A cold and hot water level balance method for heat meter durability cold and hot shock test

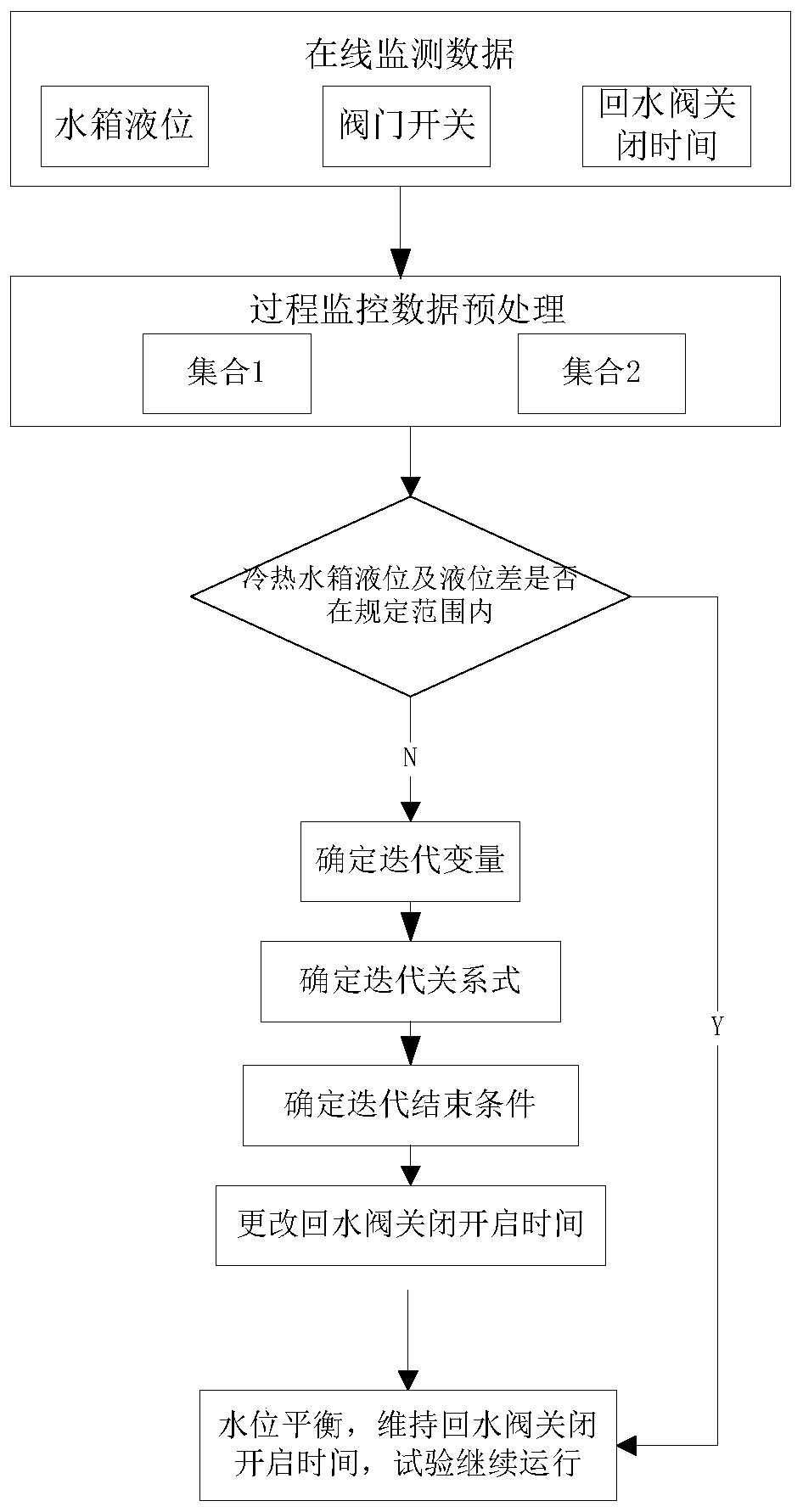

A technology of durability test and cold and heat shock, which is applied in the field of cold and hot water level balance of heat meter durability cold and heat shock test based on Newton's iterative method, can solve the problems of waste test effectiveness and reduction, and achieve the purpose of strengthening automatic control ability, The effect of ensuring temperature stability and improving monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

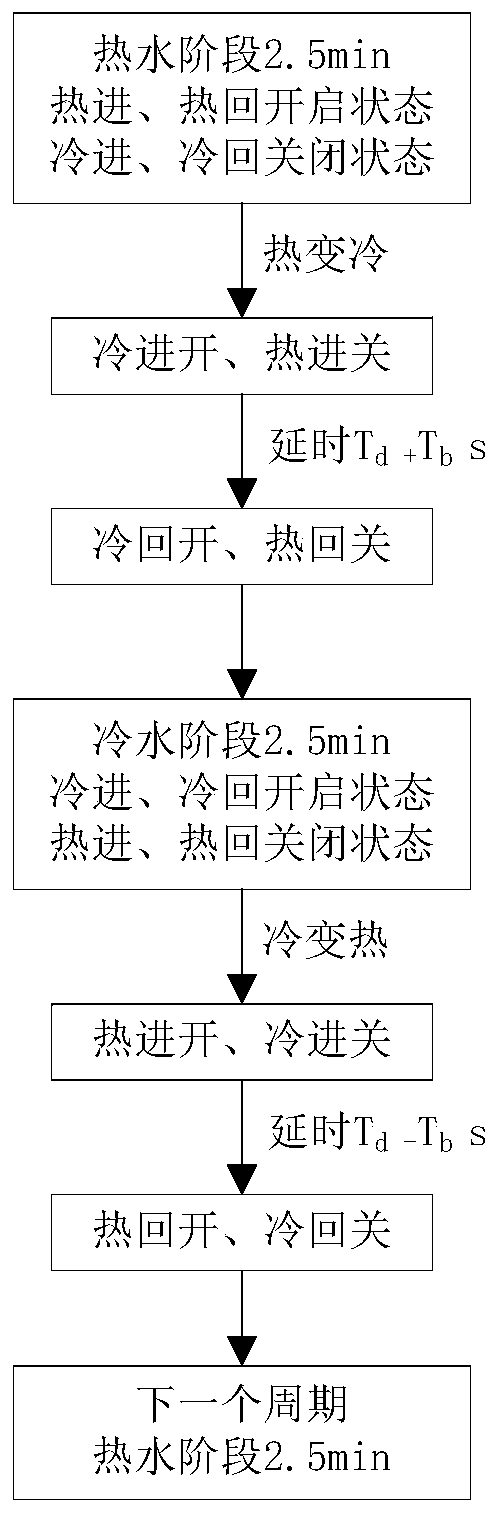

[0076]When using the heat meter durability test device of this embodiment to carry out 4000 thermal shock tests on the heat meter, the selected heat meter is a grade 3 DN25 heat meter, and the method for balancing the cold and hot water levels during the test is as follows:

[0077] (1) Take the sampling period t s = 5s is the interval pair durability test process state parameter;

[0078] (2) Establish a data set of test process state parameters, record the current sampling times as k, k≥1; sampling time t=kt s ;Cold and hot water flow through the test pipeline from the water pump until it returns to the water tank, the specific test pipeline L pip =15.0m, 4000 times of hot and cold impact instantaneous flow Q=7.0m 3 / s, 4000 thermal shock cycles T 0 =300s, therefore, the test flow rate is:

[0079]

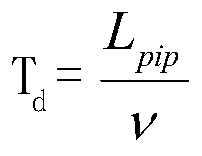

[0080] Therefore, the time T taken for hot or cold water to come out and finally flow back to the hot or cold water tank d for

[0081]

[0082] (3) Determine whethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com