Technology for preparing lens through physical vapor deposition

A physical vapor deposition, light-transmitting mirror technology, applied in metal material coating process, decorative art, superimposed layer plating and other directions, can solve the problems of unclear image edge, rough production process of light-transmitting mirror, labor-intensive and time-consuming and so on. , to achieve the effect of retaining mystery and clear light-transmitting pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Below in conjunction with accompanying drawing, the present invention is described in further detail:

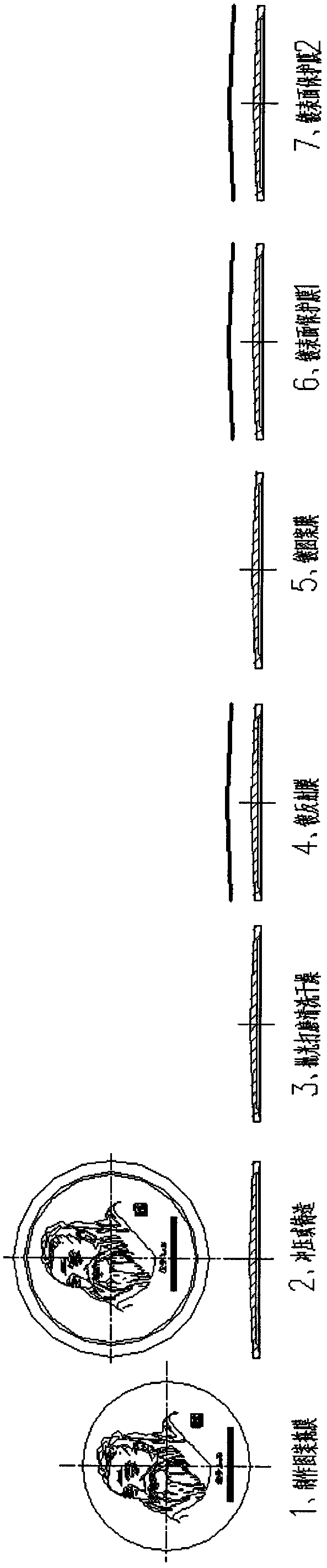

[0008] The present invention is: as figure 1 As shown, by making pattern mask (1), stamping or casting (2), polishing, grinding, cleaning, drying (3), plating reflective film (4), plating pattern mold (5), plating surface protective film 1 ( 6), plated surface protection film 2 (7) composition, it is characterized in that: make pattern mask (1) earlier, select metal, glass or plastics etc. as base material again, punch or cast (2) back pattern, then polish, Grinding, cleaning, drying (3), and then physical vapor deposition such as vacuum evaporation or magnetron sputtering to coat the reflective film (4), plate the pattern mold (5), coat the surface protection film 1 (6), and coat the surface protection film 2 (7), and finally make a mirror surface that can see through the back figure in the reflected light.

[0009] The present invention is: as figure 1 As shown, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com