Electric scissor type extension cabin

An extended cabin and electric technology, applied in the field of extended shelters, can solve the problems of increasing structural complexity, reducing reliability and maintainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

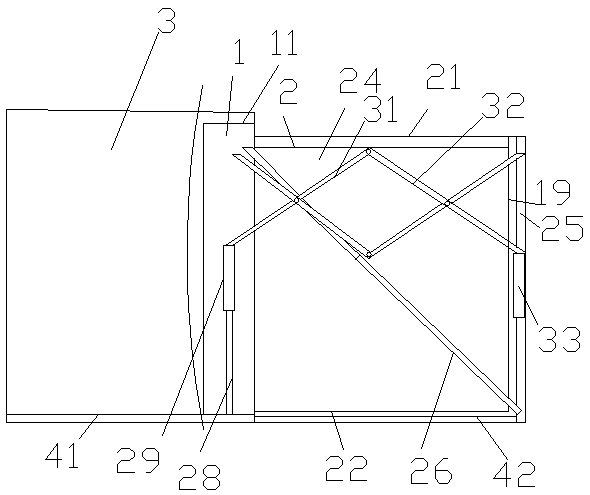

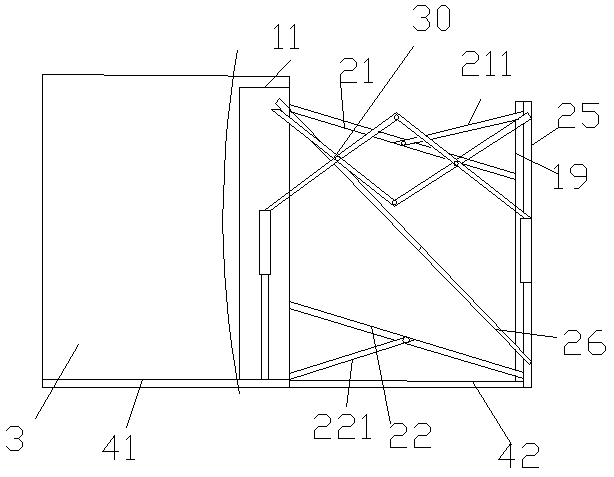

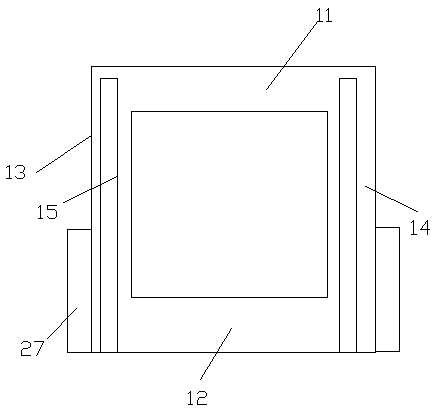

[0025] An electric scissor-type extended shelter, including an inner frame 1, an extended cabin 2, and a fixed cabin 3, the inner frame 1 is fixedly connected in the fixed cabin 3, when the expanded cabin 2 is fully opened, the expanded cabin 2 Fixedly connected to one side of the inner frame 1, the inner frame 1 includes an upper side profile 11, a lower side profile 12, a left side profile 13, a right side profile 14, the upper and lower side profiles 11, 12 and the The left and right profiles 13, 14 are fixedly connected to form a frame structure, the outer sides of the left profile 13 and the right profile 14 are provided with symmetrical first guide rails 15, and the lower profile 12 is provided with a hollow space. cavity, and a jacking device is fixed in the cavity;

[0026] The jacking device is a two-link mechanism, and the jacking device includes a first electric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com