Lifting scaffold capable of moving horizontally

A technology of lifting scaffolding and horizontal movement, applied in the field of scaffolding, can solve the problem that scaffolding cannot be installed in complex buildings, and achieve the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

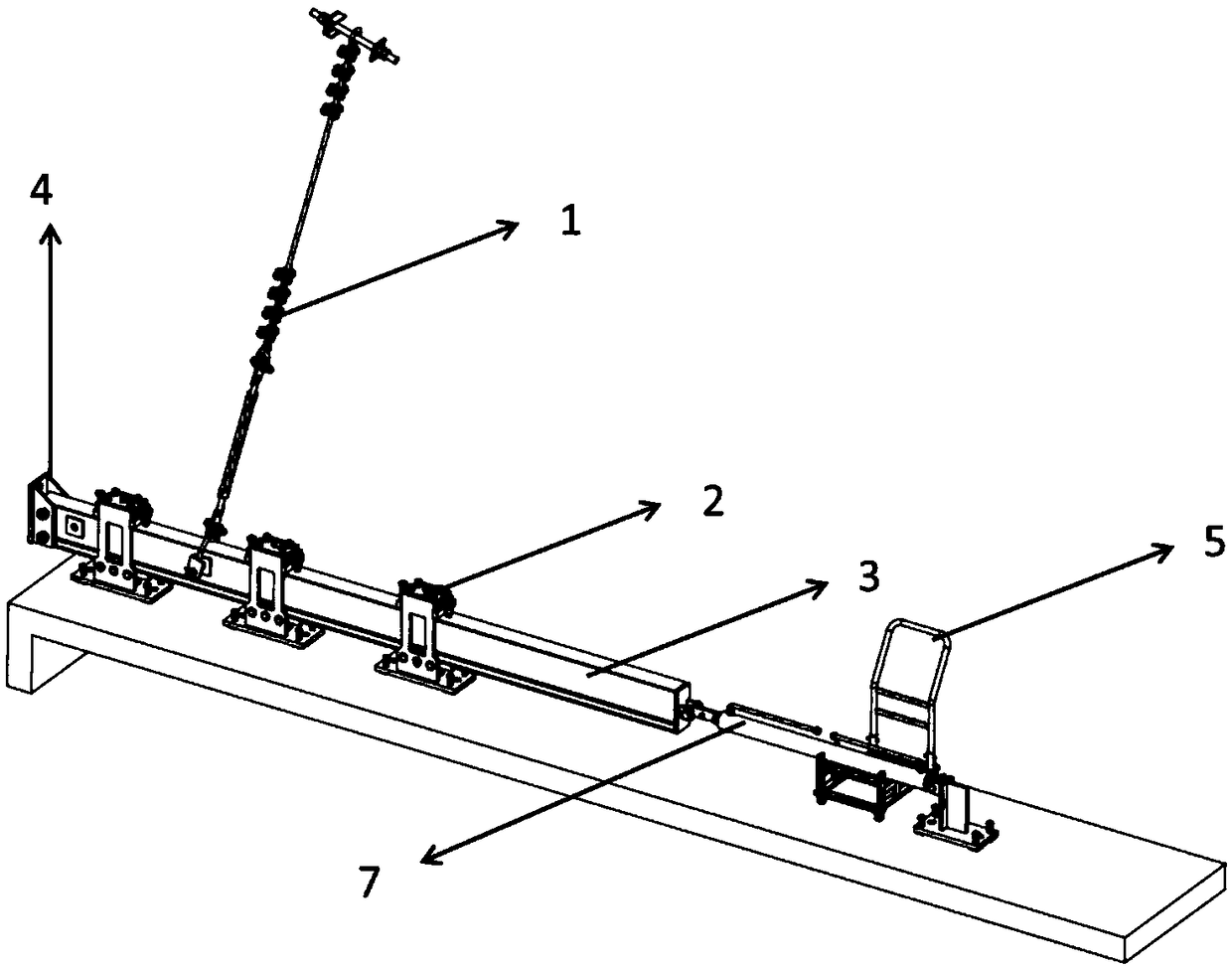

[0033] Such as Figure 1-11 As shown, a horizontally movable lifting scaffold includes a main frame, a wall-attached system, a lifting system and an intelligent control system. The lifting system includes two vertical and parallel guide rails fixed on the main frame against the wall, And several wall-attached supports, the main frame lifts through the guide rails with the attached wall supports as the fulcrum; it is characterized in that: the lifting scaffold also includes a horizontal movement system, which includes: horizontal top tension steel beam 3, steel beam support 2 , frame attachment support 4, hydraulic cylinder support 5, hydraulic cylinder 7 and hydraulic cylinder rear support seat 6;

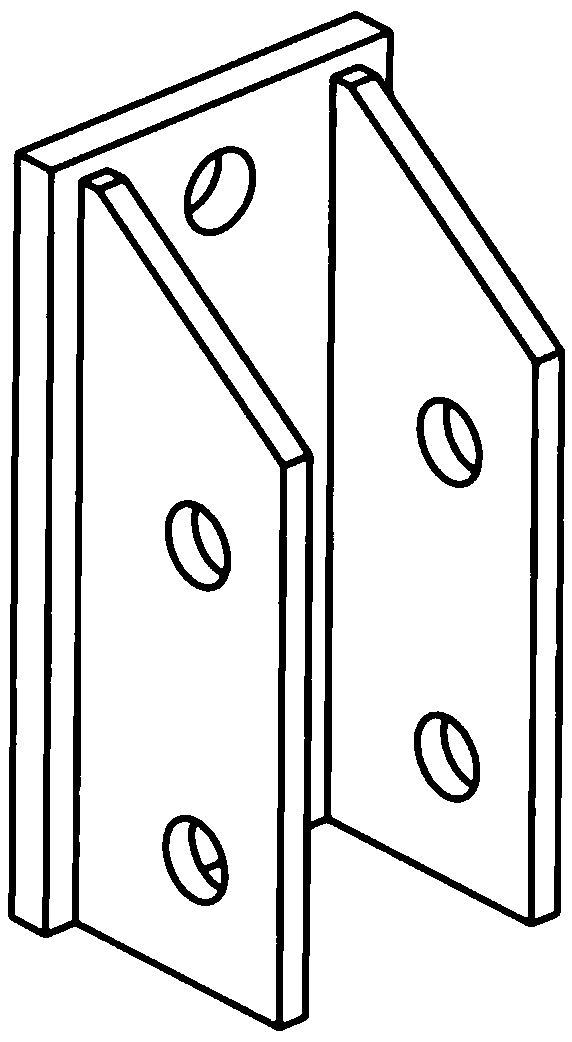

[0034] The steel beam support 2 has a horizontal hole that can accommodate the horizontal top tension steel beam 3 to pass through, and a vertical through hole for self-fixation, and is fixed on the floor with bolts;

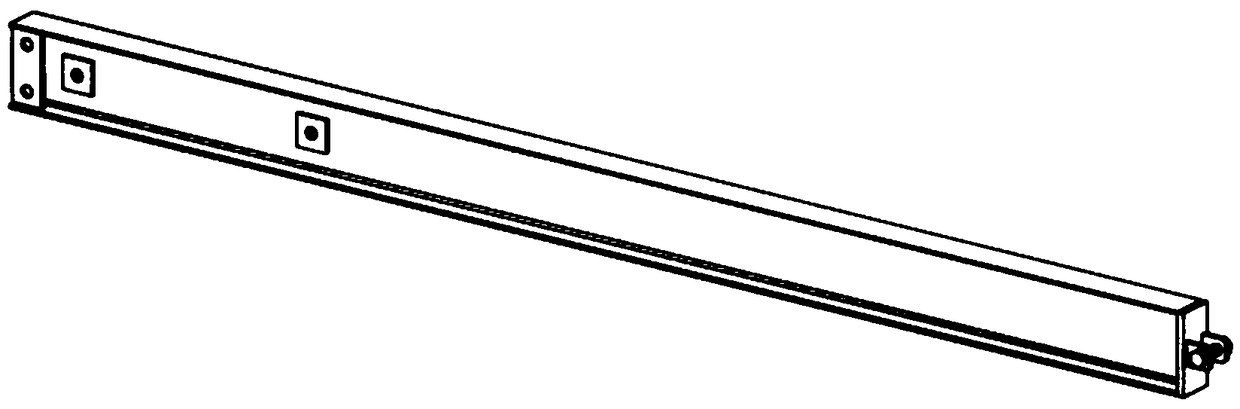

[0035] The horizontal jacking steel beam 3 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com