Patents

Literature

211results about "Movable winding electromagnets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Camera module

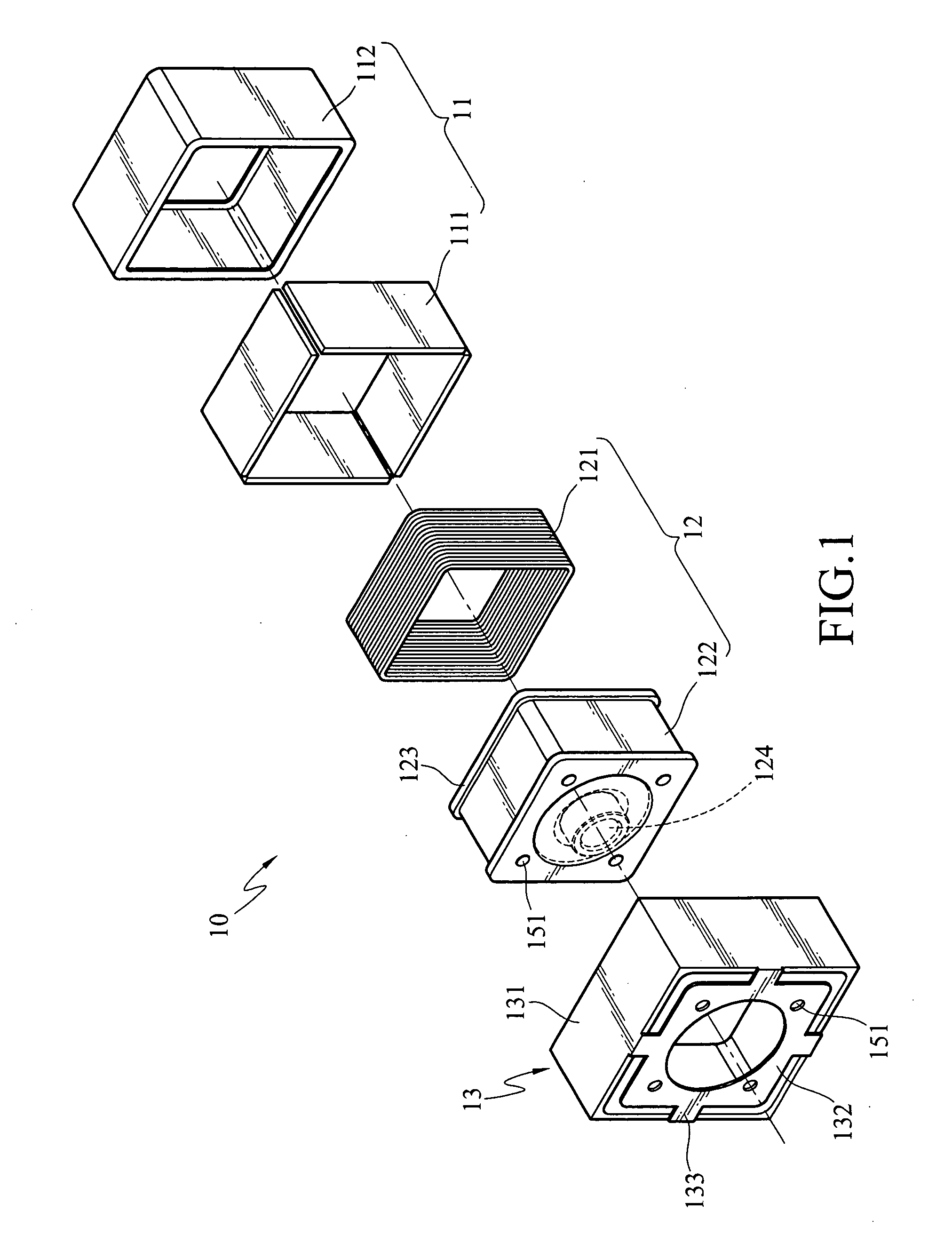

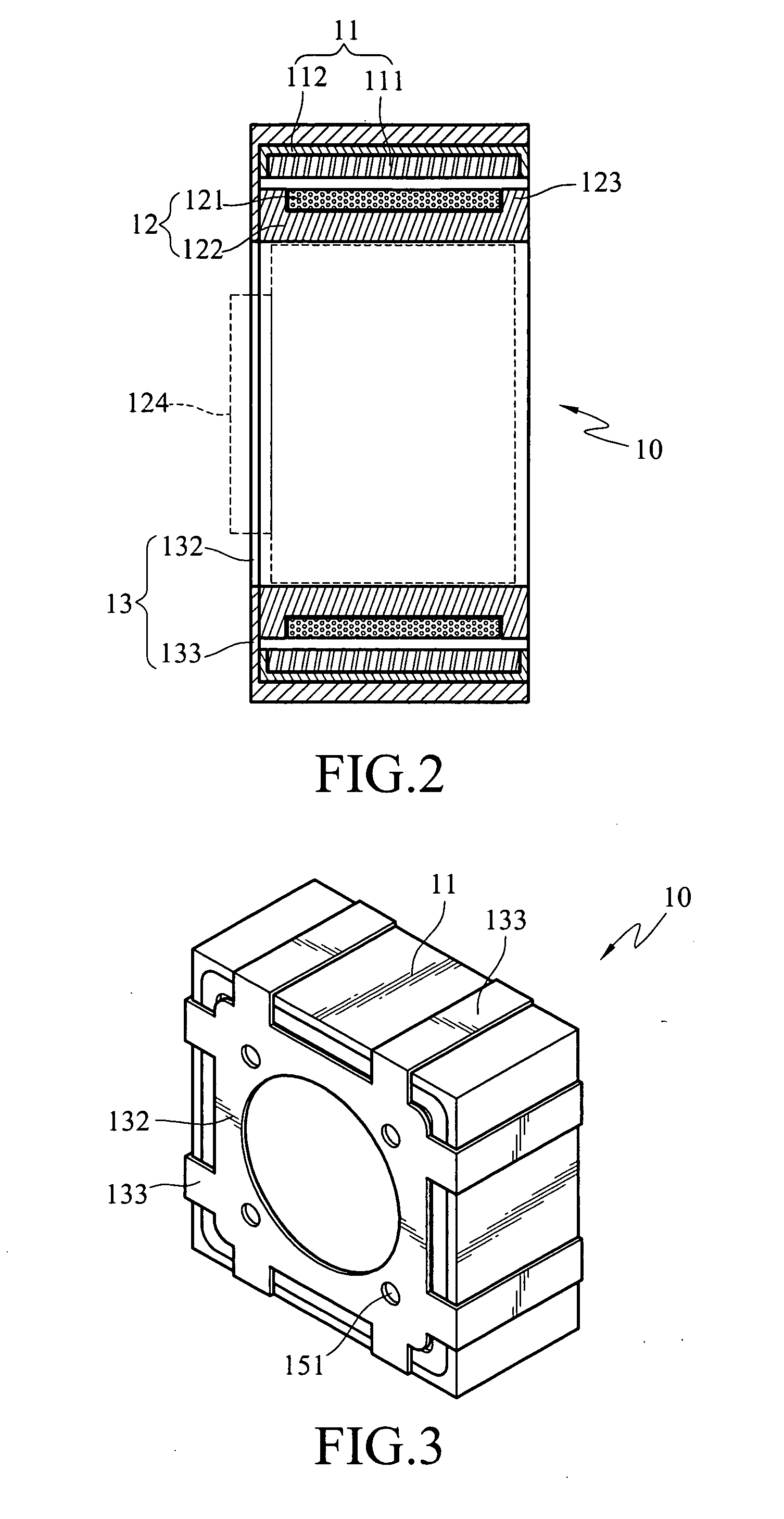

InactiveUS20090310959A1Television system detailsProjector focusing arrangementFocal positionCamera module

An exemplary camera module includes a lens mount, a lens unit, a magnet unit, a printed circuit board (PCB)-based Rogowski coil and a blade spring. The PCB-based Rogowski coil is fixed around the lens unit. The PCB-based Rogowski coil establishes an induced magnetic field when an electric current is applied thereto. The induced magnetic field interacts with the magnet unit to generate a magnetic force moving the lens unit telescopically. The blade spring includes a plurality of ribs. Each rib includes a moveable end connected with the lens unit and an opposite fixed end. The moveable end moves together with the lens unit with respect to the fixed end to cause the ribs to distort and generate an elastic force. The lens unit stops at a focal position when the magnetic force and the elastic force come to a balance.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

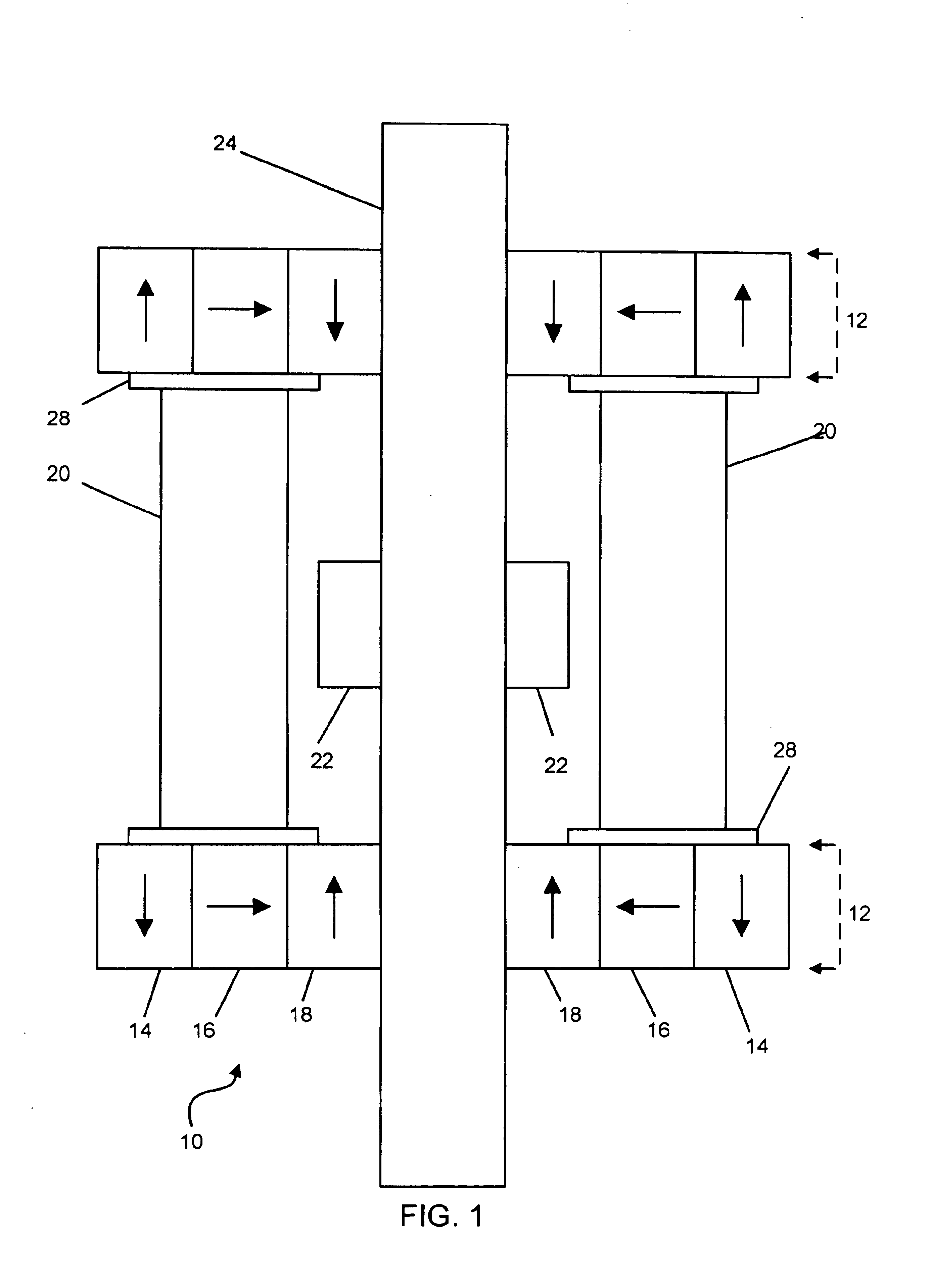

Electromagnetic opposing field actuators

ActiveUS20140354381A1Even by forceReduce in quantityPermanent magnetsElectric switchesMagnetic actuationEngineering

Electromagnetic actuators capable of generating a symmetrical bidirectional force are disclosed. The electromagnetic actuators include a housing made of a ferromagnetic material and a shaft made of a magnetically inert material movable along an axis within the housing. In one type of actuator, captive permanent magnets are arranged on opposite interior end walls of the housing and an electromagnetic coil is mounted on a central portion of the shaft. The electromagnetic coil is capable of generating a force when energized that causes linear displacement of the shaft in either direction along its axis depending on the direction of current through the electromagnetic coil. In another type of actuator, captive electromagnetic coils are arranged on opposing inner end walls of the housing, and a permanent magnet is mounted on a central portion of the shaft. The electromagnetic coils are capable of generating a force when energized that causes linear displacement of the shaft in either direction along its axis depending on a direction of current through the electromagnetic coils.

Owner:ACTIVE SIGNAL TECH

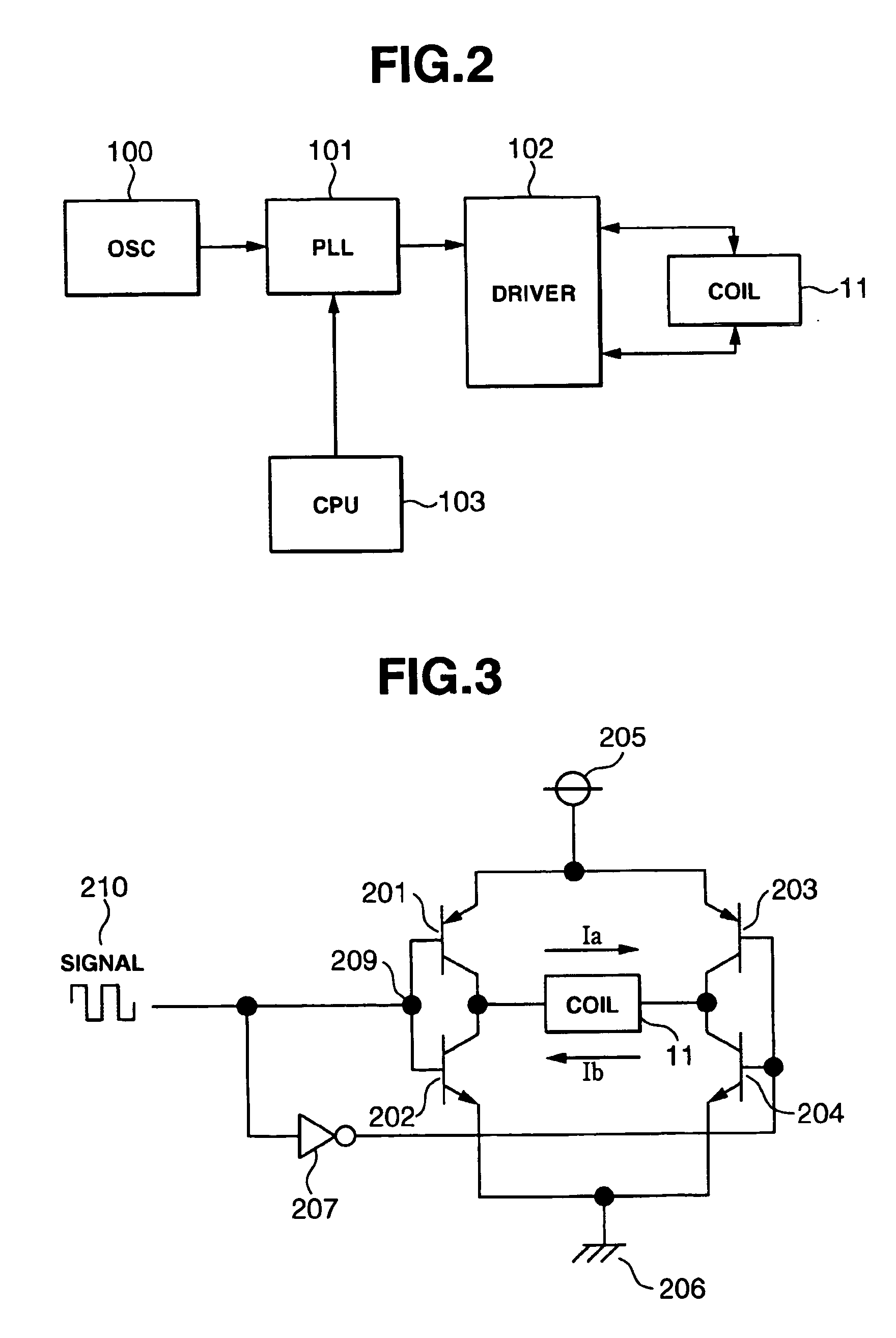

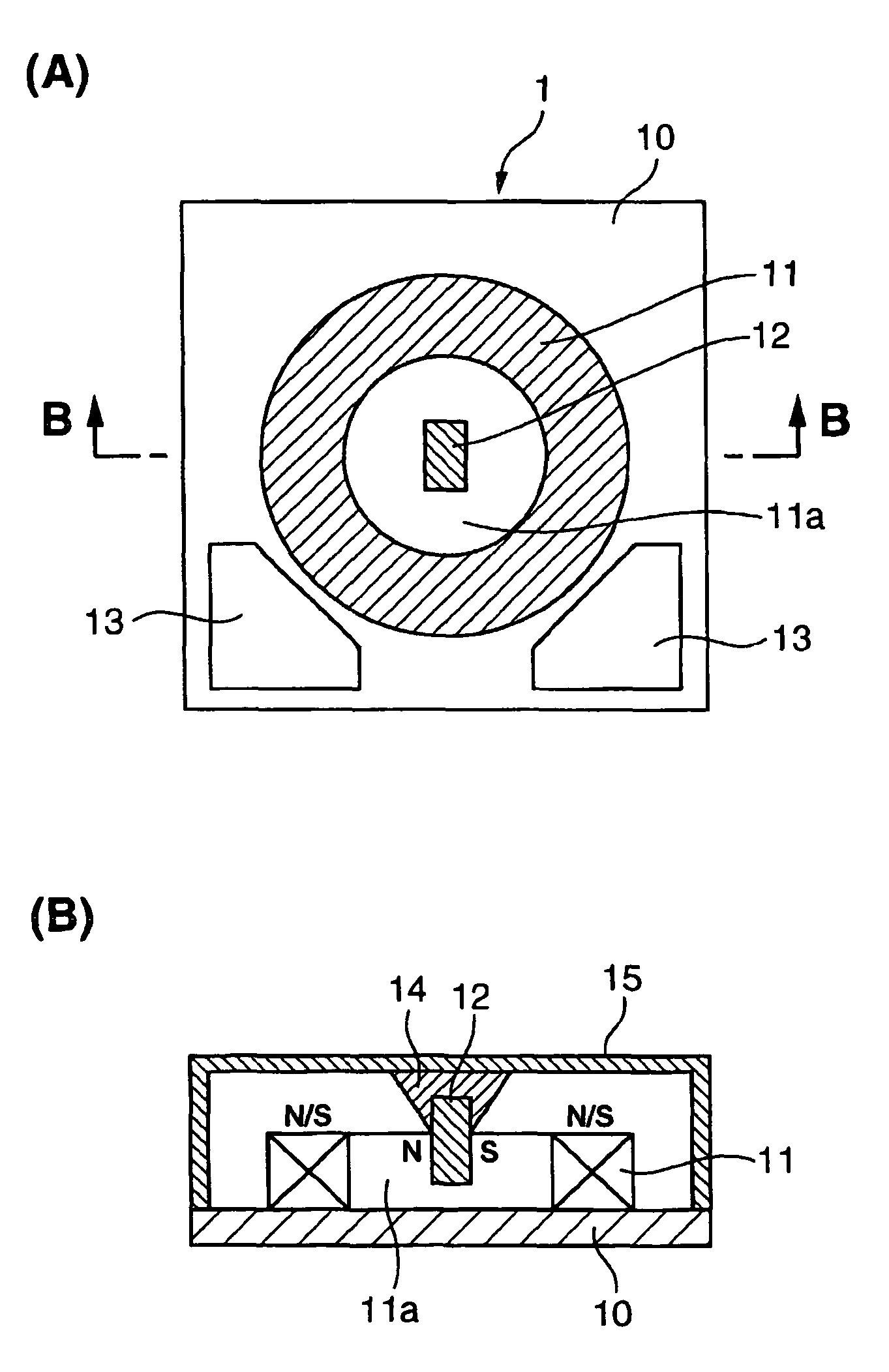

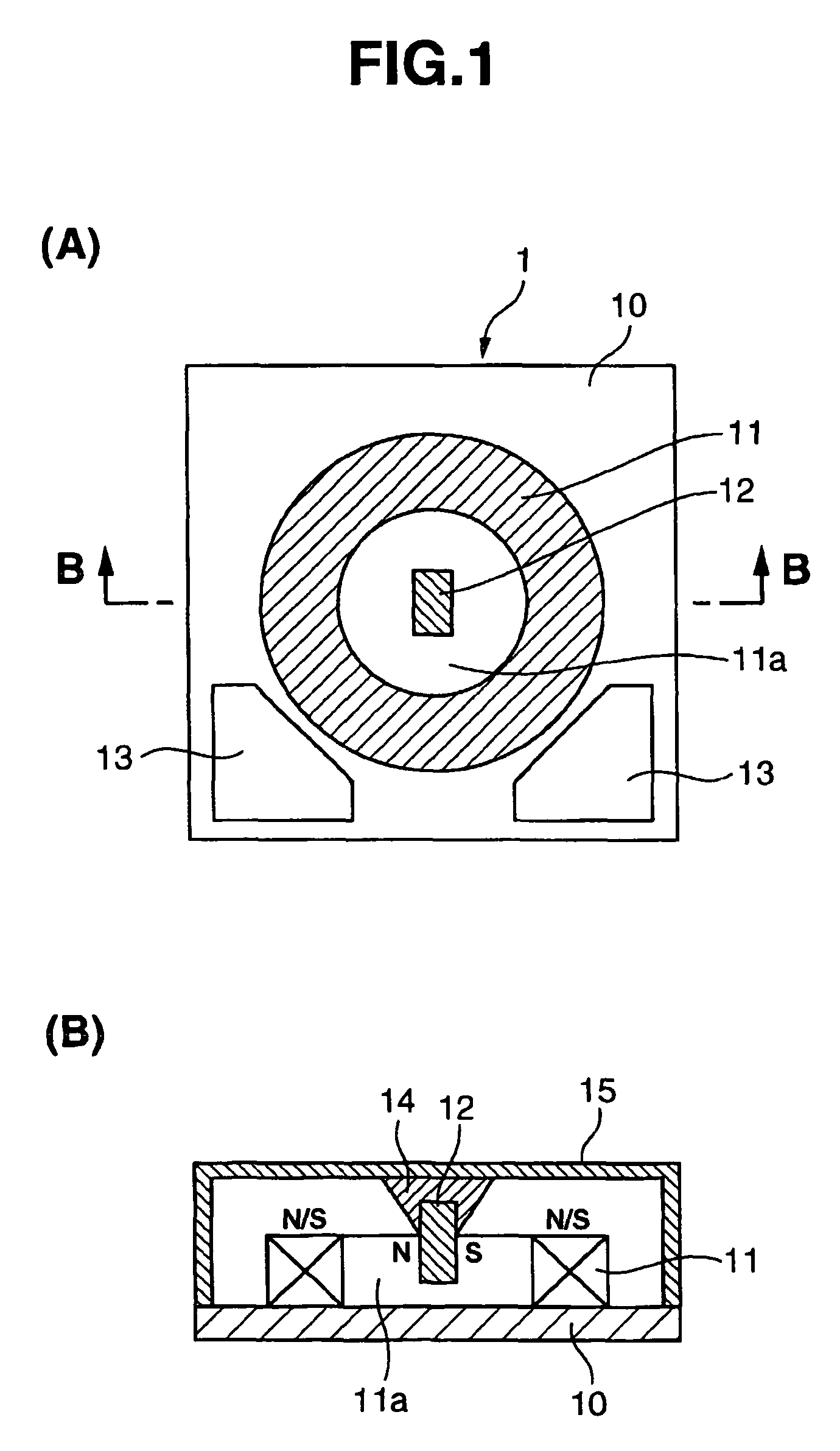

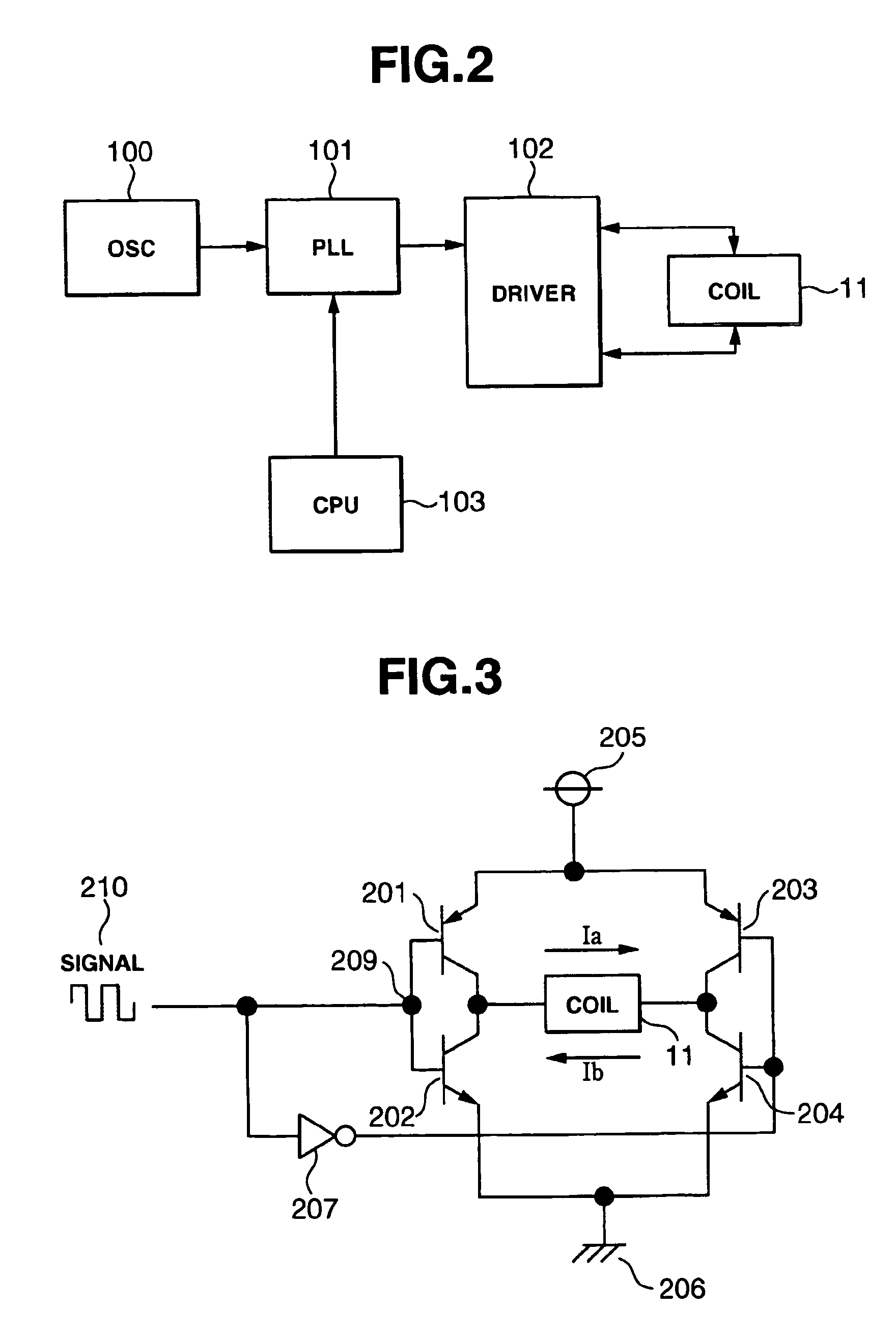

Drive mechanism

InactiveUS20060028751A1Simple magnetic body structureImprove frequency characteristicsTelevision system detailsAC motor controlEngineeringAttraction repulsion

A drive mechanism @is comprised with a set comprising a plurality of magnetic bodies, means for supplying a frequency signal to said set, and means for producing movement caused by the attraction / repulsion between the magnetic bodies. The movement is the driving source of the drive mechanism.

Owner:SEIKO EPSON CORP

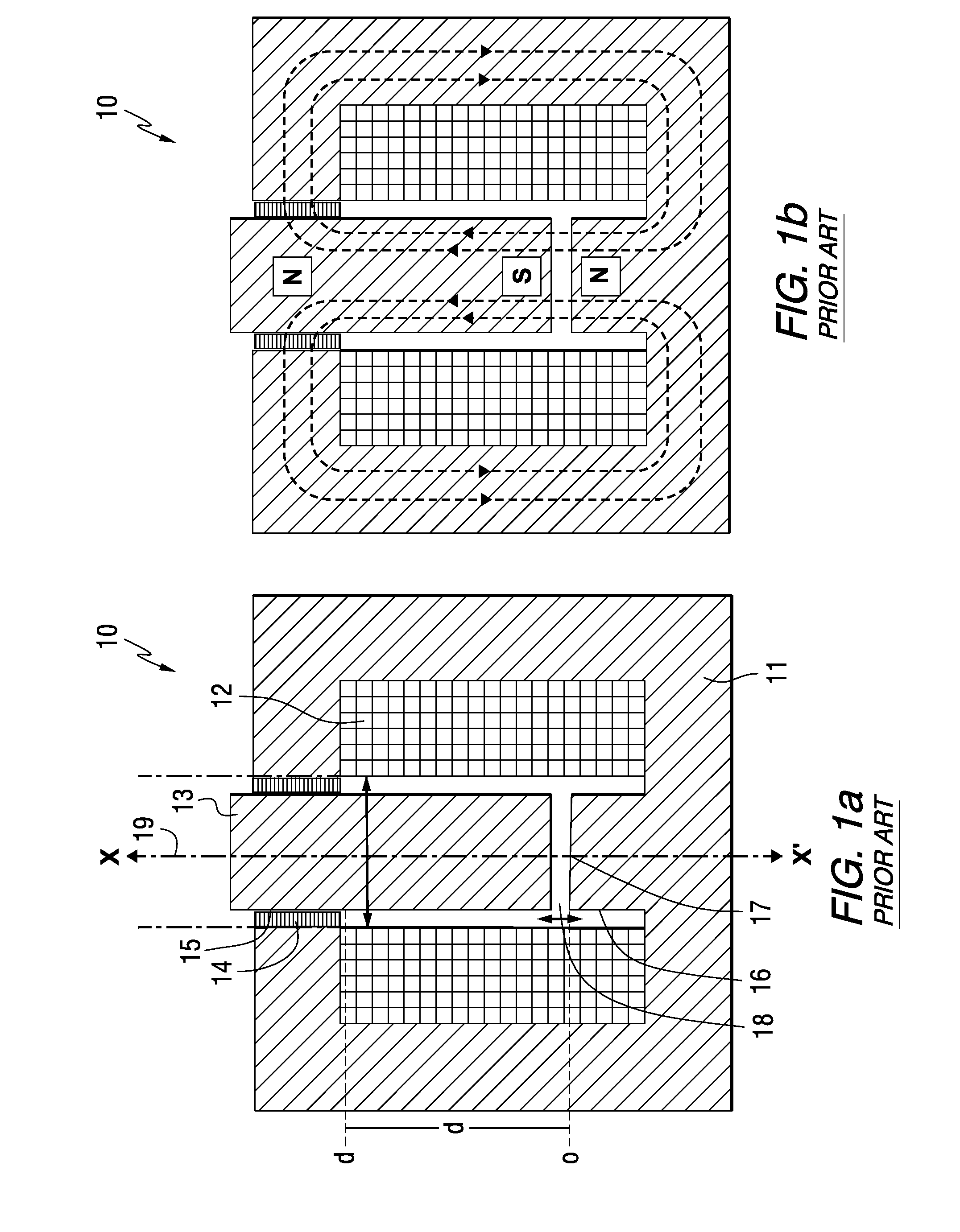

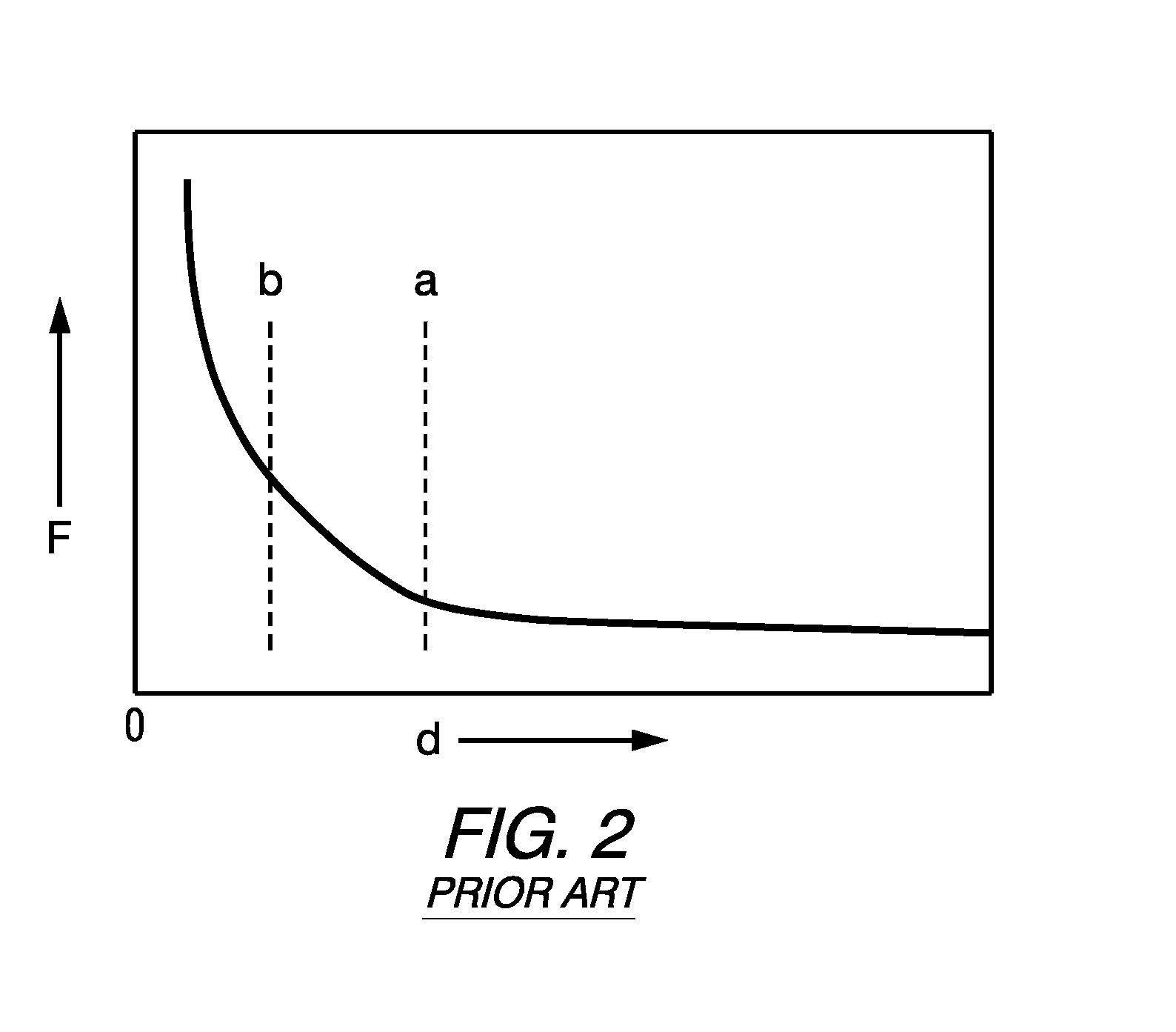

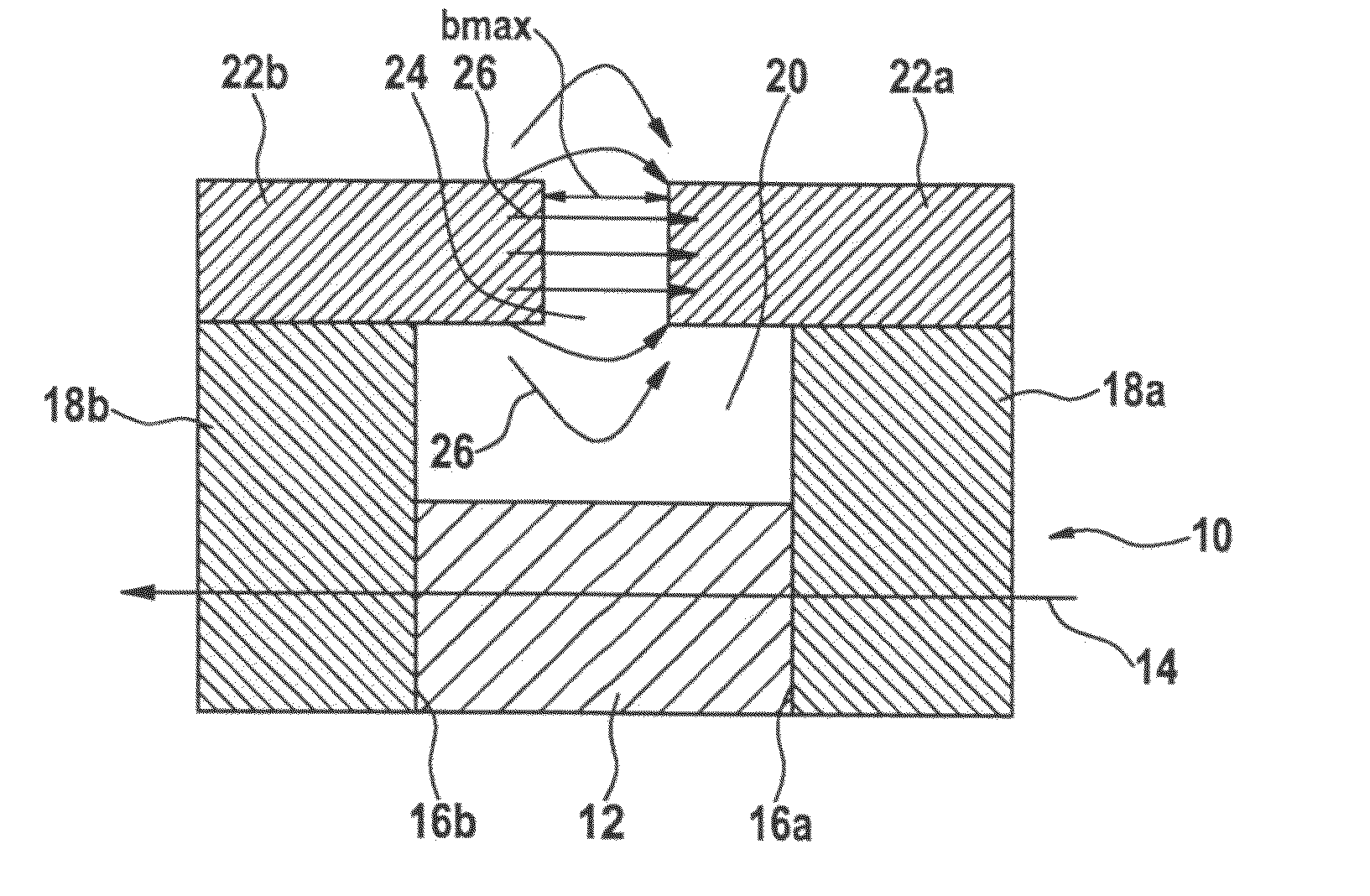

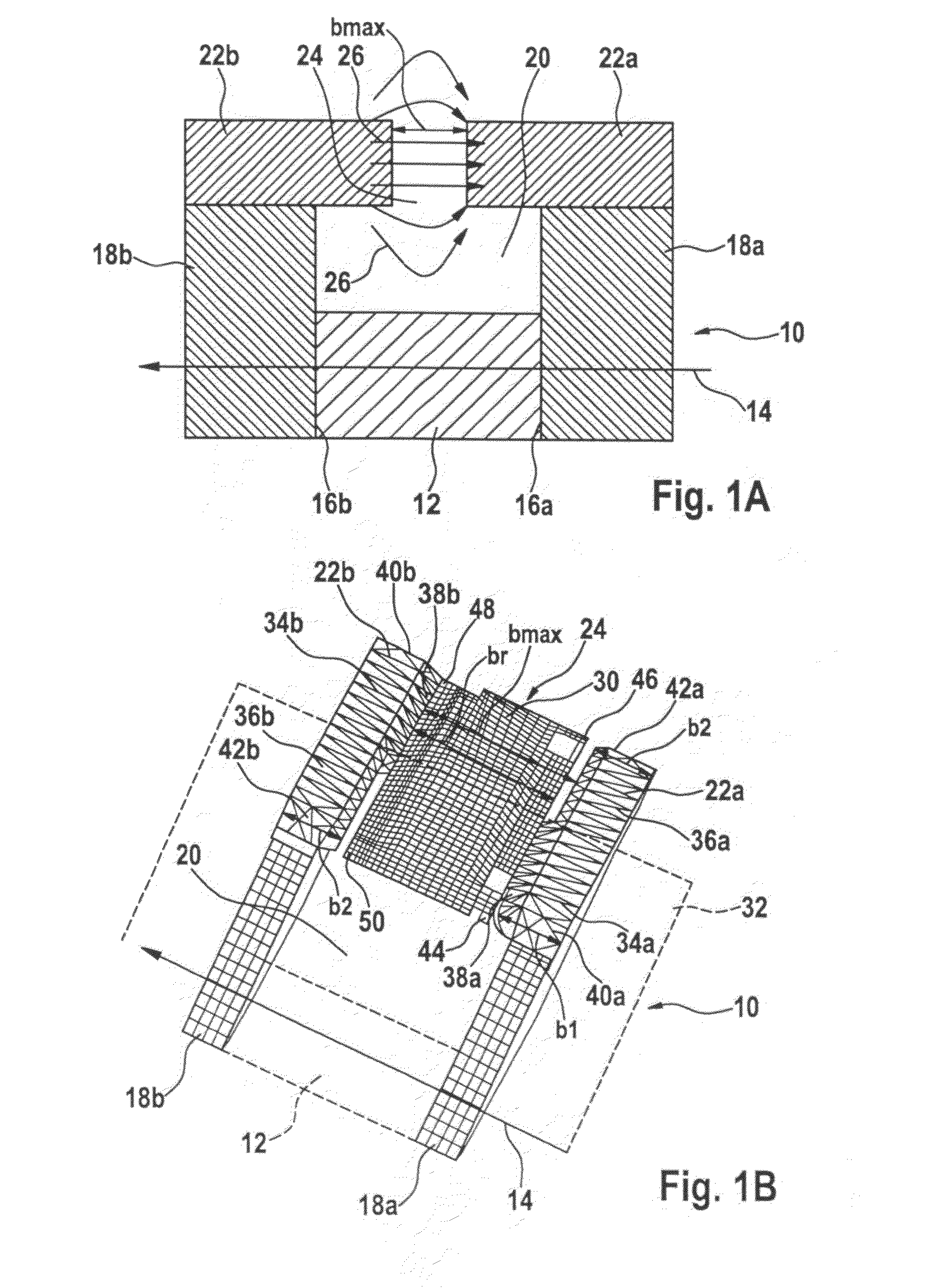

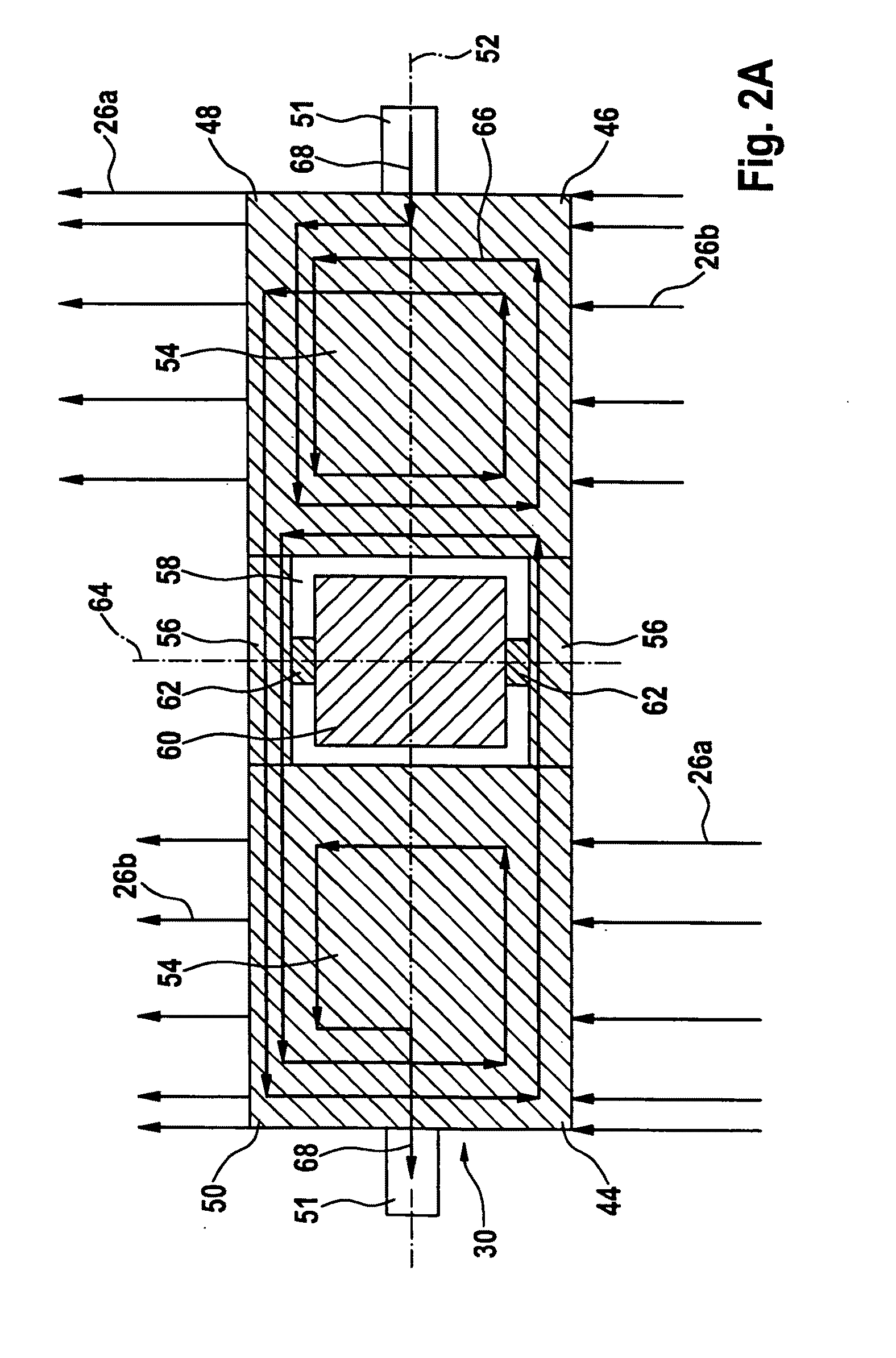

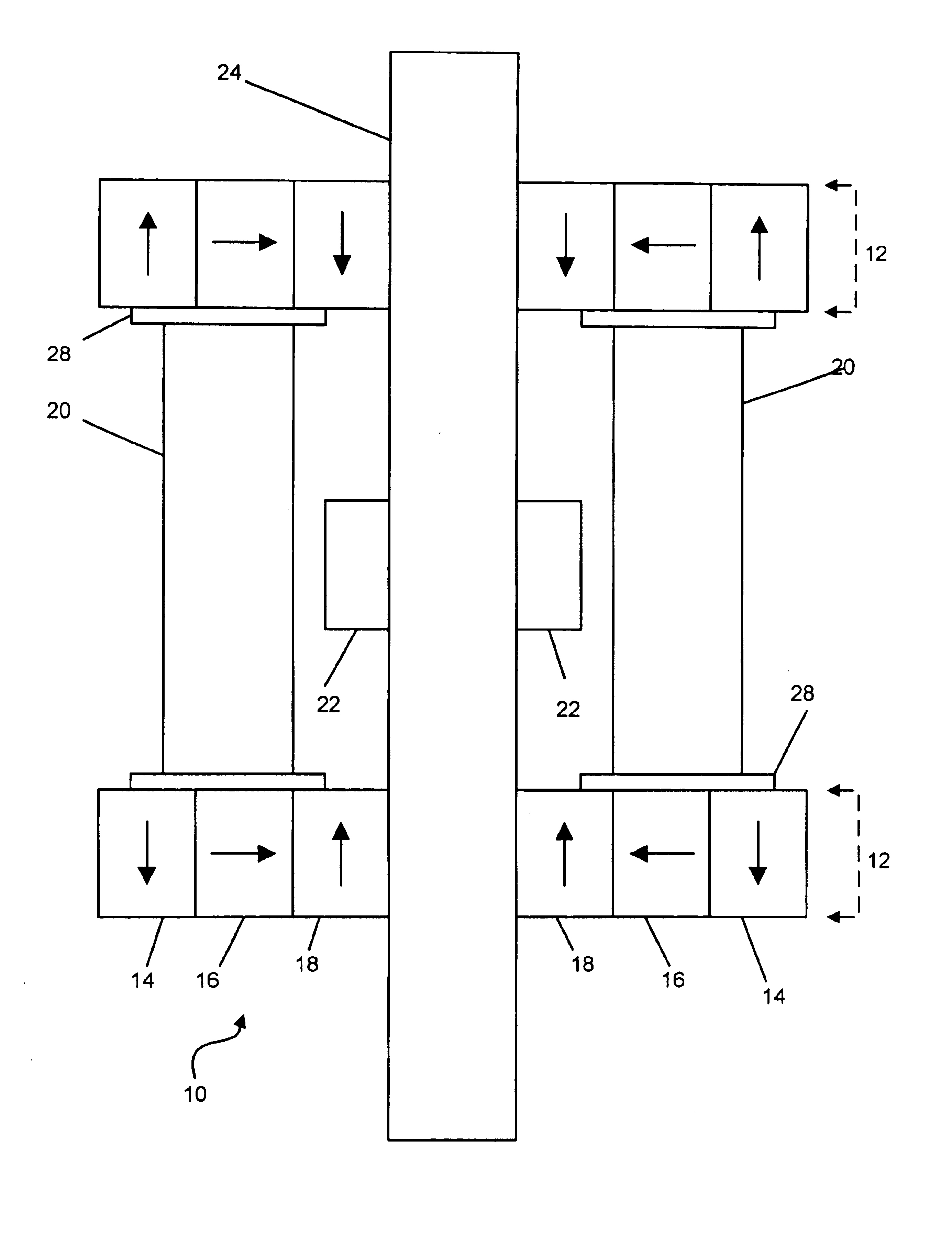

Magnetic yoke, micromechanical component, and method for the manufacture thereof

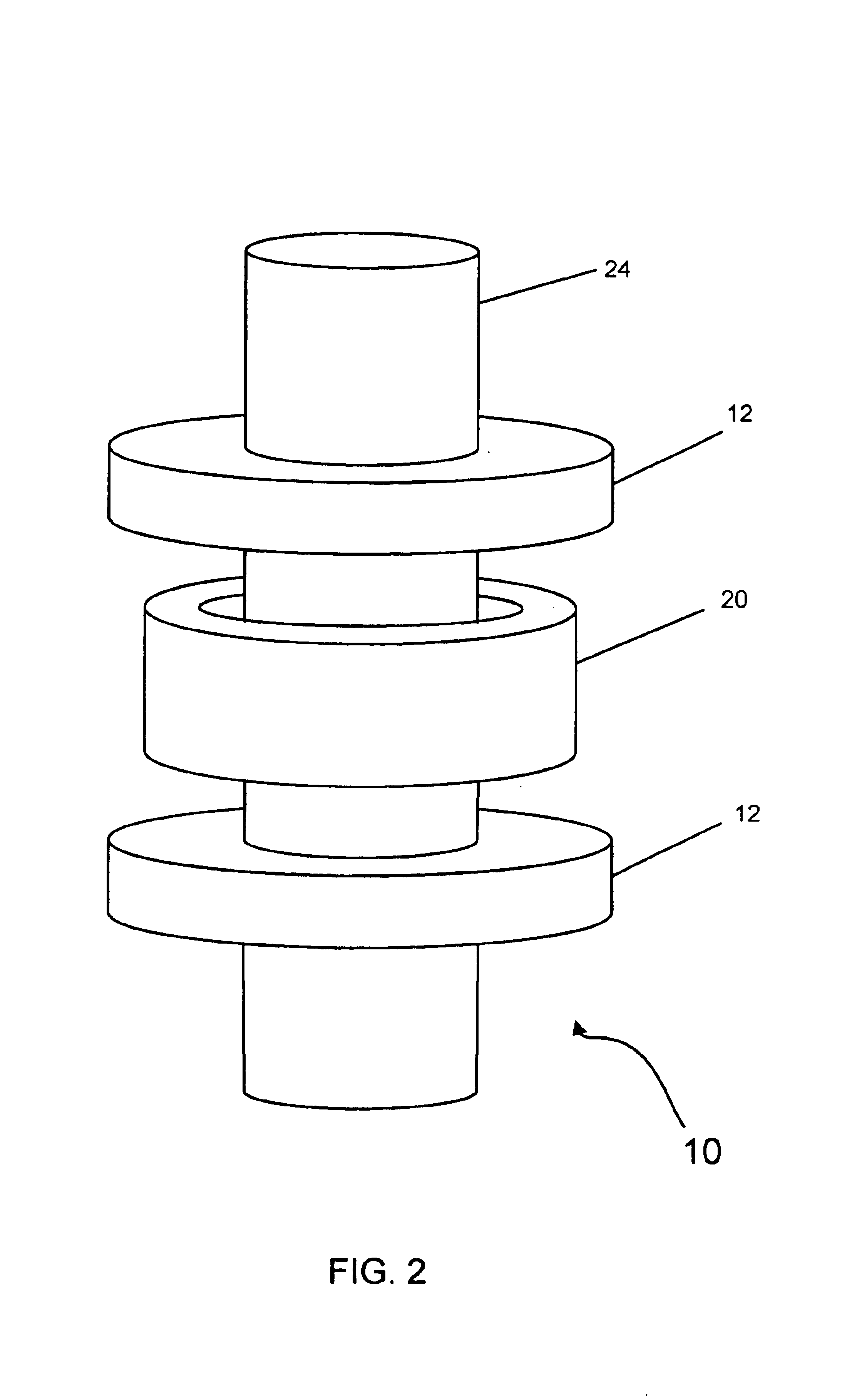

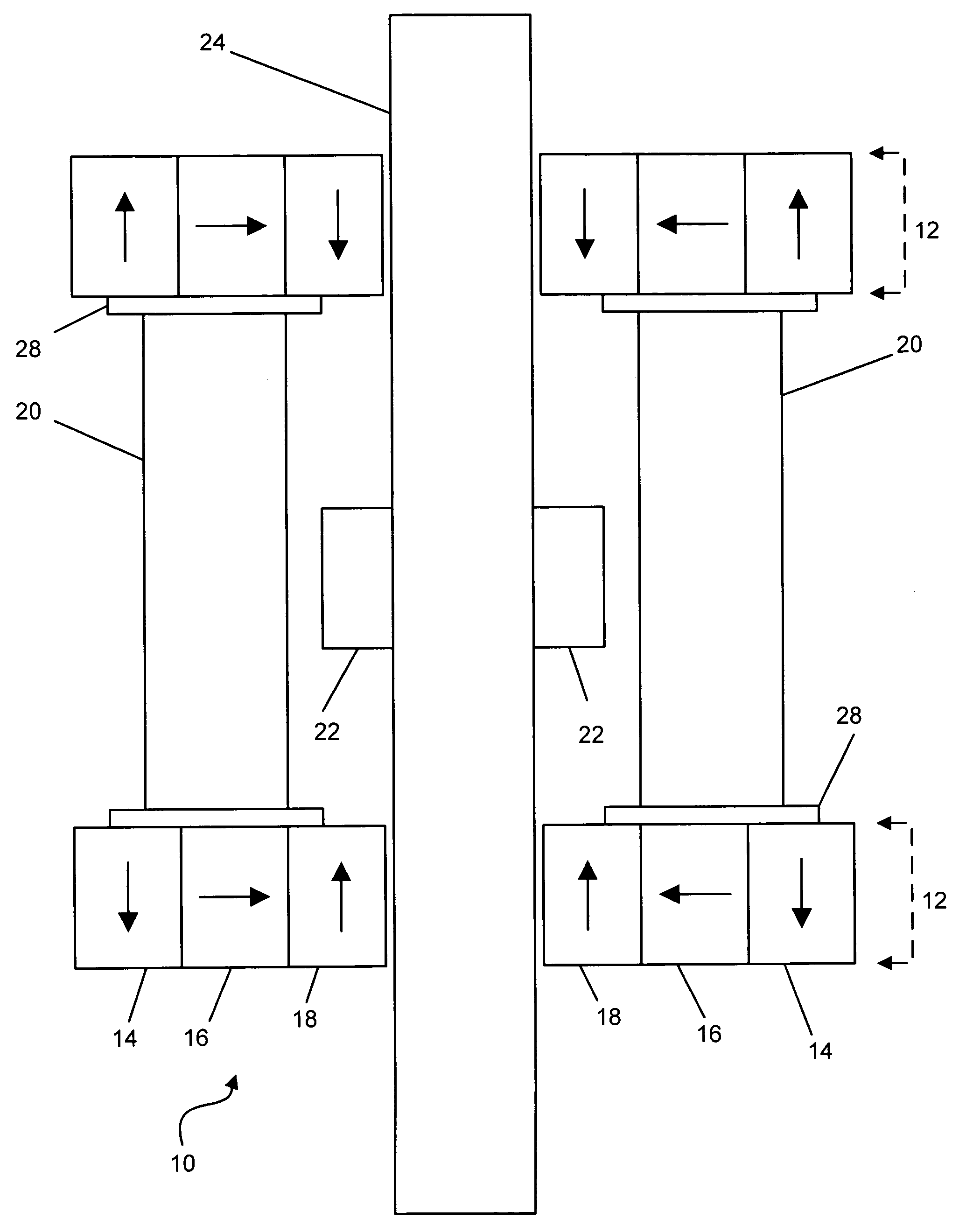

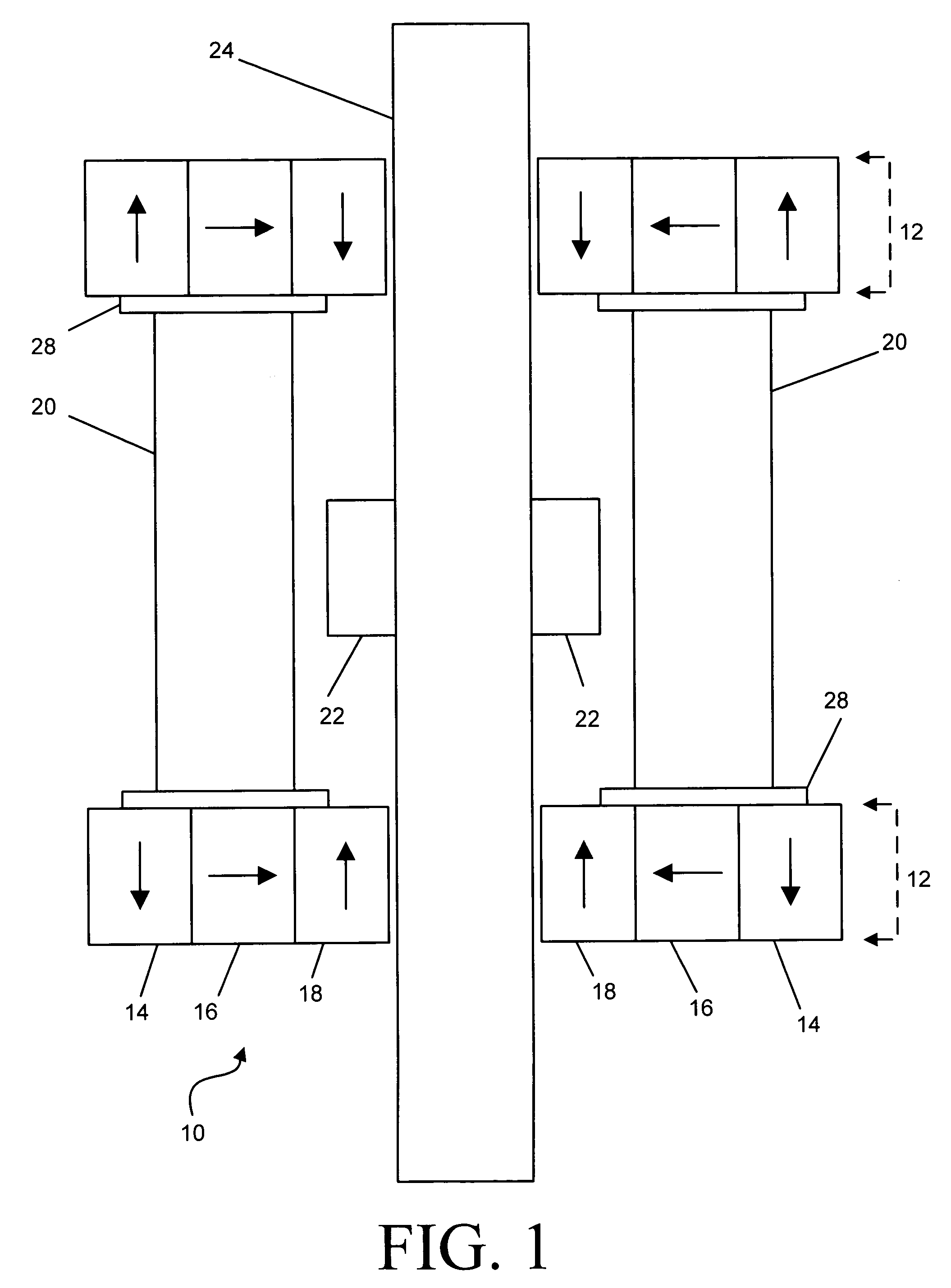

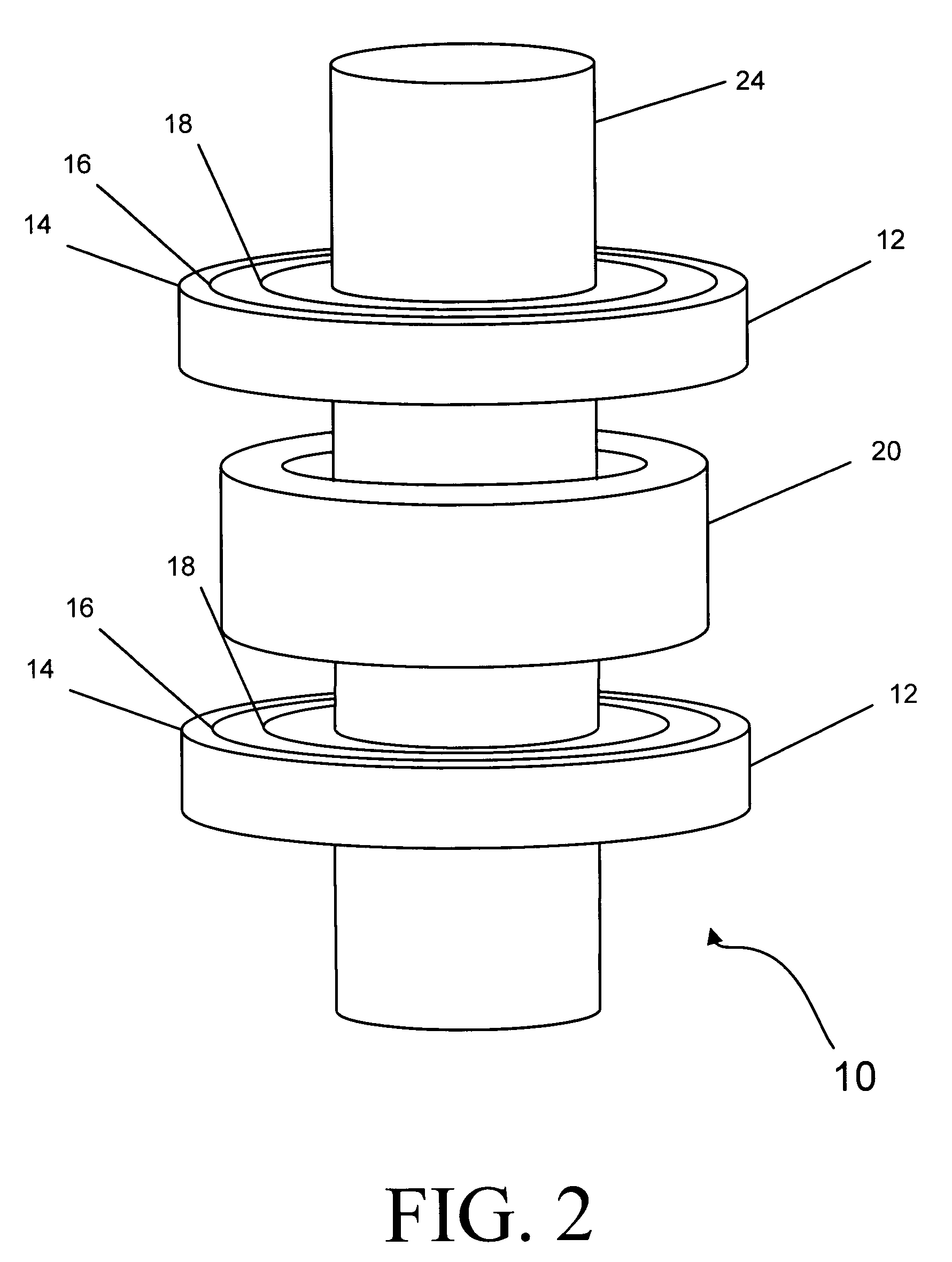

InactiveUS20110199172A1Dynamo-electric machinesMetal working apparatusMagnetizationIntermediate space

A magnetic yoke (10) having a magnet (12) having a magnetization direction (14) on which a first yoke arm (18a) and a second yoke arm (18b) are mounted in such a way that the magnet (12) and the two yoke arms (18a, 18b) define a yoke intermediate space (20) extending from a front side to a rear side of the magnetic yoke; and first pole shoe (22a) configured on the first yoke arm (18a) and a second pole shoe (22b) configured on the second yoke arm (18b), between which a yoke gap (24) is located; the first pole shoe (22a) having a first width (b1) at a first end (40a) on the front side of the magnetic yoke (10), in parallel to the magnetization direction (14) of the magnet (12), and having a second width (b2) unequal to the first width (b1) at a second end (42a) facing opposite the first end (40a) on the rear side of the magnetic yoke (10), in parallel to the magnetization direction (14) of the magnet (12).

Owner:ROBERT BOSCH GMBH

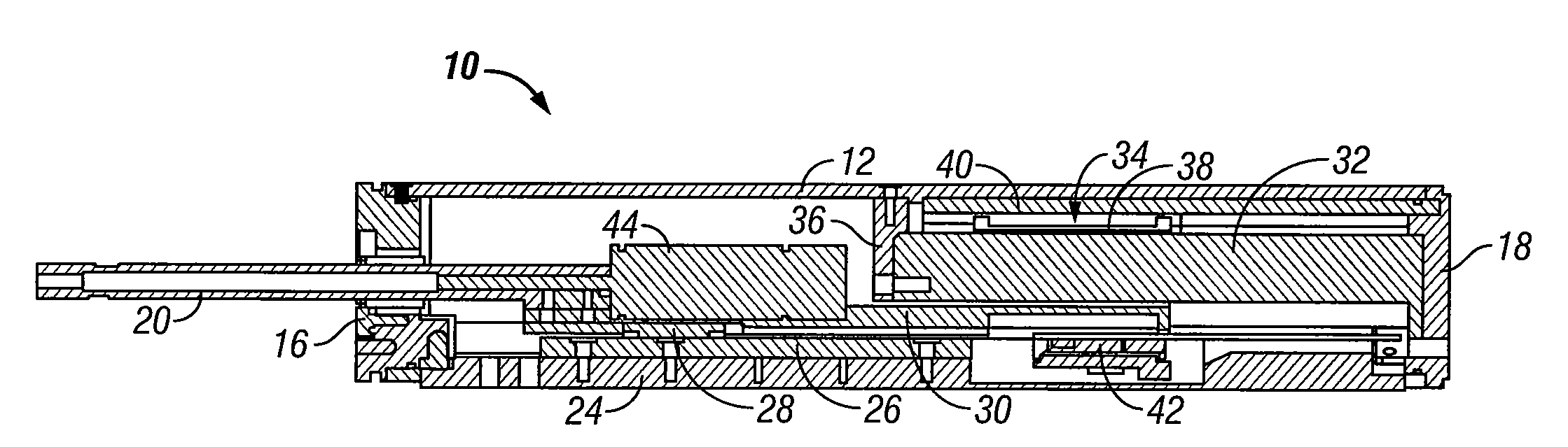

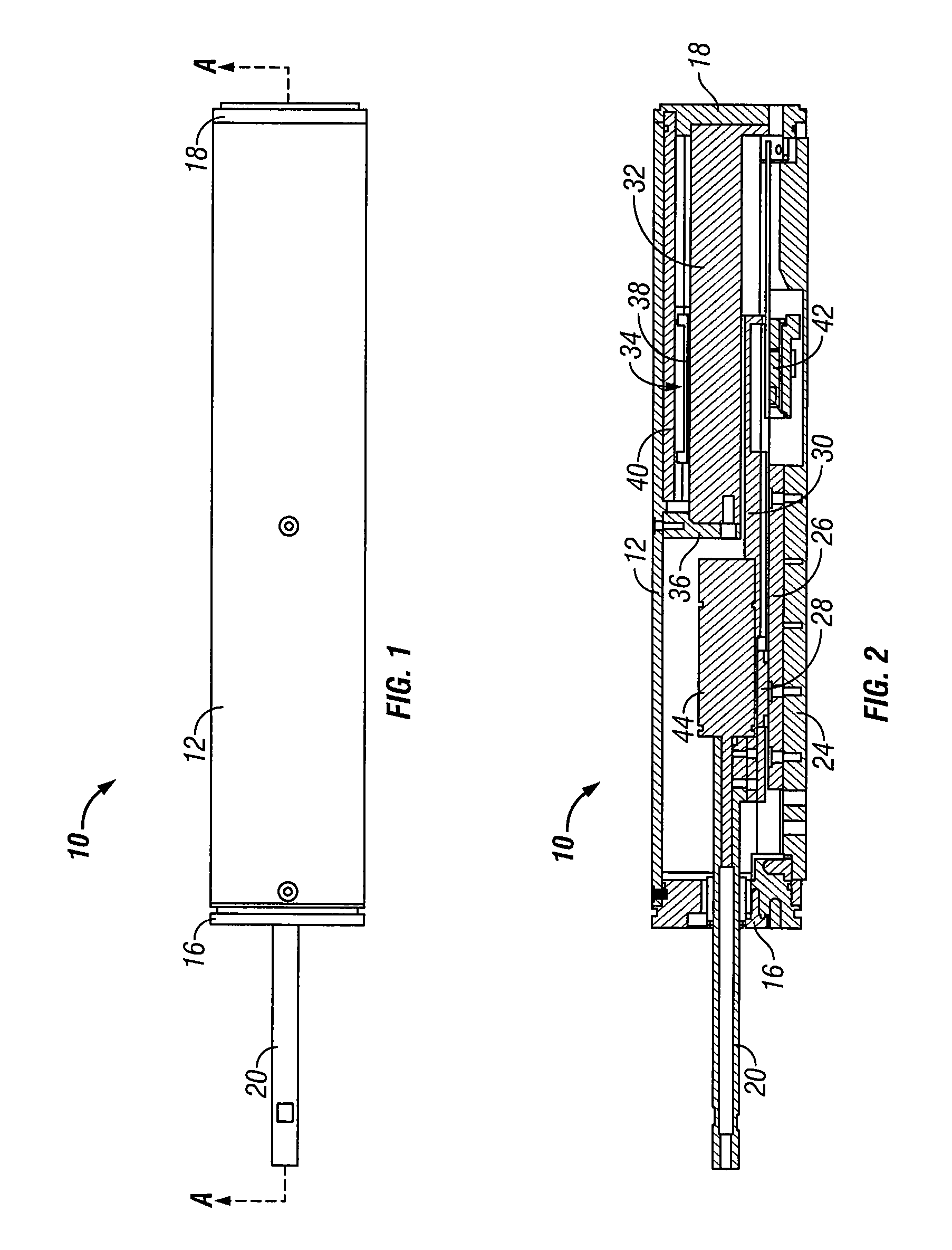

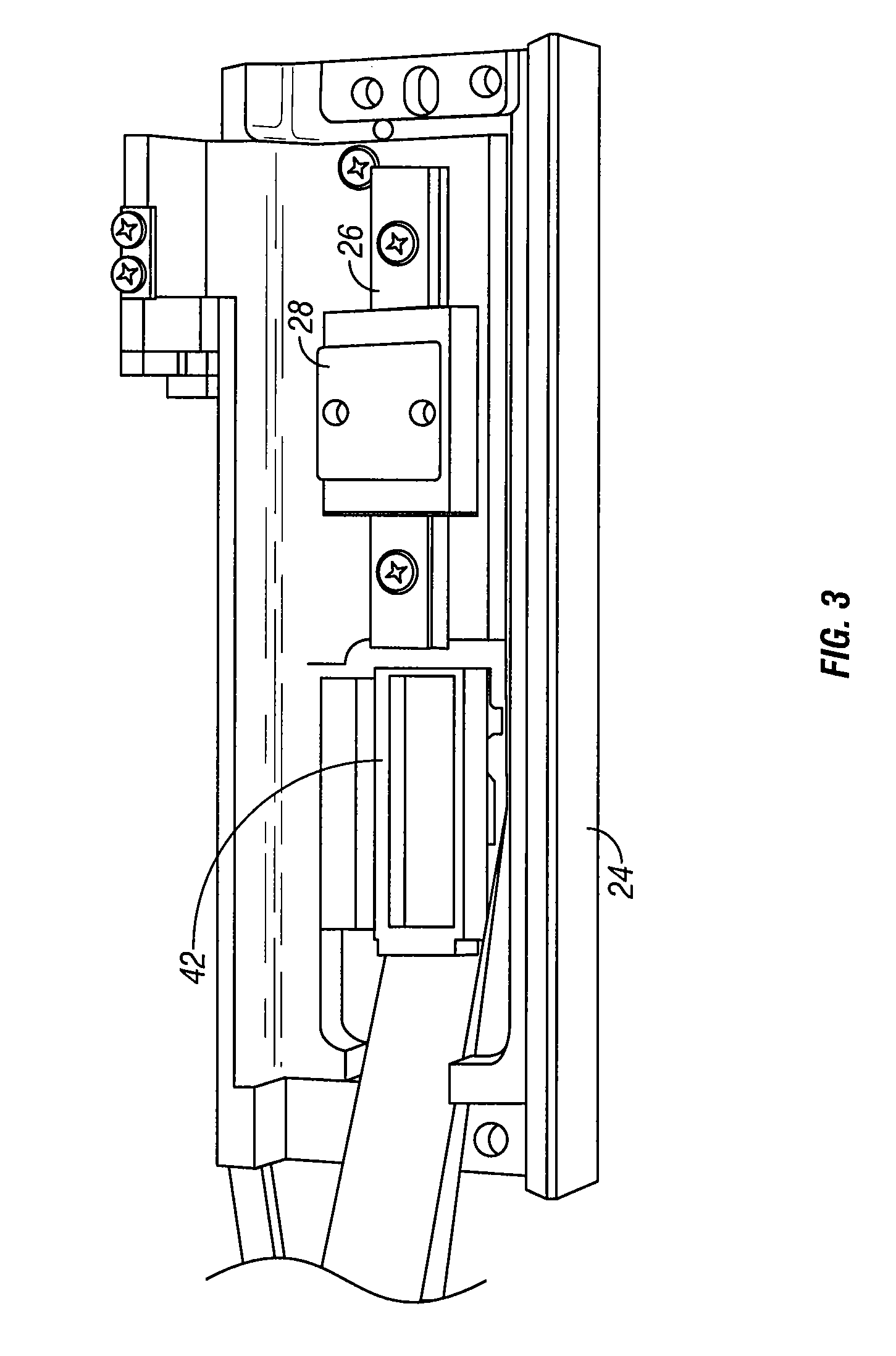

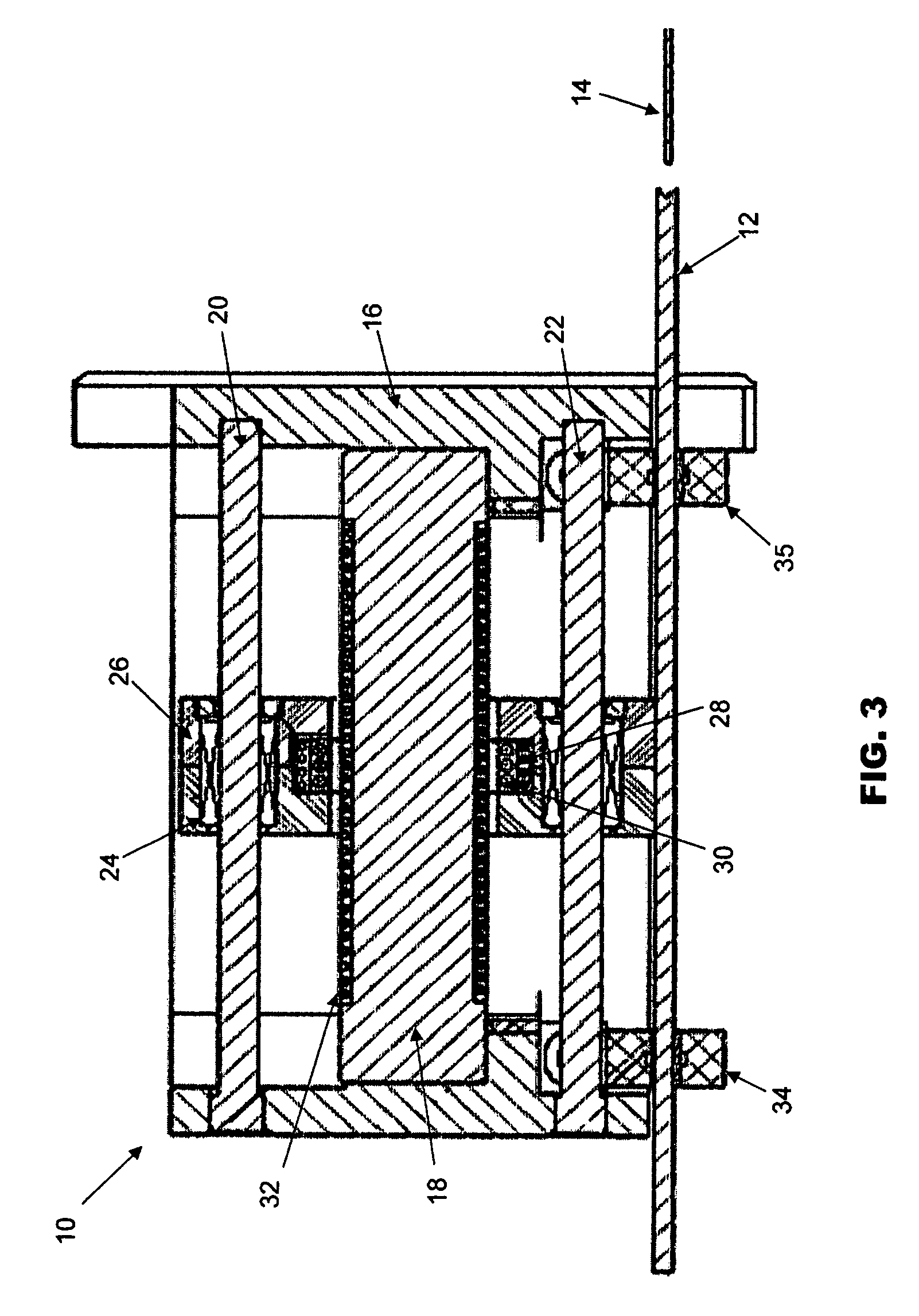

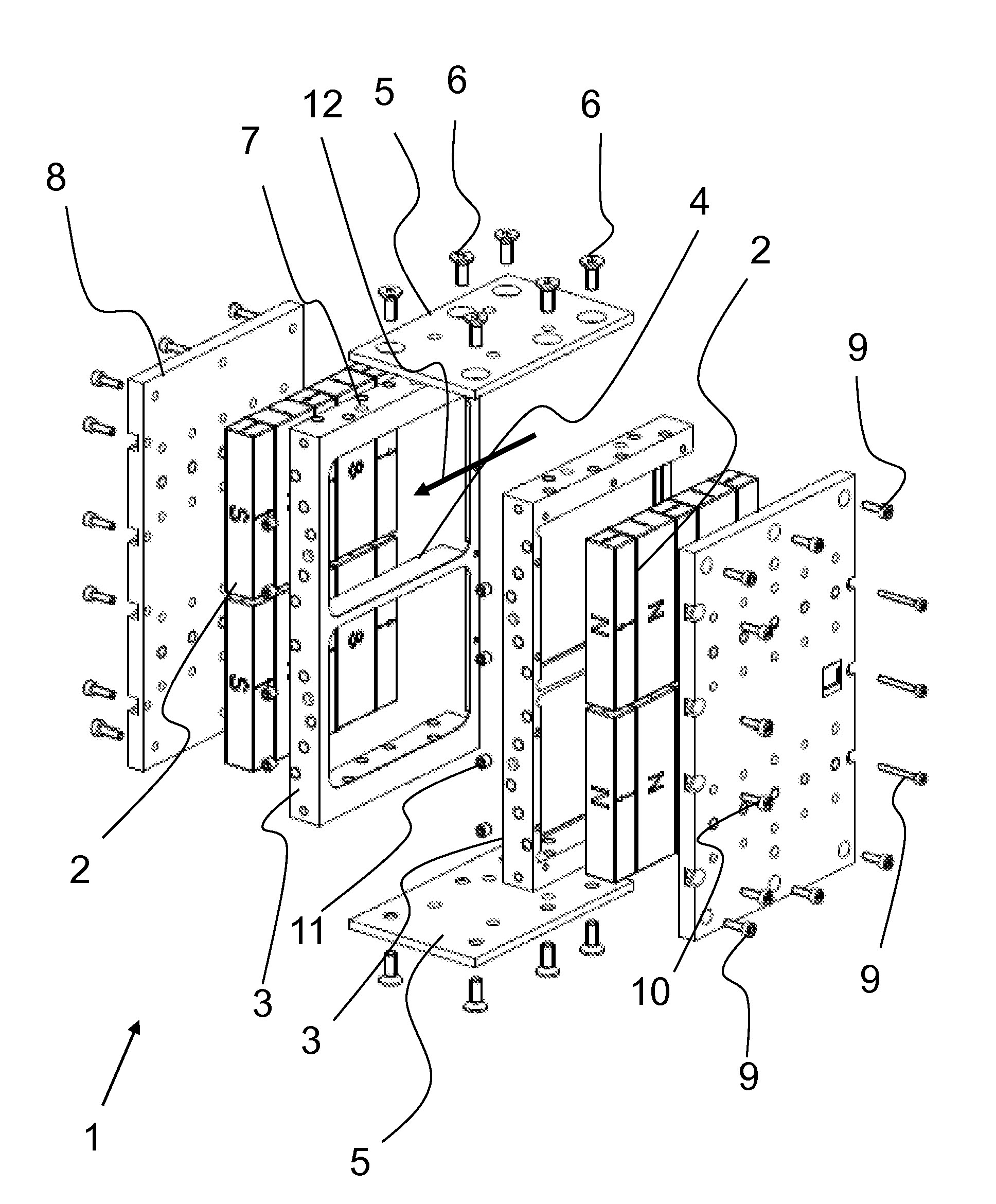

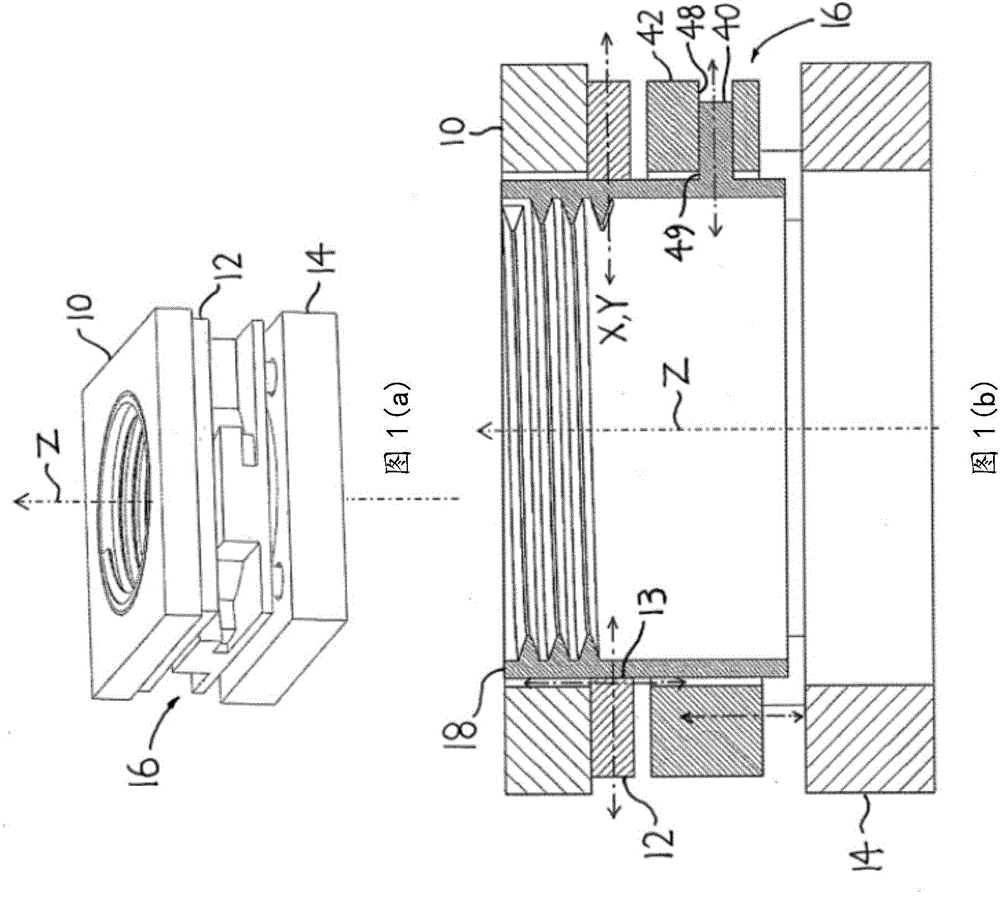

Compact linear actuator and method of making same

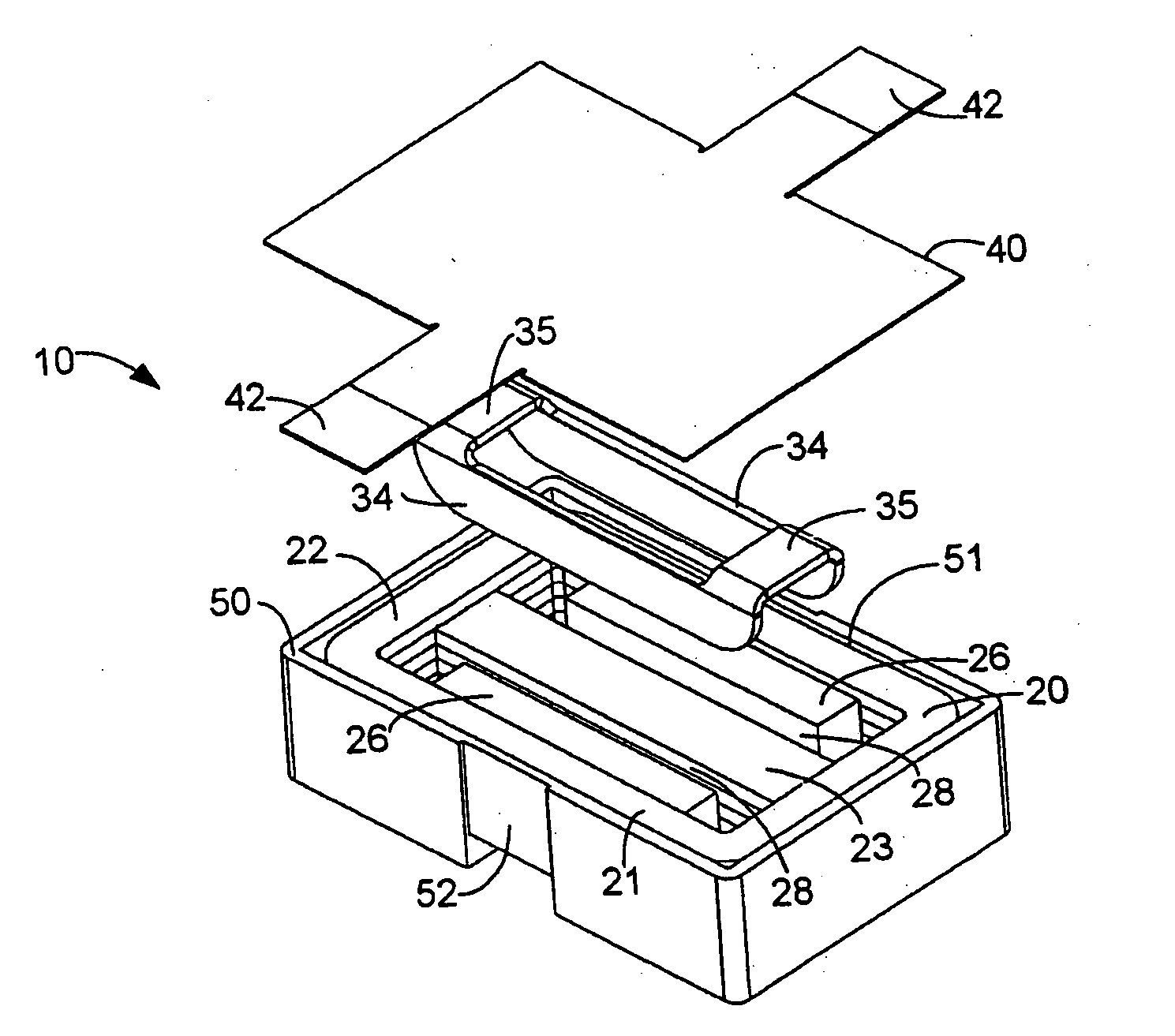

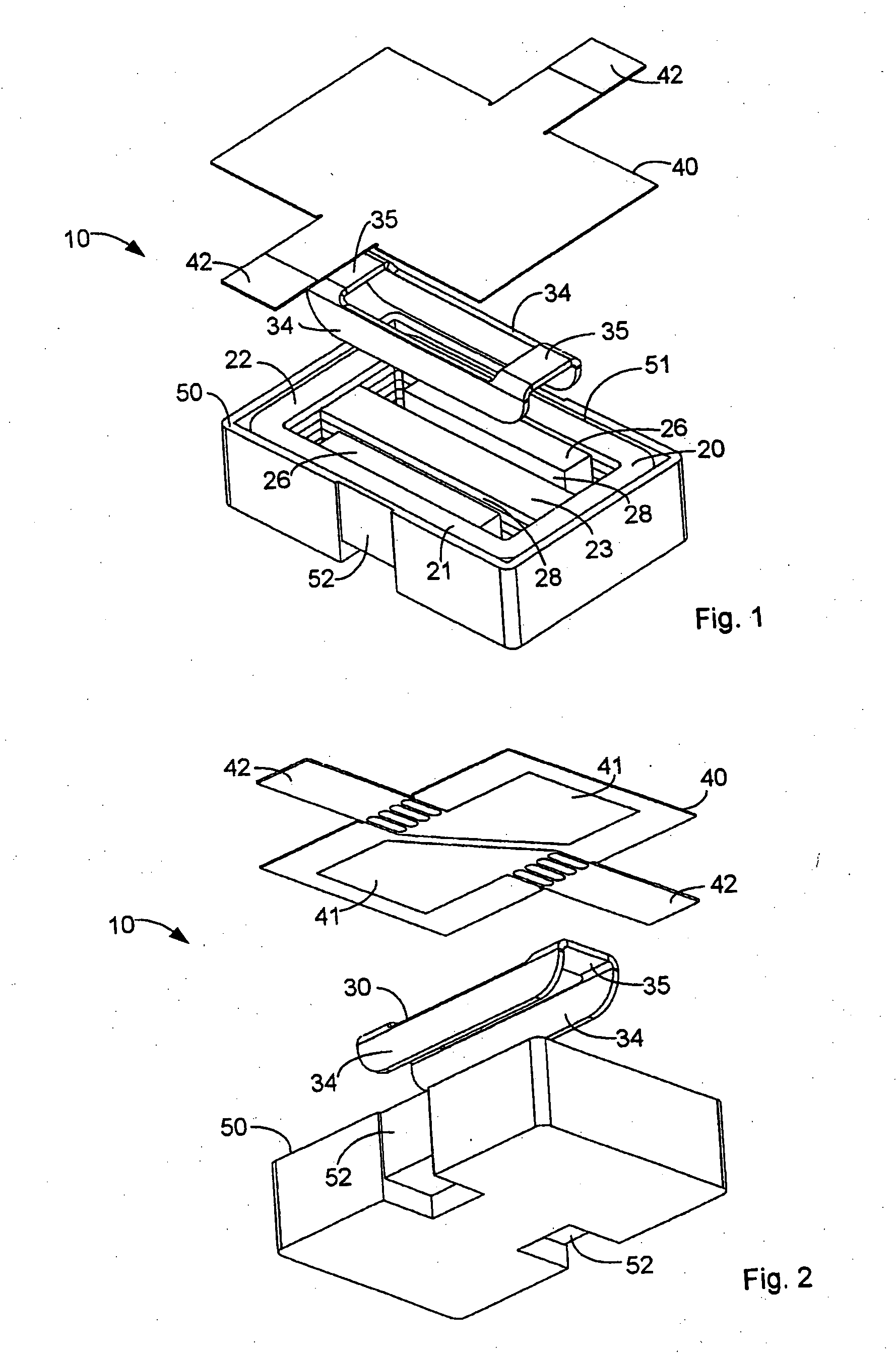

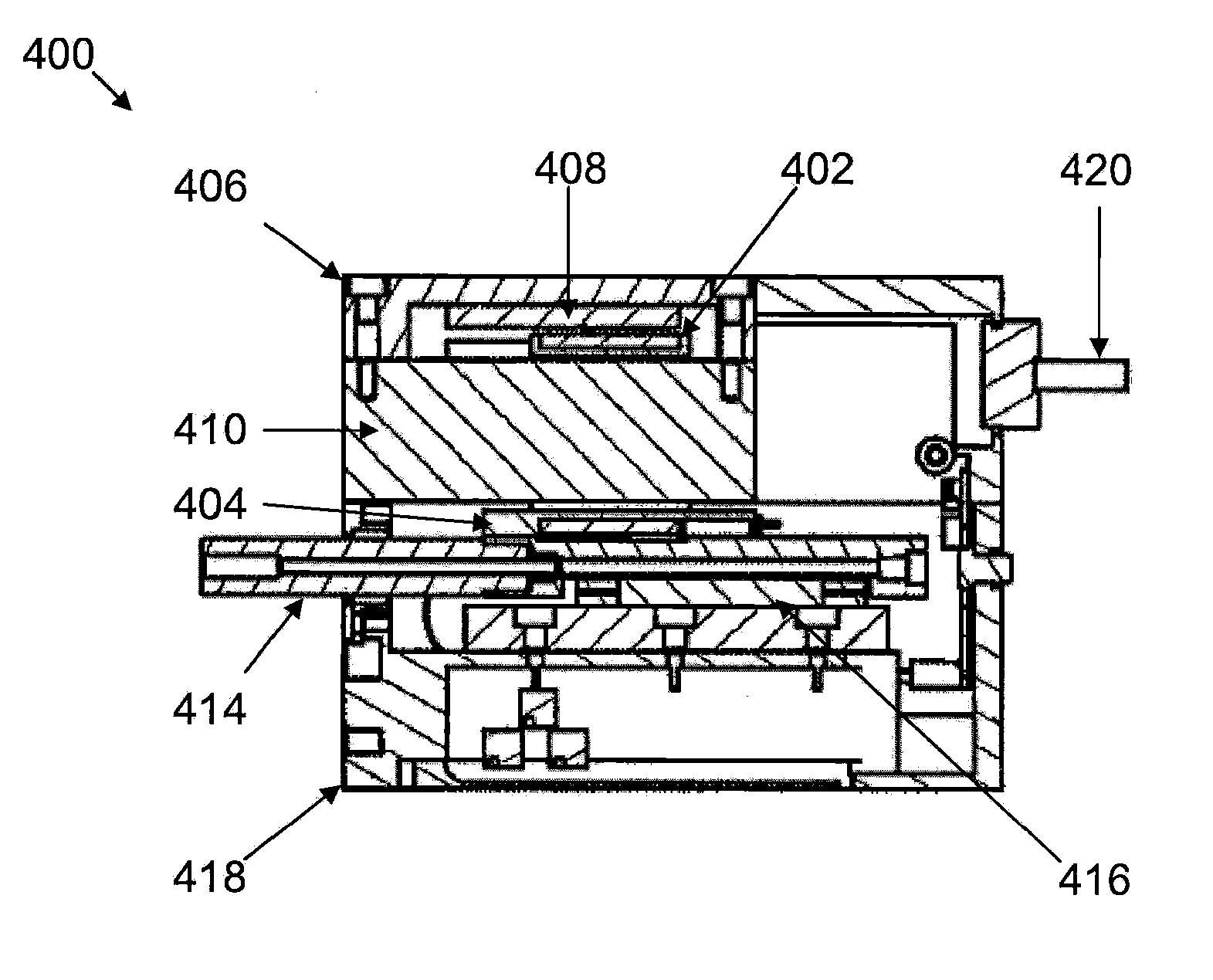

InactiveUS20090058581A1Mechanical energy handlingMovable winding electromagnetsCompact dimensionBobbin

This invention describes a compact linear moving coil actuator that incorporates a piston bobbin coil assembly that provides a shaft with linear reciprocal movement. Optionally, a rotary motor can be coupled to the shaft to provide rotary reciprocal movement. The piston and bobbin sections of the piston bobbin coil assembly may be integrally formed as a single unitary piece and easily changed in size and / or configuration during manufacture to enable easier and more cost-effective assembly of various actuator sizes and configurations. Additionally, the compact size of the actuator requires less work space and also allows multiple actuators to be positioned next to each for various applications.

Owner:SMAC SRL

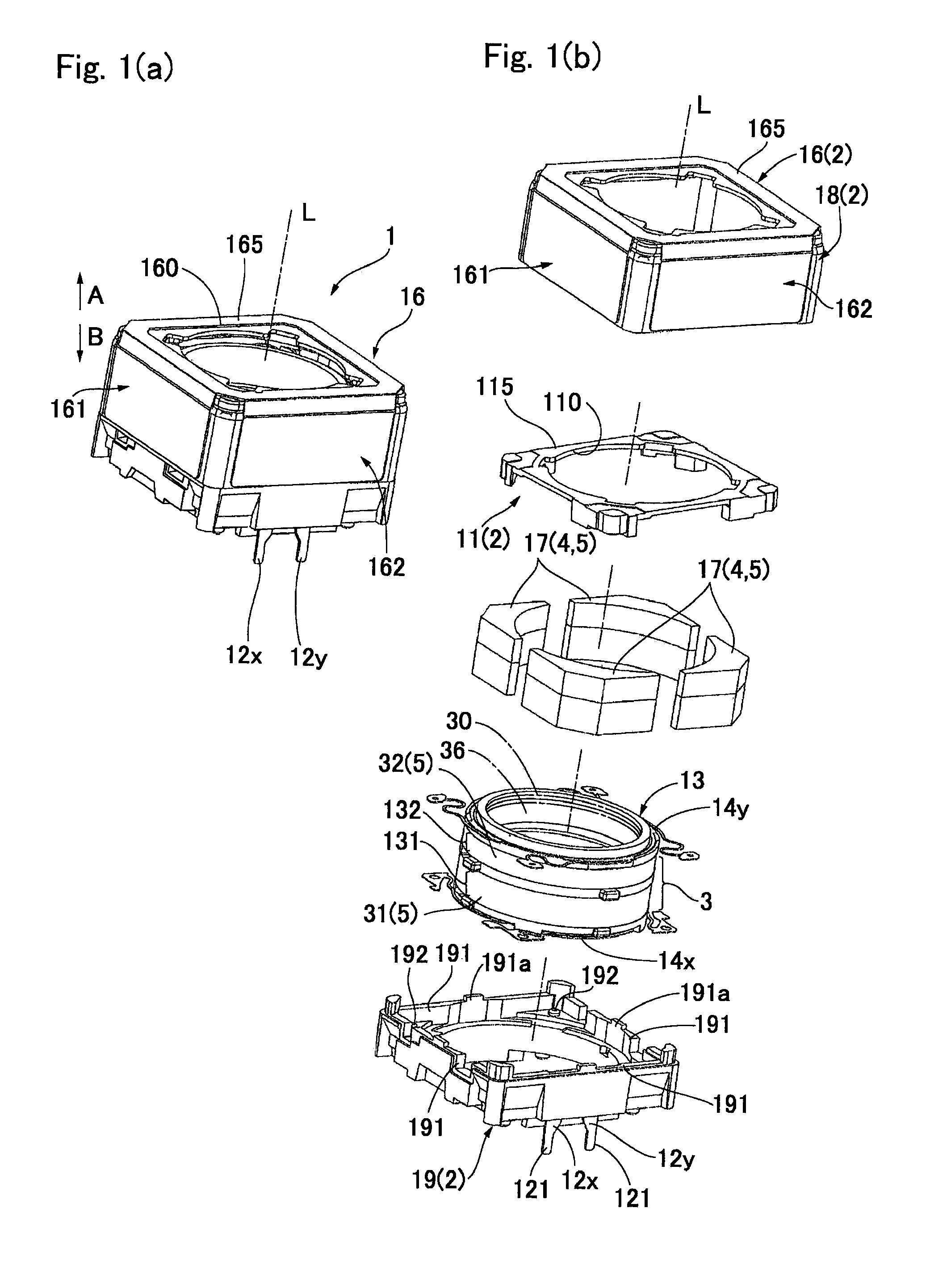

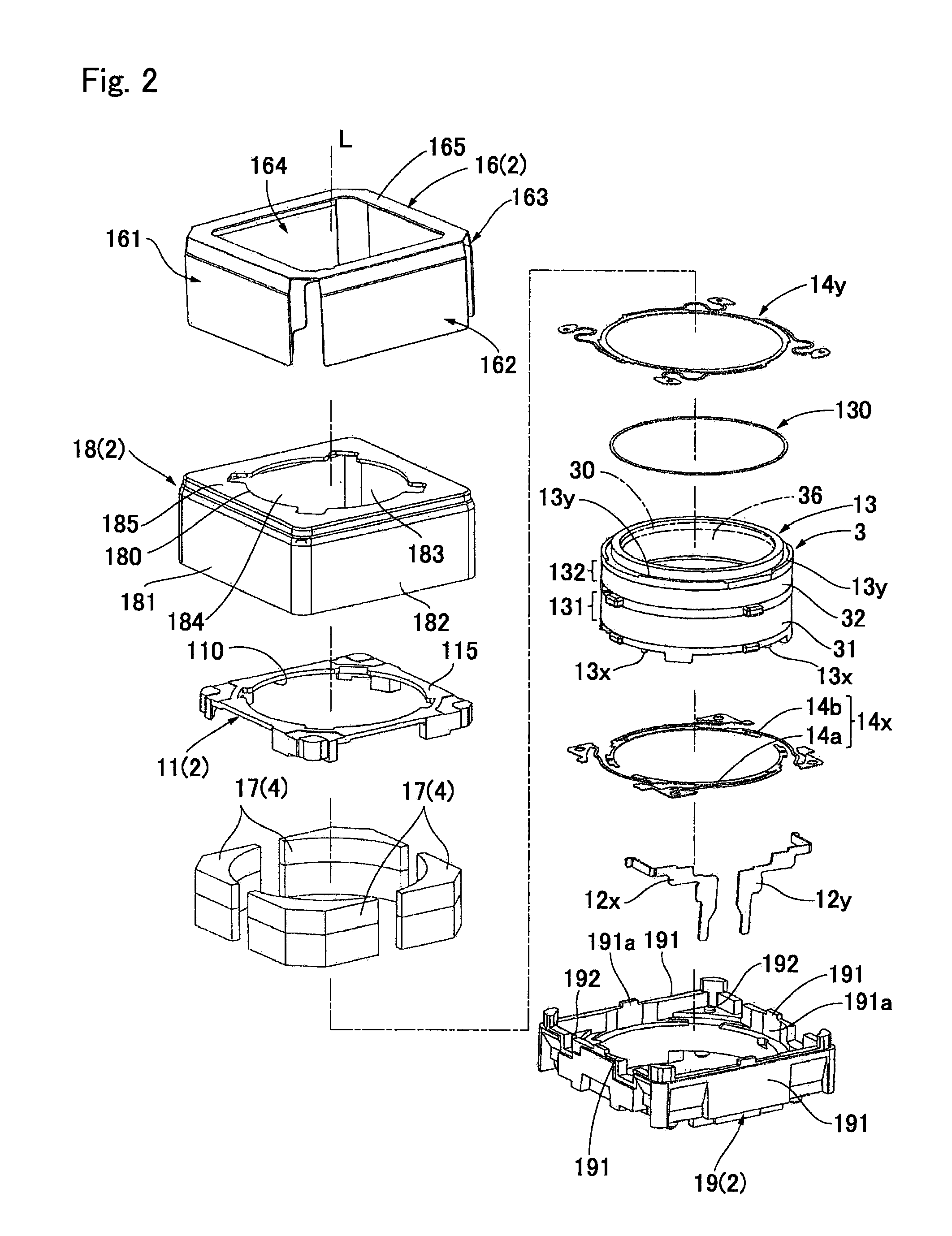

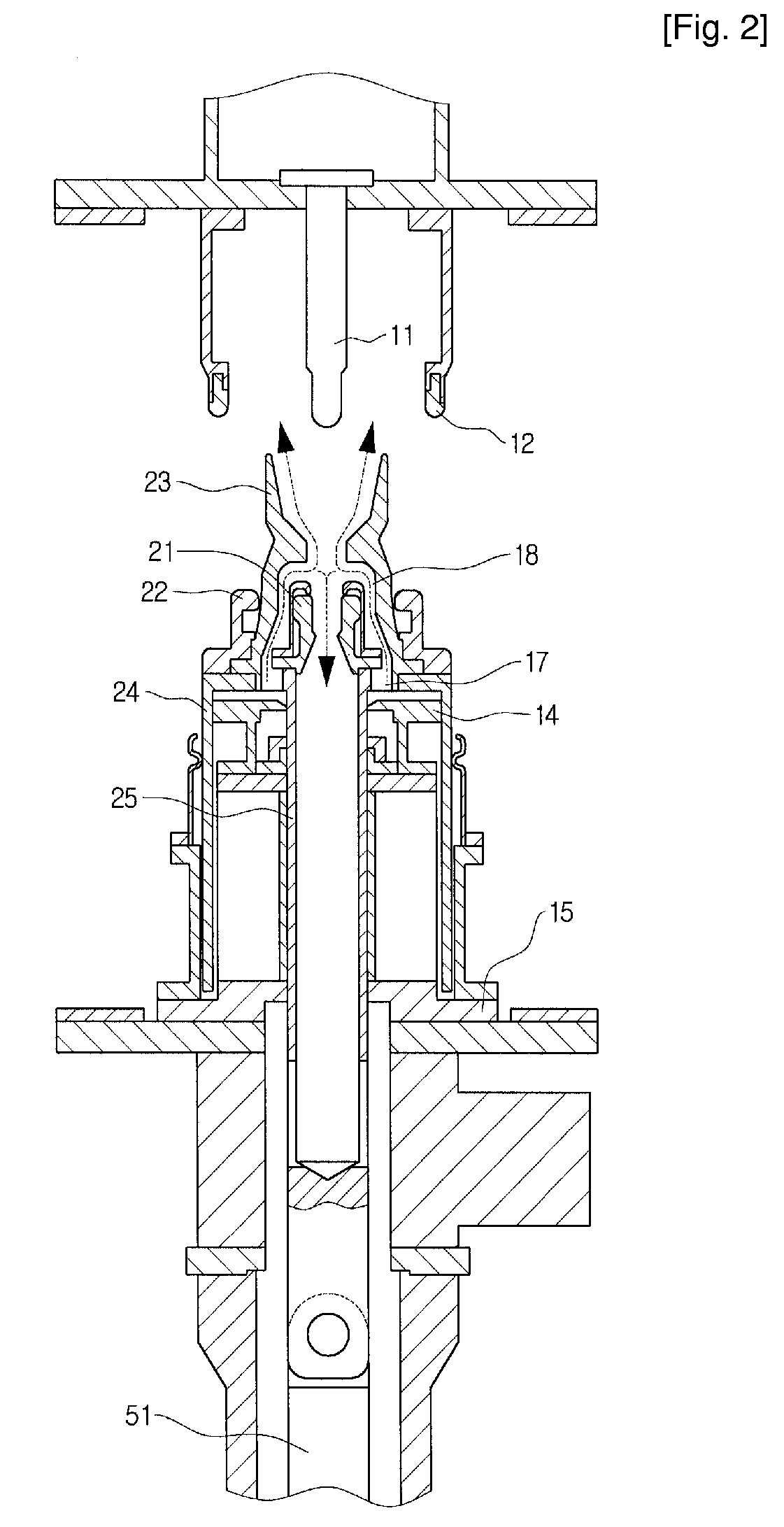

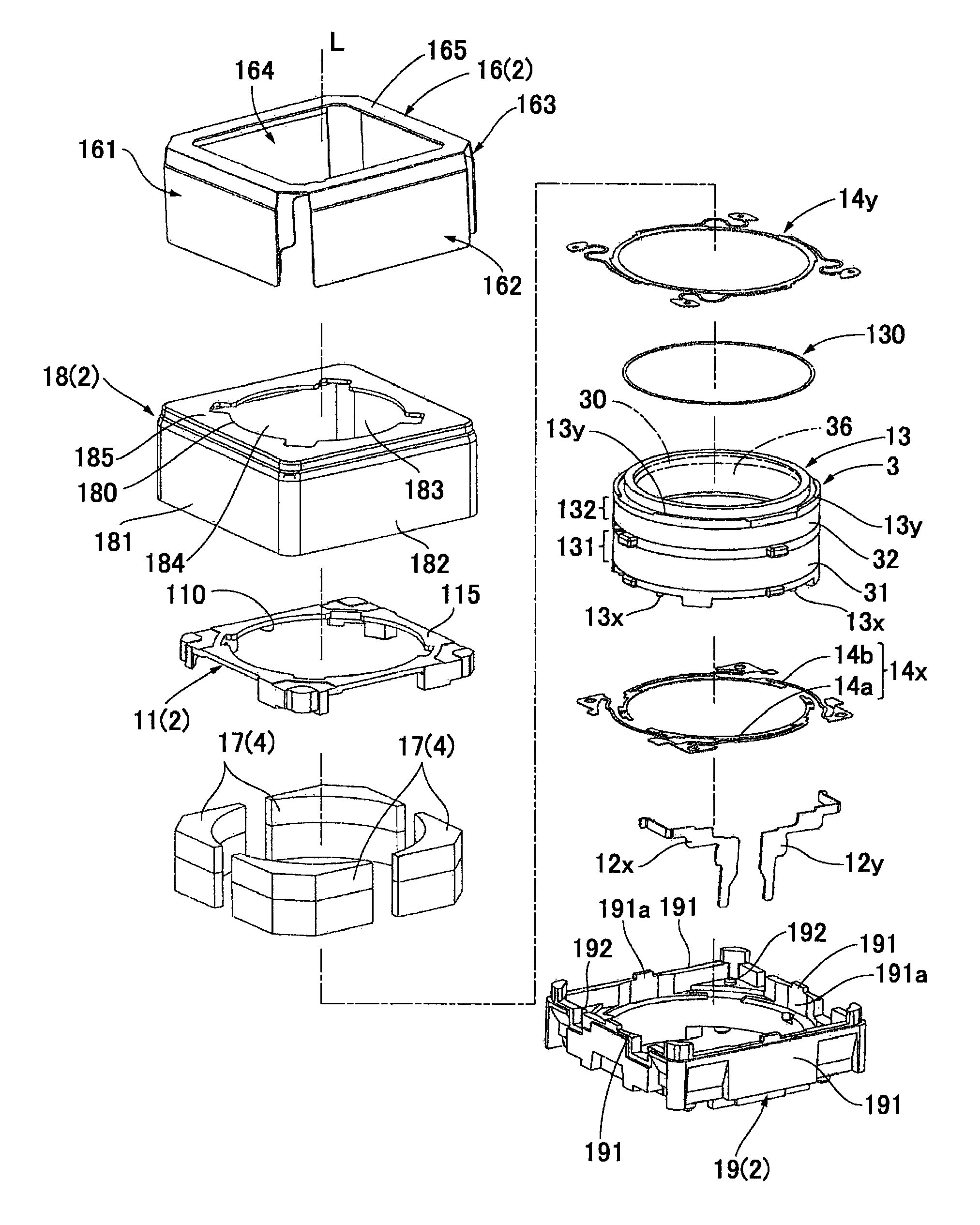

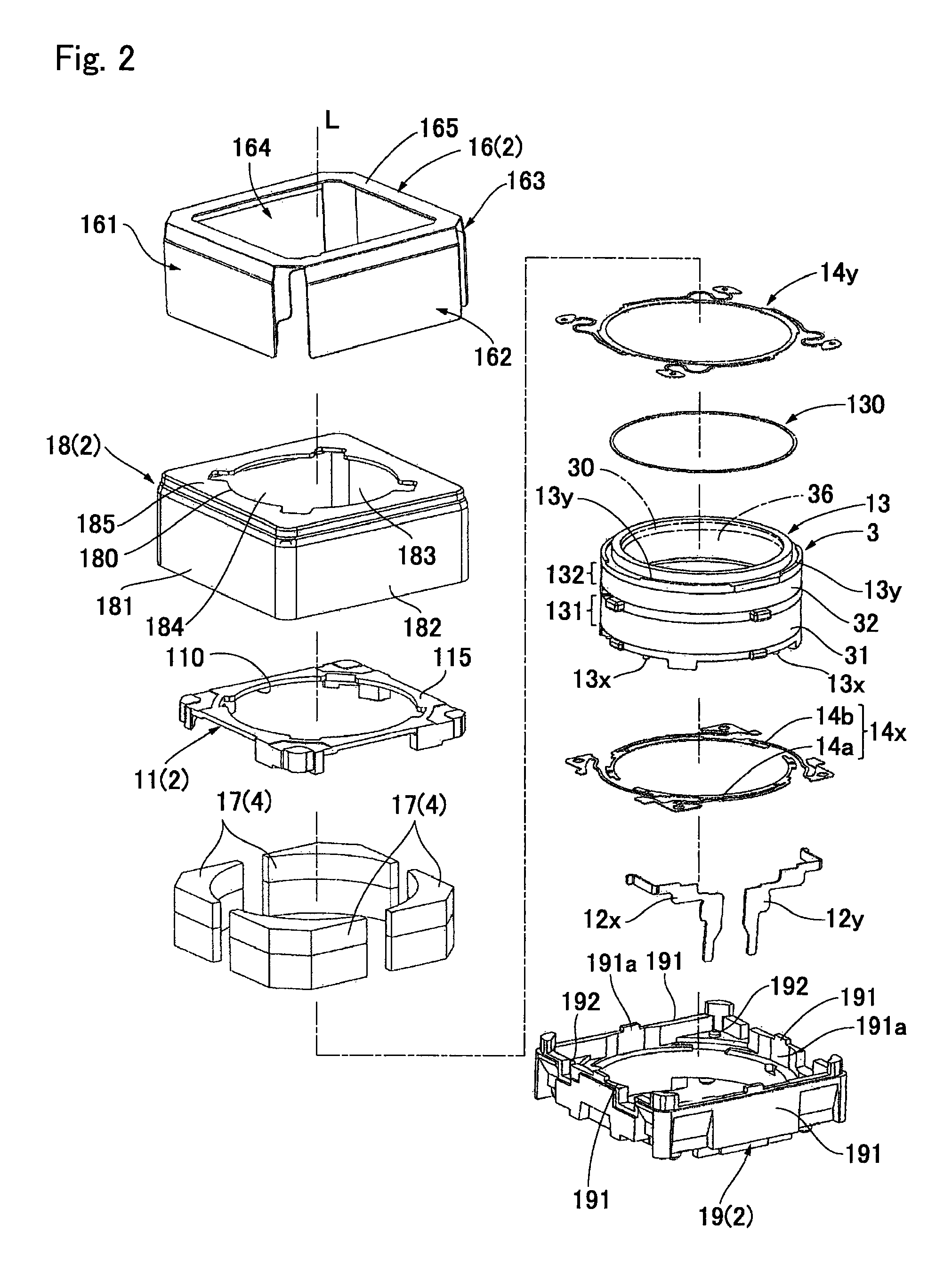

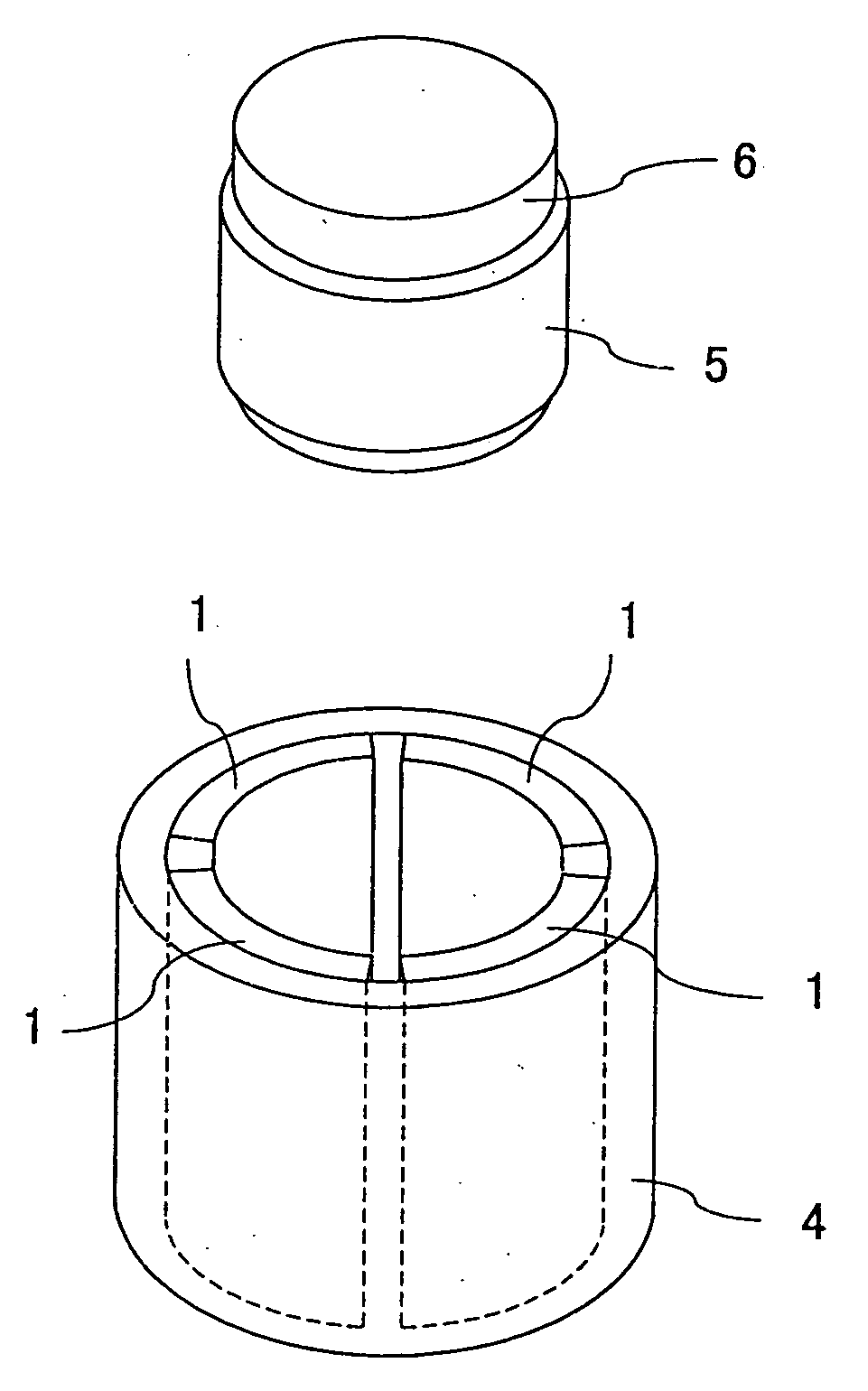

Lens drive device

A lens drive device may include a support body, a movable body having a lens, a magnetic drive mechanism for magnetically driving the movable body in a lens optical axis direction, and a spring member connected between the support body and the movable body. The magnetic drive mechanism includes a coil held by the movable body and both end parts of the coil are electrically connected to different spring pieces of the spring member through terminals. The support body includes an insulation member which holds the terminals, and each of the terminals includes an outside connecting terminal part which is located on an outer side of the insulation member, and a long elongated connecting part which is extended along an inner wall of the insulation member from the outside connecting terminal part and connected with the spring piece of the spring member.

Owner:SANKYO SEIKI MFG CO LTD

High intensity radial field magnetic array and actuator

At least one set of two nested magnetic arrays is provided, each nested magnetic array having an outer magnet, a middle magnet, and an inner magnet. The outer magnet has a magnetization pointing in an at least partially axial direction. The middle magnet has a magnetization substantially perpendicular to the magnetization of the outer magnet. The inner magnet has a magnetization directed substantially anti-parallel to the magnetization of the outer magnet. The apparatus also includes at least one electrically conductive coil positioned at least partially between the two nested magnetic arrays. At least one substantially magnetically permeable object is positioned at least partially between the two nested magnetic arrays. A rod is integral with the substantially magnetically permeable object.

Owner:ENG MATTERS

Electroacoustic transducer

InactiveUS20060215873A1Same sensitivityReduced stray magnetic fieldTransducer detailsTransformers/inductances coils/windings/connectionsTransducerEngineering

An electroacoustic transducer includes a magnetic circuit of a magnetically conductive material with a pair of opposed surfaces defining a gap therebetween. The magnetic circuit includes a magnet inducing a magnetic field in the gap, the magnet having a surface constituting one of the opposed surfaces. The magnetic circuit further includes a diaphragm and a coil having electrically conducting paths secured to the diaphragm. The coil has portions of its paths situated in the gap.

Owner:HANSEN KAJ BORGE +1

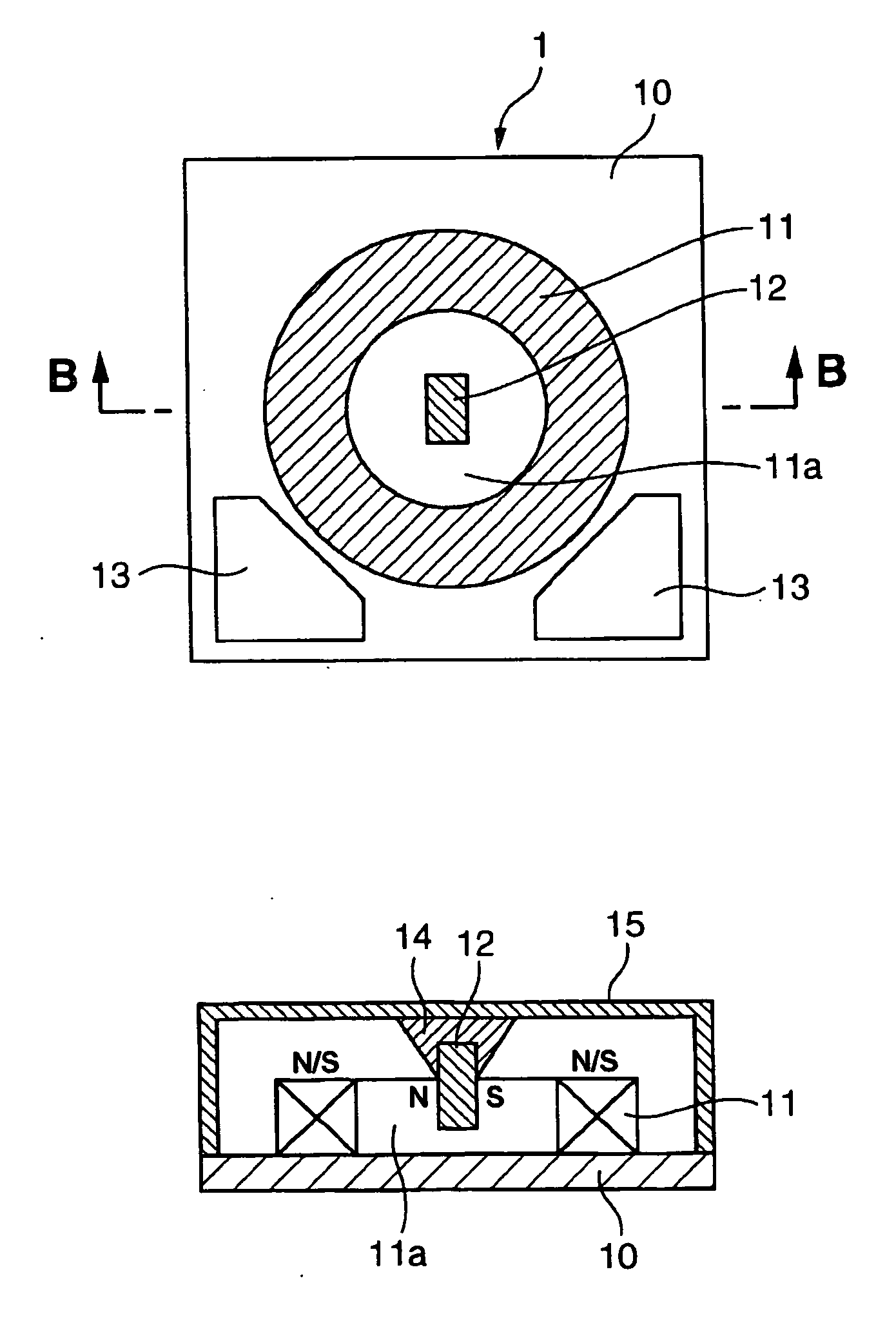

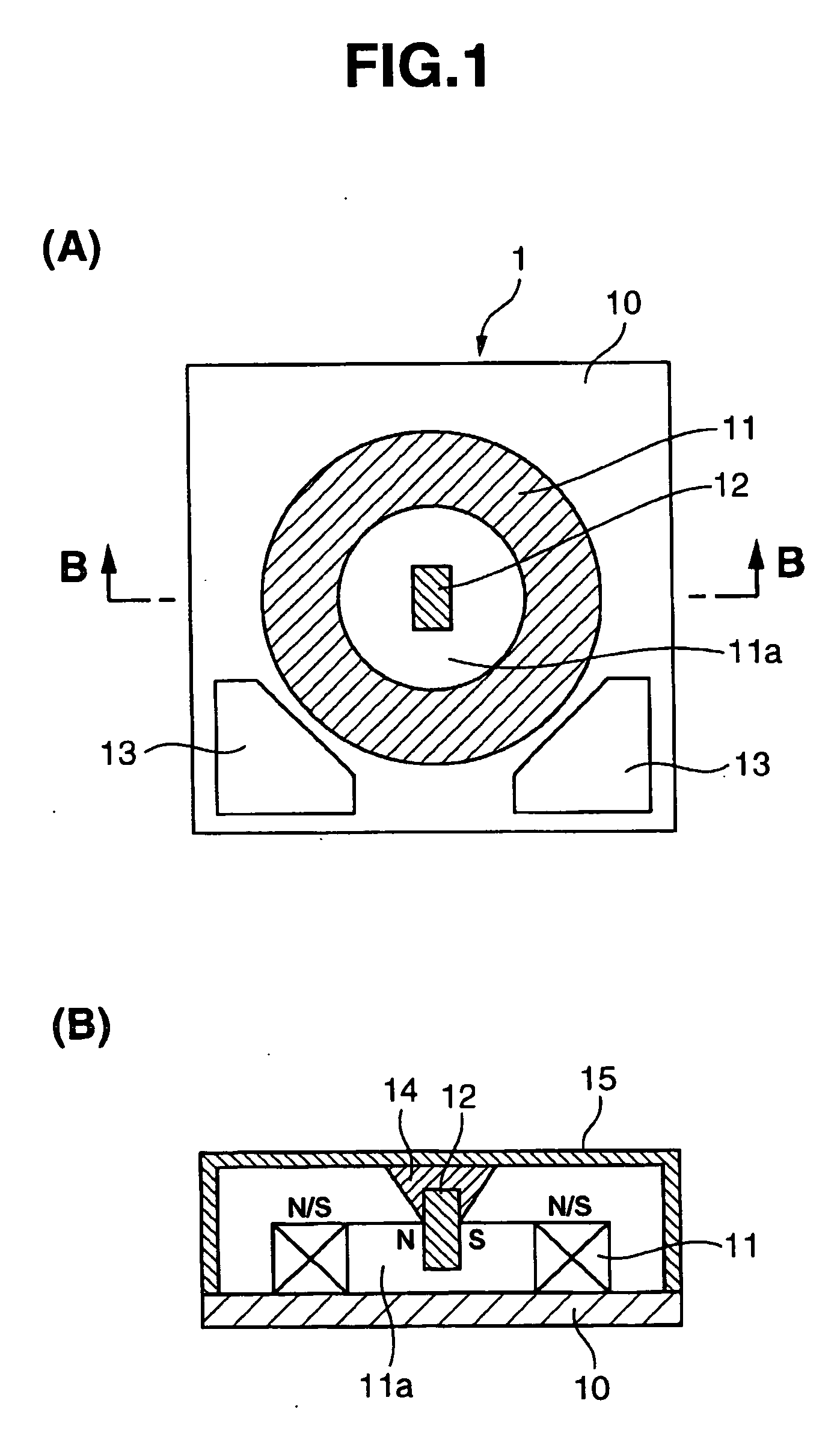

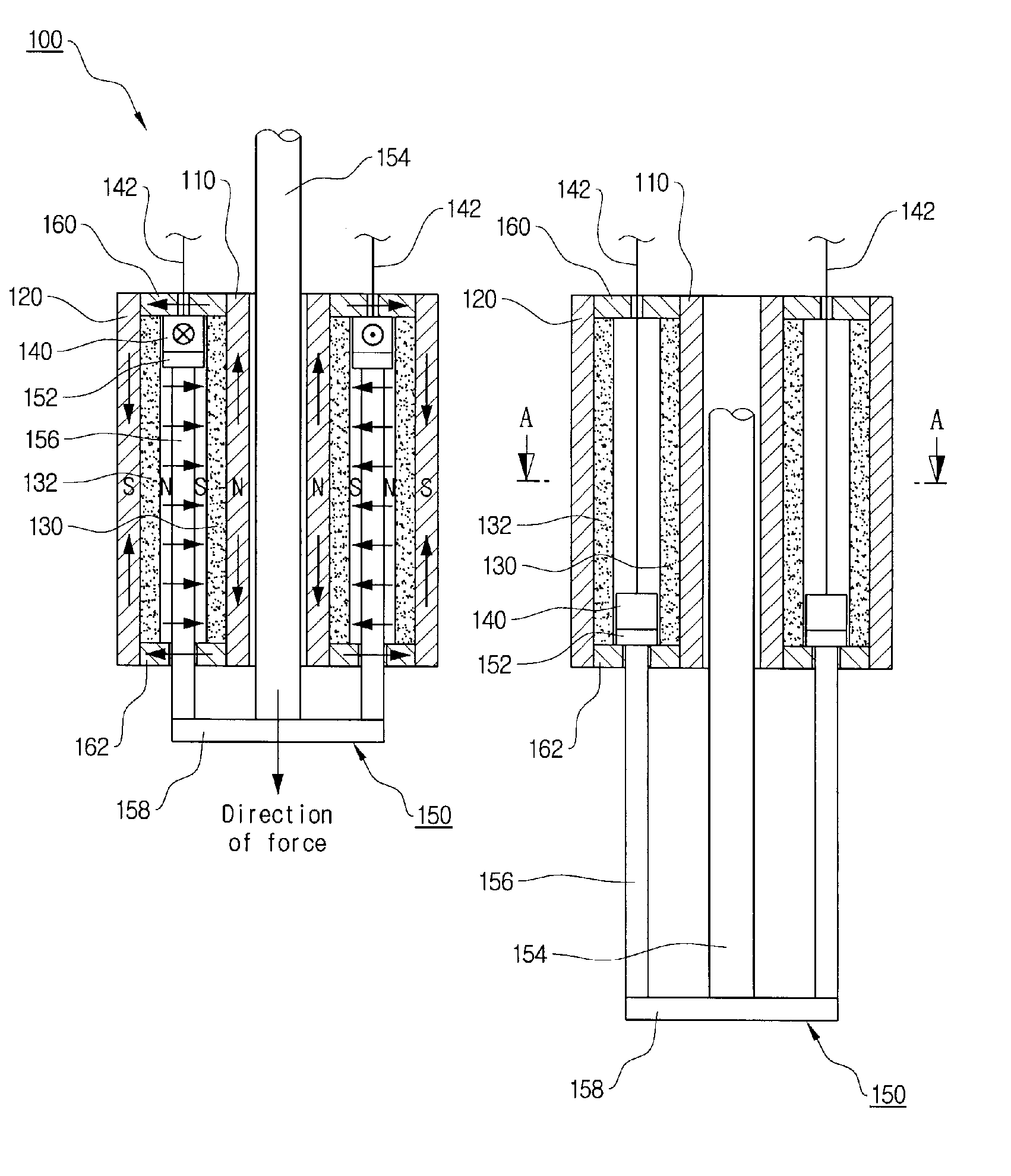

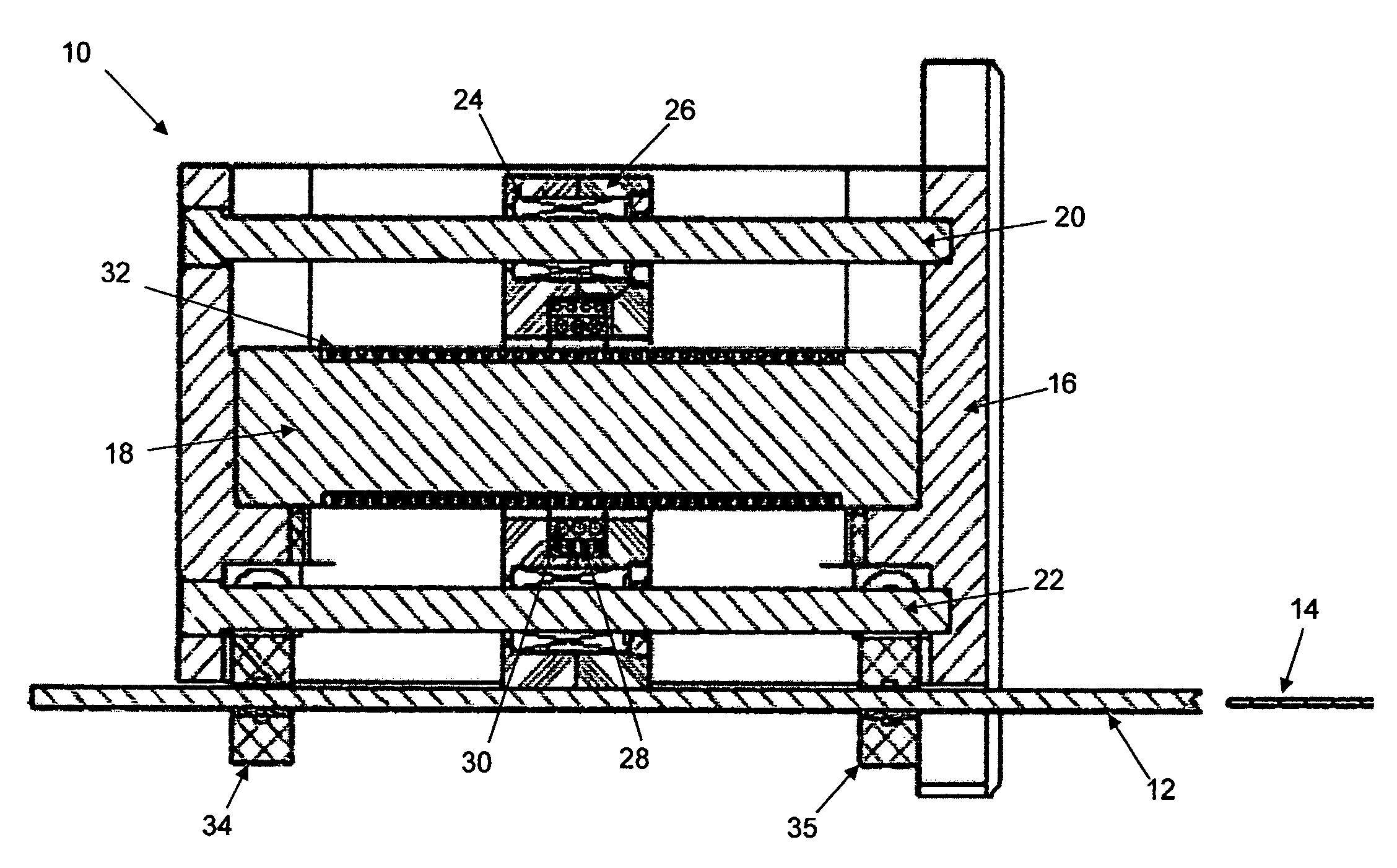

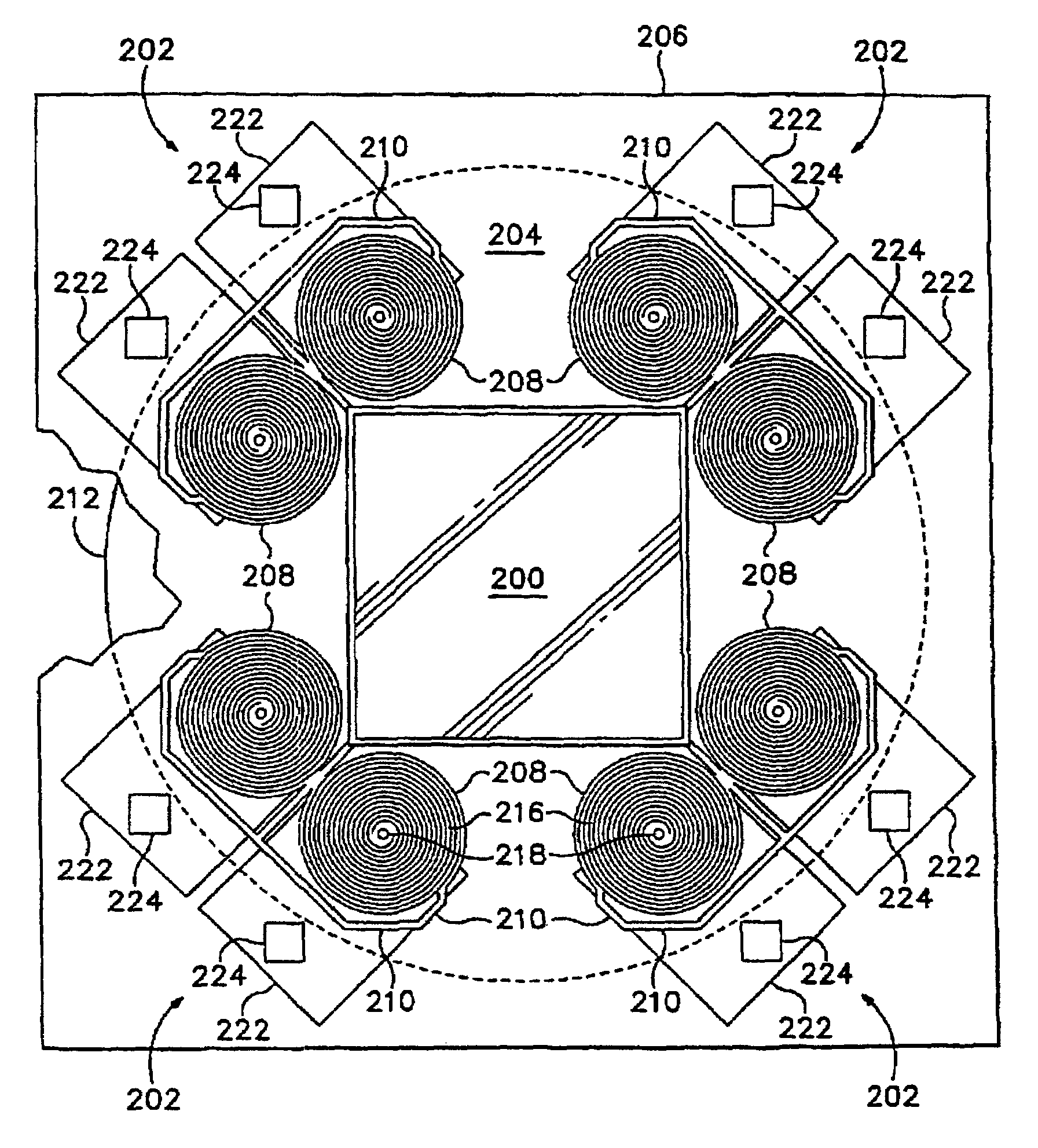

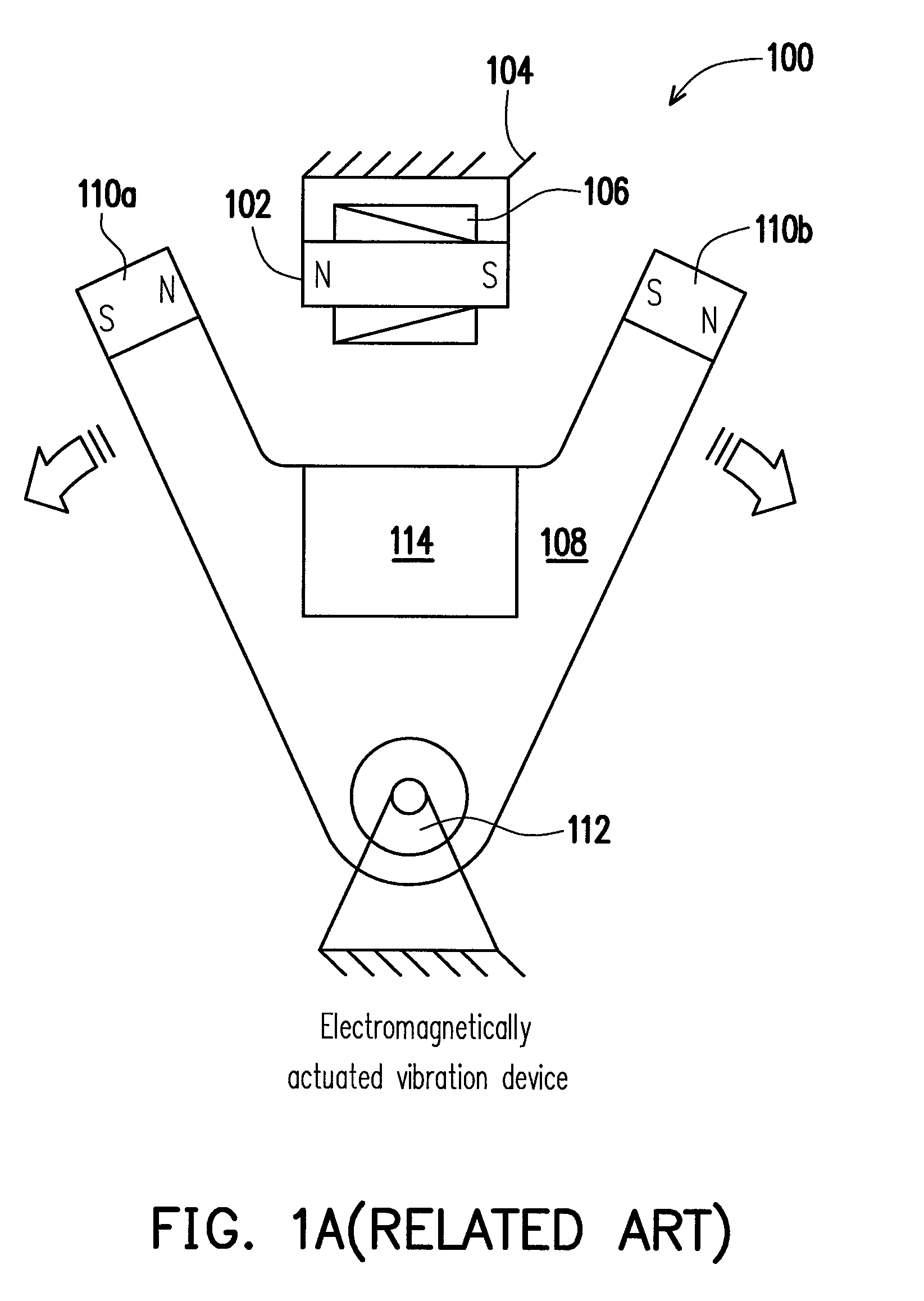

Electromagnetic actuator using permanent magnets

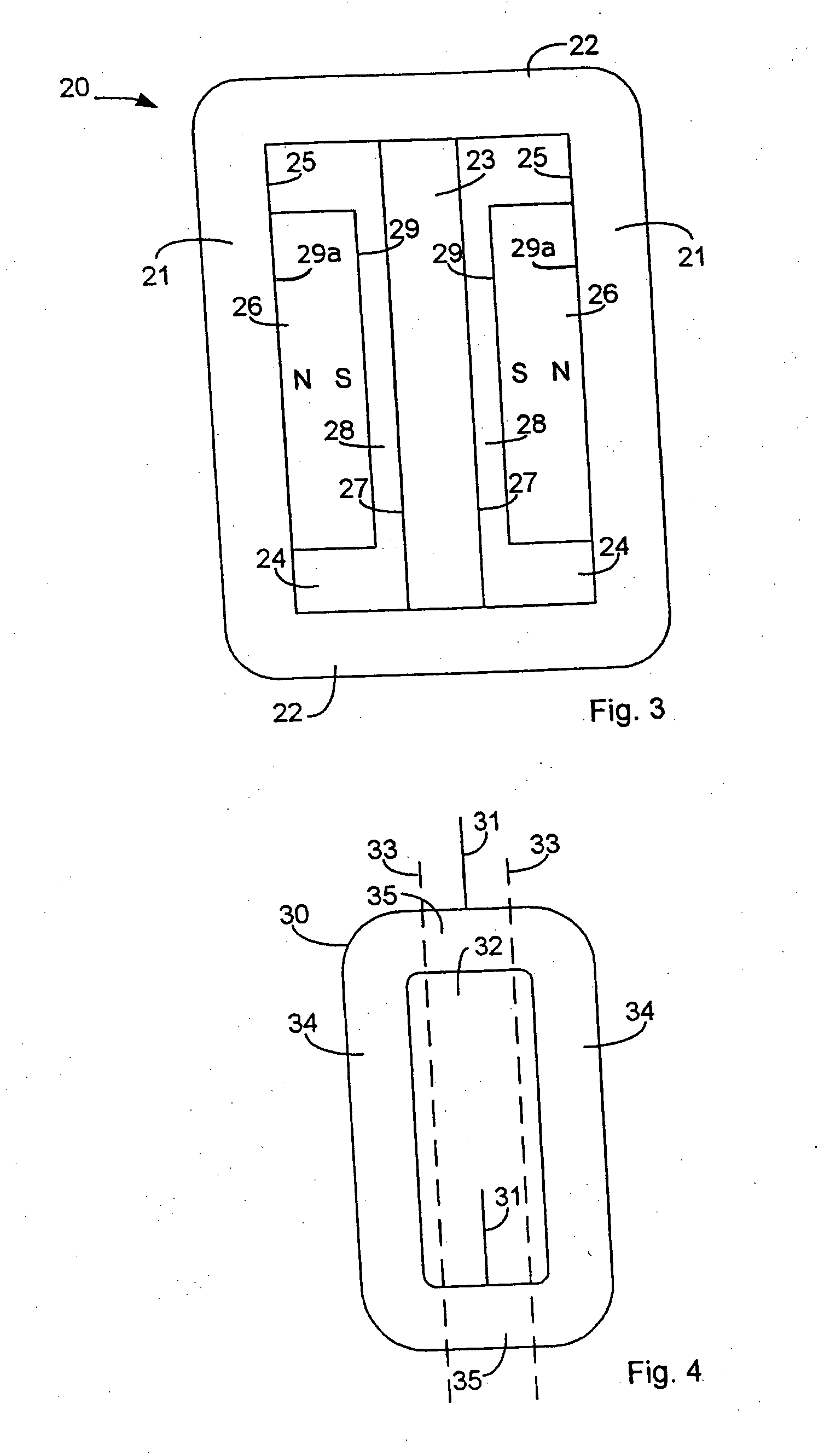

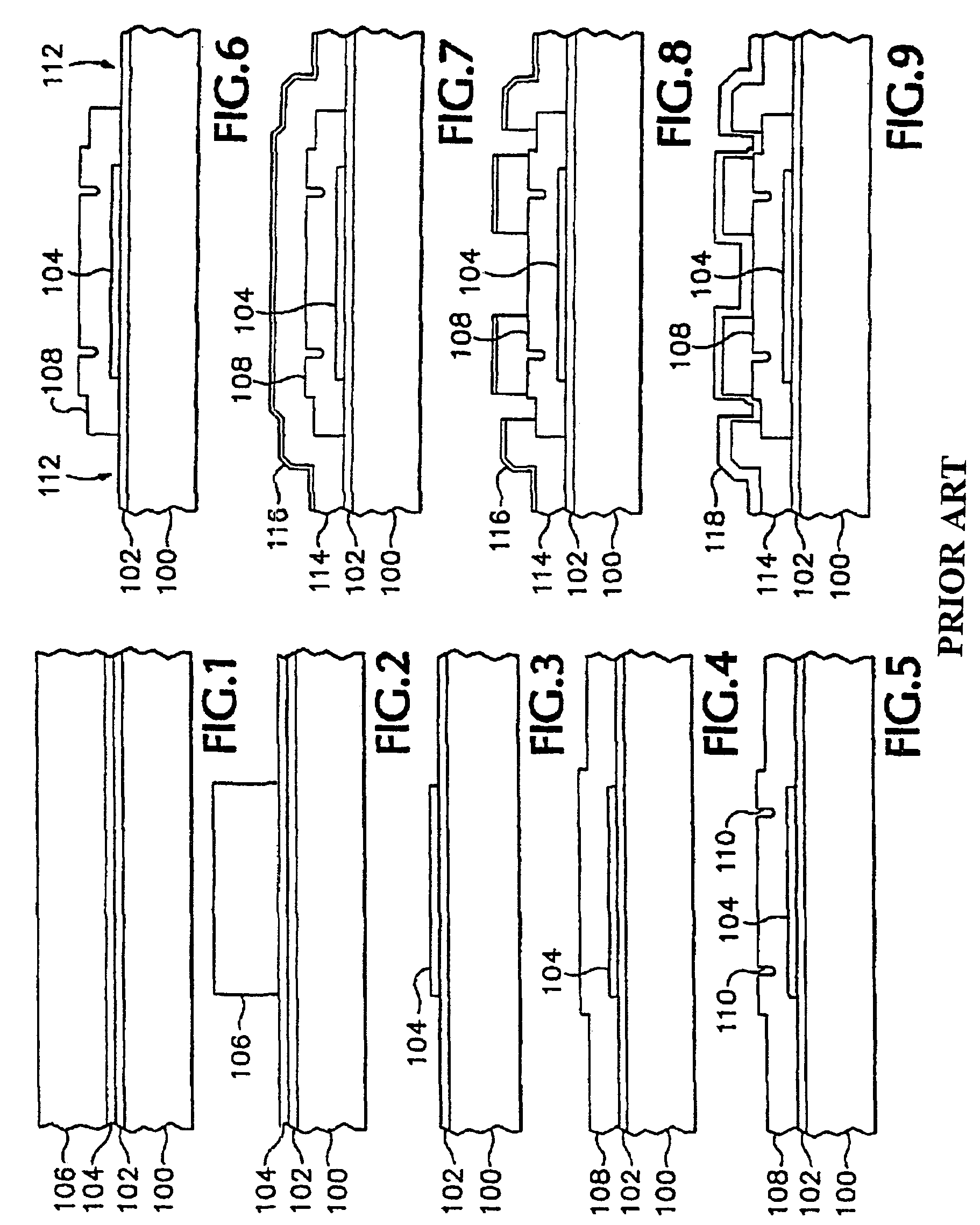

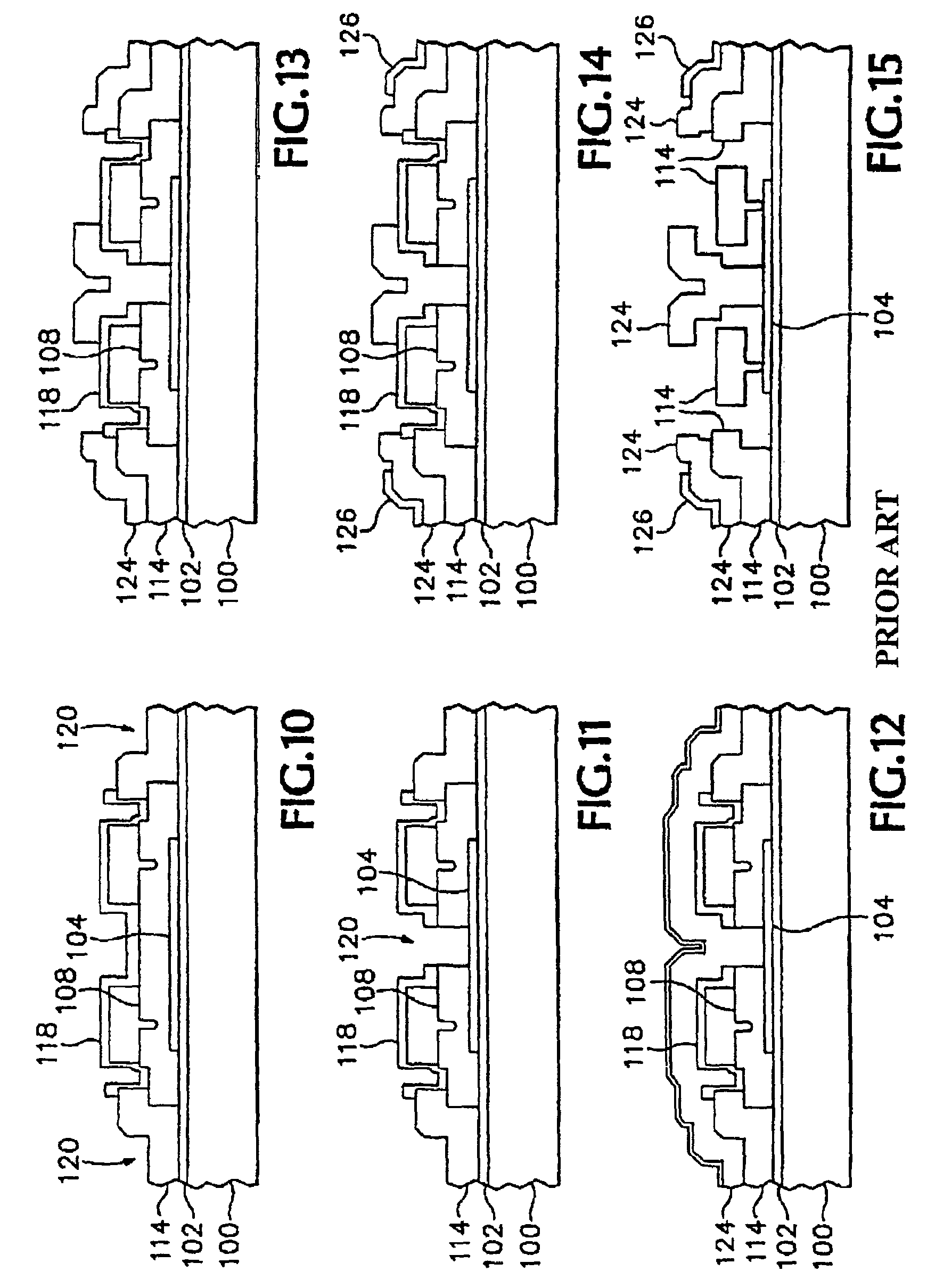

InactiveUS7439640B2Efficiently usStrong pullPropulsion systemsMovable winding electromagnetsMagnetic polesEngineering

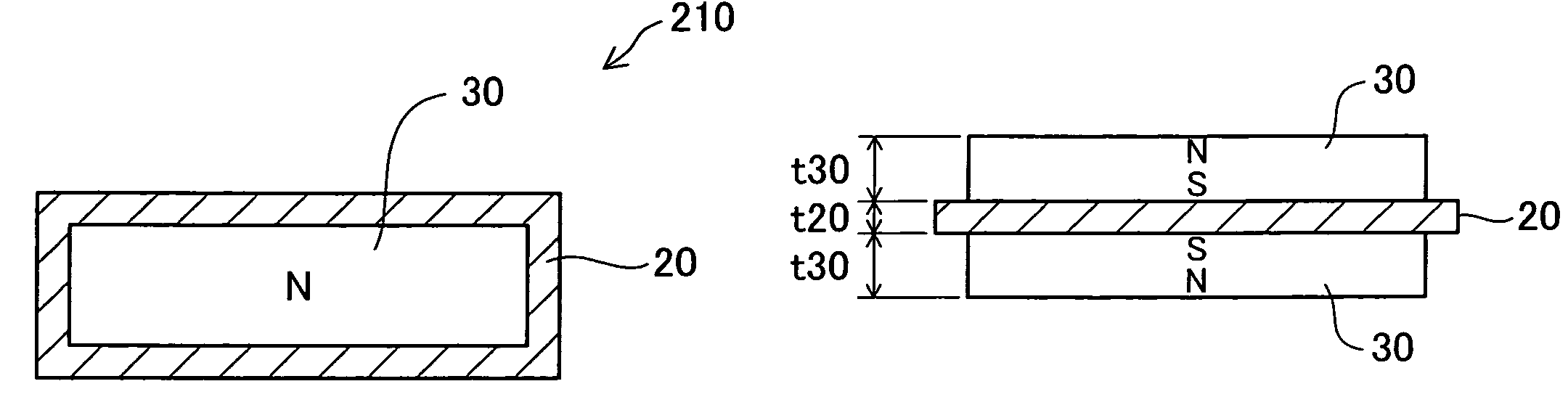

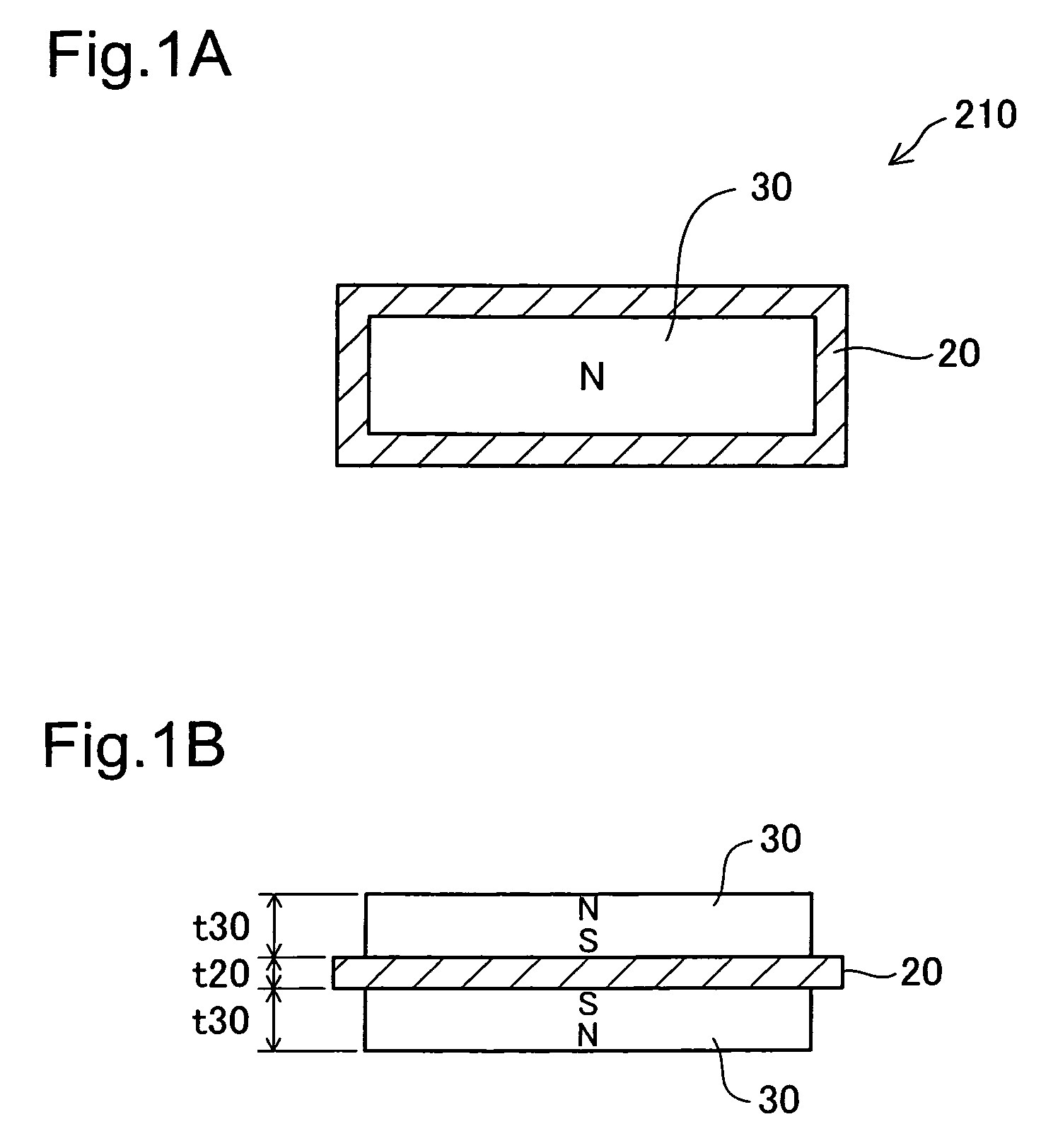

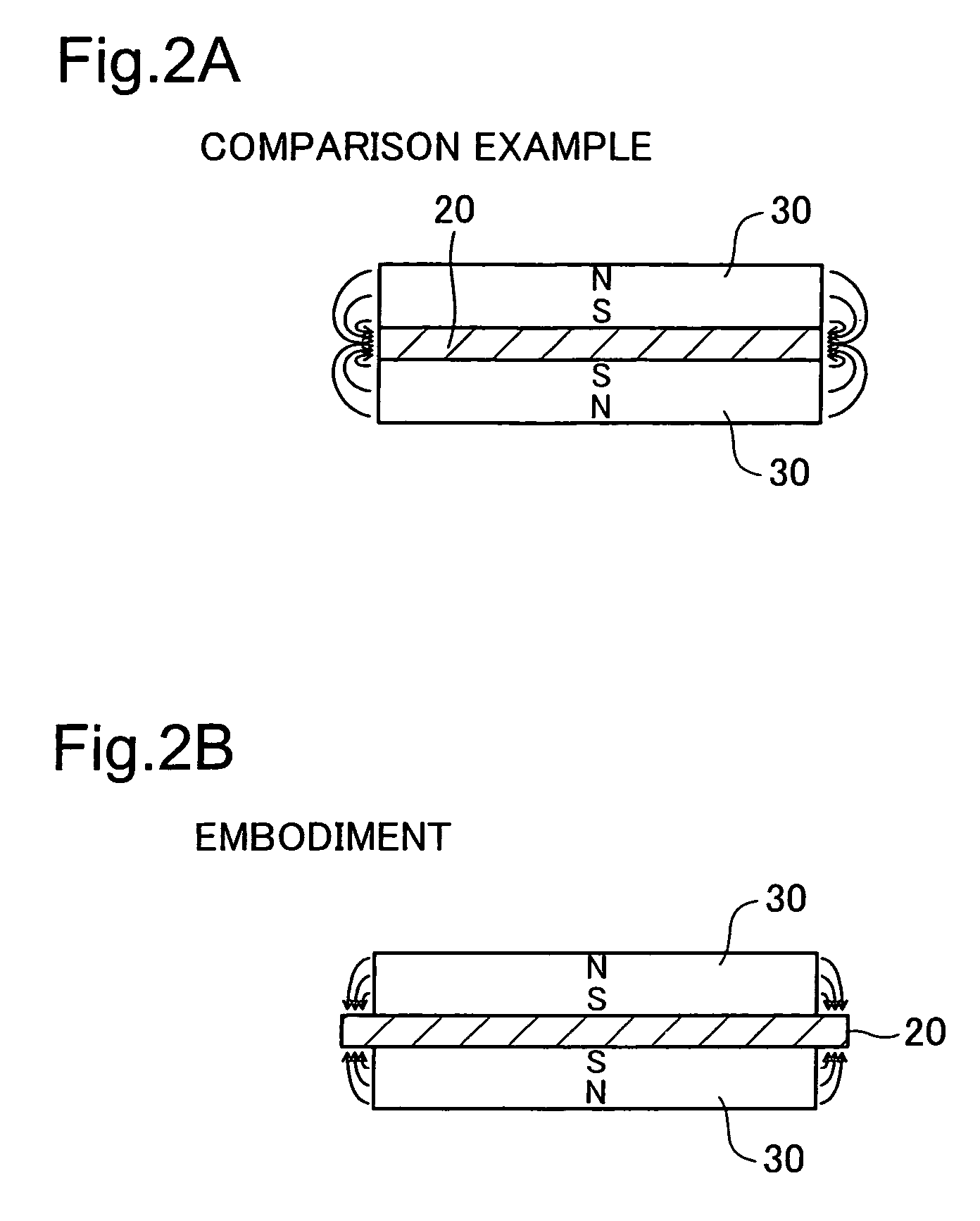

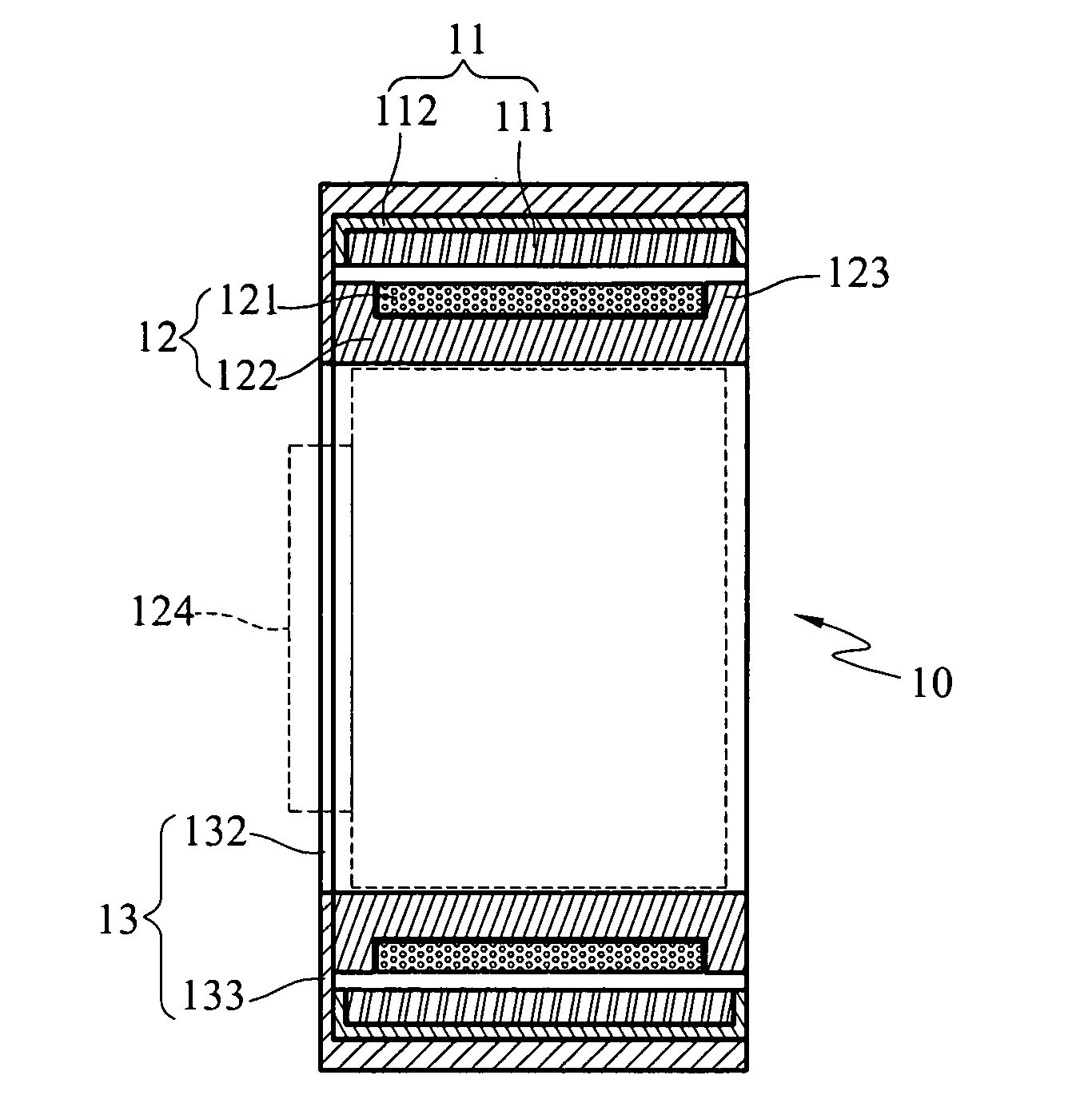

An actuator mechanism having a different magnet polarity arrangement than the conventional mechanisms is provided. The actuator mechanism 100 has a magnet unit 210 that includes magnets 30 and an electromagnetic coil unit 110 that includes an electromagnetic coil. the relative positions of the magnet unit 210 and the magnetic coil unit 110 can change. The magnet unit 210 includes a yoke member 20 and two or more magnets 30. The two magnets 30 are pulled toward the yoke member 20 in the state where identical poles face each other across the yoke member 20.

Owner:GK BRIDGE 1

Axially actuating device having elastic joining portion

InactiveUS20070159010A1Reduce manufacturing costEliminate the problemProjector focusing arrangementElectrodynamic brake systemsAxial displacementRelative displacement

An axially actuating device having an elastic joining portion is provided, which is used for carrying an object and actuating the object to move axially, and comprises a fixed portion, a moving portion, and a joining member. The joining member is used to combine the fixed portion with the moving portion, such that the fixed portion and the moving portion are axially coupled with each other. Moreover, the fixed portion and the moving portion are respectively a fixed magnet and a coil, such that when a current is applied to the moving portion, the moving portion generates a relative displacement with respect to the fixed portion according to the current, so as to provide an axial displacement. Meanwhile, the moving energy is generated due to the repulsive interaction of the magnetic field, and thus a shock proofing efficacy is also provided.

Owner:IND TECH RES INST

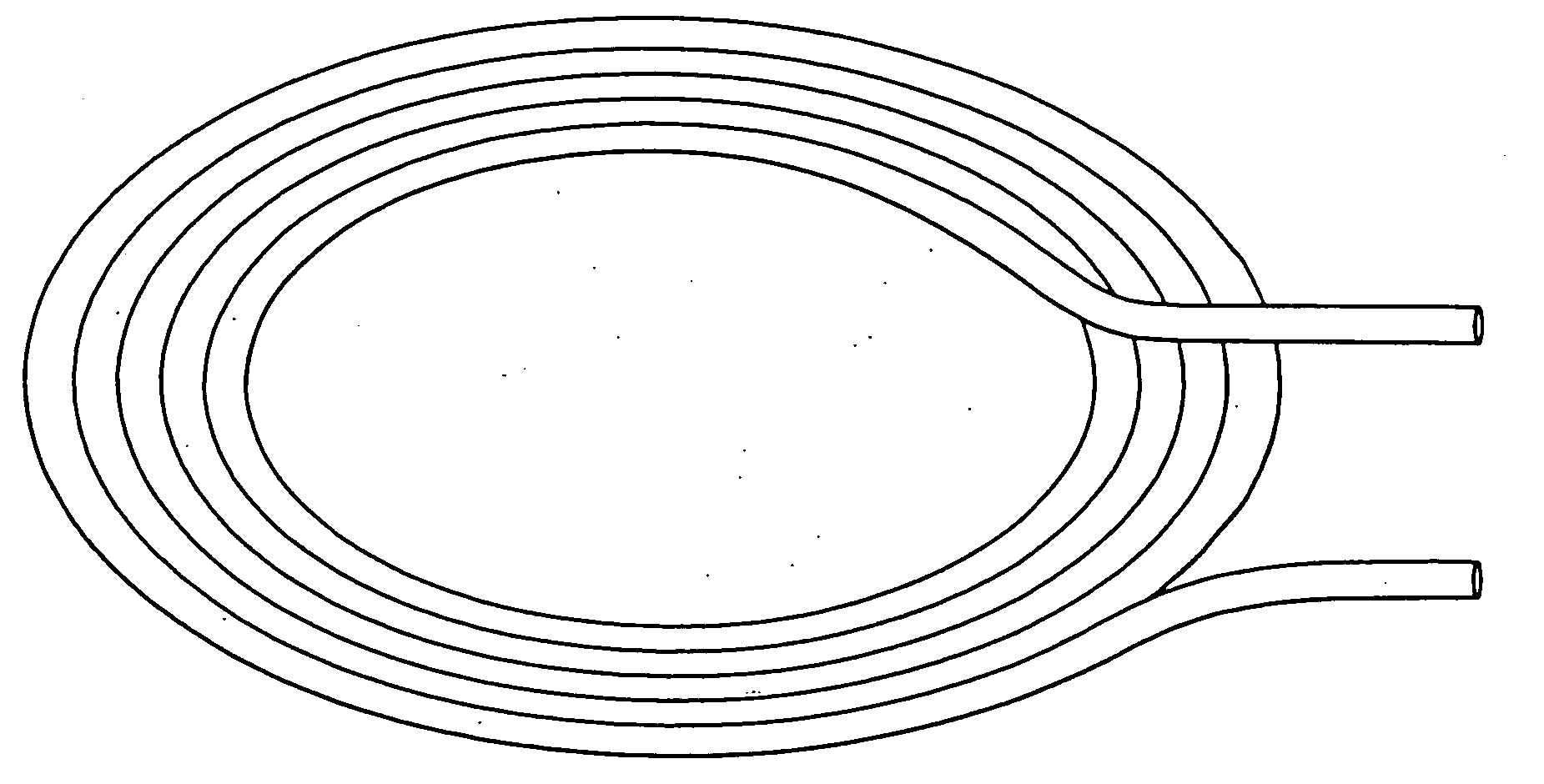

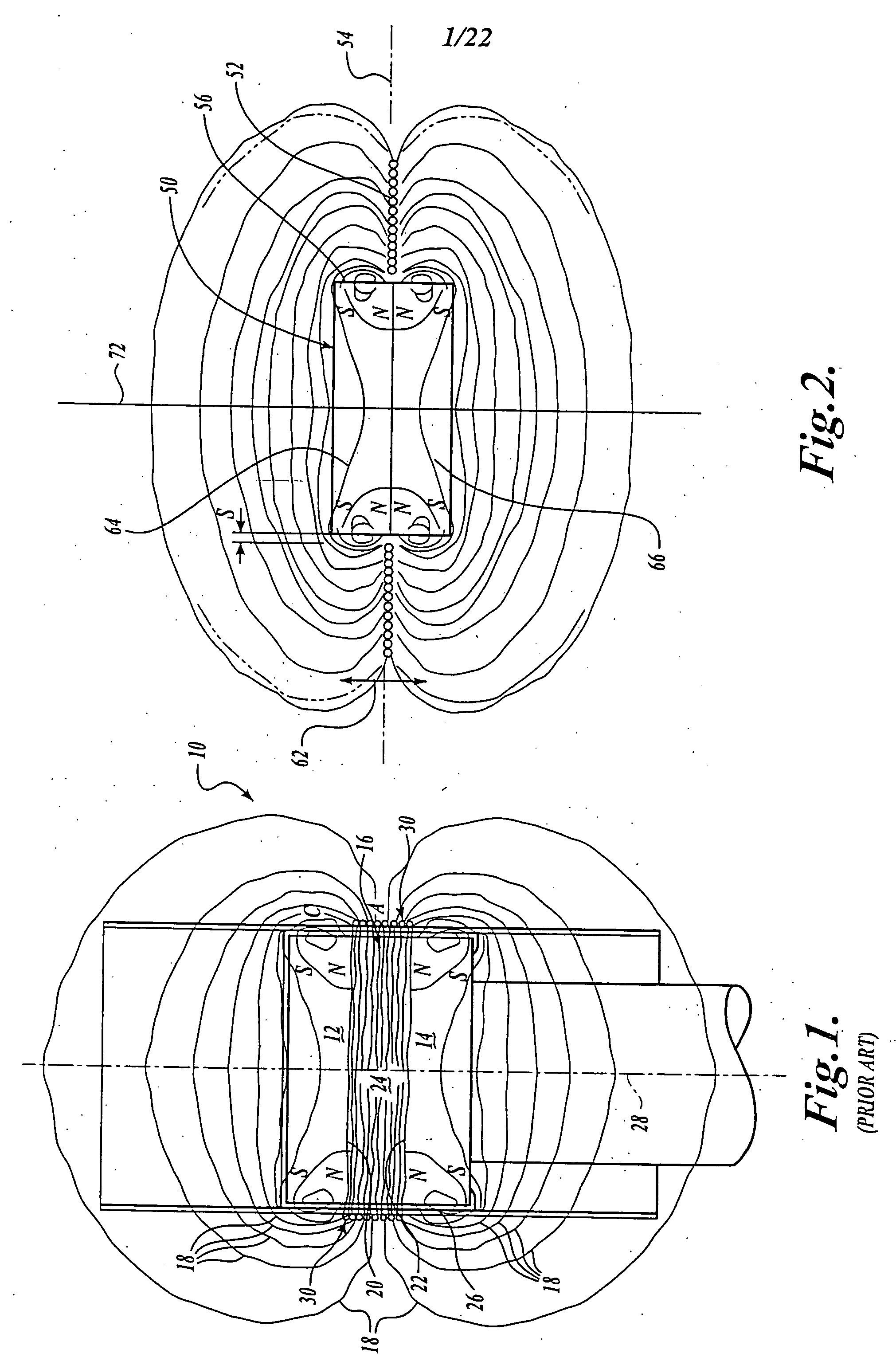

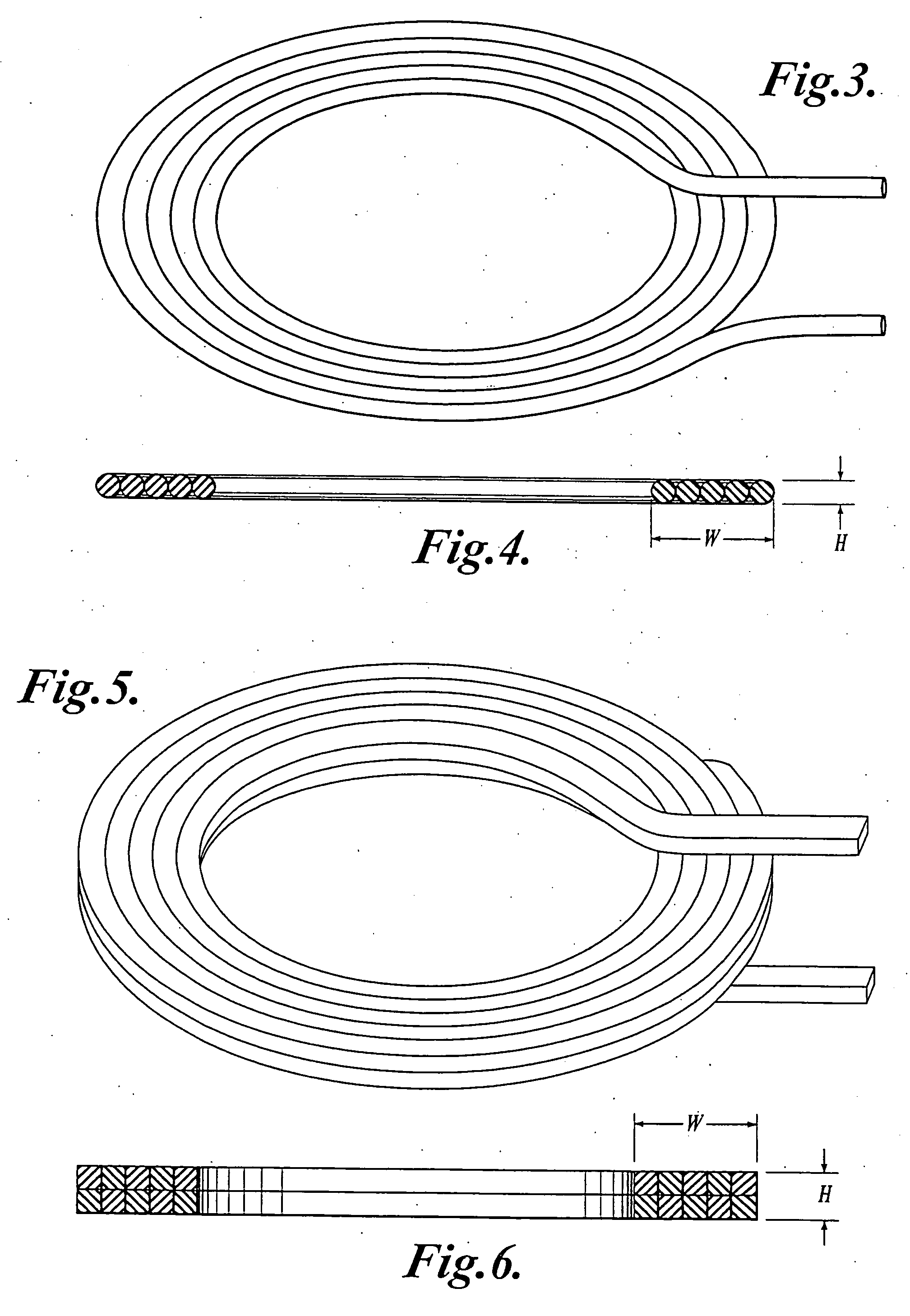

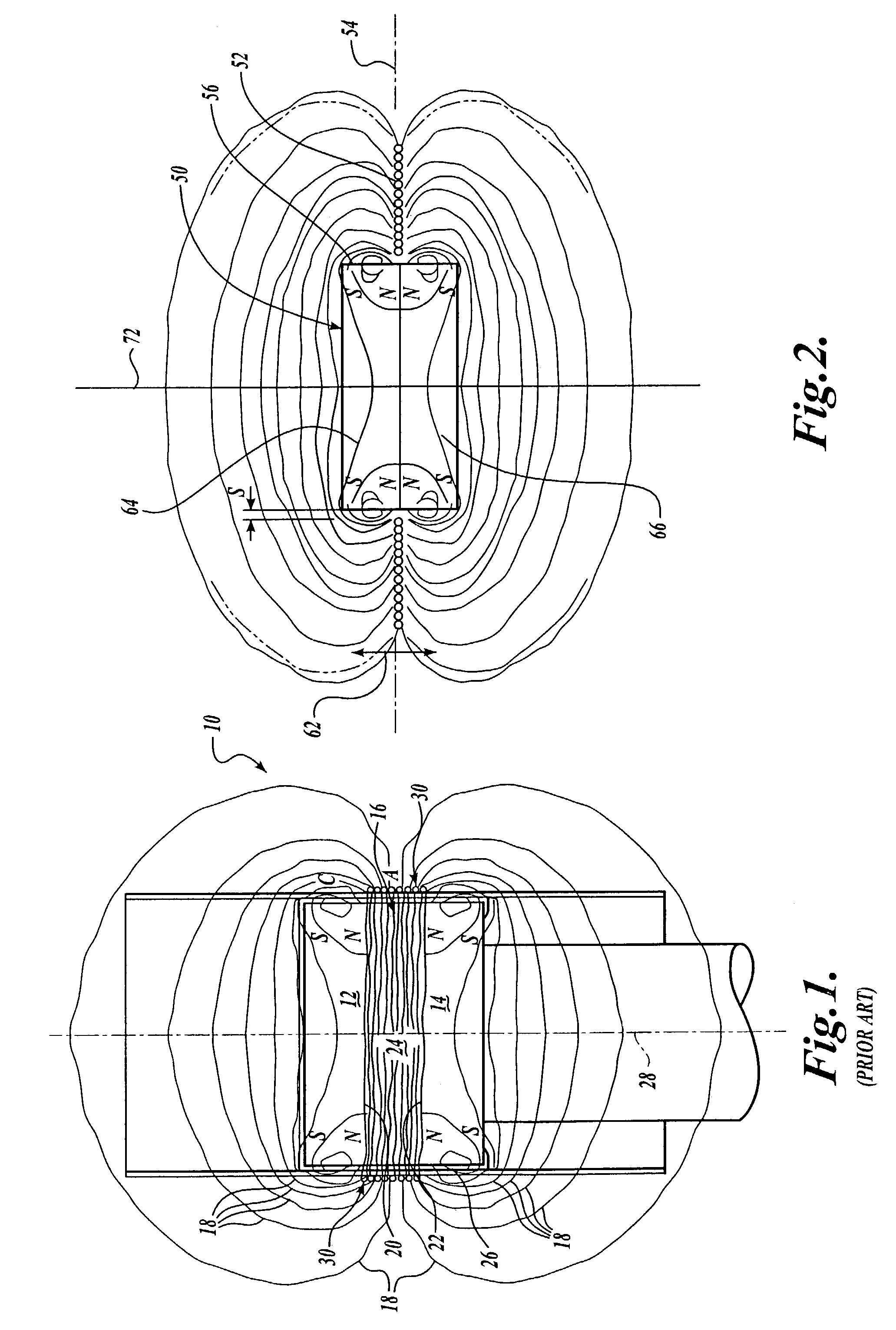

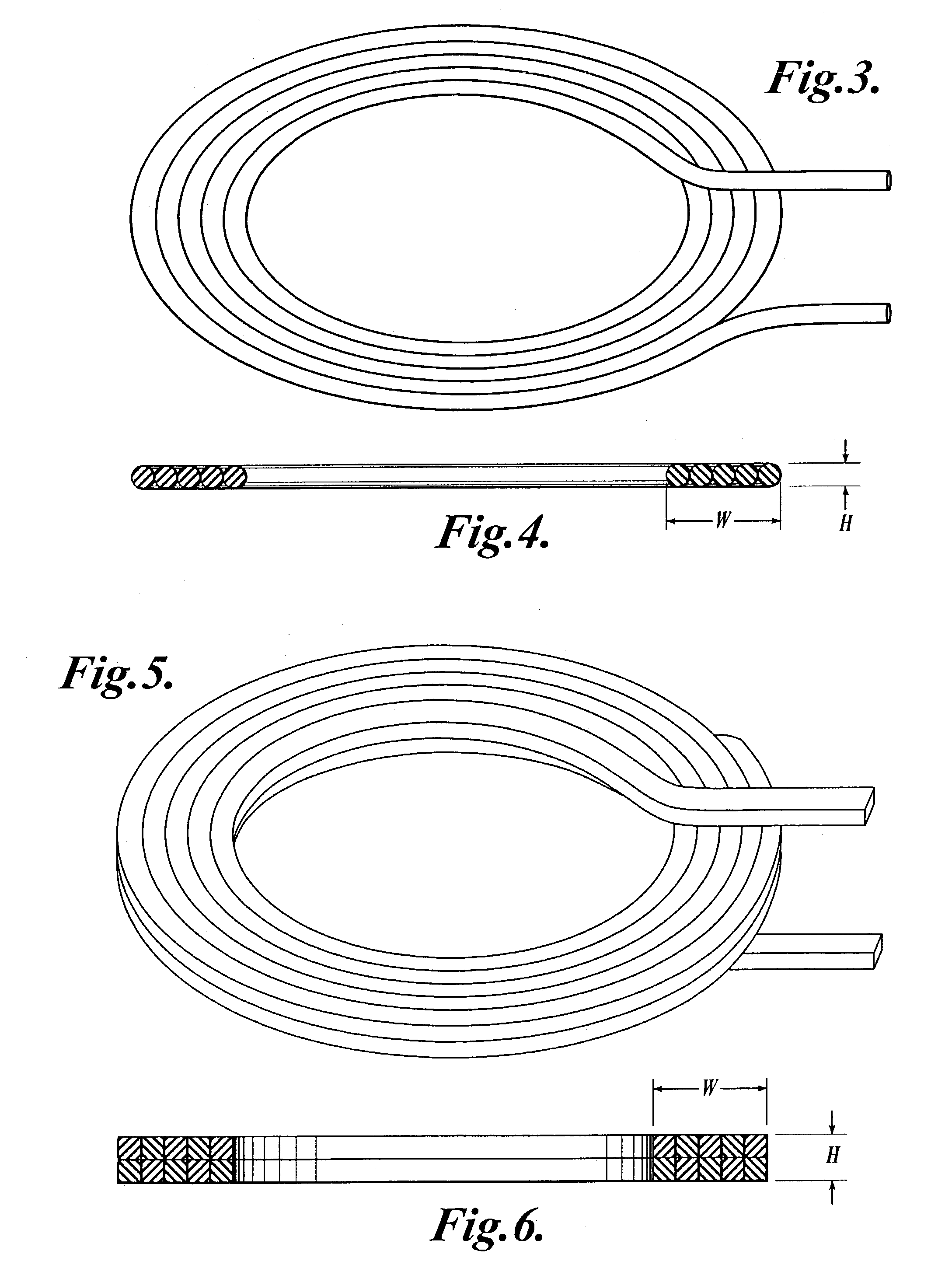

Microphone assembly

An electromagnetic transducer is described including a magnet assembly (50) and a conductive drive coil (52). The magnet assembly provides an emanating magnetic field within which the drive coil is located. The drive coil is a flat ring coil having a width that is equal to or greater than its height. As assembled, the drive coil is mounted in close proximity to the magnet assembly such that relative axial motion may occur between them during use. In one embodiment, the magnet assembly includes two permanent disc magnets (64), (66) having axial magnetizations and being oriented with like poles facing one another to produce a radially emanating magnetic field. In another embodiment, the magnet assembly includes a pair of axially magnetized permanent ring magnets (64), (66) also oriented with like poles facing one another.

Owner:TRANDAFIR ROLAND PIERRE

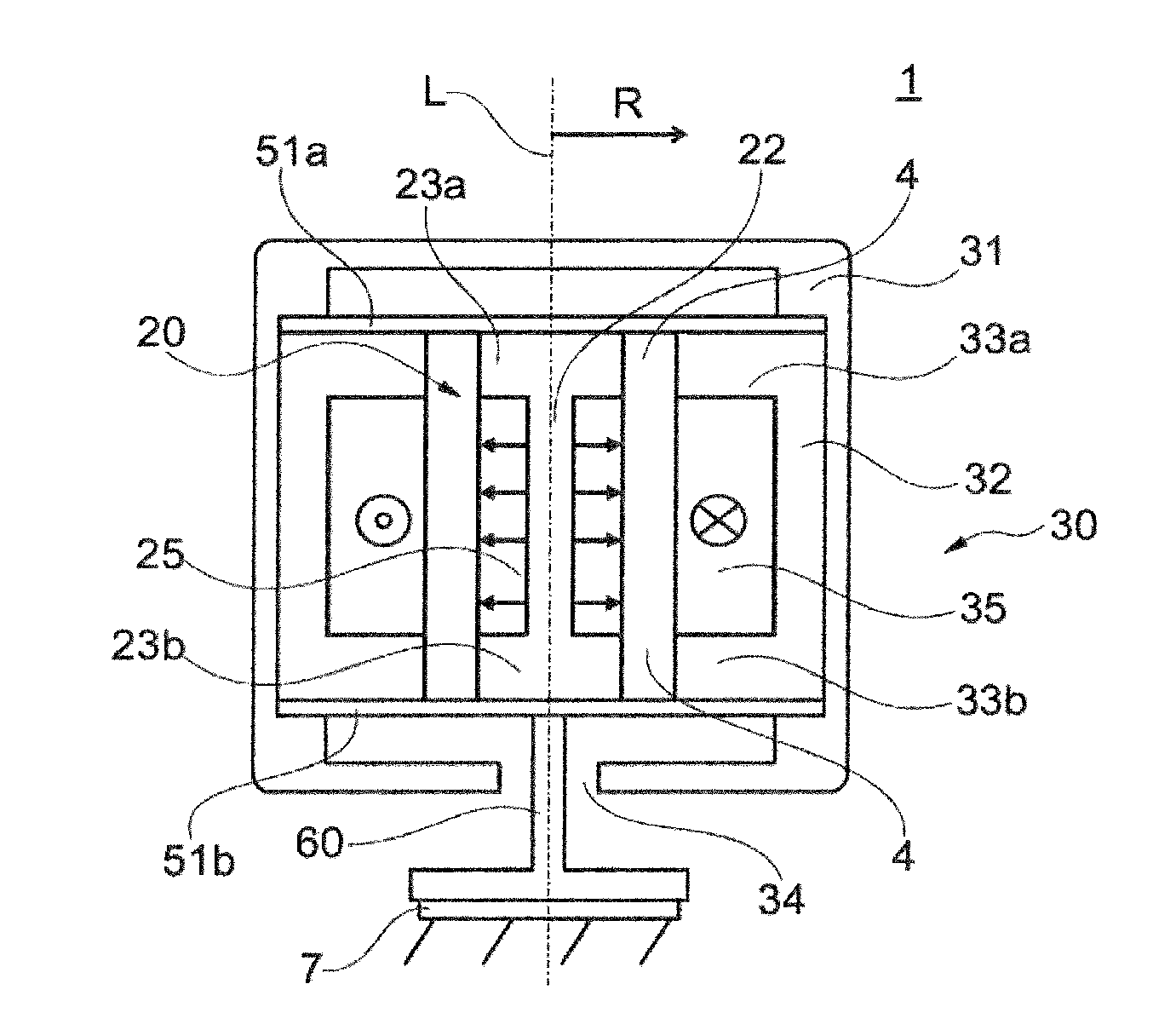

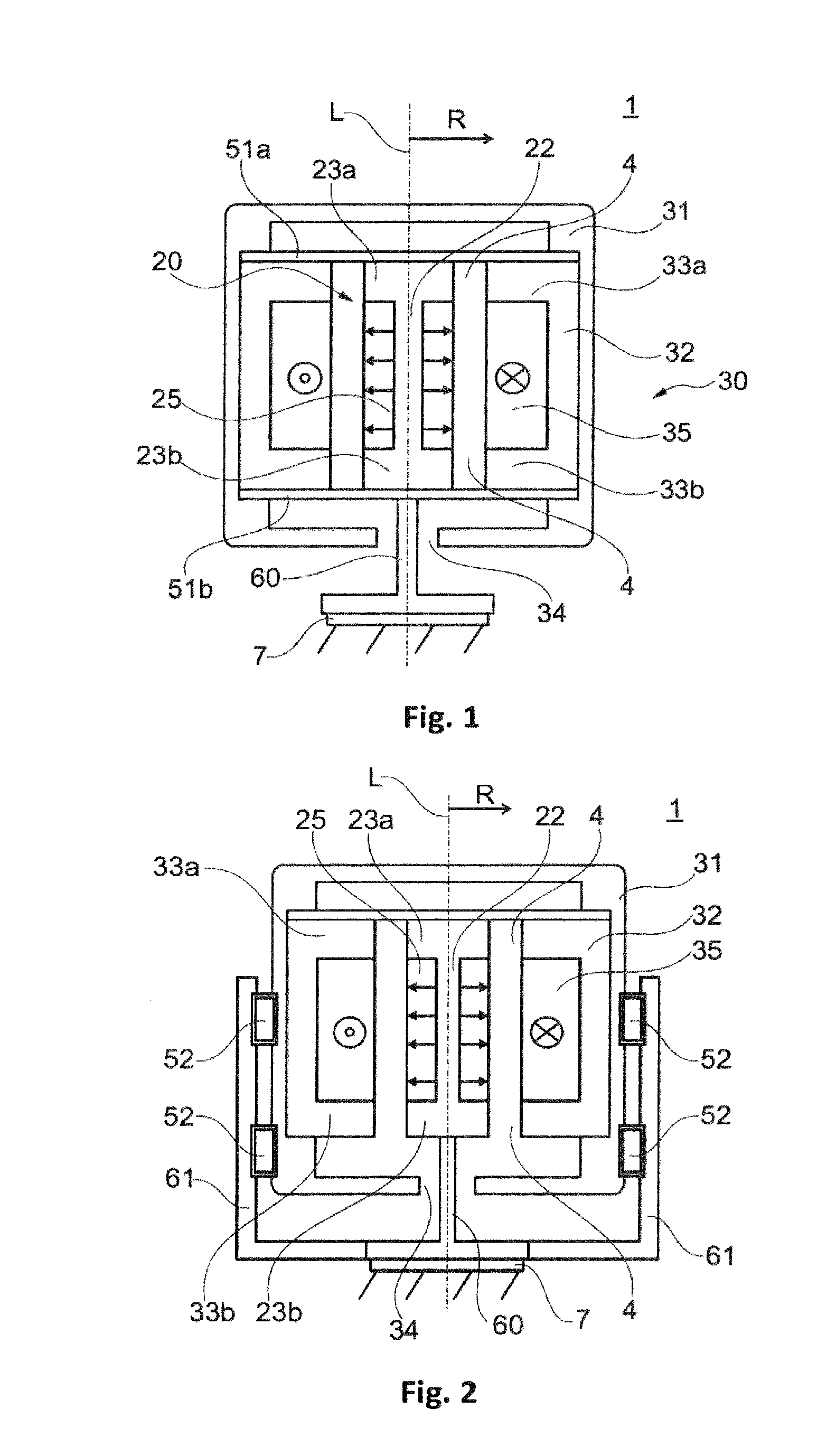

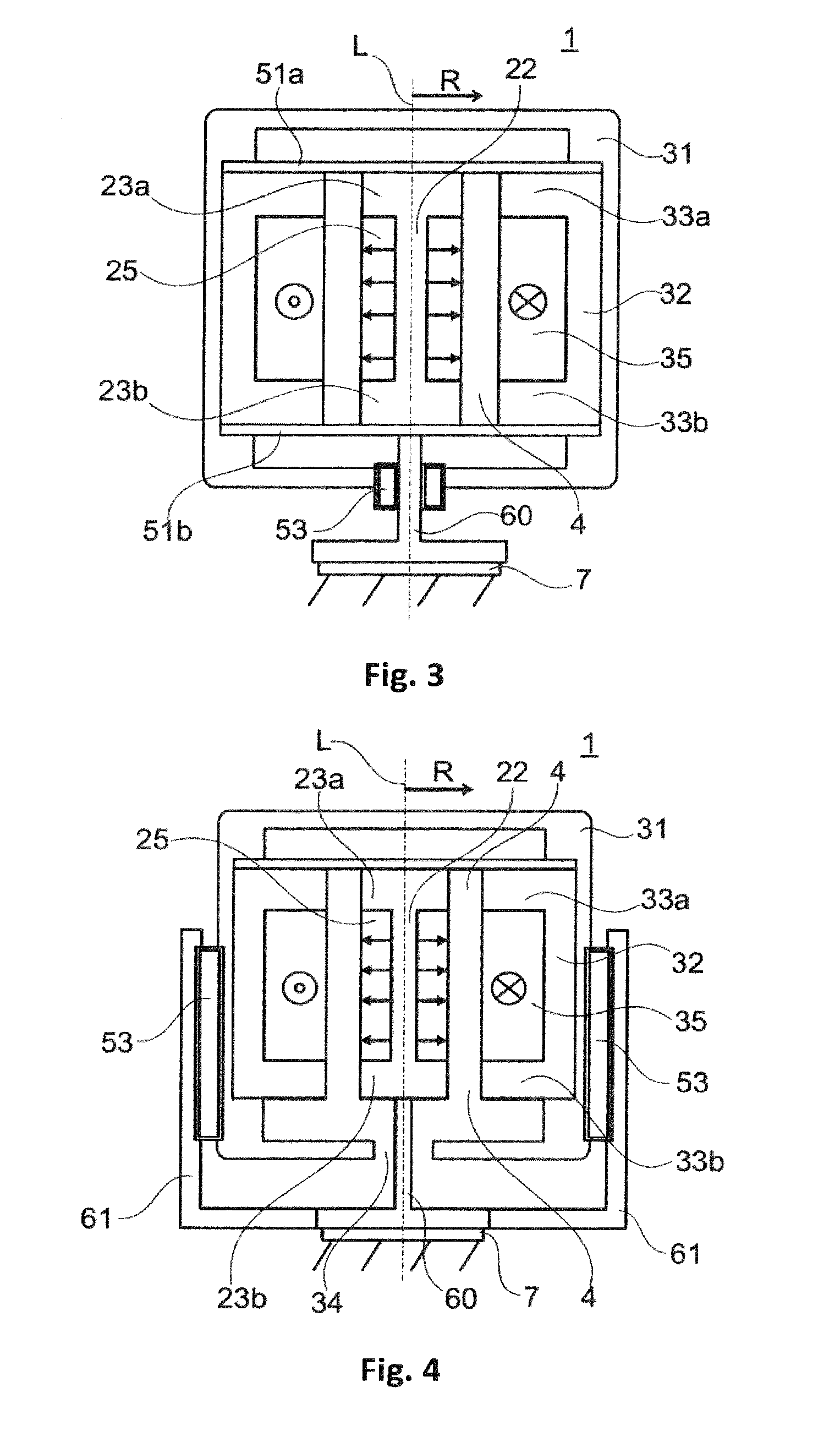

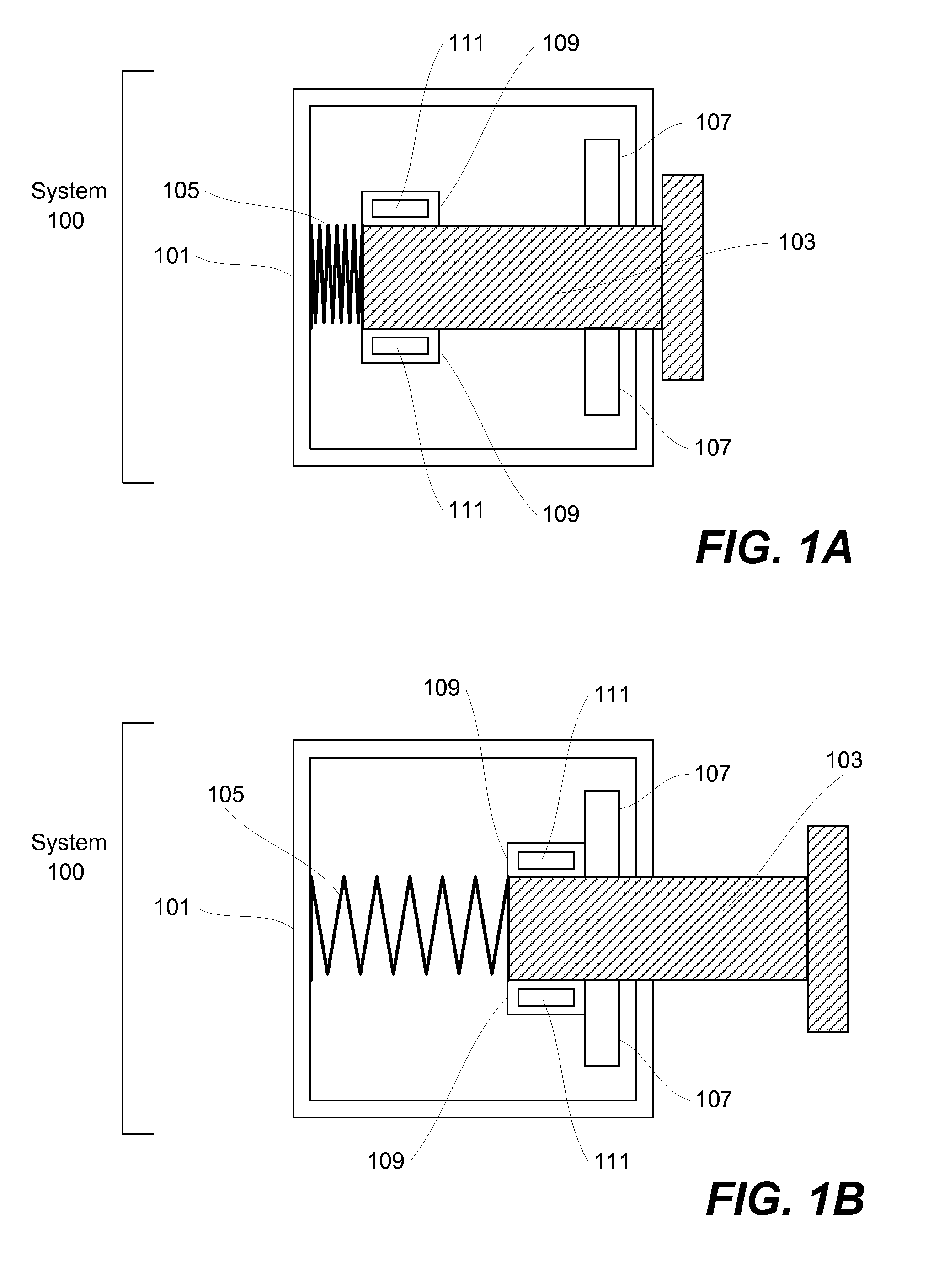

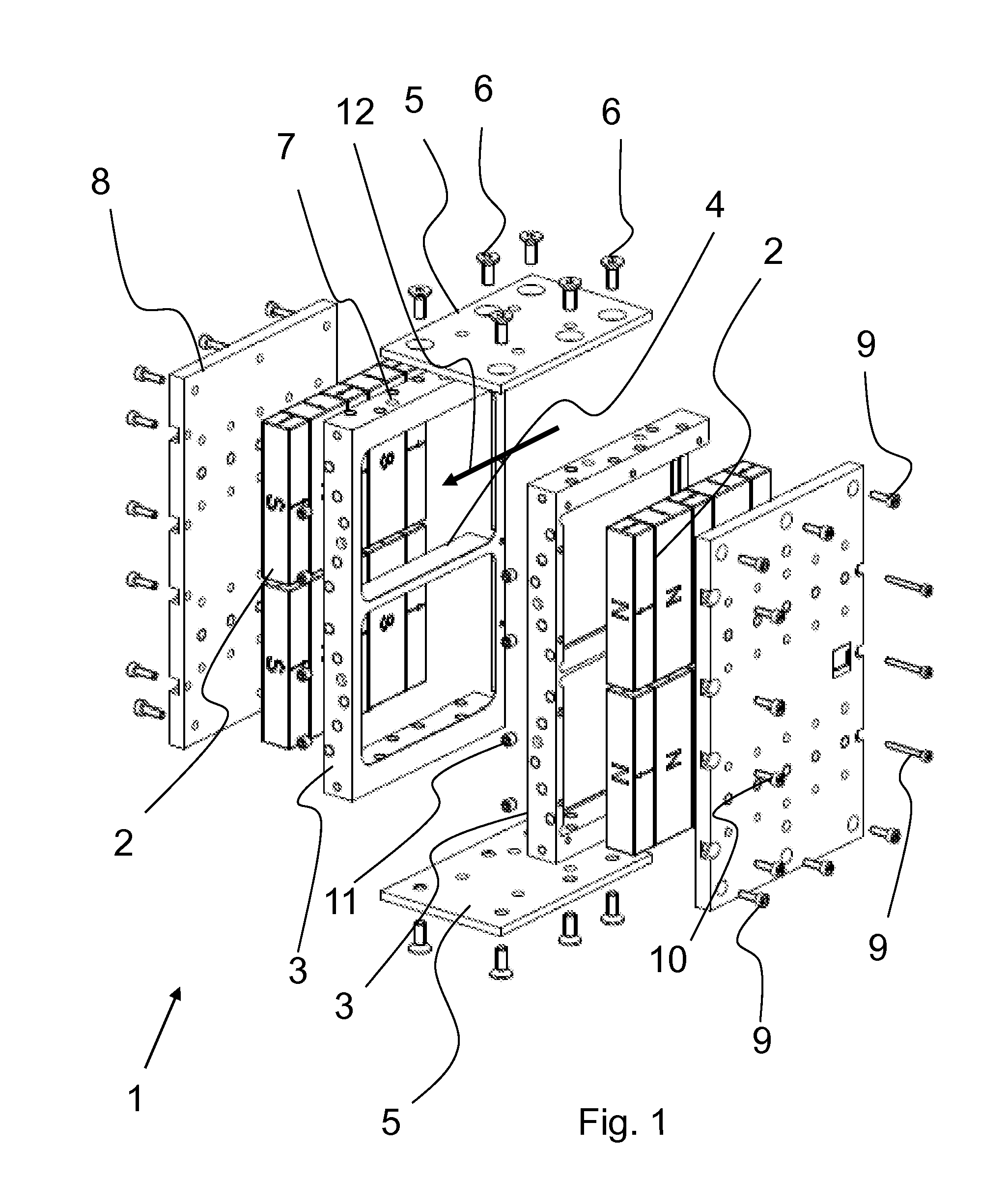

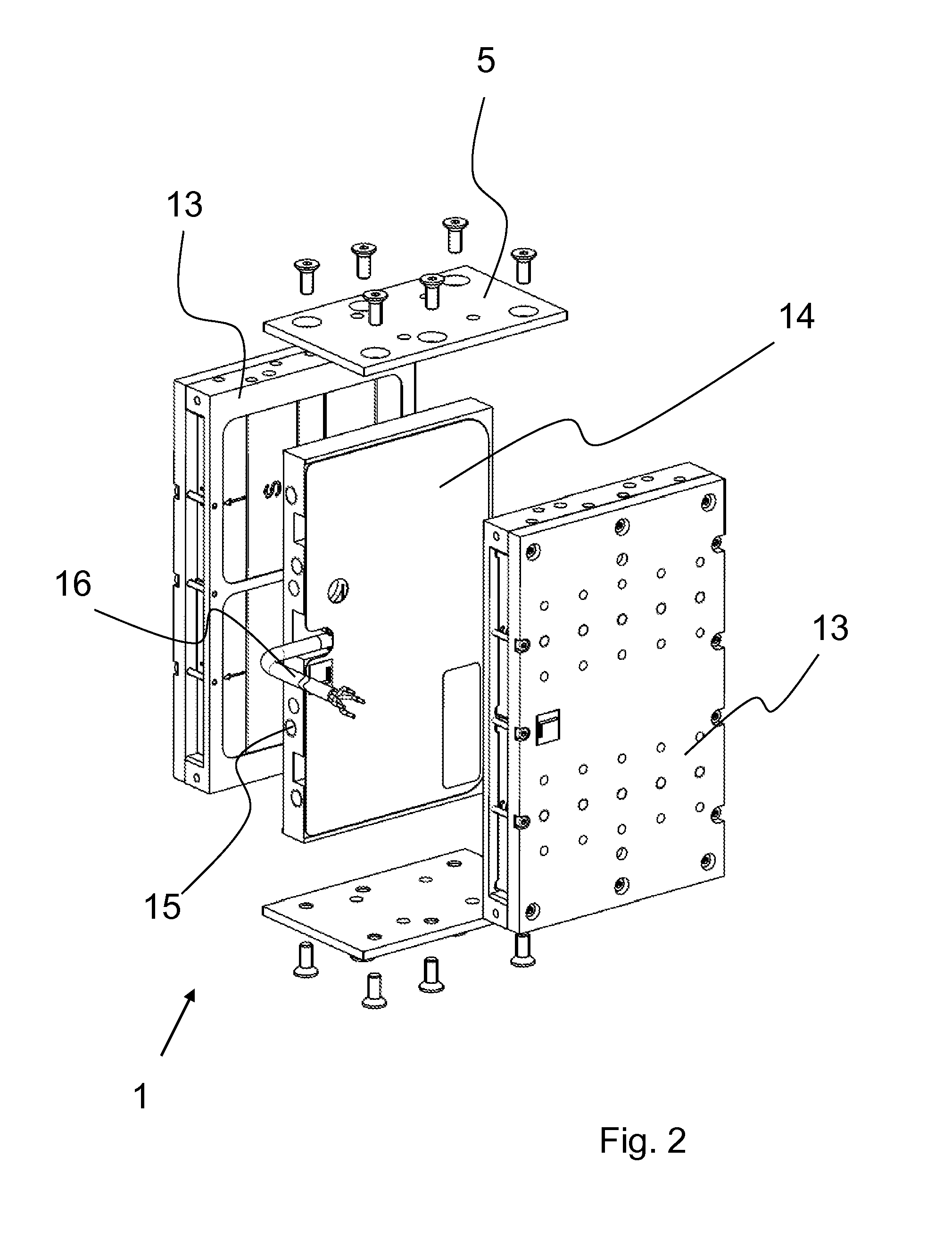

Actuator for damping low-frequency oscillations

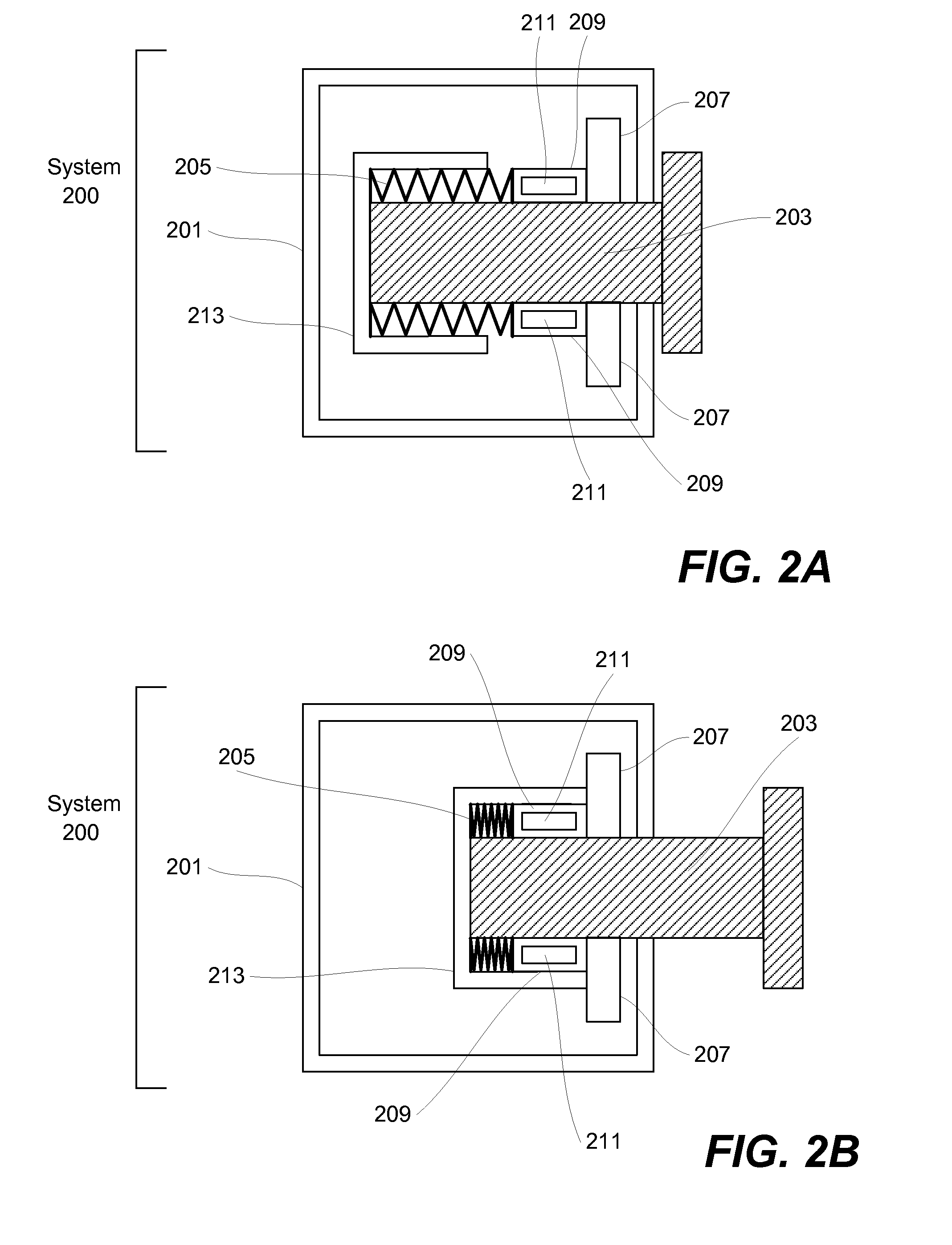

ActiveUS20150015091A1Compact structureDamping effectMechanical energy handlingMovable winding electromagnetsEngineeringLow-frequency oscillation

An actuator has an electrically conductive coil which has a longitudinal axis and windings through which a current can flow. The coil is surrounded by a highly permeable first ferromagnetic body so that the first body has projections of highly permeable ferromagnetic material above and below the coil in the longitudinal direction. The actuator has a magnet spaced apart from the coil so that a gap forms therebetween. The magnet is surrounded by a highly permeable second ferromagnetic body so that the second body has projections of highly permeable ferromagnetic material above and below the magnet in the longitudinal direction. The magnet is statically mounted with the second body and the coil is spring mounted with the first body so that the coil and first body oscillate in the longitudinal direction when an alternating current flows through the coil. The coil is outside the magnet perpendicular to the longitudinal axis.

Owner:CONTITECH VIBRATION CONTROL

Drive mechanism

InactiveUS8144380B2Simple magnetic body structureImprove frequency characteristicsTelevision system detailsAC motor controlEngineeringElectrical and Electronics engineering

A drive mechanism @is comprised with a set comprising a plurality of magnetic bodies, means for supplying a frequency signal to said set, and means for producing movement caused by the attraction / repulsion between the magnetic bodies. The movement is the driving source of the drive mechanism.

Owner:SEIKO EPSON CORP

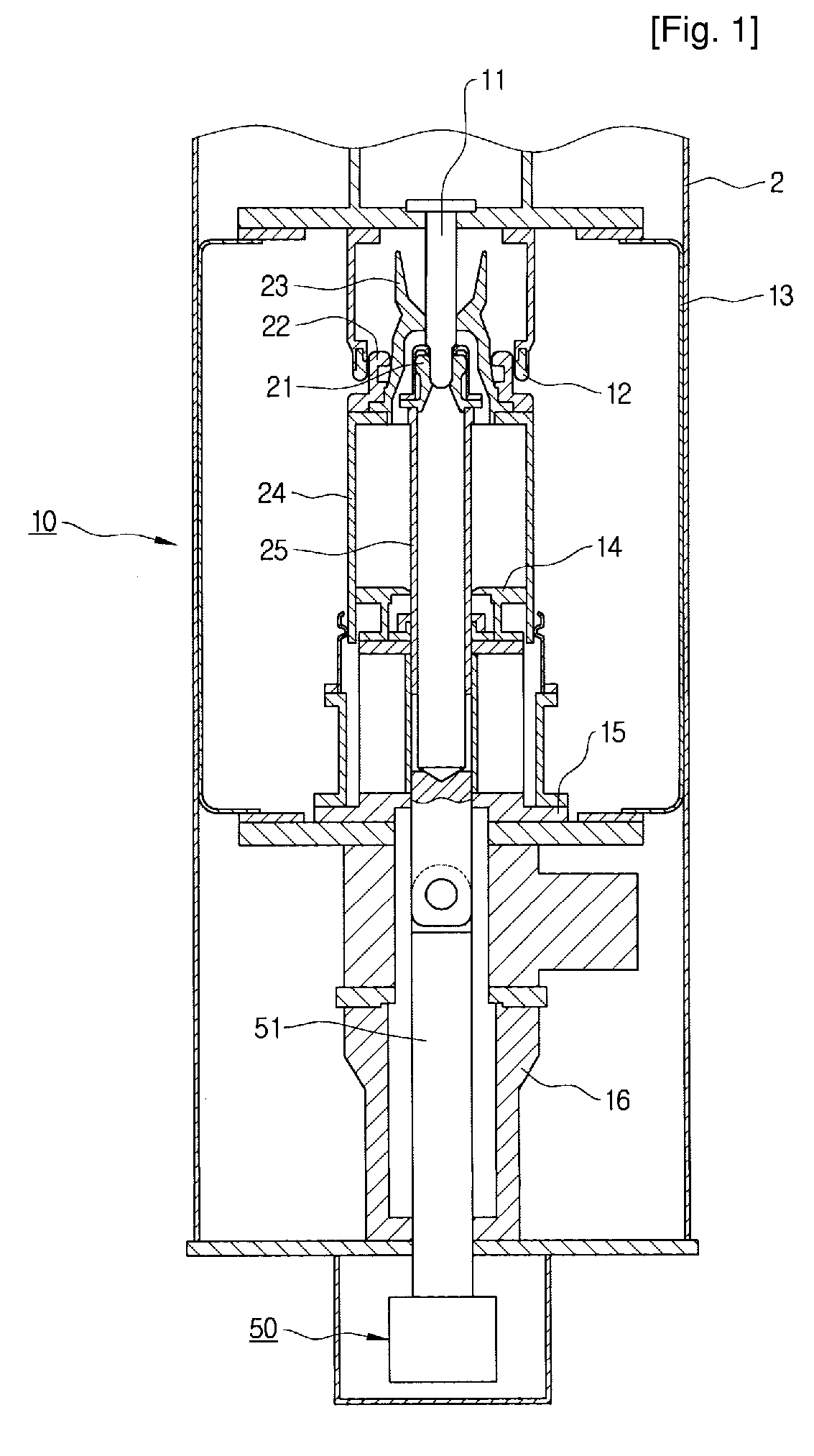

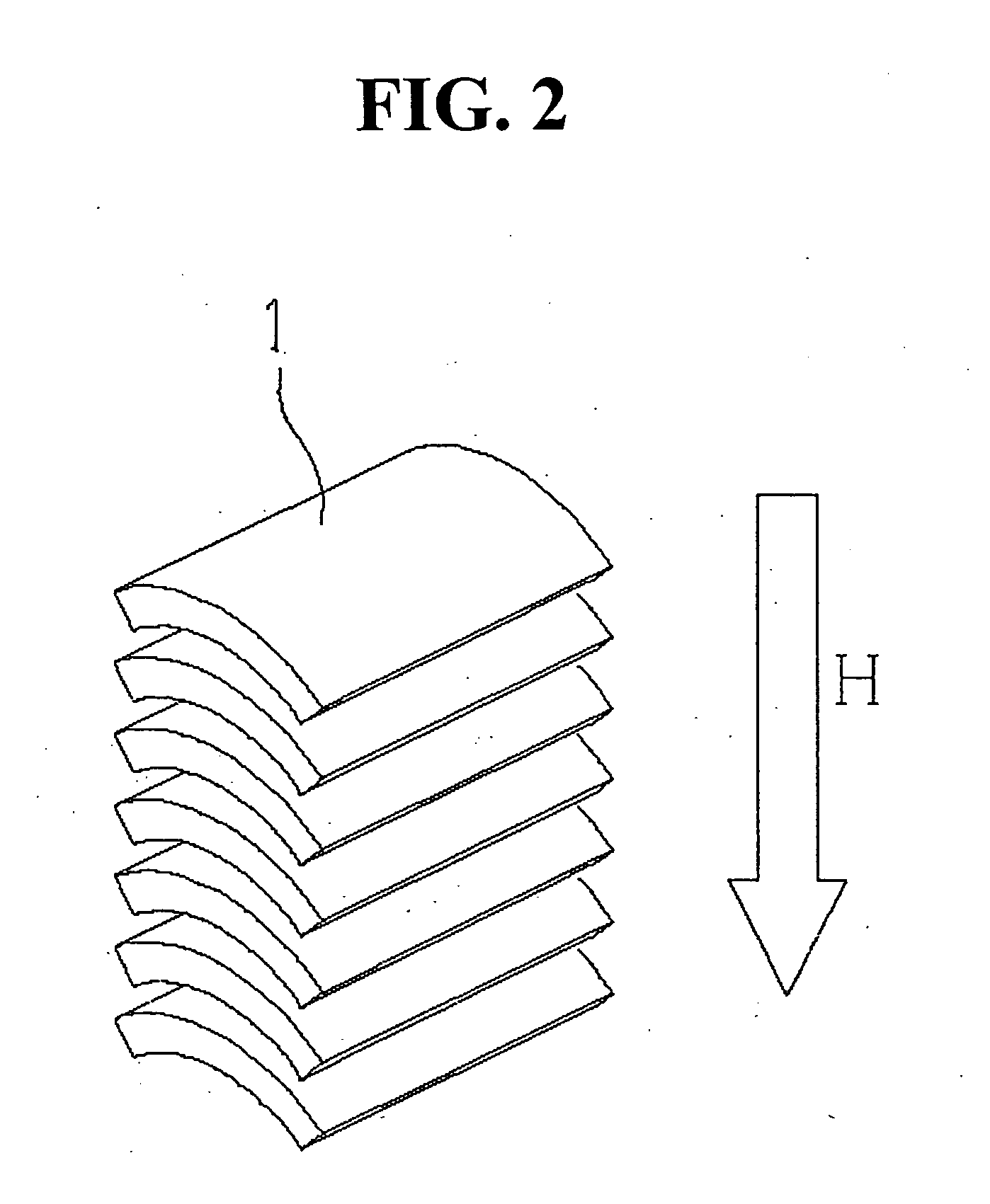

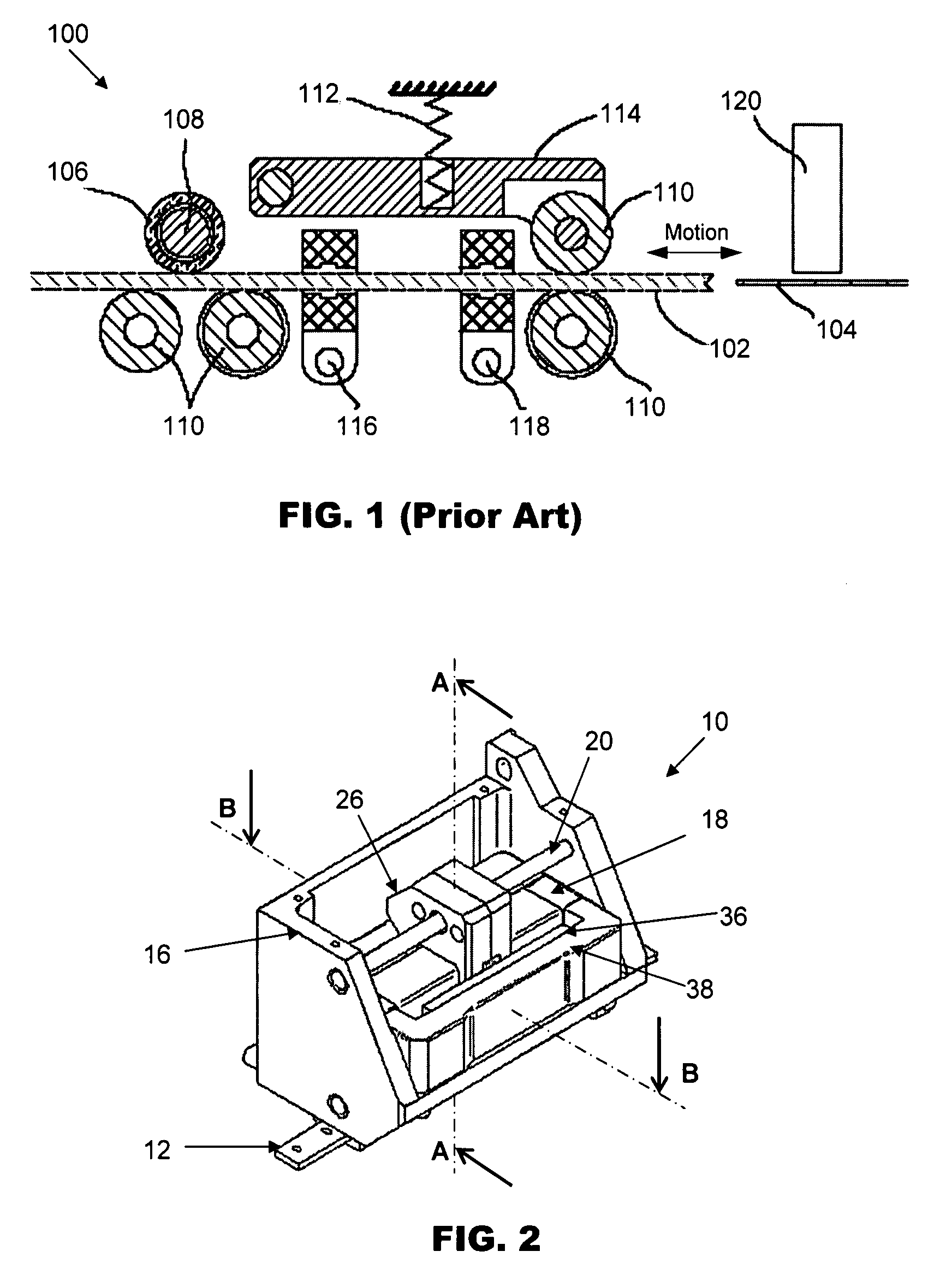

Electro-Magnetic Force Driving Actuator and Circuit Breaker Using the Same

InactiveUS20070273461A1Maximizing actuating speedMaximizing forceCircuit-breaking switches for excess currentsProtective switchesActuatorNon magnetic

Disclosed are an electro-magnetic force driving actuator and a circuit breaker comprising the actuator. The actuator comprises a hollow inner case made of magnetic material; an outer case made of magnetic material and being concentric with the inner case and radially mounted at an interval outwardly from the inner case; inner and outer permanent magnets abutting on an outer surface of the inner case and an inner surface of the outer case, respectively and positioned to maintain a predetermined gap between the magnets; a coil mounted to be linearly movable in an axial direction between the inner and outer permanent magnets; and a non-magnetic movable member having an end to which the coil is provided and linearly moving in the axial direction between the inner and outer permanent magnets with electromagnetic repulsive forces occurring due to magnetic fields by the inner and outer permanent magnets and a current density of the coil when current is supplied to the coil. The circuit breaker comprises the actuator and an insulation-actuating rod connected to another end of the movable member and linearly moving by the movable member to perform closing and opening operations.

Owner:EMATECH INC KOREA ELECTRICAL ENG & SCI RES INST

Lens drive device

Owner:SANKYO SEIKI MFG CO LTD

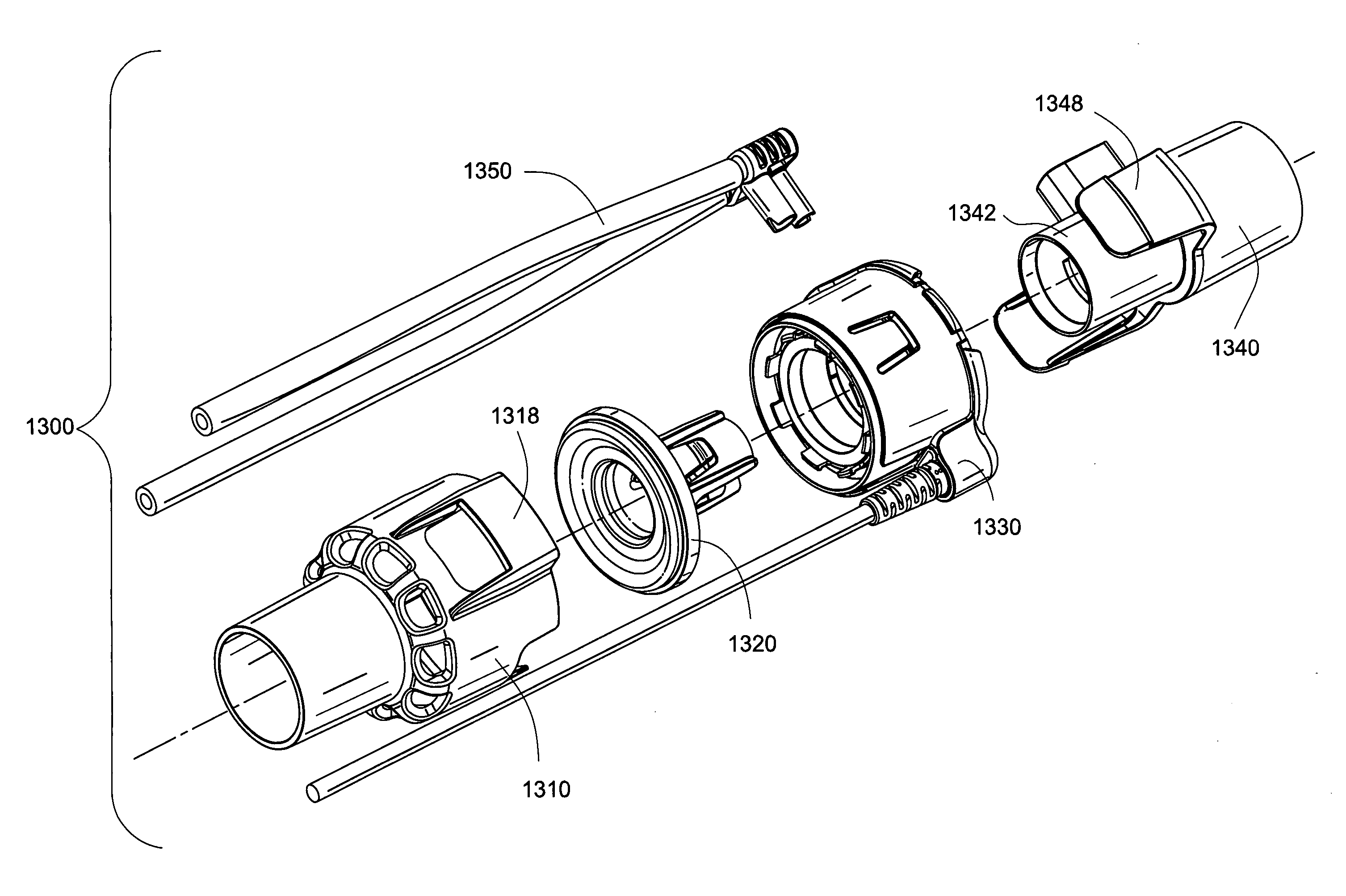

Breathing assistance device with linear actuated gas regulating valve

ActiveUS20120085348A1Operating means/releasing devices for valvesRespiratory masksLinear actuatorControl theory

A breathing assistance device includes a gas regulating valve (1300). The gas regulating valve is operated by a linear actuator (1330). The linear actuator may include a movable member that moves an obstruction member between an open position and a closed position. The linear actuator is isolated from a gas flow path through the valve.

Owner:RESMED LTD

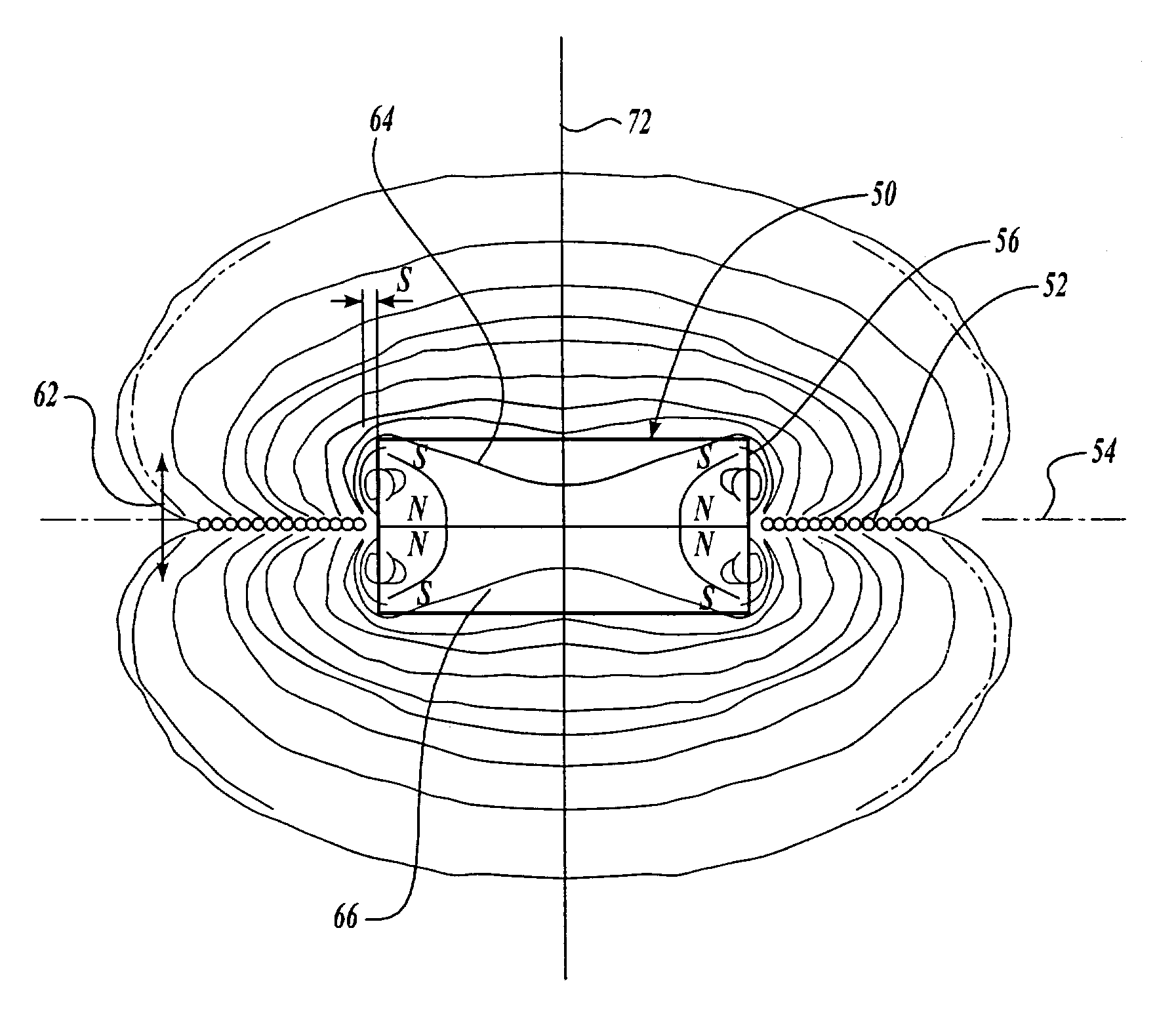

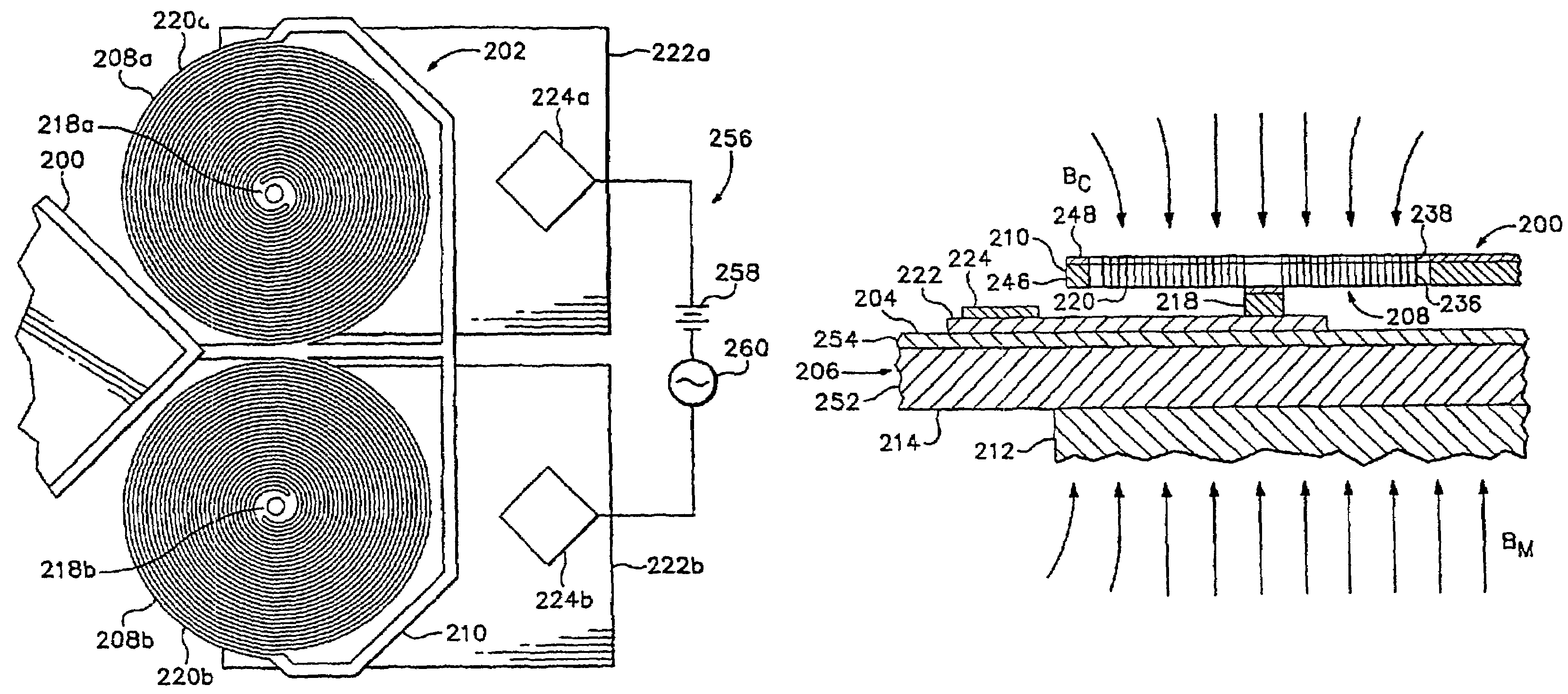

High intensity radial field magnetic actuator

InactiveUS7352268B2Electromagnets without armaturesPermanent magnetsMagnetic tension forceMagnetization

At least one set of two magnets is provided, at least one of the magnets having an outer magnet portion, a middle magnet portion, and an inner magnet portion. The outer magnet portion has a magnetization pointing in an at least partially axial direction. The middle magnet portion has a magnetization substantially perpendicular to the magnetization of the outer magnet portion. The inner magnet portion has a magnetization directed substantially anti-parallel to the magnetization of the outer magnet portion. The apparatus also includes at least one electrically conductive coil positioned at least partially between the set of two magnets. At least one substantially magnetically permeable object is positioned at least partially between the set of two magnets. A rod is integral with the substantially magnetically permeable object.

Owner:ENG MATTERS

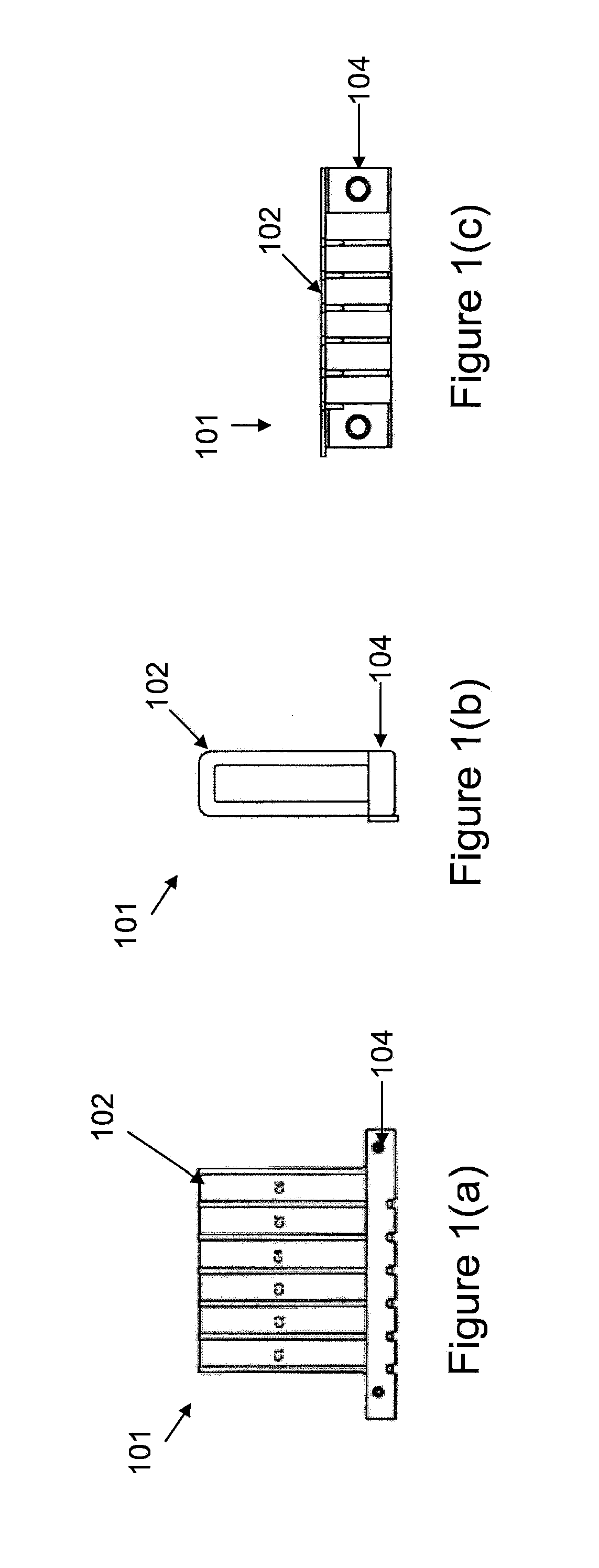

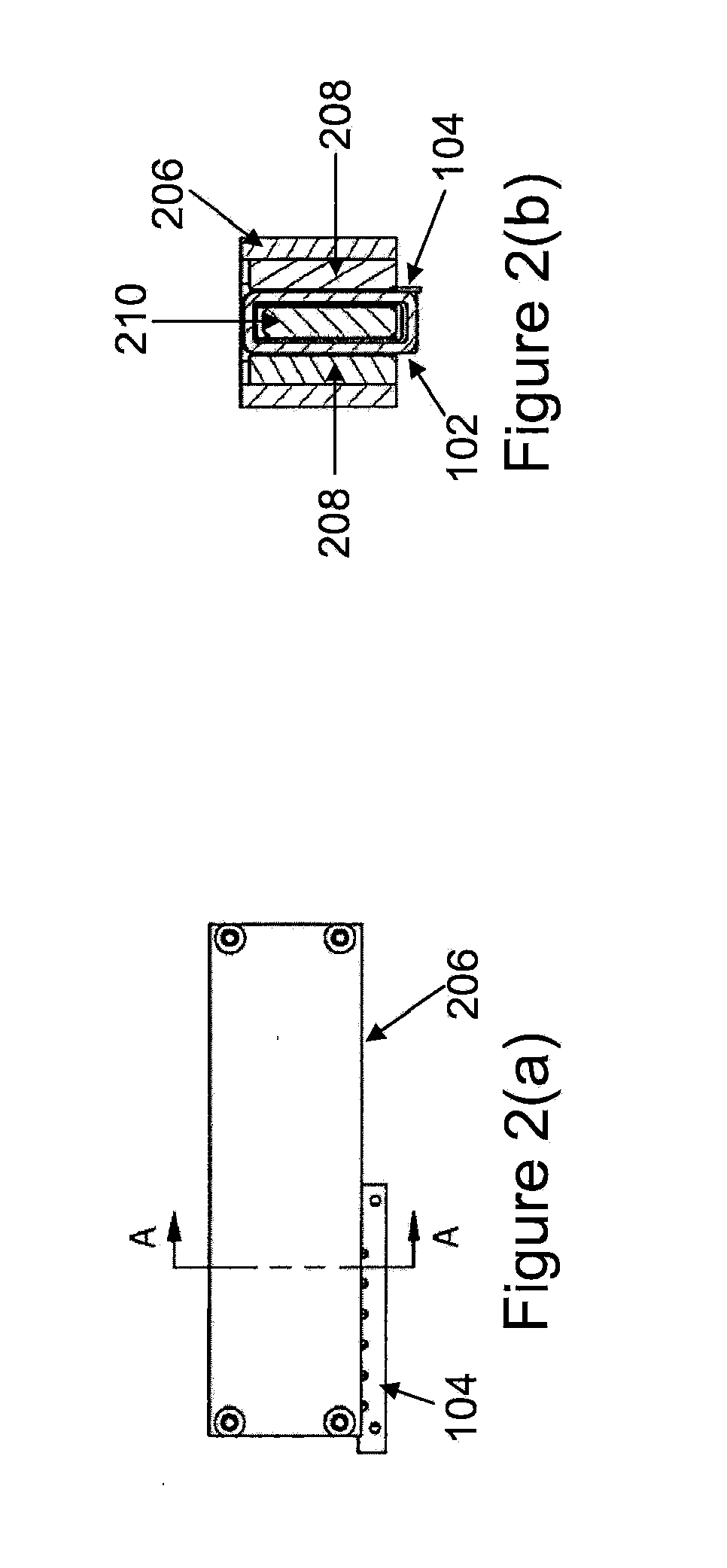

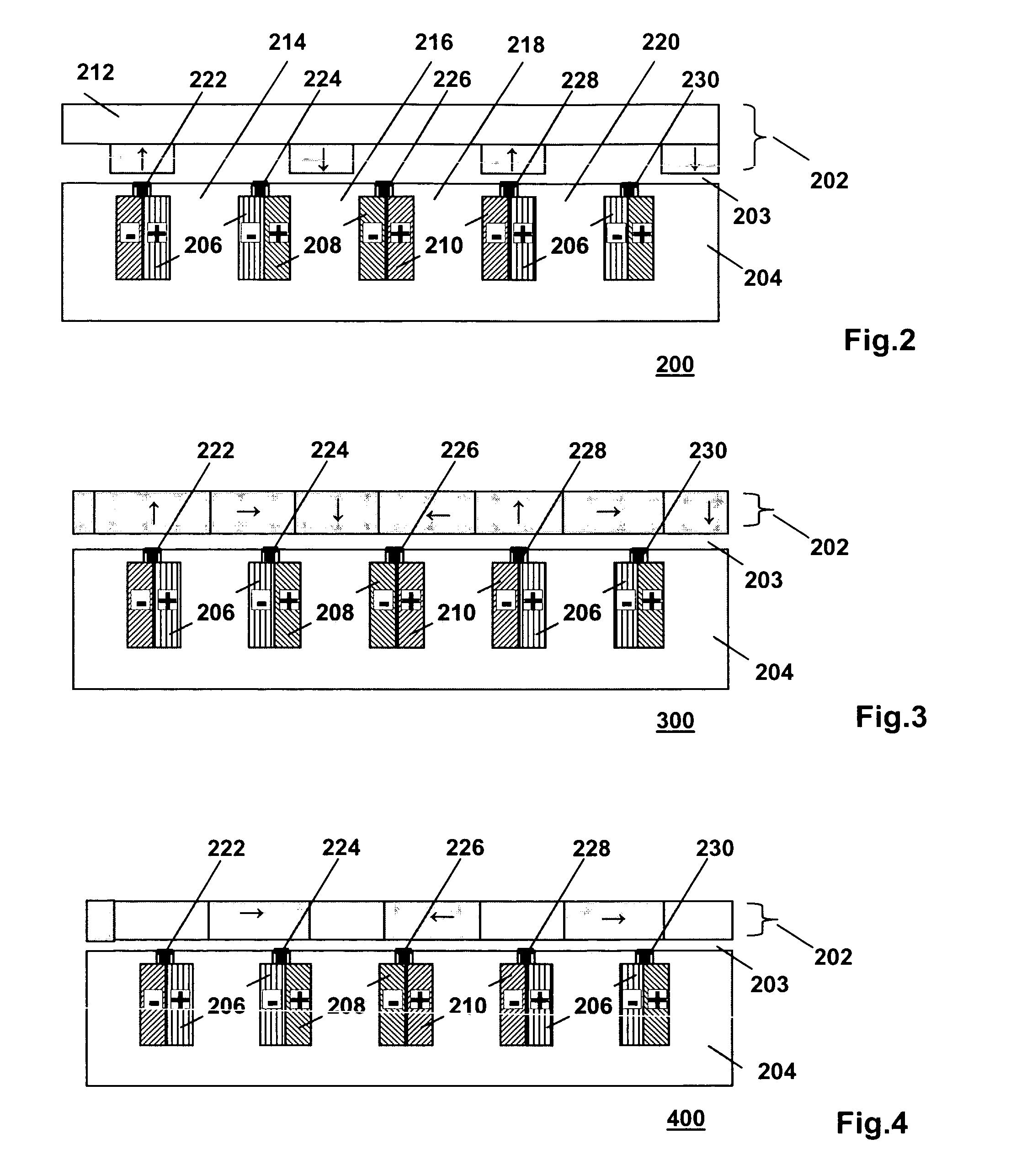

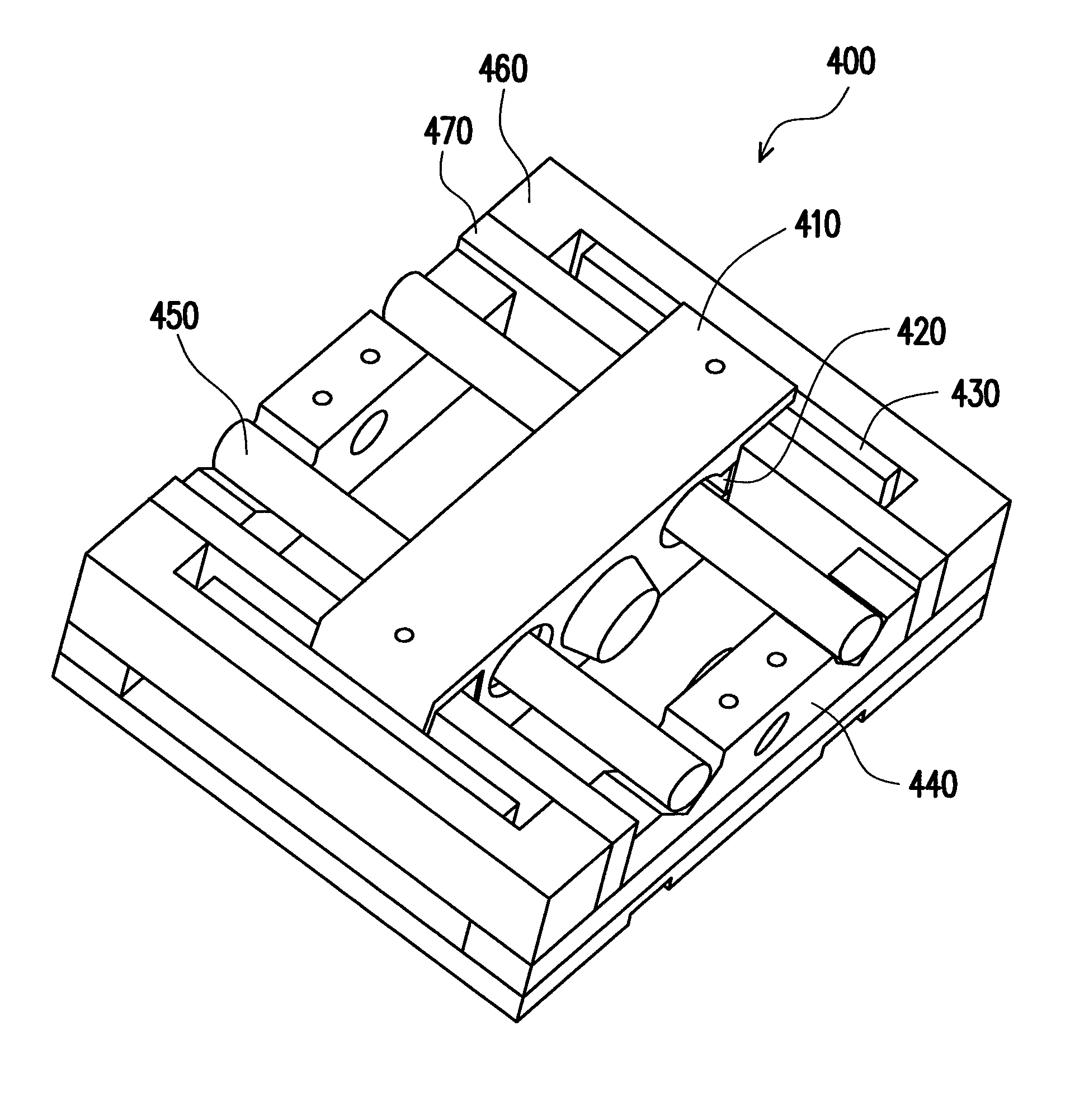

Low cost multi-coil linear actuator

ActiveUS20120080960A1Easy to appreciatePropulsion systemsMovable winding electromagnetsMulti coilLinear actuator

Disclosed herein are methods and systems for low cost linear actuators that can deliver strokes and forces at different values. The embodiments presented herein have parts and components that may be usable for both multi-coil and single-coil actuator designs. According to one embodiment, a magnet housing may removably or permanently coupled to a coil assembly having any number of coils. According to a further embodiment, an actuator housing may be coupled to a magnet housing having any number of magnets or coils.

Owner:SYST MASCH AUTOMATION COMPONENTS CORP

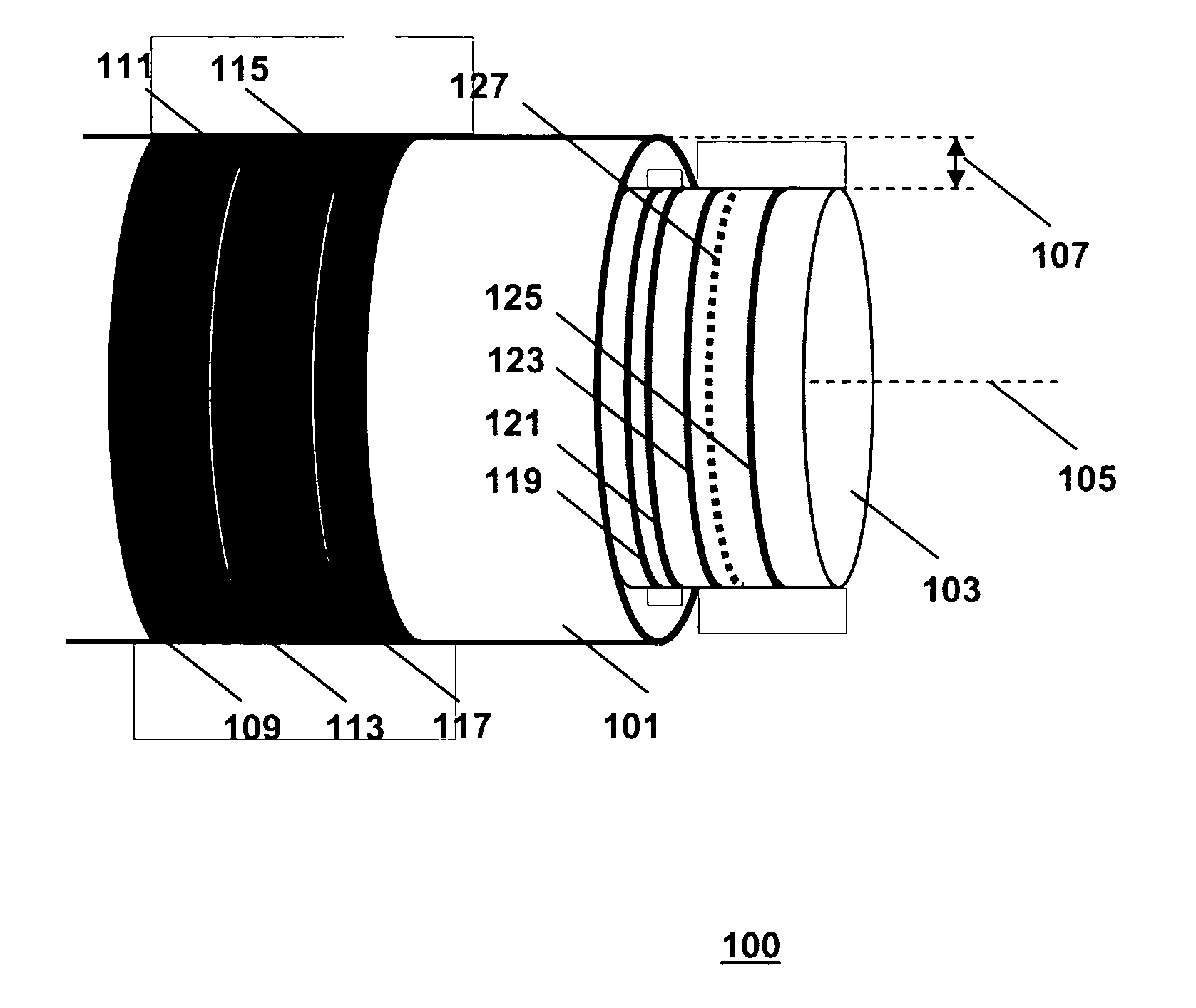

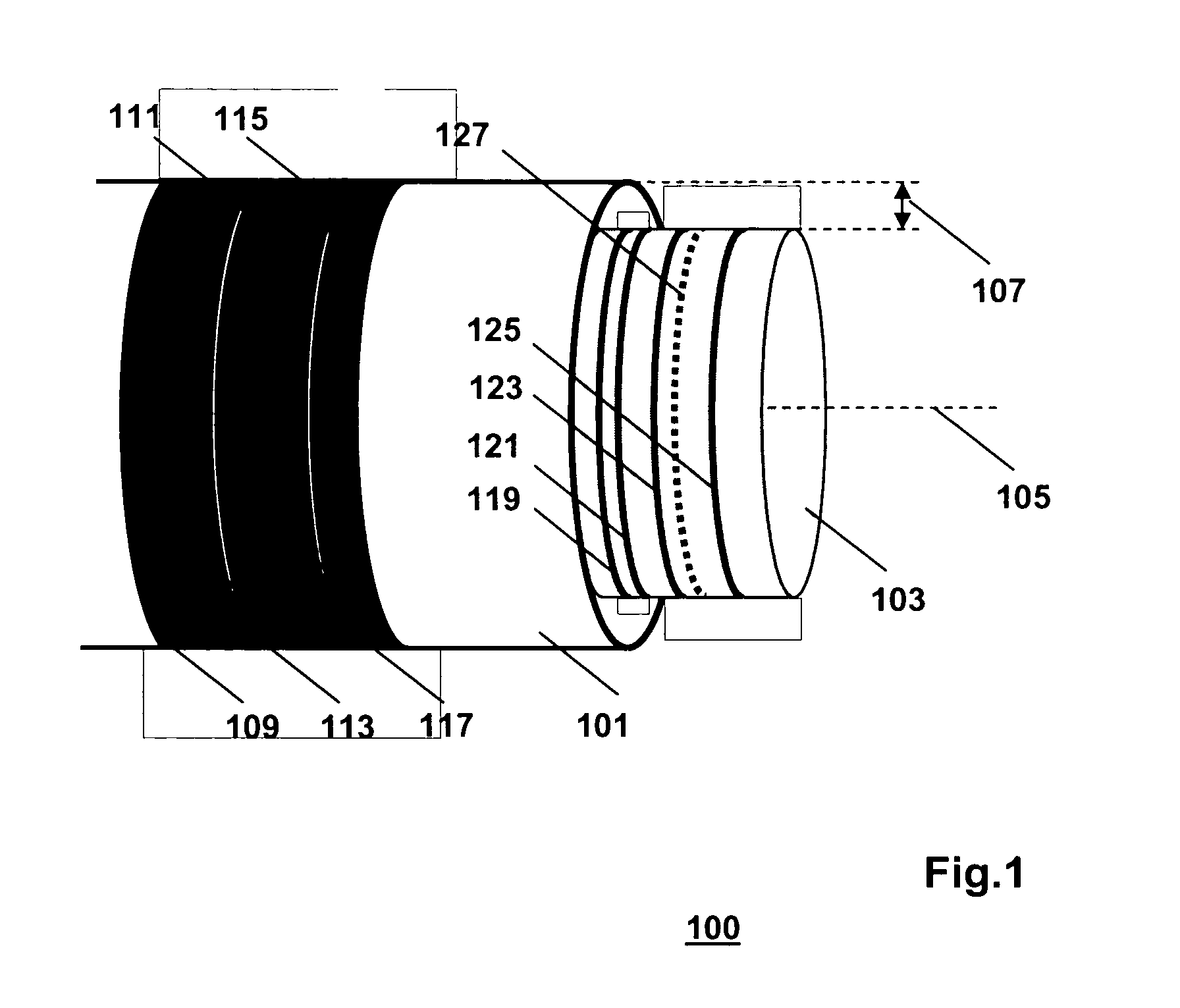

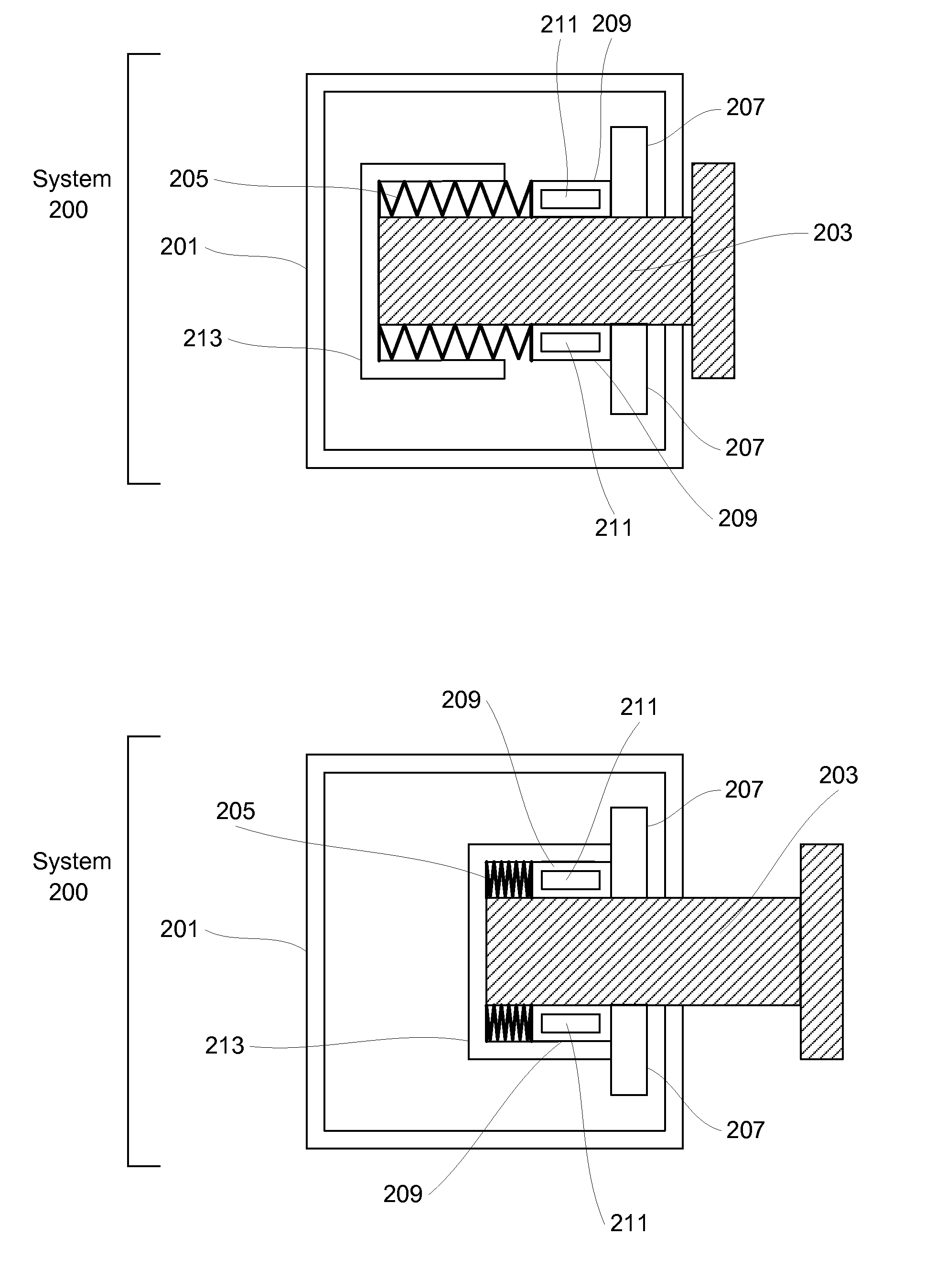

Electromagnetic actuator with integrated passive damper

ActiveUS20120193179A1Designing can be facilitatedImprove conductivitySynchronous machine detailsNon-rotating vibration suppressionElectrical conductorPower flow

An electromagnetic actuator (100) comprises magnets (109, 111, 113, 115, 11), and a ferromagnetic structure (103) accommodating control conductors (118, 121, 123, 125). The magnets and the structure can move with respect to one another under control of control currents in the control conductors. The magnetic field in a gap (107) between the magnets and the ferromagnetic structure is oriented perpendicular to the direction of relative movement. The structure (103) accommodates damping conductors (127) that form closed loops of an electrically conductive material, different from the ferromagnetic material. The damping conductors (127) provide a damping force induced by the relative movement.

Owner:TECH UNIV EINDHOVEN

Speaker assembly

An electromagnetic transducer is described including a magnet assembly (50) and a conductive drive coil (52). The magnet assembly provides an emanating magnetic field within which the drive coil is located. The drive coil is a flat ring coil having a width that is equal to or greater than its height. As assembled, the drive coil is mounted in close proximity to the magnet assembly such that relative axial motion may occur between them during use. In one embodiment, the magnet assembly includes two permanent disc magnets (64), (66) having axial magnetizations and being oriented with like poles facing one another to produce a radially emanating magnetic field. In another embodiment, the magnet assembly includes a pair of axially magnetized permanent ring magnets (64), (66) also oriented with like poles facing one another.

Owner:TRANDAFIR ROLAND PIERRE

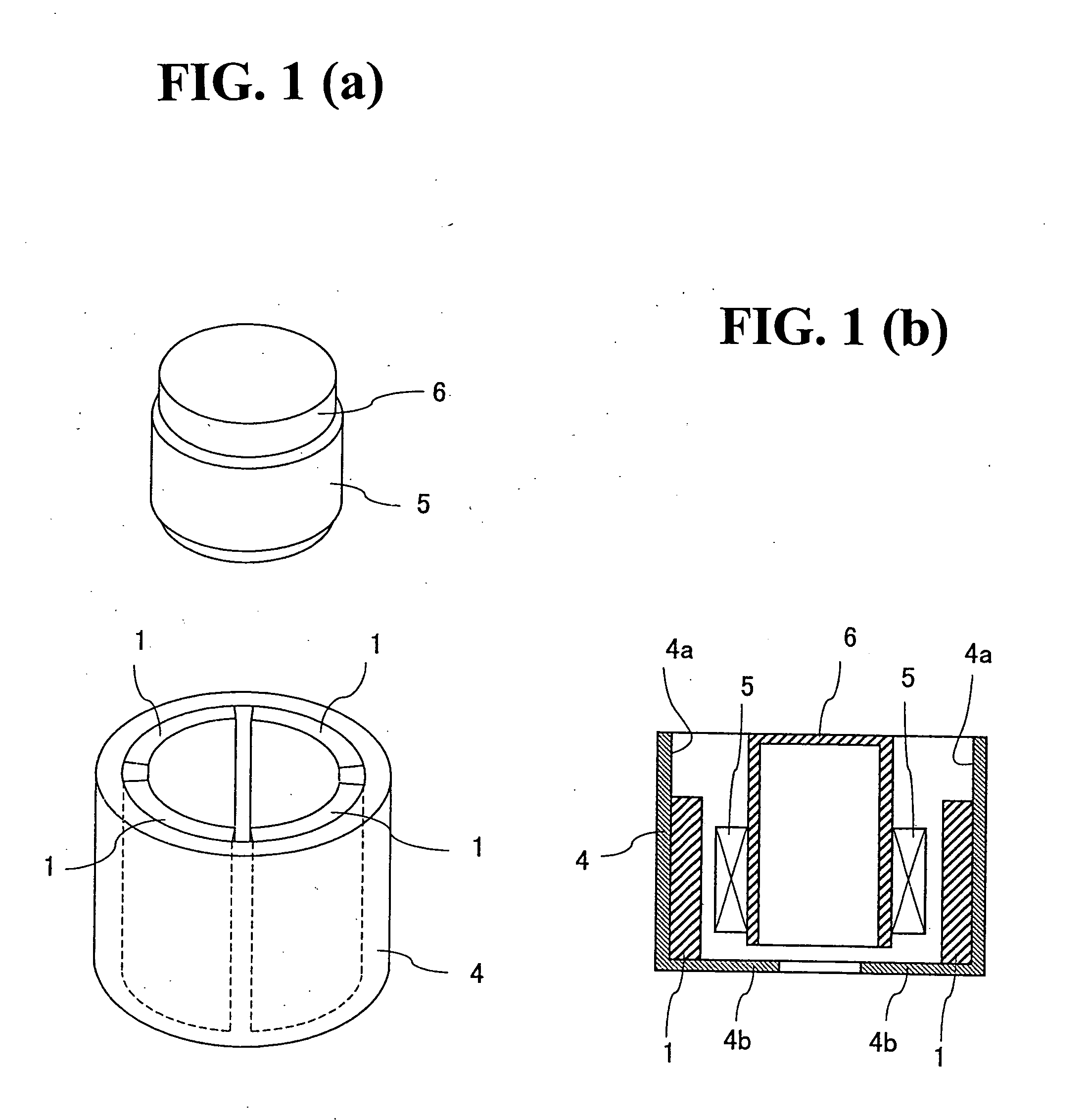

Magnetic circuit and method and apparatus for the manufacture thereof

ActiveUS20080061635A1Low costEliminate difficultiesTransducer detailsWave amplification devicesActuatorLoudspeaker

A magnetic circuit includes a cylindrical yoke member having an inner circumferential surface and a collar formed at one end thereof and turned back substantially at right angles, and a plurality of permanent magnet segments of a partially circular arc in cross section having respective outer surfaces attracted magnetically to the inner circumferential surface of the cylindrical yoke member and respective one end faces attracted magnetically to the collar of the cylindrical yoke member. The magnetic circuit is manufactured by a method including the steps of magnetically attracting the permanent magnet segments to an outer peripheral surface of a center rod, causing the magnet segments in a magnetically attracted state to face the yoke member, using a nonmagnetic supporter to regulate the magnet segments in position, extracting the center rod from the magnet segments in a position-regulated state, and magnetically attracting and fixing the magnet segments to the yoke member. The magnetic circuit is applied to an actuator or a speaker.

Owner:TDK CORPARATION

Linear actuator comprising velocity sensor

ActiveUS7327054B2Effective and cost-efficientAvoid disadvantagesDC motor speed/torque controlGain controlMotion systemLinear actuator

A linear actuator for a motion system is provided with a velocity sensor for monitoring a velocity of an actuation arm that it is driving. The linear actuator comprises a magnetic field, a first coil that is controllably movable within the magnetic field by adjusting a current flowing through the first coil whereby to drive the actuation arm and a second coil that is movable with the first coil and configured such that a voltage is inducible in the second coil that is proportional to its velocity. A controller device is connected to the second coil for receiving feedback indicating the voltage induced in the second coil whereby a velocity of the actuation arm is determinable, wherein the controller device is further connected to the first coil and is operative to adjust the current flowing in the first coil based upon said feedback for controllably driving the actuation arm.

Owner:ASM TECH SINGAPORE PTE LTD

Positioning system for an electromechanical actuator

Provided is a shaft positioning system for an electromechanical actuator. According to various examples, the positioning system includes a shaft coupled to an electromechanical actuator. The shaft moves along a linear axis and the electromechanical actuator is free to translate during normal operation. An electromagnetic coil positioned around at least a portion of the shaft. The electromagnetic coil produces a magnetic field when electrical current is applied. A metal housing surrounds at least a portion of the electromagnetic coil. The shaft is placed in a predetermined position when the metal housing is in contact with a first magnet and translational motion of the electromechanical actuator is restricted when the shaft is placed in the predetermined position.

Owner:THE BOEING CO

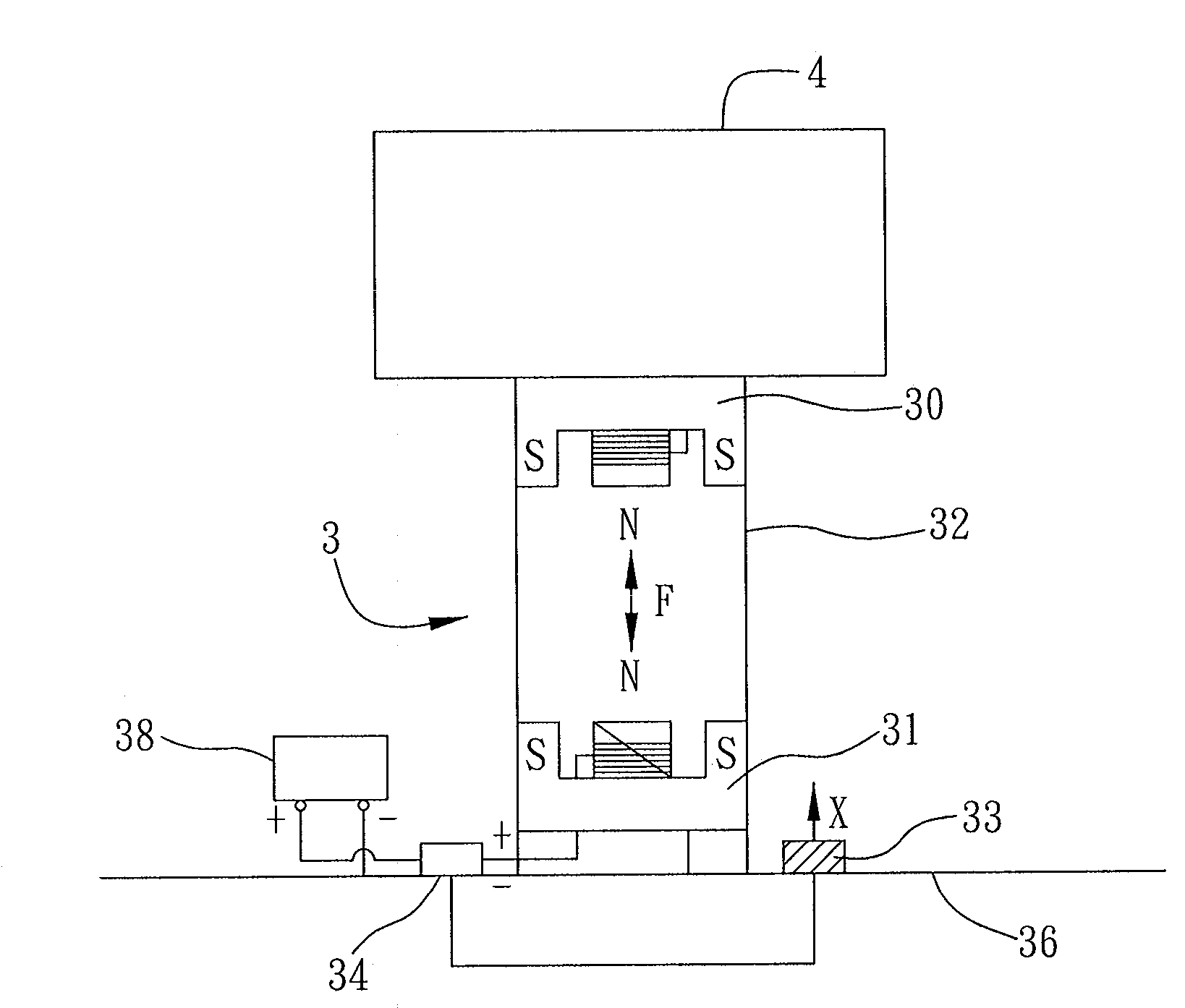

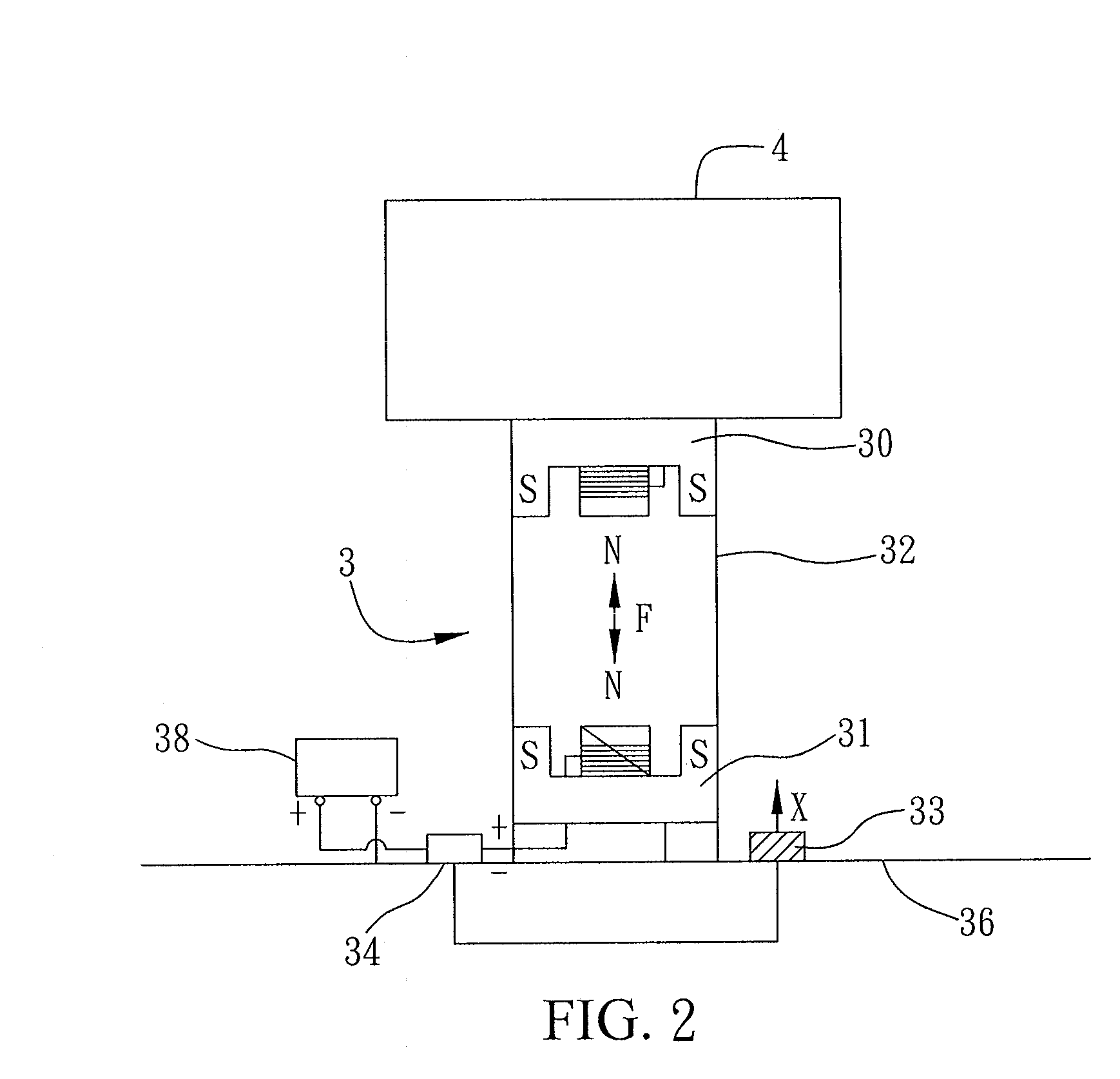

Vibration-proof holder applicable to communication/navigation devices for vehicle use

InactiveUS20090256665A1Simple structureLow costElectromagnets without armaturesInstruments for road network navigationMarine navigationControl unit

A vibration-proof holder applicable to a communications / navigation device for vehicle use is provided, characterized by the use of a gap-detecting unit to detect position variations of the communications / navigation device, and an electromagnetic control unit to adjust magnetic intensity of magnetic bodies fixedly installed in the vehicle, wherein first and second magnetic bodies are limited to remain in the same track and to face one another with the same magnetic polar end thereof, such that the communications / navigation device can return to its initial position to achieve the vibration-proof effect.

Owner:MITAC INT CORP

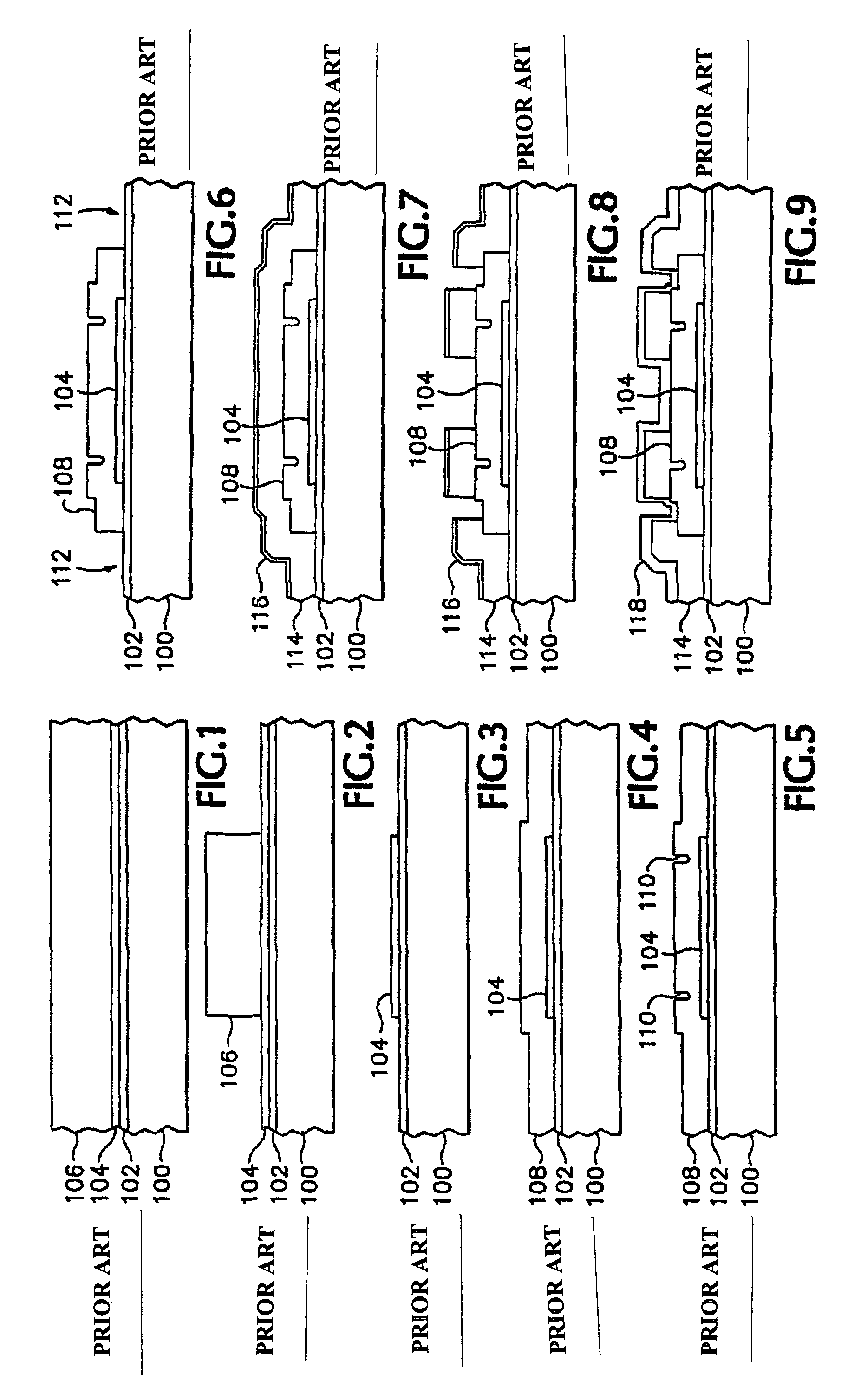

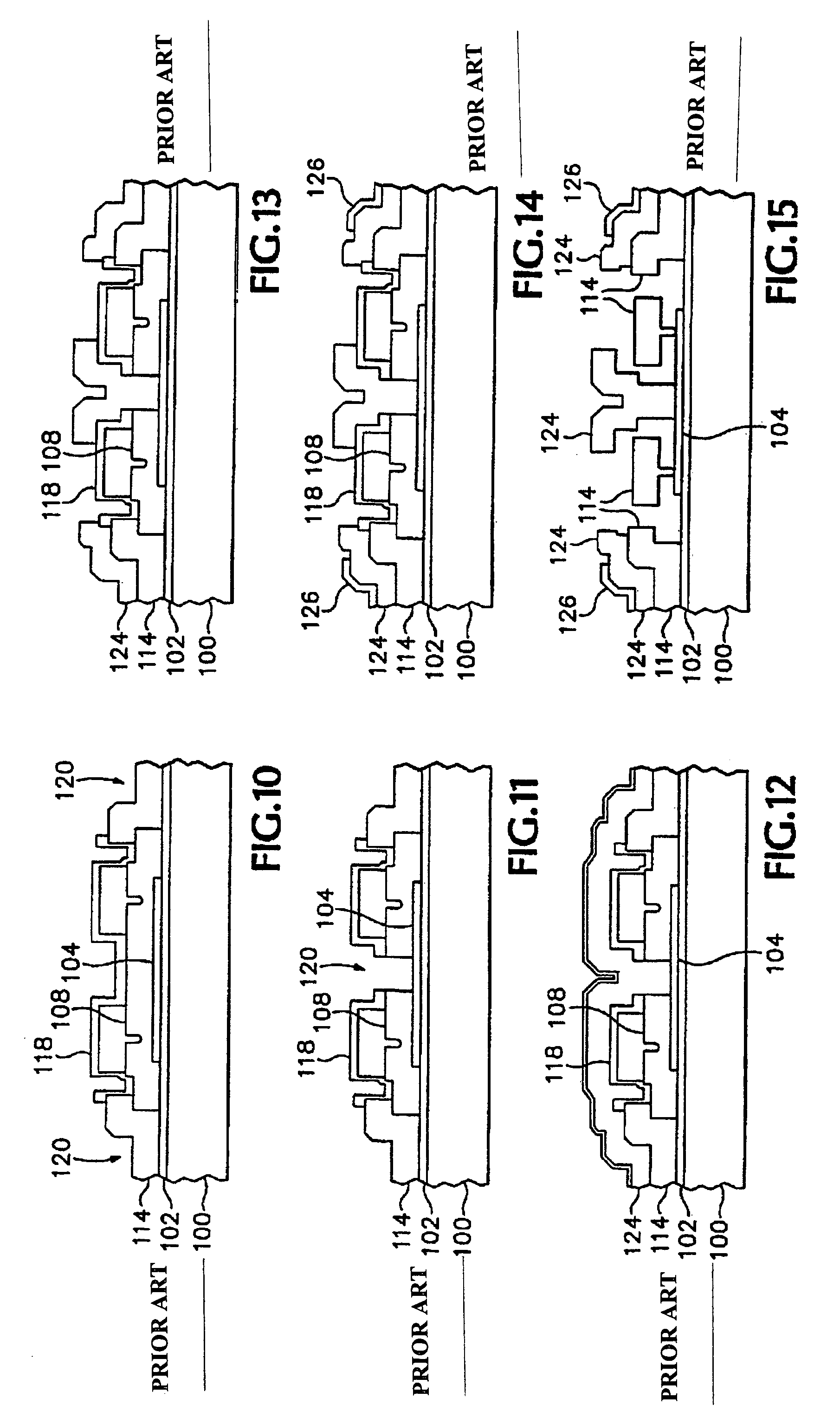

Magnetically actuated microelectrochemical systems actuator

InactiveUS7064879B1Prevent cross-talk and excessive and possibly damaging currentConvenient ArrangementPiezoelectric/electrostriction/magnetostriction machinesSnap-action arrangementsEngineeringActuator

Owner:MICROSOFT TECH LICENSING LLC

Magnetic Actor and a Method for its Installation

ActiveUS20110169346A1Quick installationEasy to installNon-rotating vibration suppressionManufacturing stator/rotor bodiesEngineeringMagnet

Owner:INTEGRATED DYNAMICS ENG

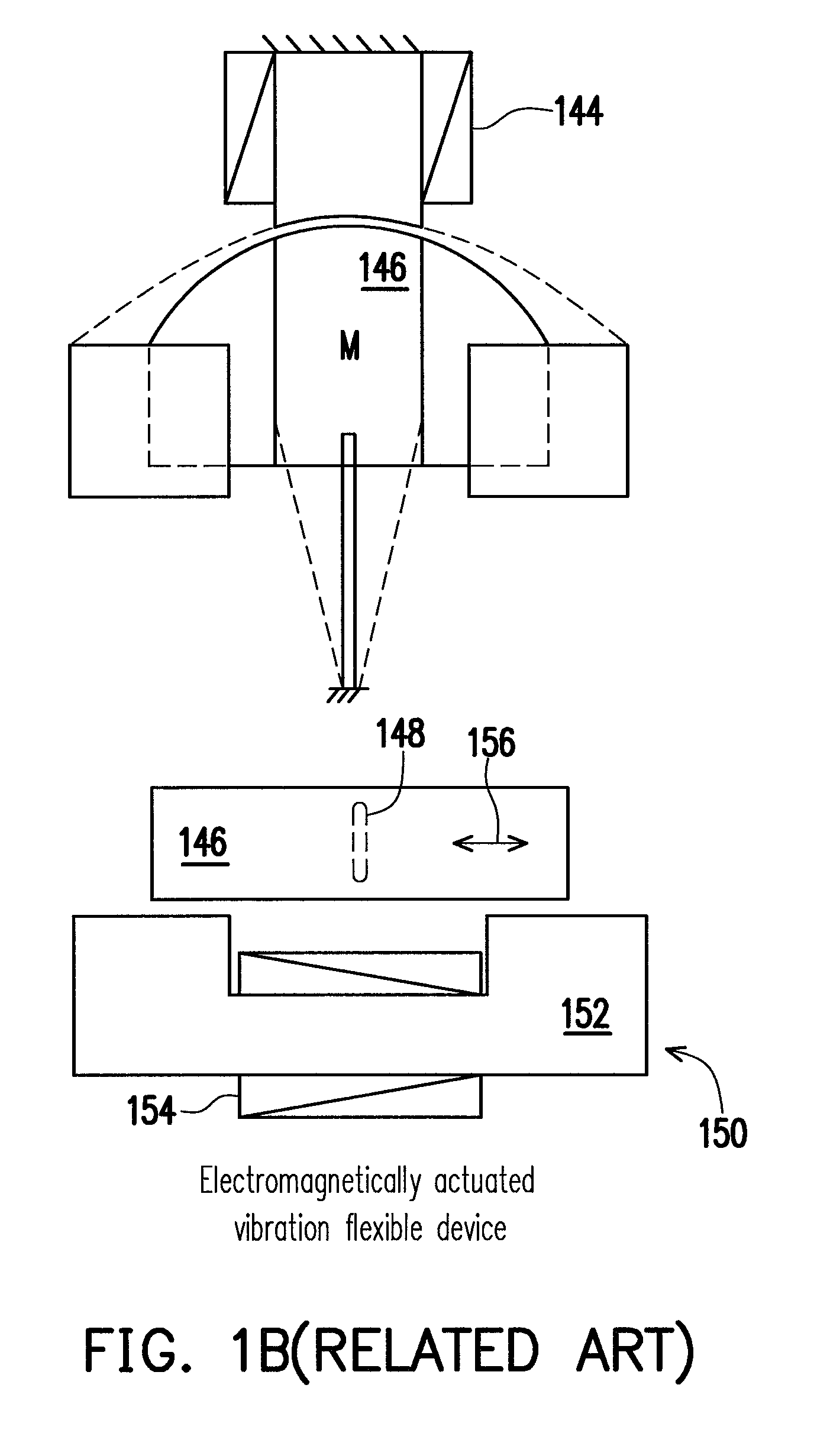

Impact force feedback device and interactive system using the same

Owner:IND TECH RES INST

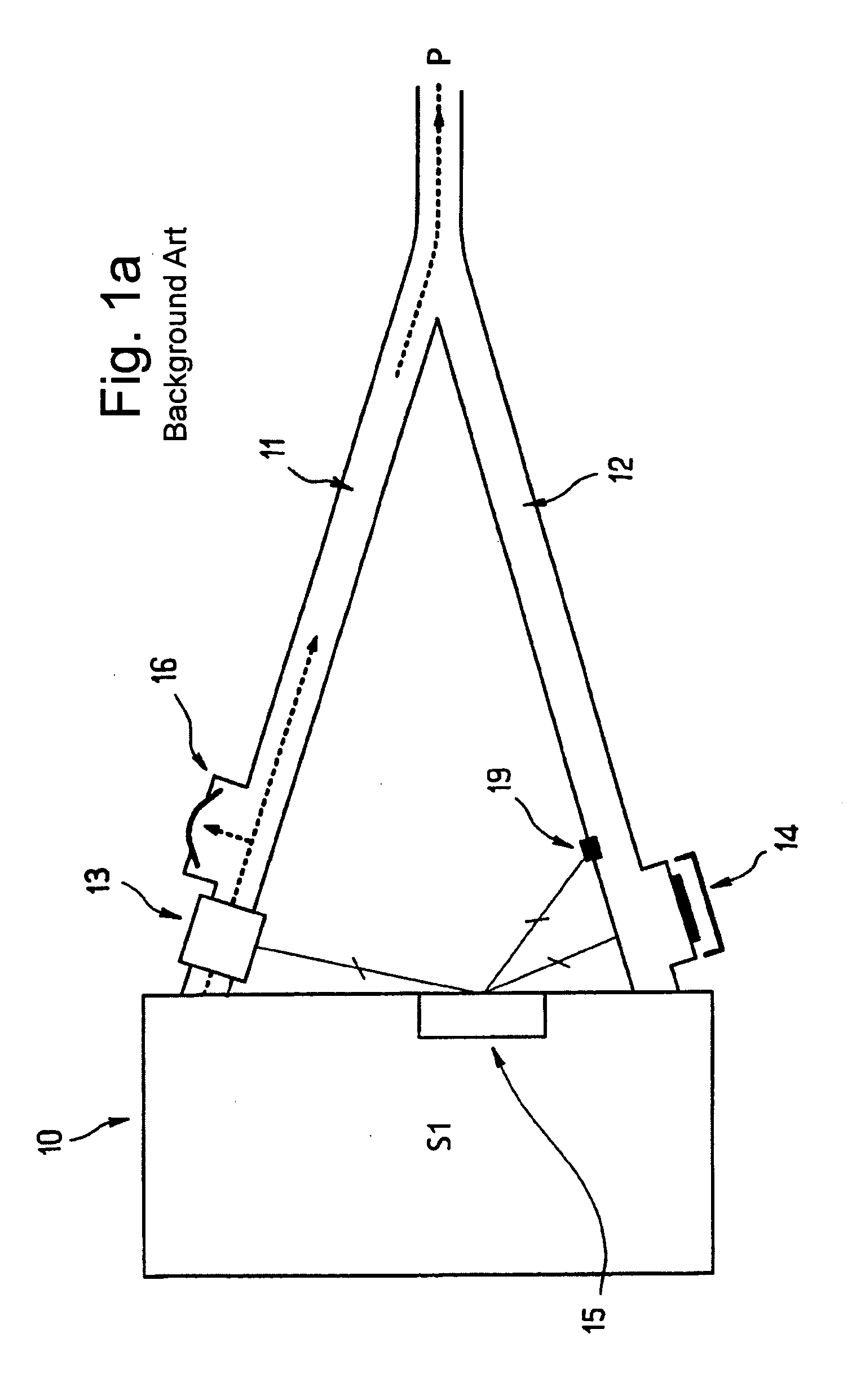

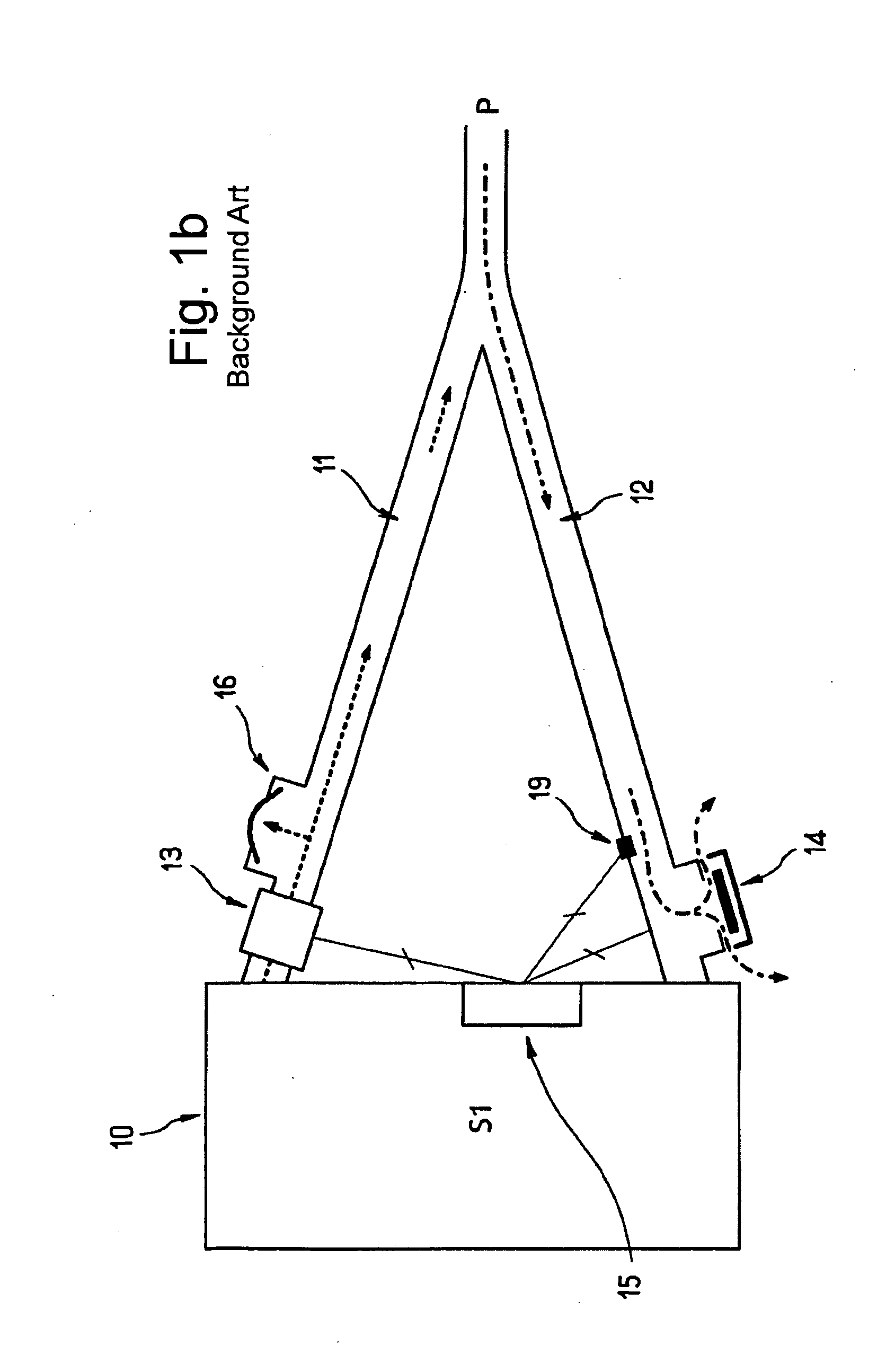

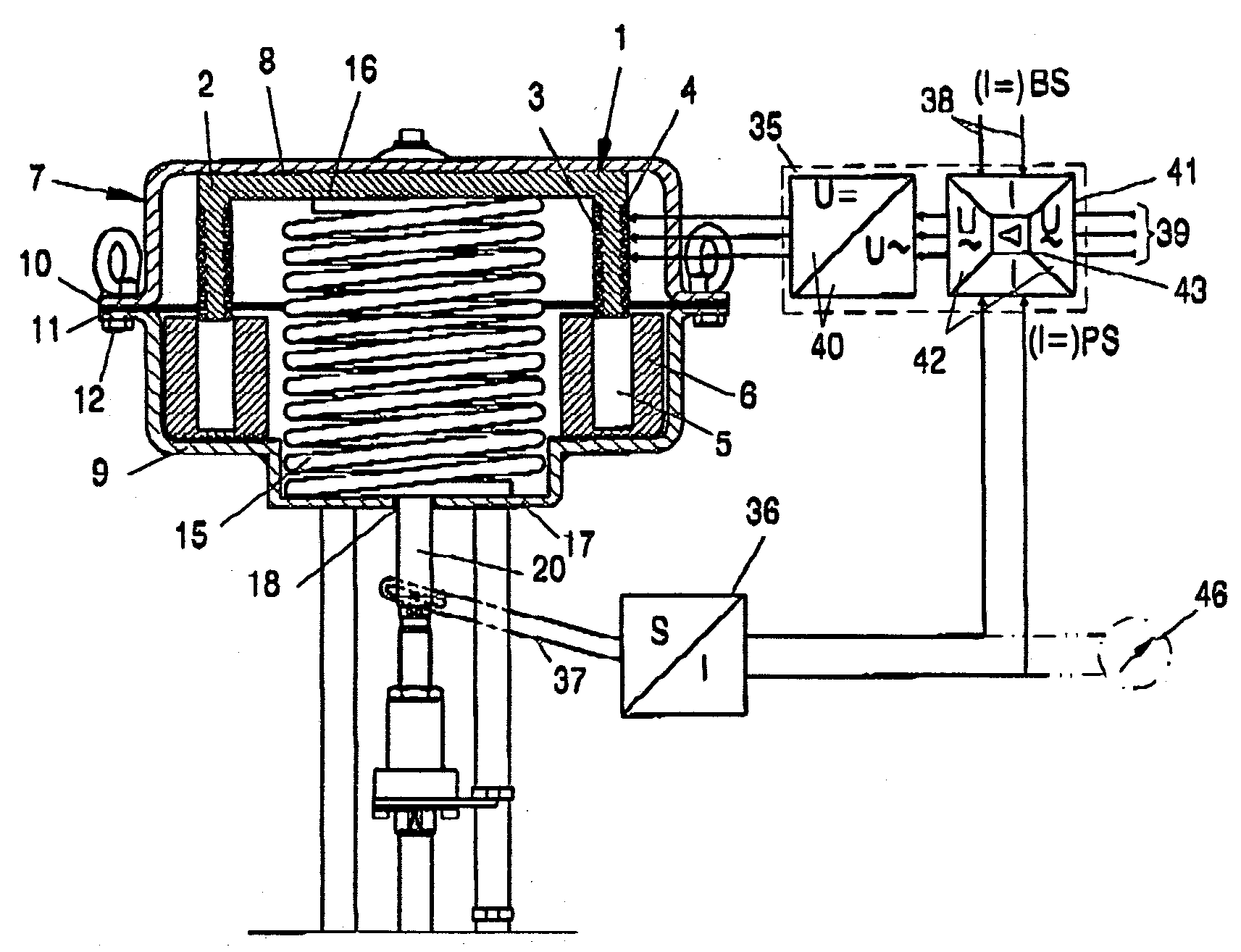

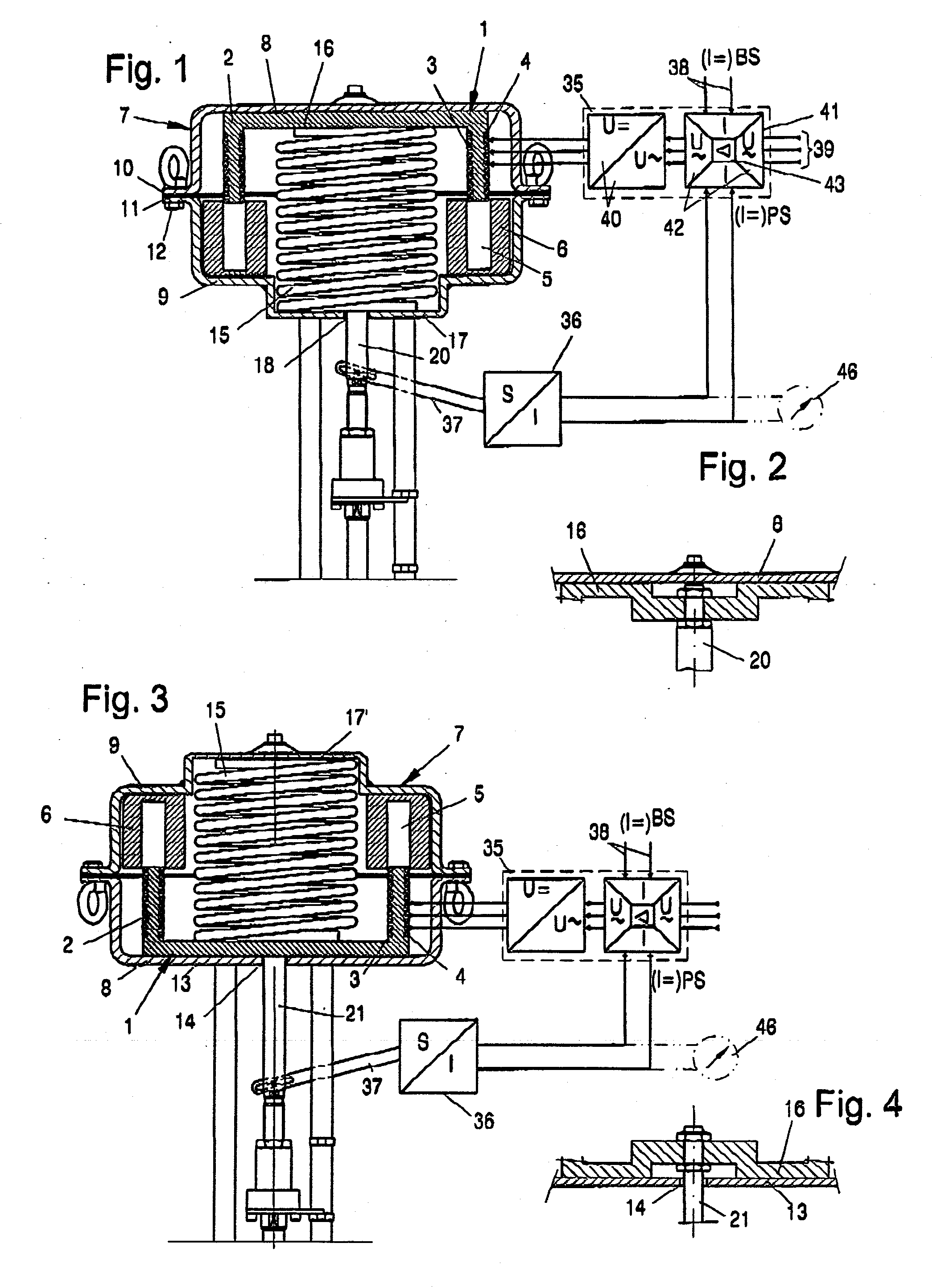

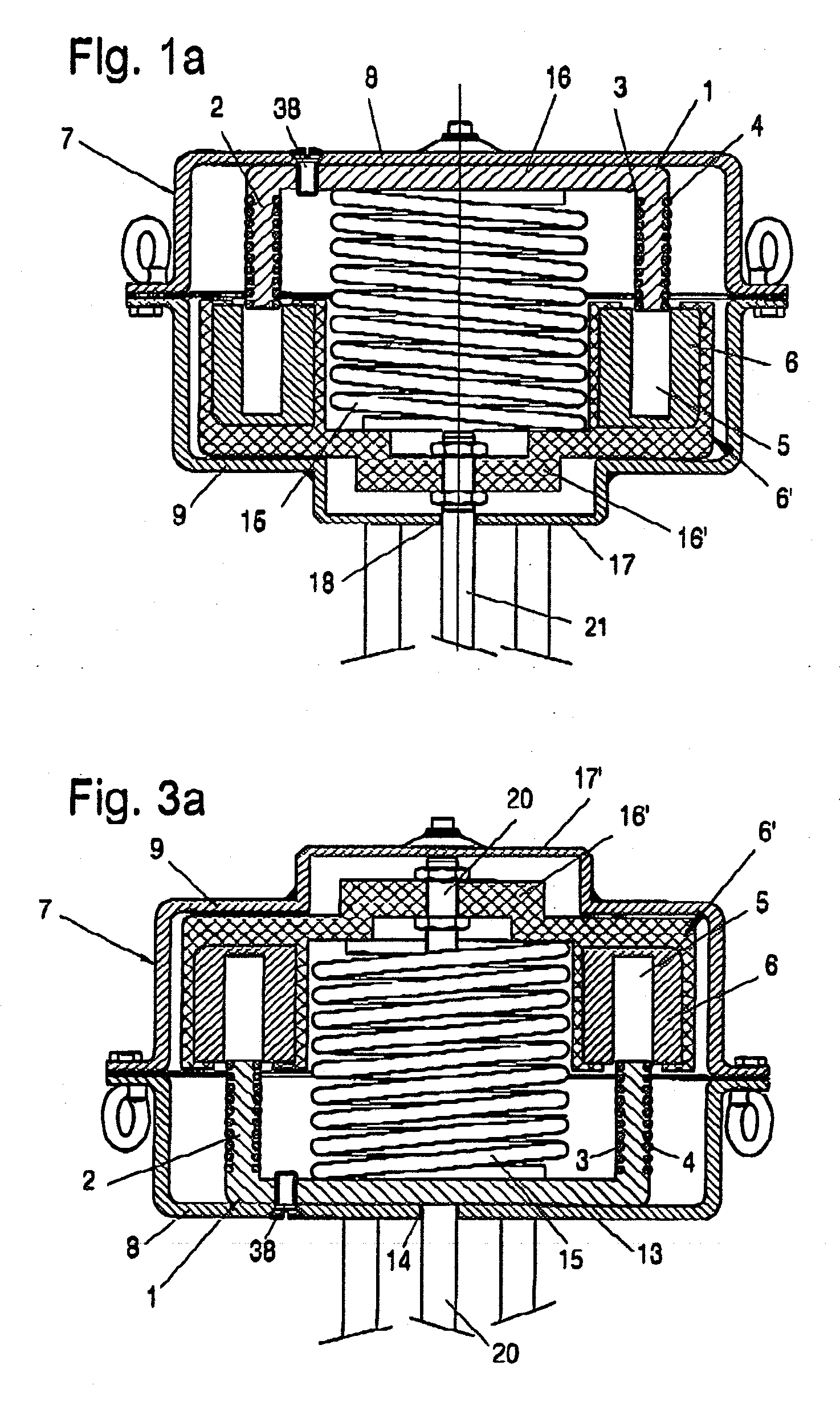

Actuator for control valves and/or shut-off devices

InactiveUS20080204175A1Easy to operateOperating means/releasing devices for valvesElectric switchesState of artActuator

The subject of the present invention is an actuator for control valves and / or shut-off devices with an actuating element acting on a closing or opening element, in which the actuating element comprises a push or pull rod (20, 21), which is in drive connection with the axially movable part of an electromagnetic drive unit designed as a moving coil from a magnet coil (3, 4) and a cylindrical solenoid plunger (1) and is moved into its inoperative position by a resetting spring (15) and is held in that position. To make it possible to use such an actuator instead of the prior-art electric motor, pneumatic or hydraulic drives, provisions are made for the respective actual positions of the actuating element (20, 21) to be detected by an electrical or electronic position controller (36) and transmitted to an electronic actuating amplifier (35), which sends an operating voltage, which is necessary for actuating the actuating element (20, 21) and can be varied between a minimum and a maximum, to the moving coil (3, 4) when a command signal (BS) is present, until the position controller (36) signals the position of the actuating element (20, 21) as feedback, which is preset with the command signal (BS).

Owner:BARABAS LAMMERT KURT

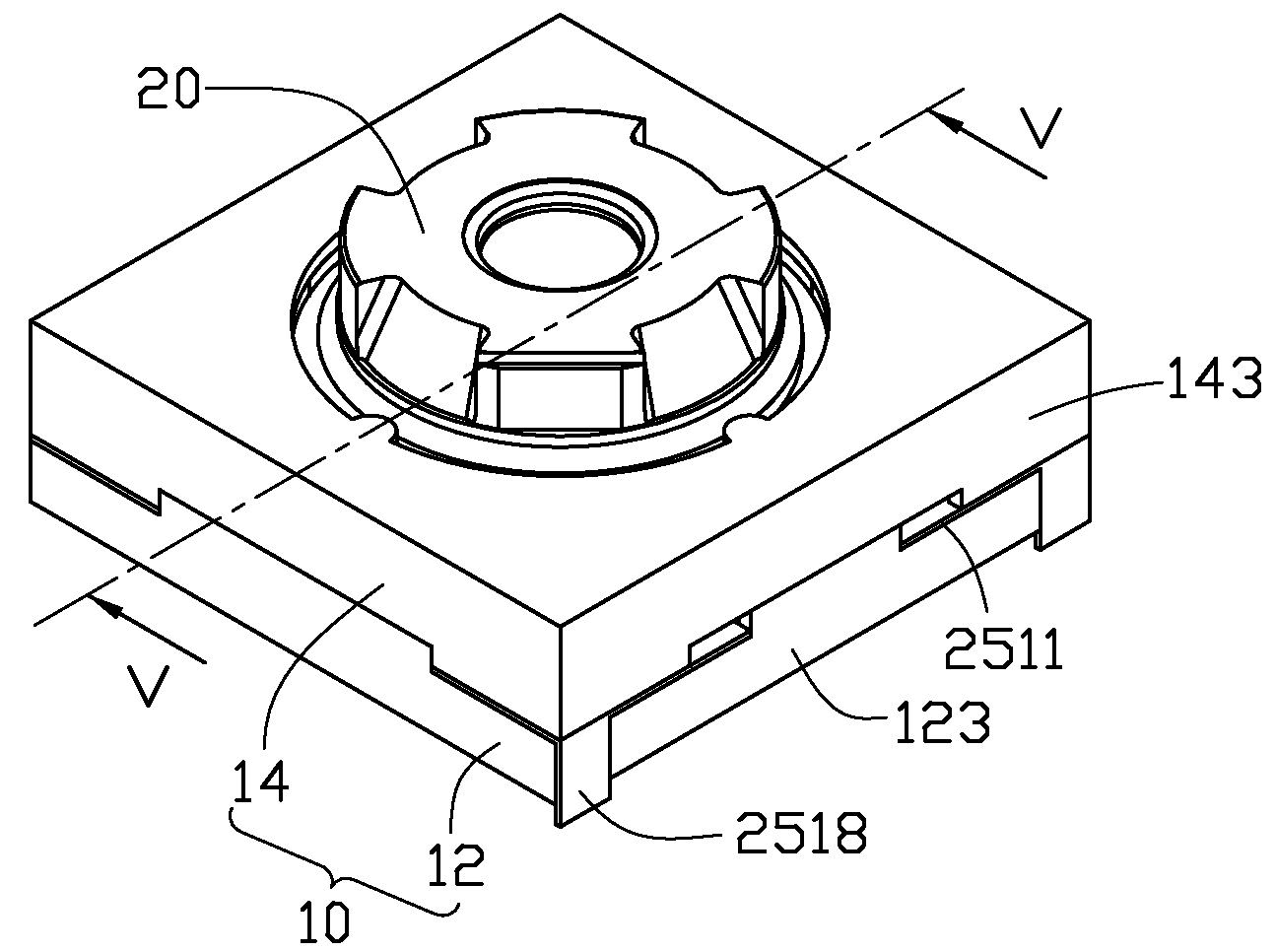

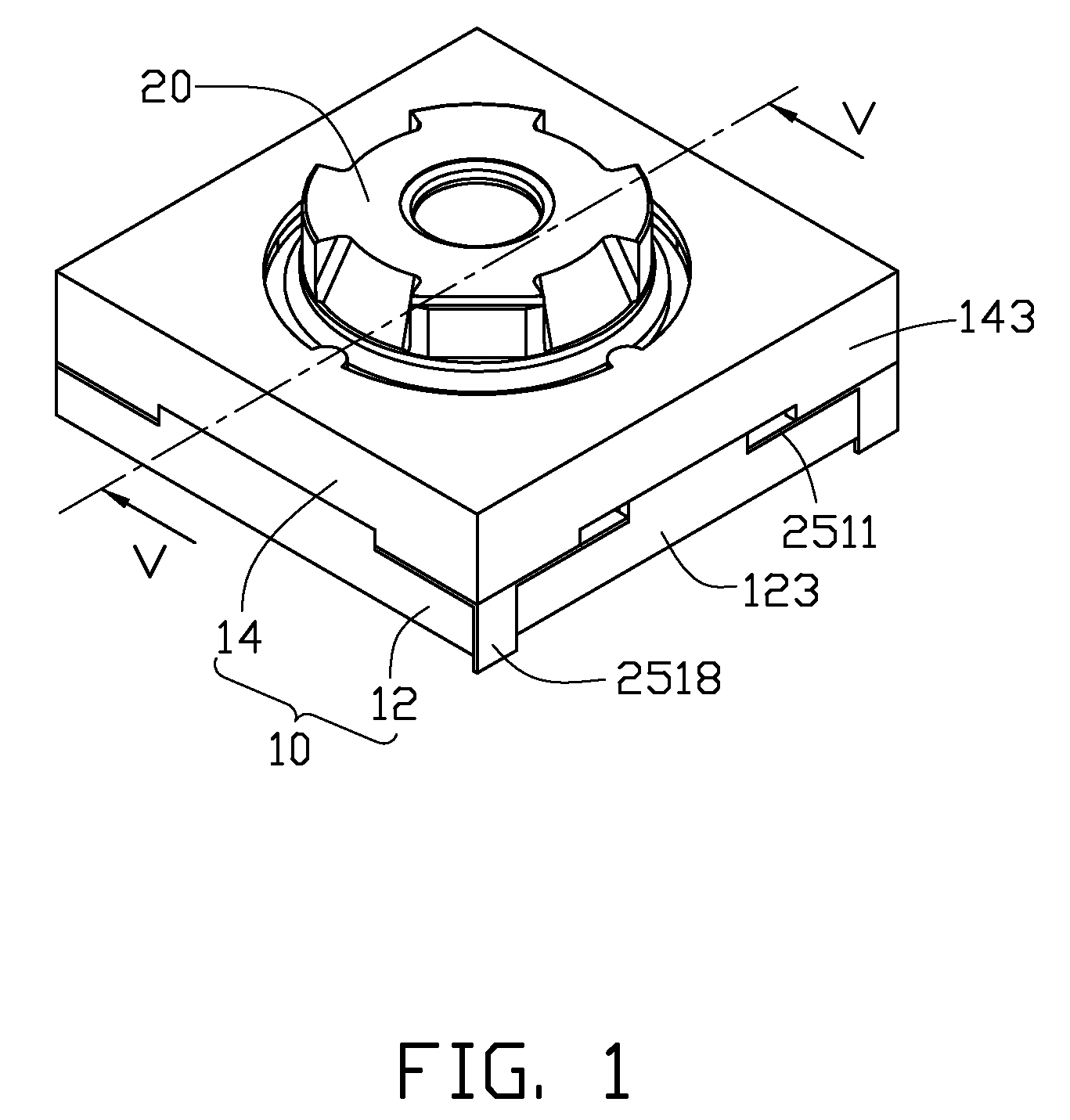

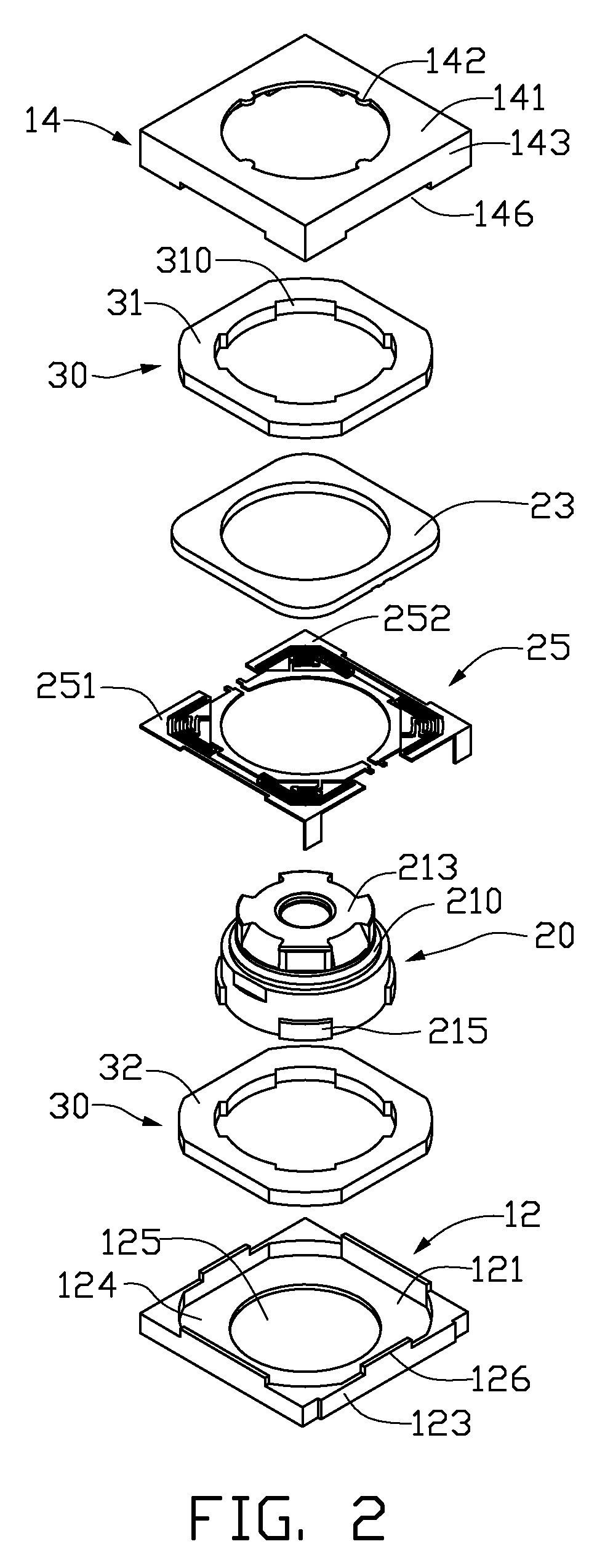

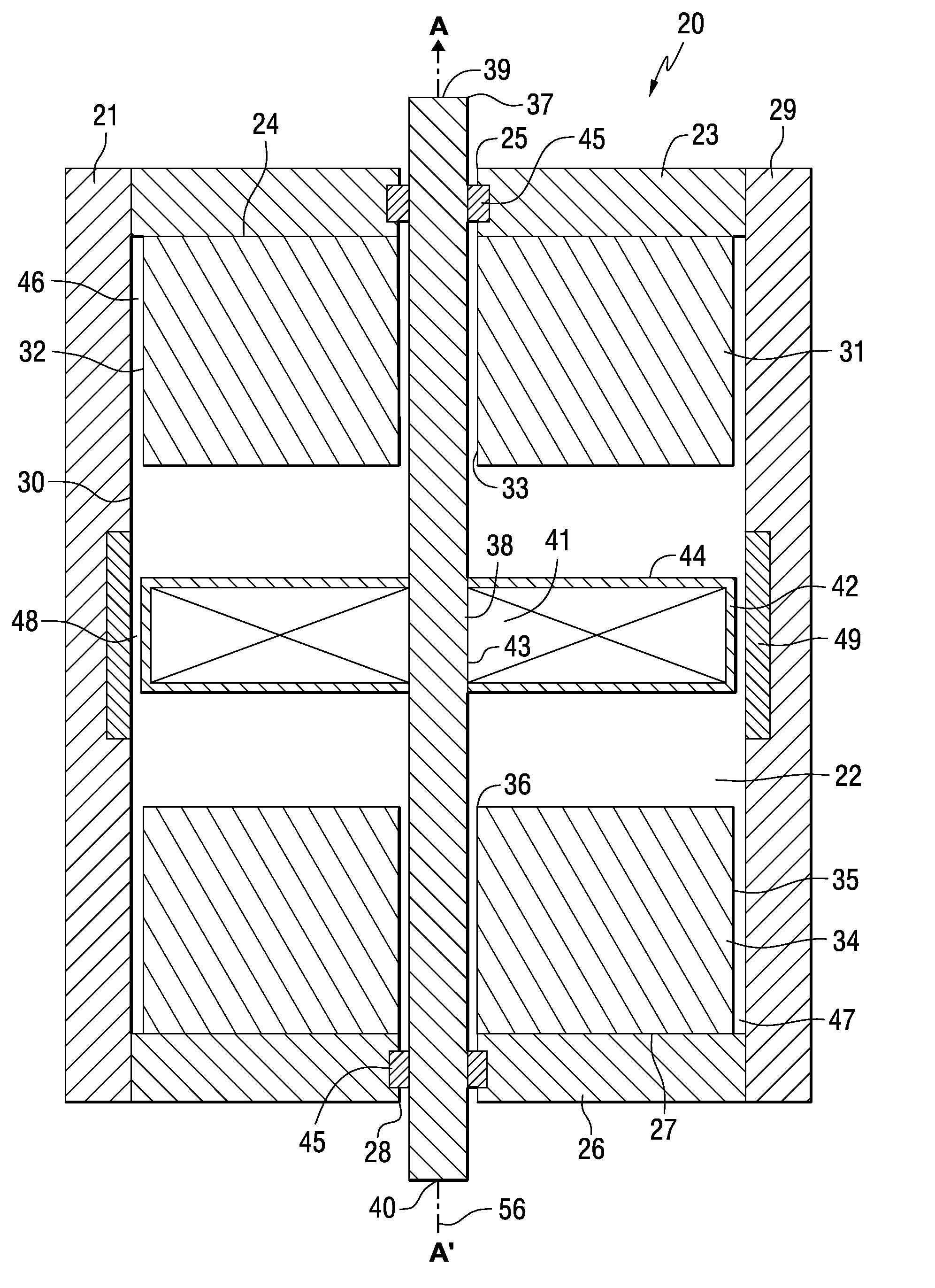

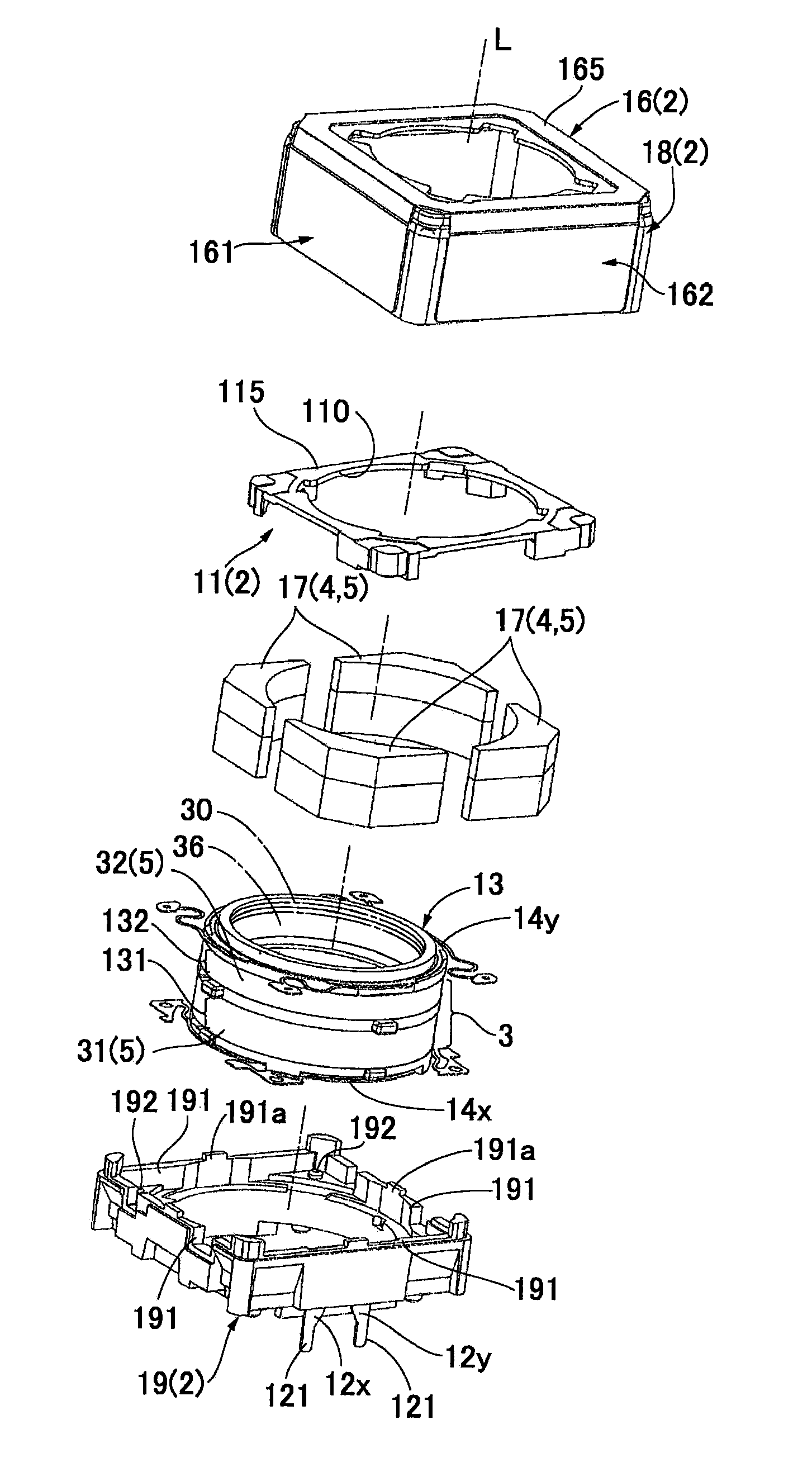

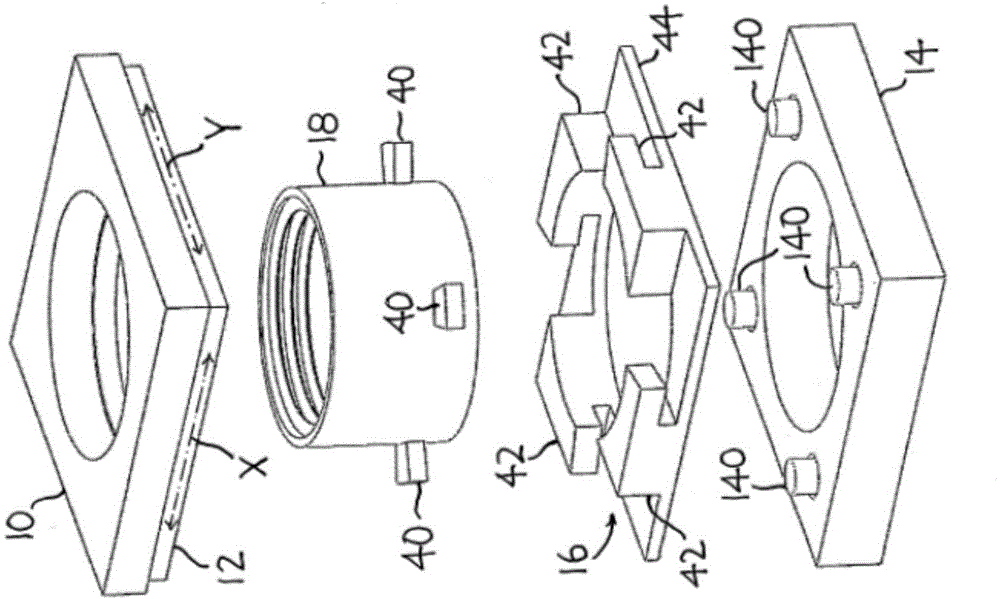

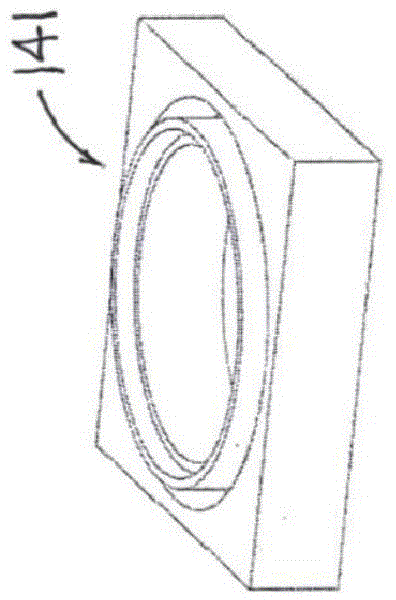

Compact electromagnetic actuator

InactiveCN104460183ATelevision system detailsProjector focusing arrangementLinear motionOptical axis

A compact electromagnetic actuator for driving a lens includes a lens holder (18) used to hold a lens or a lens assembly which defines an optical axis, an image stabilization (IS) actuator (10) provided at one end of the lens holder (18) for producing a linear motion in a plane perpendicular to the optical axis, and an autofocus (AF) actuator (14) provided at an opposite end of the lens holder (18) for producing a linear motion along the optical axis. An AF connection mechanism (16) can be used to connect the autofocus actuator (14) to the lens holder (18). An IS connection mechanism (12) can be used to connect the image stabilization actuator (10) to the lens holder (18).

Owner:SUNMING TECH HK

Magnetically actuated microelectromechanical systems actuator

InactiveUS7221247B2Prevent cross-talk and excessive and possibly damaging currentConvenient ArrangementPiezoelectric/electrostriction/magnetostriction machinesSnap-action arrangementsMicroelectromechanical systemsActuator

Owner:MICROSOFT TECH LICENSING LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com