Oil field waste liquid treatment coagulation air floatation apparatus

A technology for waste liquid treatment and coagulation and air flotation, which is applied in mining wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problem of polluting the environment, unable to achieve process continuity and automation, and long-term accumulation of waste oil. and other issues to achieve the effect of improving water quality, achieving continuity and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

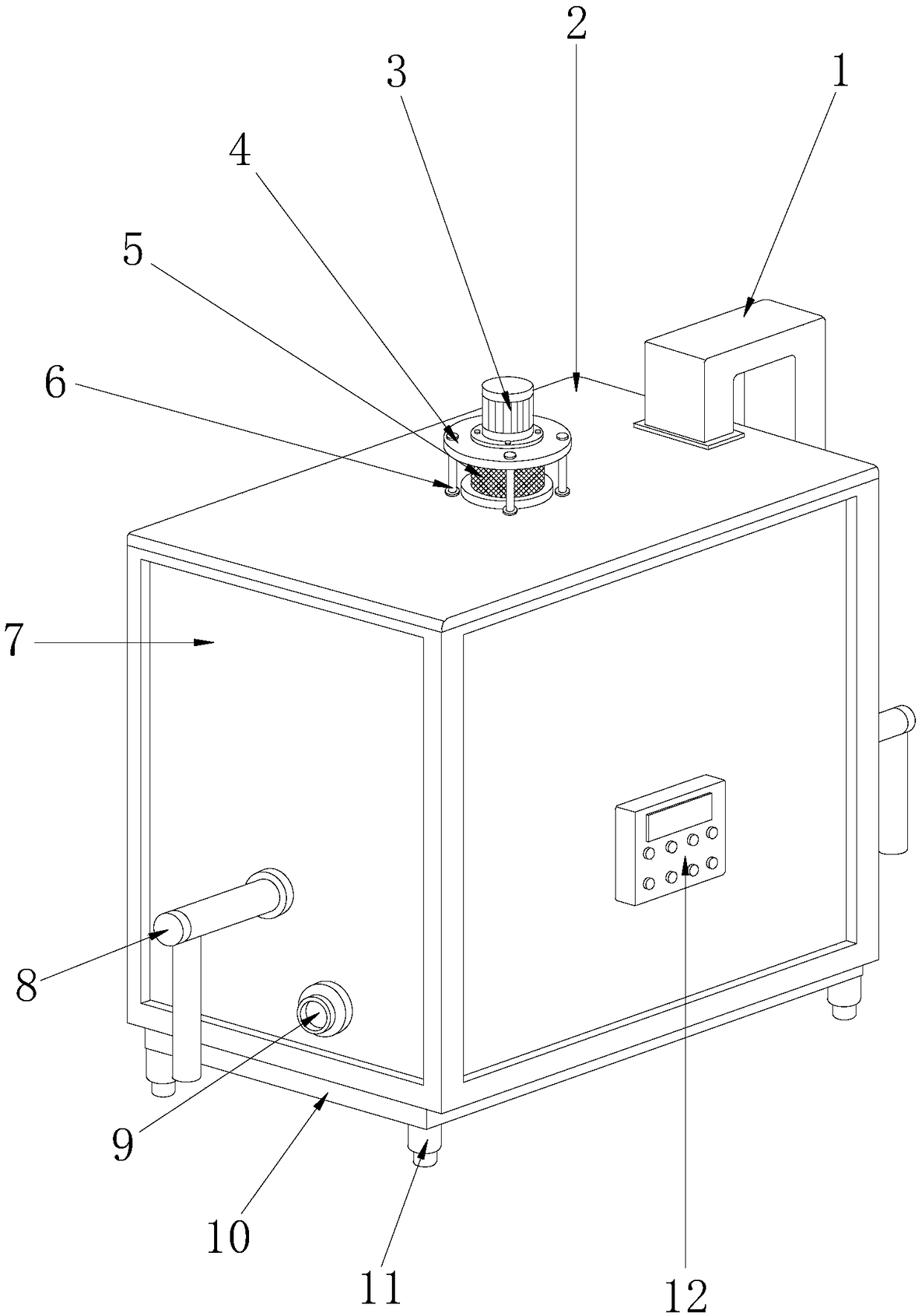

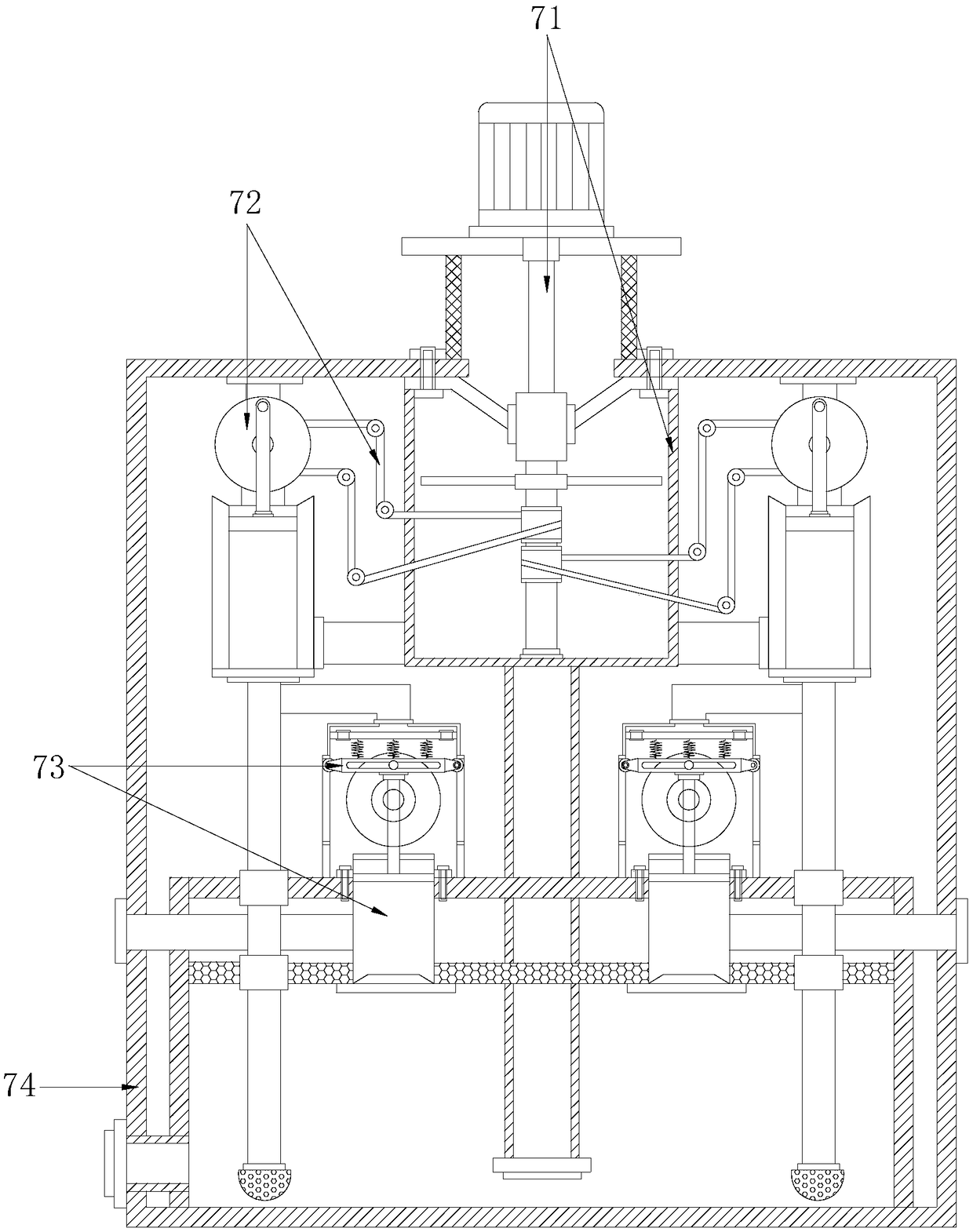

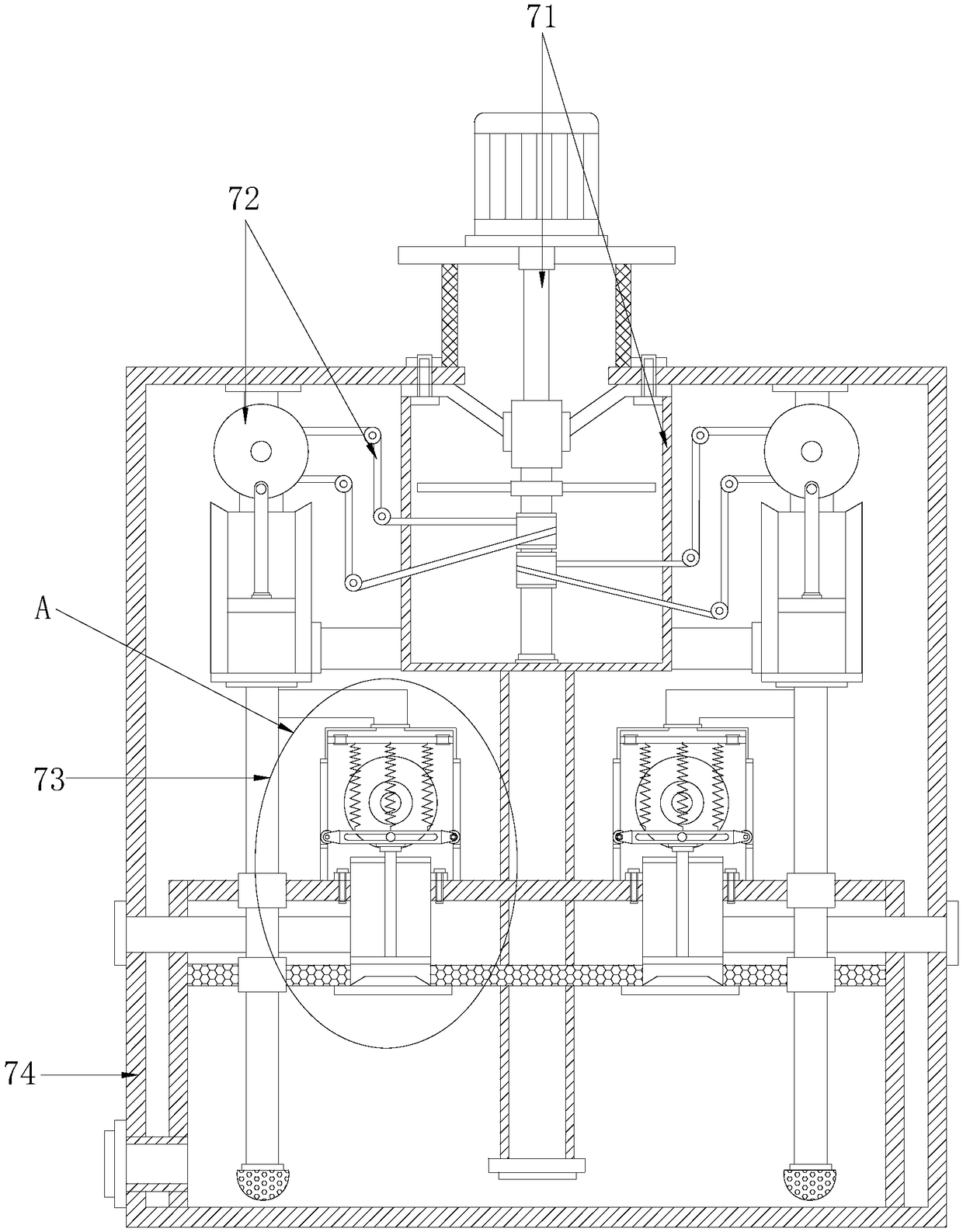

[0022] see Figure 1-Figure 5 , The present invention provides a coagulation and air flotation device for oil field waste liquid treatment. Liquid processing device 7, solid material scum discharge conduit 8, drain valve 9, base 10, support feet 11, controller 12, the base 10 has four support feet 11 evenly and equidistantly at the bottom of the base 10, and the two use Thread matching, the top of the base 10 is provided with an air flotation waste liquid treatment device 7 and the two are interlocked, the front end of the air flotation waste liquid treatment device 7 is provided with a controller 12 and the two cooperate, the described air flotation waste liquid treatment device 7 One side of the air flotation waste liquid treatment device 7 is provided with a drain valve 9 and the two are interlocked, and both sides of the air flotation waste liquid treatment device 7 are provided with solid material scum discharge conduits 8. The solid material One end of the scum discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com