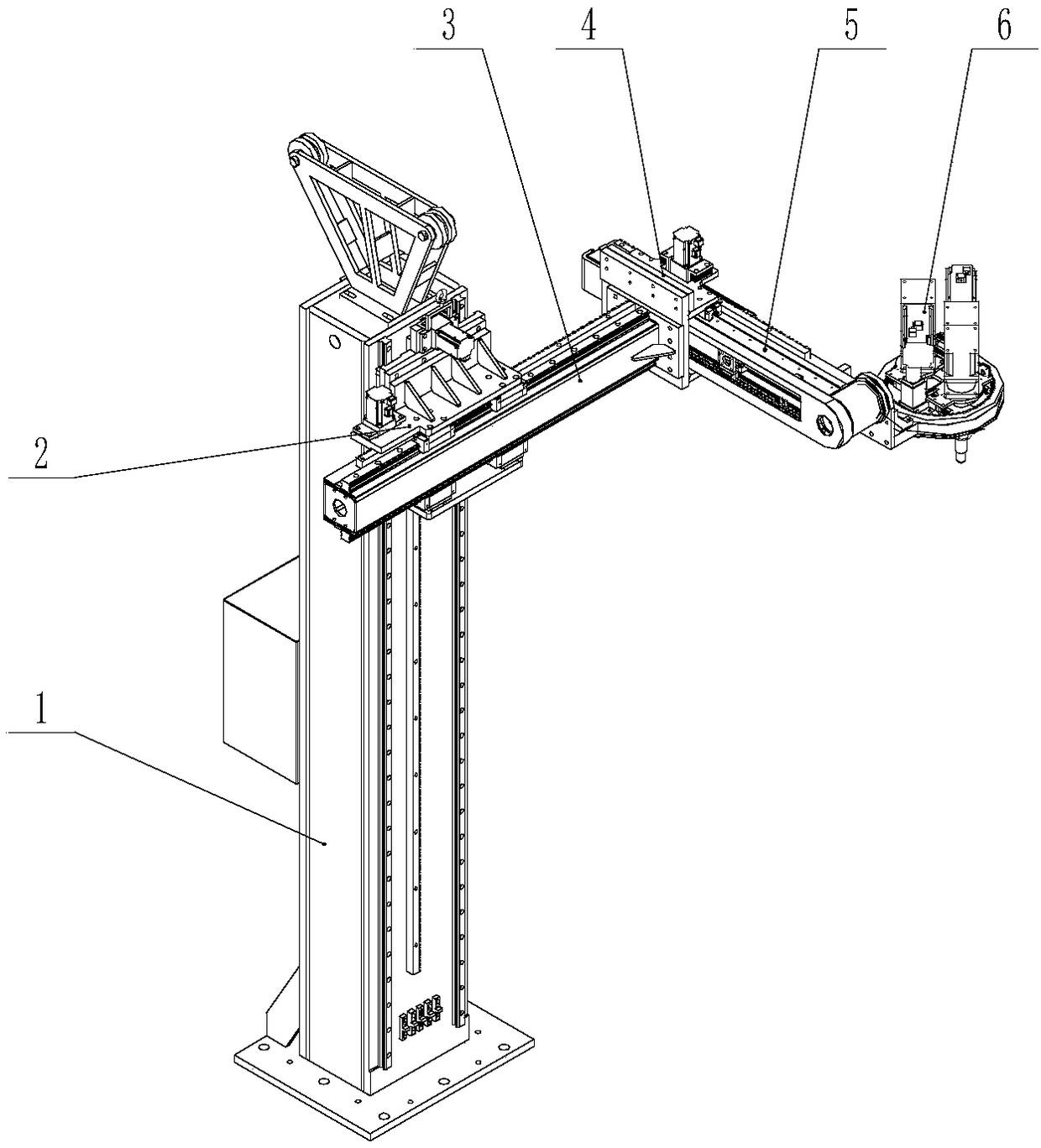

[0038] Such as figure 1 As shown, the automatic double-axis tightening machine for flange bolts according to the present invention includes a frame device 1, a boom connector 2, a boom device 3, a turning arm connector 4, a turning arm device 5, and a rotating tightening device 6 and electrical control system.

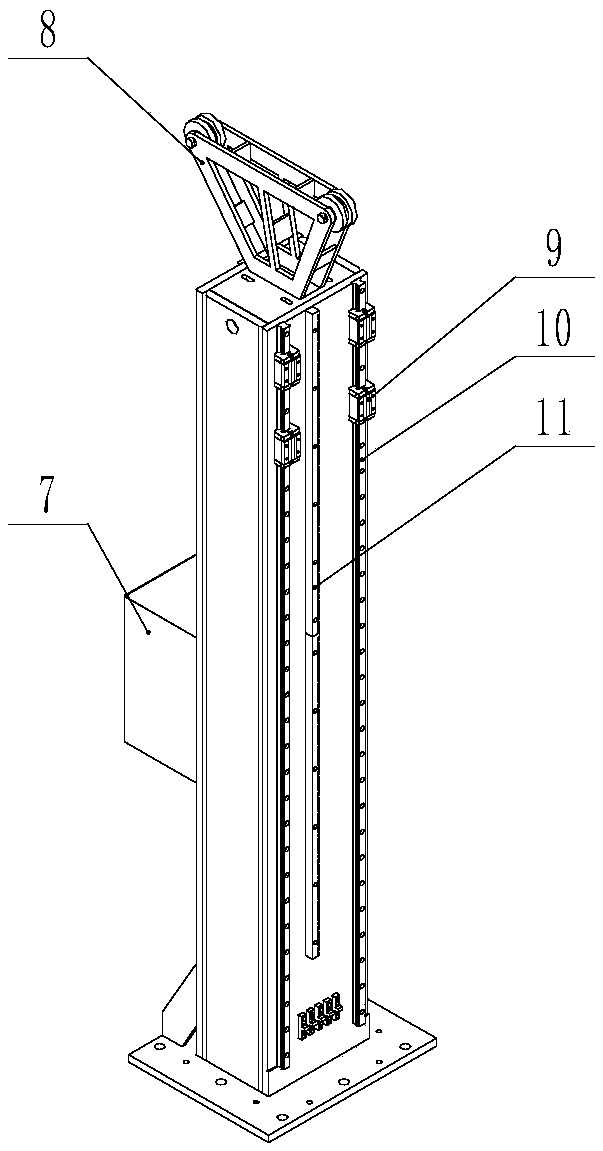

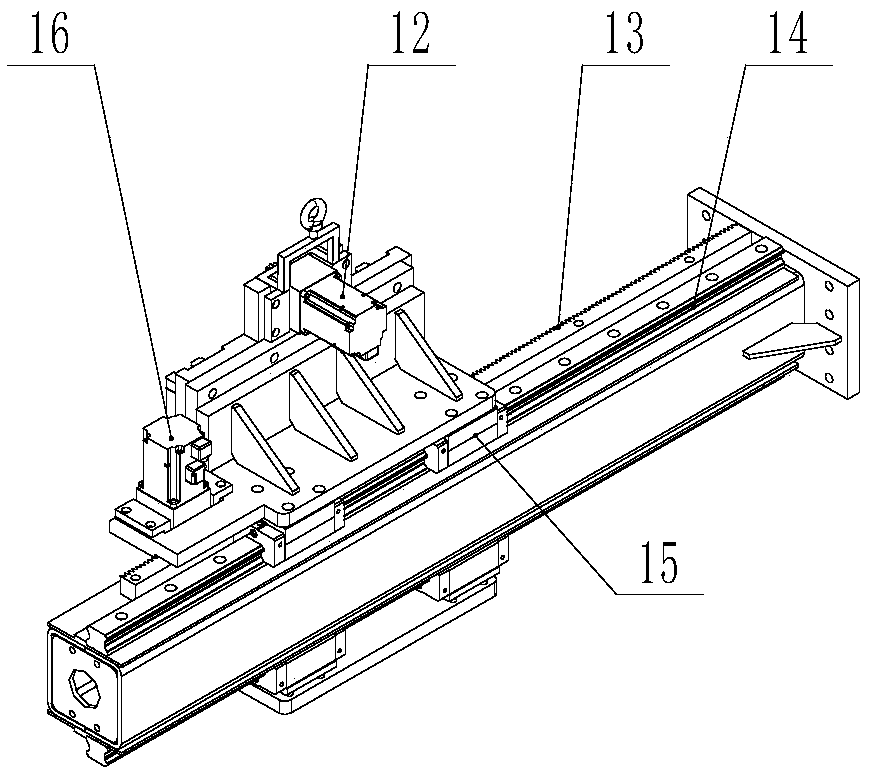

[0039]The frame device 1 is connected to the boom connecting part 2 through the Z-axis driving device that controls the moving of the boom connecting part 2 along the Z axis; the boom connecting part 2 is connected with the X-axis driving device that controls the moving of the boom device 3 along the X axis It is connected with the swing arm device 3; the swing arm device 3 is connected with the turning arm connecting part 4, and the turning arm connecting part 4 is connected with the turning arm device 5 through the Y-axis driving device which controls the turning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com