A 3D modeling system for large complex geophysical models

A technology for complex geological and physical models, applied in the field of large-scale three-dimensional physical model preparation, which can solve problems such as reducing the labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

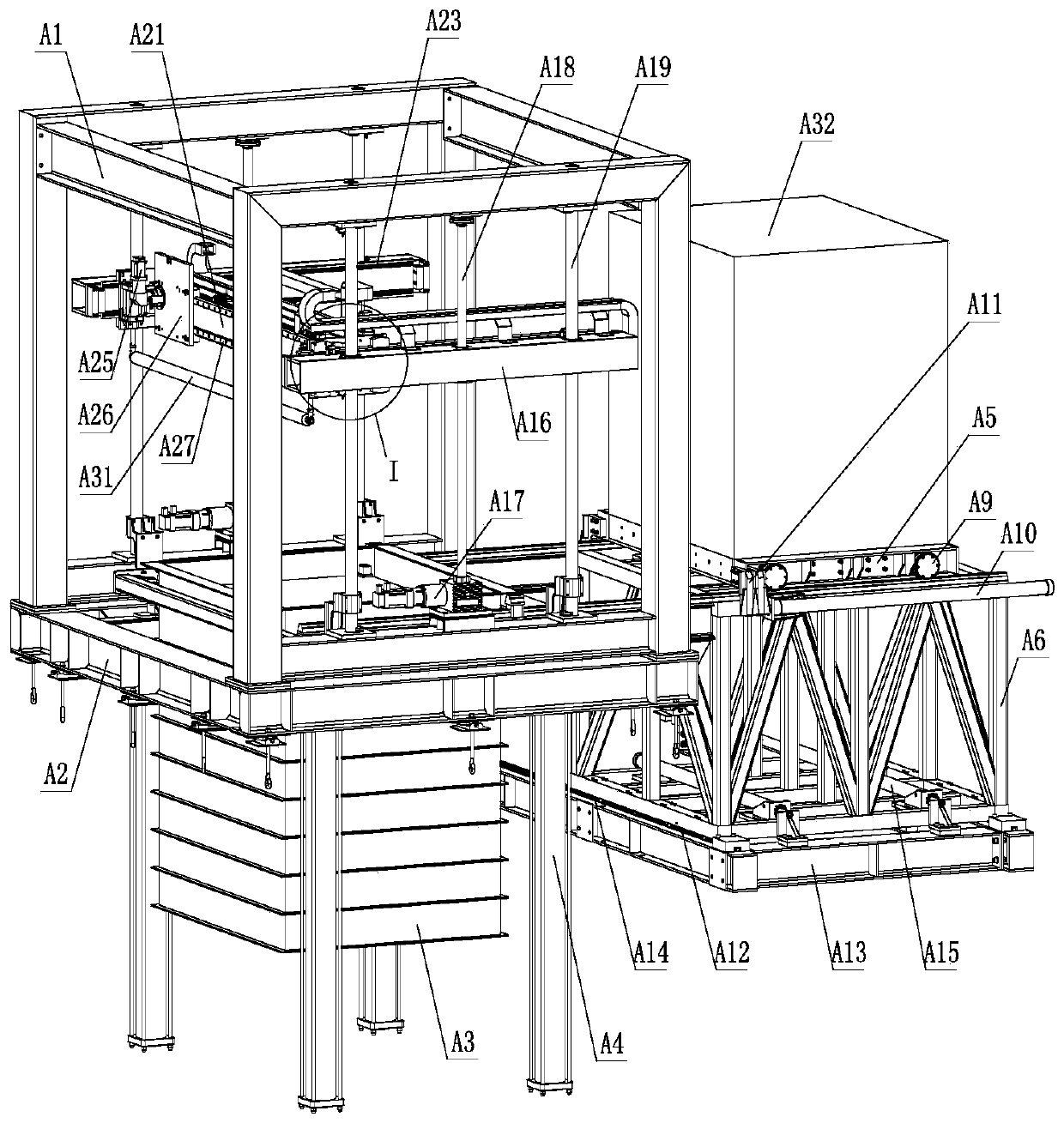

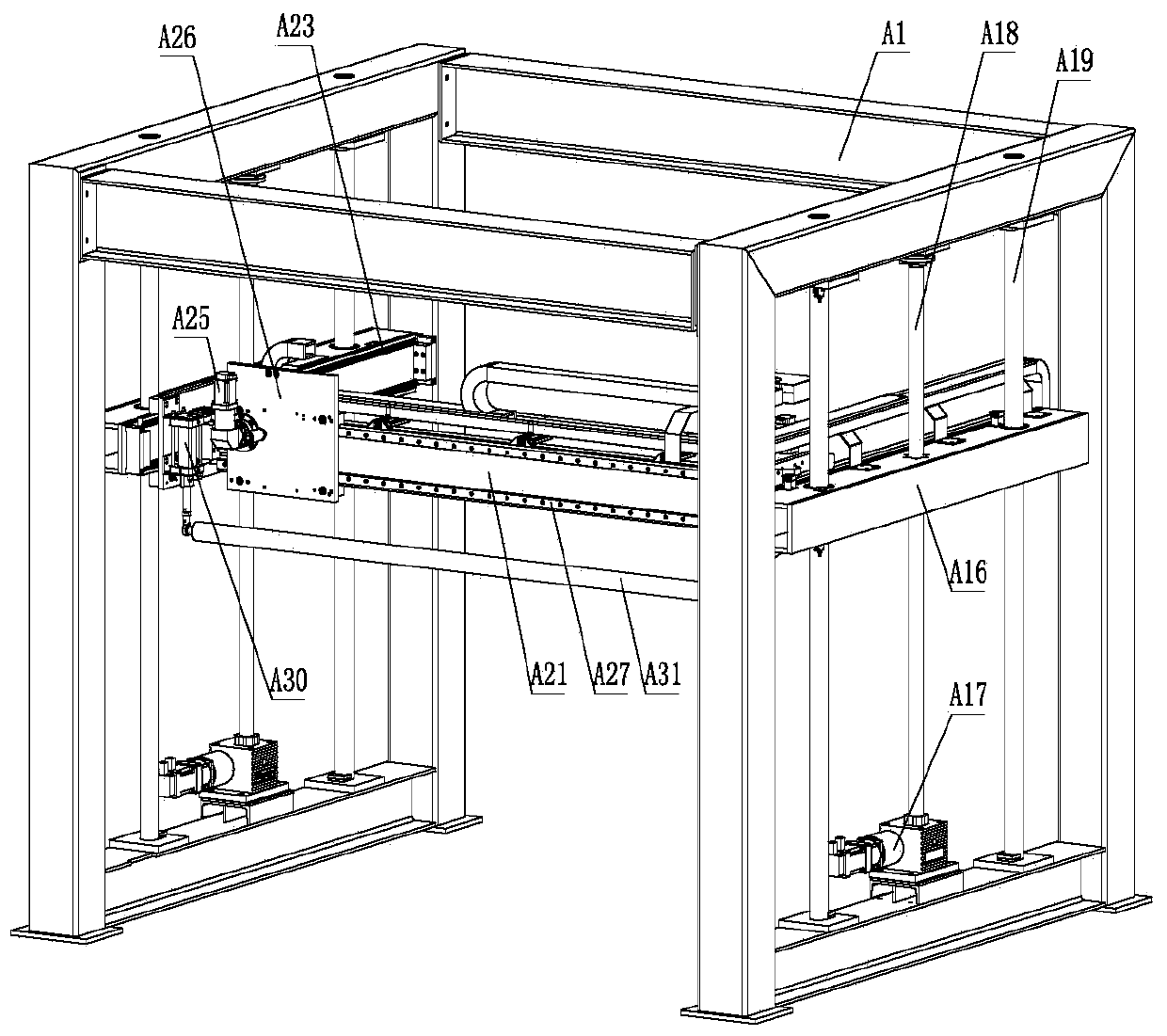

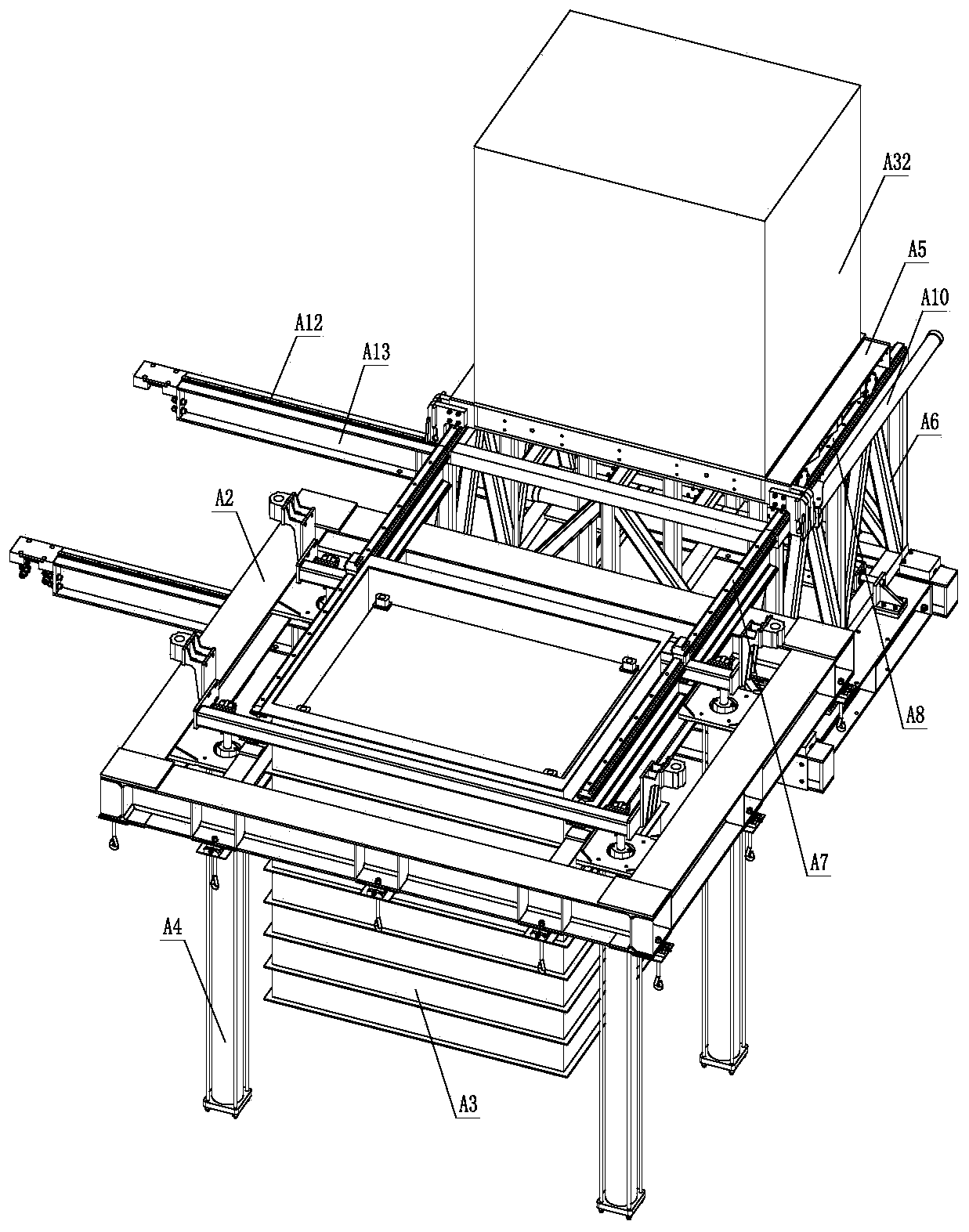

[0067]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0068] A 3D molding system for a large complex geological physical model, including a 3D molding machine, a mixer, a feeding controller, a print head, and a console; the printing head is installed on the 3D molding machine, and the printing head is connected to the mixer through a feeding controller The platform uniformly controls the mixing, feeding and printing processes; the feeding controller includes two structural forms, which are air pump-driven structure and motor-driven structure;

[0069] Such as Figure 1~5 As shown, the 3D molding machine includes a three-axis model printing assembly and a model carrying and transfer assembly; the three-axis model printing assembly includes a printing frame A1, a Z-direction lifting part, a Y-direction horizontal movement part, an X-direction horizontal movement part and Print head; the Z-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com