EGR gas inlet rail

A track and air intake technology, applied in the direction of exhaust gas recirculation, engine components, machines/engines, etc., can solve problems that affect engine life and performance, uneven intake of engine cylinders, uneven engine air pressure, etc., to avoid airflow Straight into the engine cylinder, wide range of airflow adjustment, uniform gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

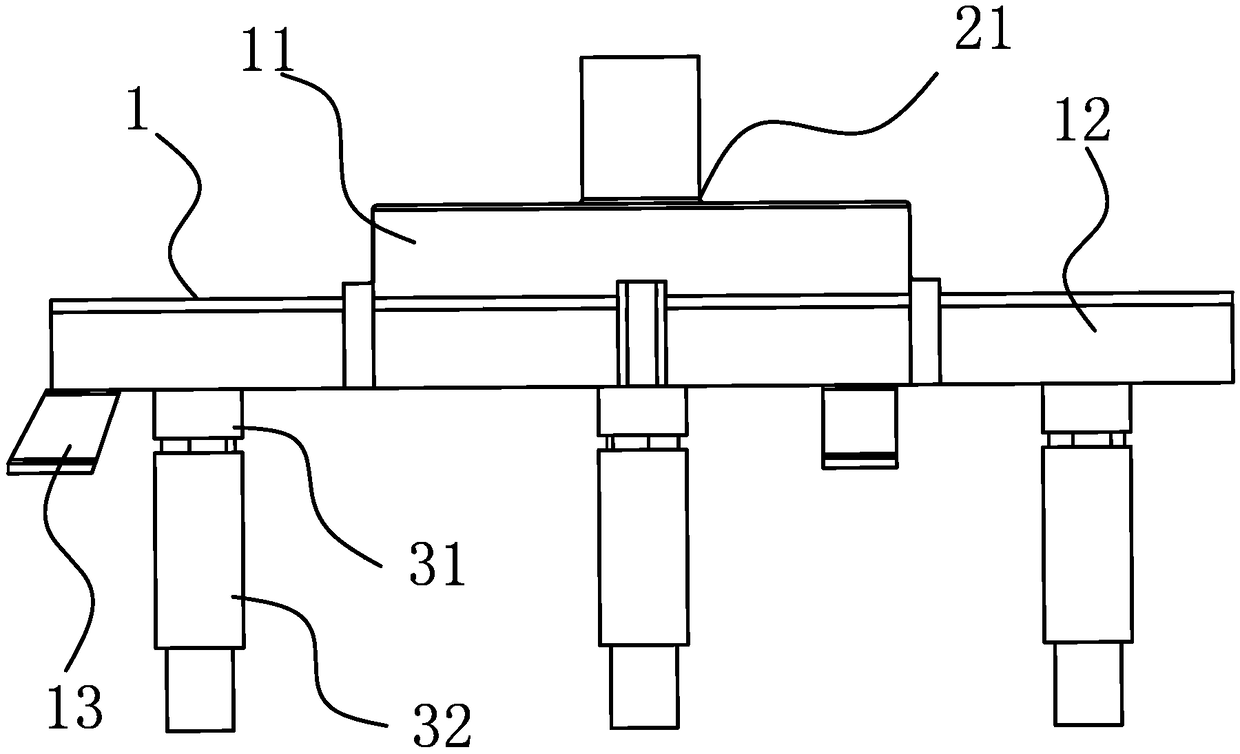

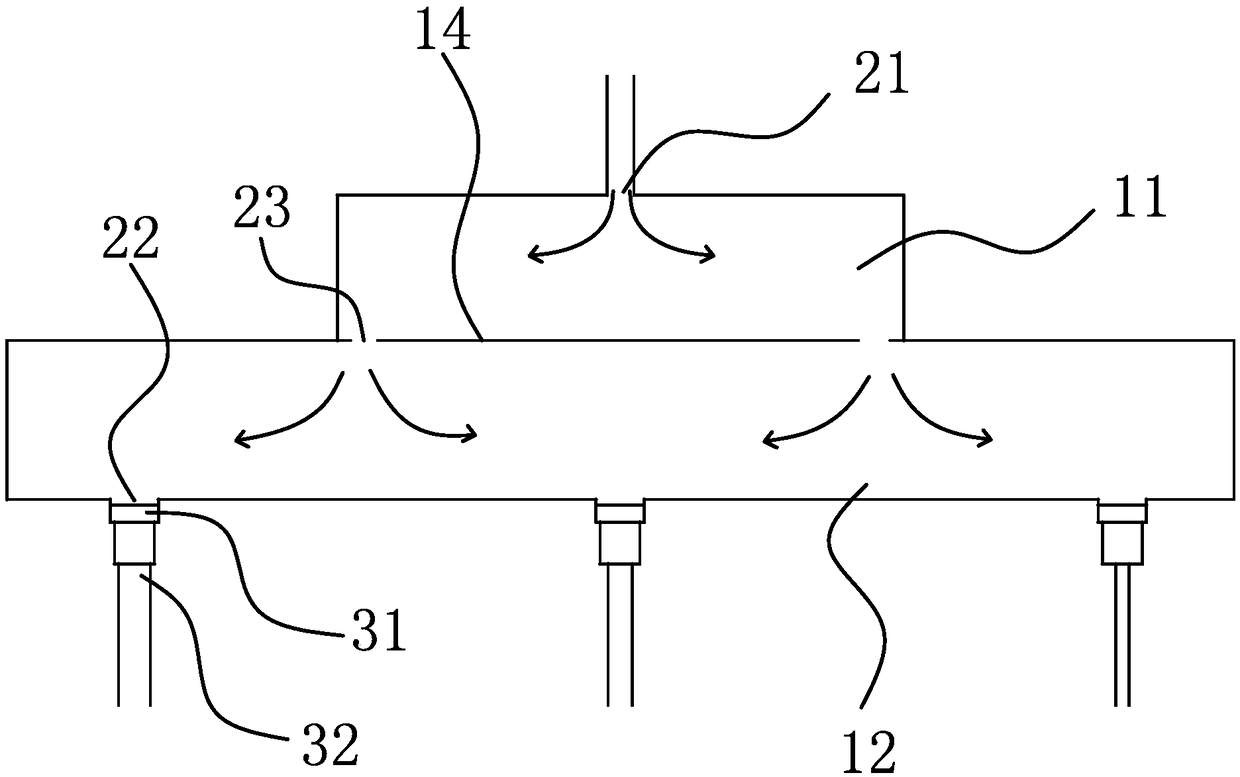

[0027] Such as figure 1 and figure 2 As shown, an EGR intake rail includes a housing 1 , and an upper air chamber 11 and a lower air chamber 12 are arranged inside the housing 1 . The top of the upper air chamber 11 is provided with an air inlet 21 for connecting the EGR air duct, the upper air chamber 11 and the lower air chamber 12 are separated by a partition 14, and an air guide port 23 for communication is provided on the partition 14. An air outlet 22 is provided at the bottom of the lower air chamber 12, and the air outlet 22 is used to introduce the gas in the lower air chamber 12 into the engine cylinder. The inner top wall of dividing plate 14 and upper floor air chamber 11 is parallel to each other, and air inlet 21 is positioned on the inner top wall of upper floor air chamber 11, and the inner bottom wall of dividing plate 14 and lower floor air chamber 12 is parallel mutually, upper floor air chamber 11 and The inside of the lower floor air chamber 12 is a squ...

Embodiment 2

[0033] The difference between the second embodiment and the first embodiment lies in the detachable connection between the intake branch pipe 32 and the movable block 31. The overlapping part is kept relatively fixed by the clamp. The other end of the sebific tube is fixed on the engine cylinder head and communicates with the air intake of the engine cylinder head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com