Work clamping device

A clamping device and workpiece technology, applied in workpiece clamping devices, positioning devices, metal processing machinery parts, etc., can solve the problems of increasing the volume and weight of the mechanism, increasing the manufacturing cost, etc., reducing the volume and weight, and increasing the reliability. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

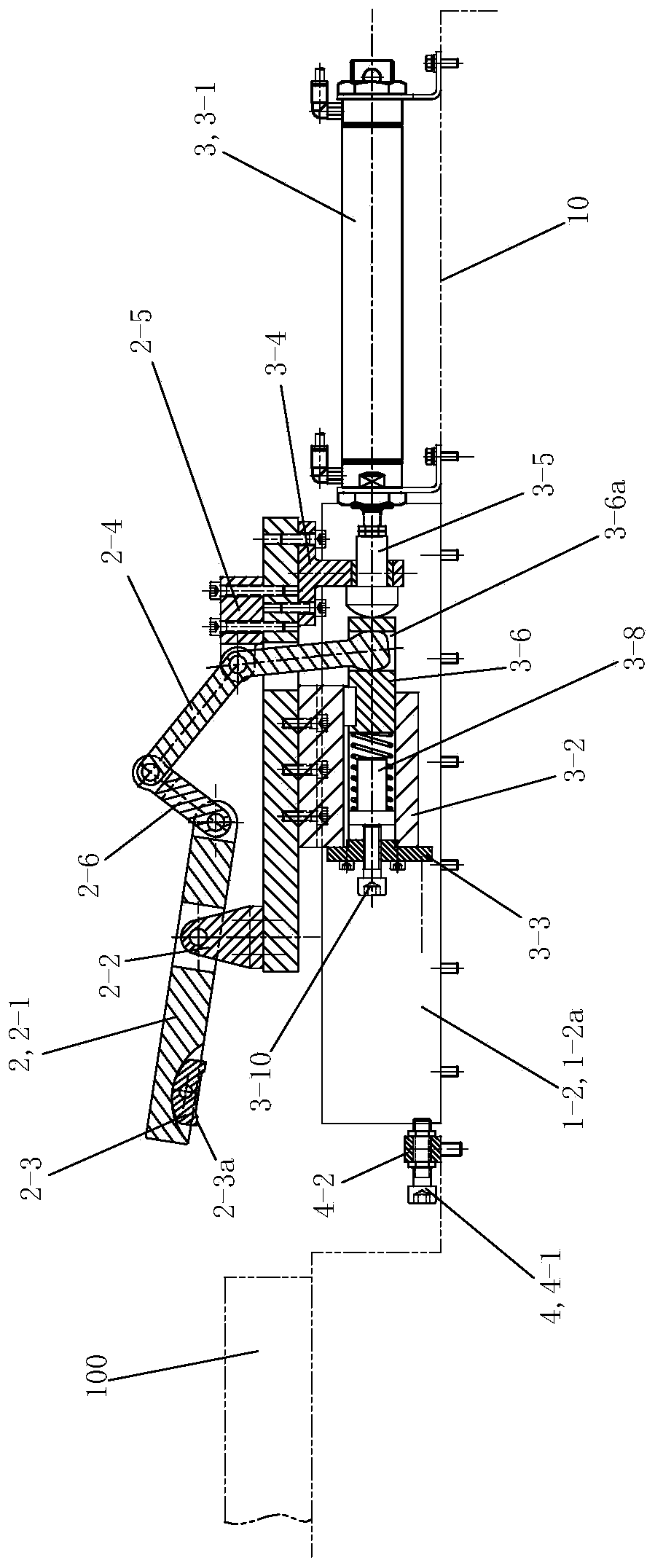

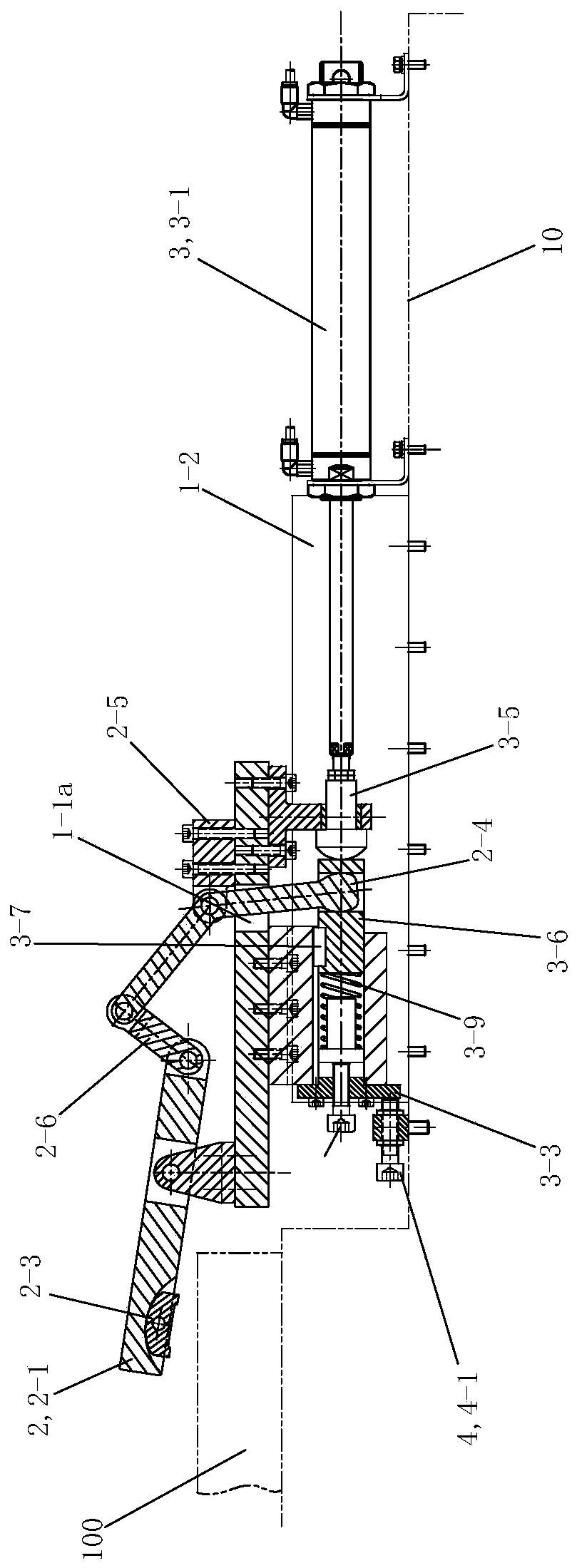

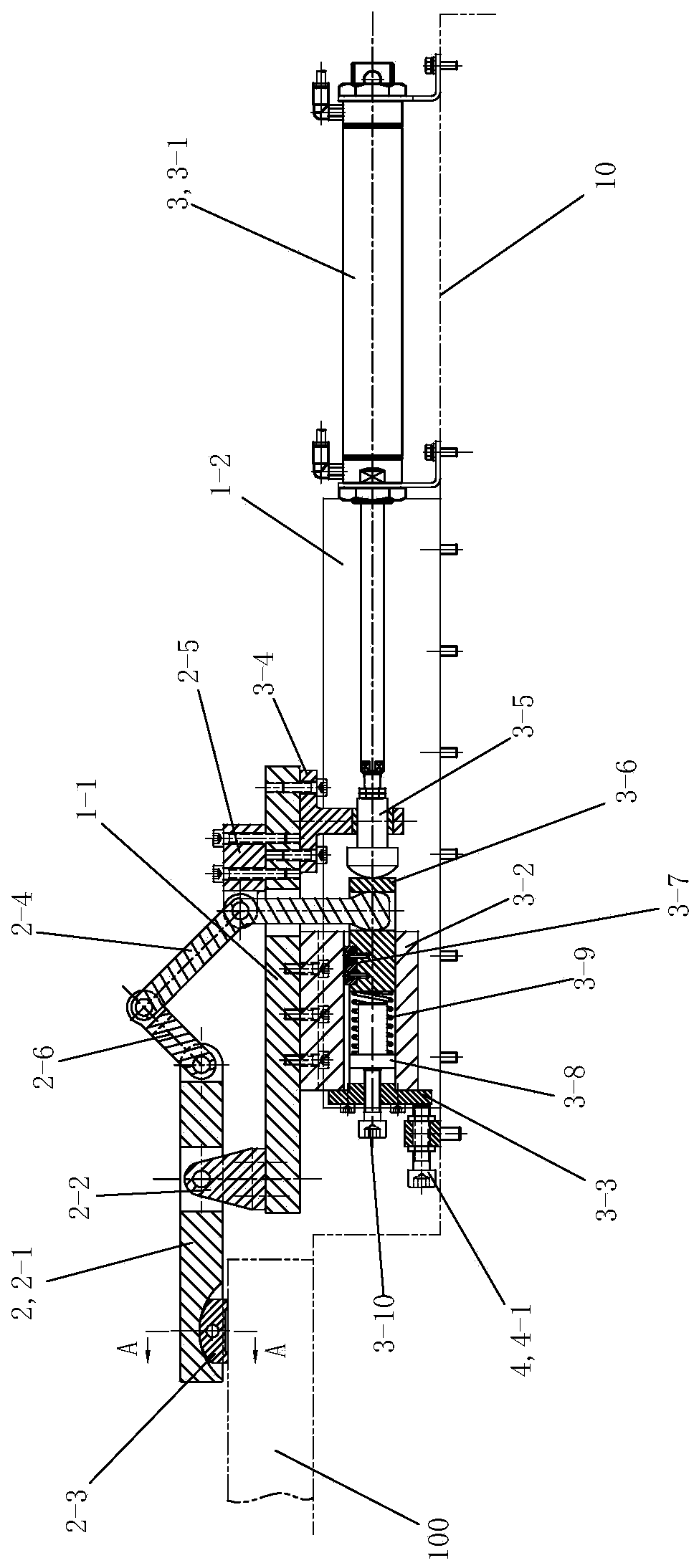

[0040] See Figure 1 to Figure 14 , The workpiece clamping device of the present invention includes a sliding table assembly 1 , a pressing assembly 2 , a driving assembly 3 and a limiting assembly 4 .

[0041] See Figure 1 to Figure 4 , Figure 6 and Figure 7 , The sliding table assembly 1 includes a sliding table 1-1 and a linear guide rail 1-2. The front and back of the slide table 1-1 is provided with a lever hole 1-1a that runs through it up and down. There are two linear guide rails 1-2, and the two linear guide rails 1-2 all adopt four-direction equal-load rolling linear guide rail pairs. The two linear guide rails 1-2 are arranged sequentially from front to back, and are parallel to each other. The guide rails 1-2a of the two linear guide rails 1-2 are fixedly arranged on the corresponding workbenches 10 along the left and right directions. The slide table 1-1 is fixedly arranged on the slide blocks 1-2b of the two linear guide rails 1-2. The slide table 1-1 i...

Embodiment 2)

[0047] See Figure 13 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the lower side pressing surface 2-3a of the indenter 2-3 is a rough surface, which is used for pressing the workpiece 100 with a relatively rough surface.

Embodiment 3)

[0049] See Figure 14 , The rest of this embodiment is the same as that of Embodiment 1, the difference is that: the lower pressing surface 2-3a of the indenter 2-3 is an upwardly concave curved surface, which is used for pressing workpieces whose surface is a corresponding curved surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com