A rapid detection method for light transmittance of bright-colored asphalt

A technology of bright-colored asphalt and detection method, which is applied in the direction of color/spectral characteristic measurement, measurement device, and test sample preparation, etc., which can solve the problems of cumbersome preparation of samples and test panels, large errors, and inconsistent contrast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

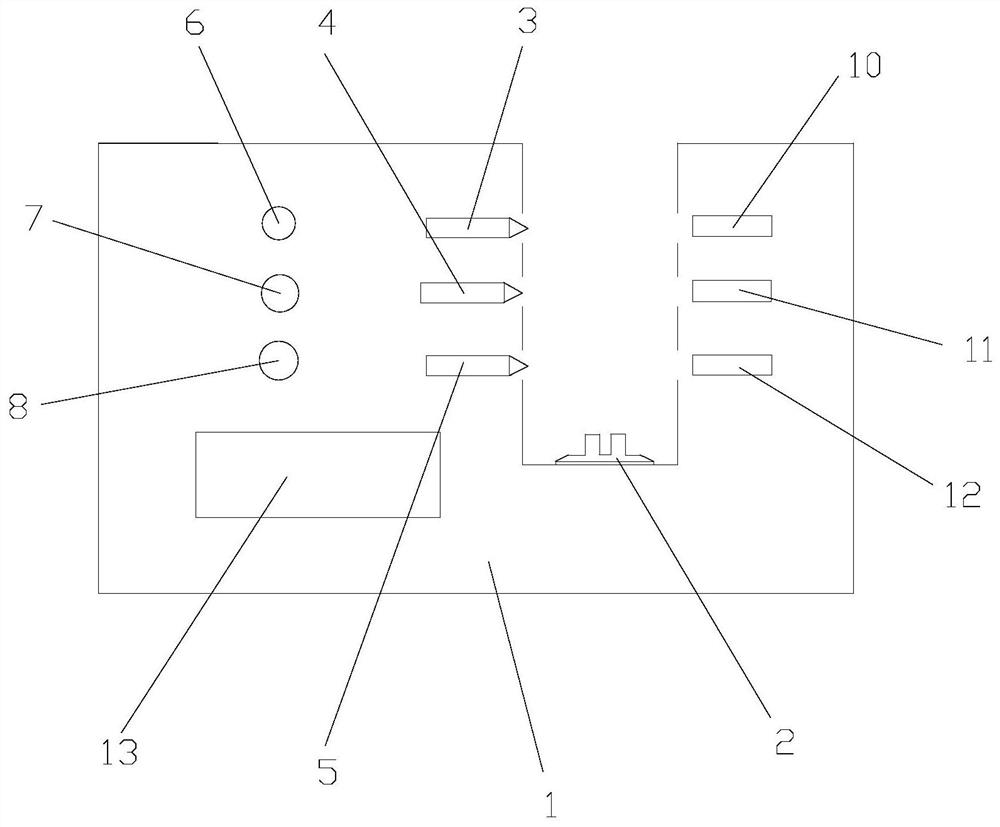

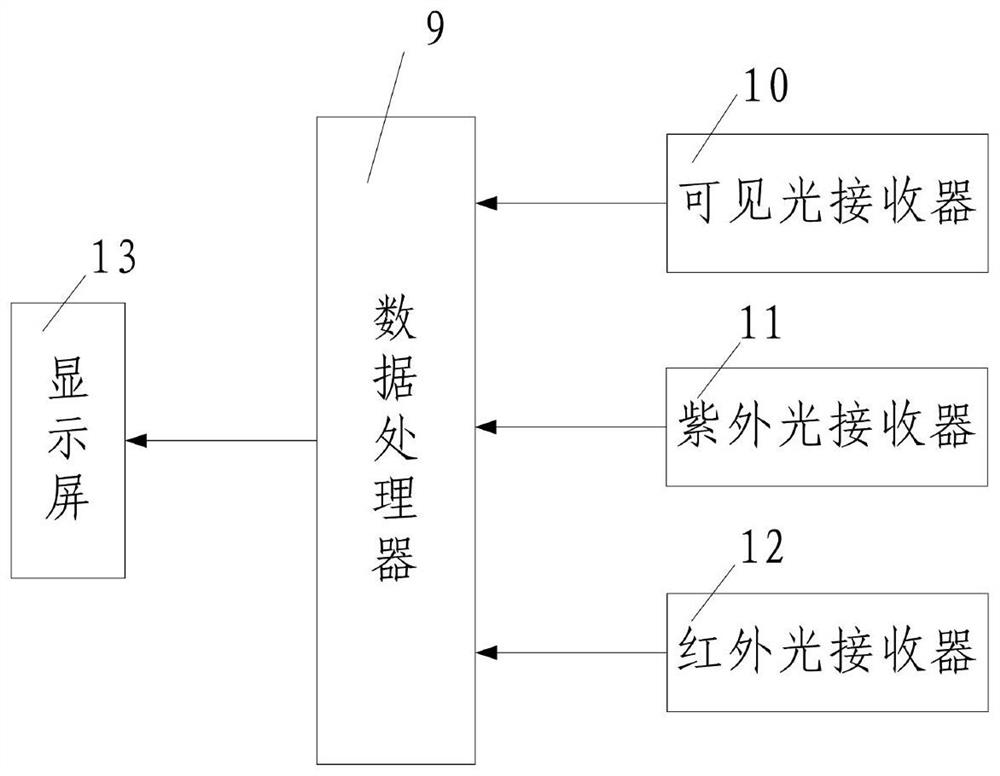

[0088] Step 1, the preparation of the bright-color asphalt test plate to be detected:

[0089] Step 101, heat treatment: heat-treat the coated substrate, clear asphalt and applicator to be painted, to obtain the coated substrate, clear asphalt and applicator after heat treatment; wherein, the coated substrate after heat treatment The coated substrates include a plurality of glass plate substrates to be coated, a plurality of quartz plate substrates to be coated and a plurality of semiconductor silicon chip substrates to be coated;

[0090] Step 102, painting bright-colored asphalt: using the heat-treated applicator to paint the heat-treated bright-colored asphalt on one of the largest surfaces of the plurality of glass plate substrates to be coated, and A bright-color asphalt layer is formed on one of the largest surfaces of the glass plate substrates to be coated to obtain a plurality of clear-color asphalt glass plates; the heat-treated light-color asphalt is respectively pa...

Embodiment 2

[0160]The light transmittance detection method of a bright-colored asphalt in this embodiment differs from that of Example 1 only in that: the temperature of the heat treatment in step 101 is 140°C, the time of the heat treatment is 30 minutes, and the light-colored asphalt layer described in step 102 The thickness is 12 μm; the temperature of heat preservation treatment in step 103 is 140°C, and the time of heat preservation treatment is 10min;

[0161] The horizontal distance between the clear asphalt layer on the clear asphalt glass test plate described in step 2011 and the visible light source 3, the ultraviolet light source 4 and the infrared light source 5 is 11mm; The asphalt layer is 11mm from the horizontal spacing of the ultraviolet light source 3, the ultraviolet light source 4 and the infrared light source 5; The horizontal spacing of the infrared light sources 5 is 11 mm;

[0162] The incident intensity of visible light described in step 2012 is 1500cd×sr / m 2 , ...

Embodiment 3

[0170] The difference between the light transmittance detection method of a bright-colored asphalt in this embodiment and Example 1 is that the temperature of the heat treatment in step 101 is 120° C., and the time of the heat treatment is 23 minutes. The light-colored asphalt layer described in step 102 is The thickness is 10 μm; the temperature of heat preservation treatment in step 103 is 120°C, and the time of heat preservation treatment is 8min;

[0171] The horizontal spacing of the clear asphalt layer on the clear asphalt glass test plate described in step 2011 from the visible light source 3, the ultraviolet light source 4 and the infrared light source 5 is 10mm; The asphalt layer is 10mm away from the horizontal spacing of the ultraviolet light source 3, the ultraviolet light source 4 and the infrared light source 5; The horizontal spacing of the infrared light sources 5 is 10 mm;

[0172] The incident intensity of visible light described in step 2012 is 1000cd×sr / m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com