Automatic system for analysis pretreatment on nitrate nitrogen and oxygen isotope samples

An automated system and oxygen isotope technology, applied in the preparation of test samples, etc., can solve the problems of safety hazards, health hazards of operators, and low processing efficiency, so as to improve efficiency and avoid health hazards and safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

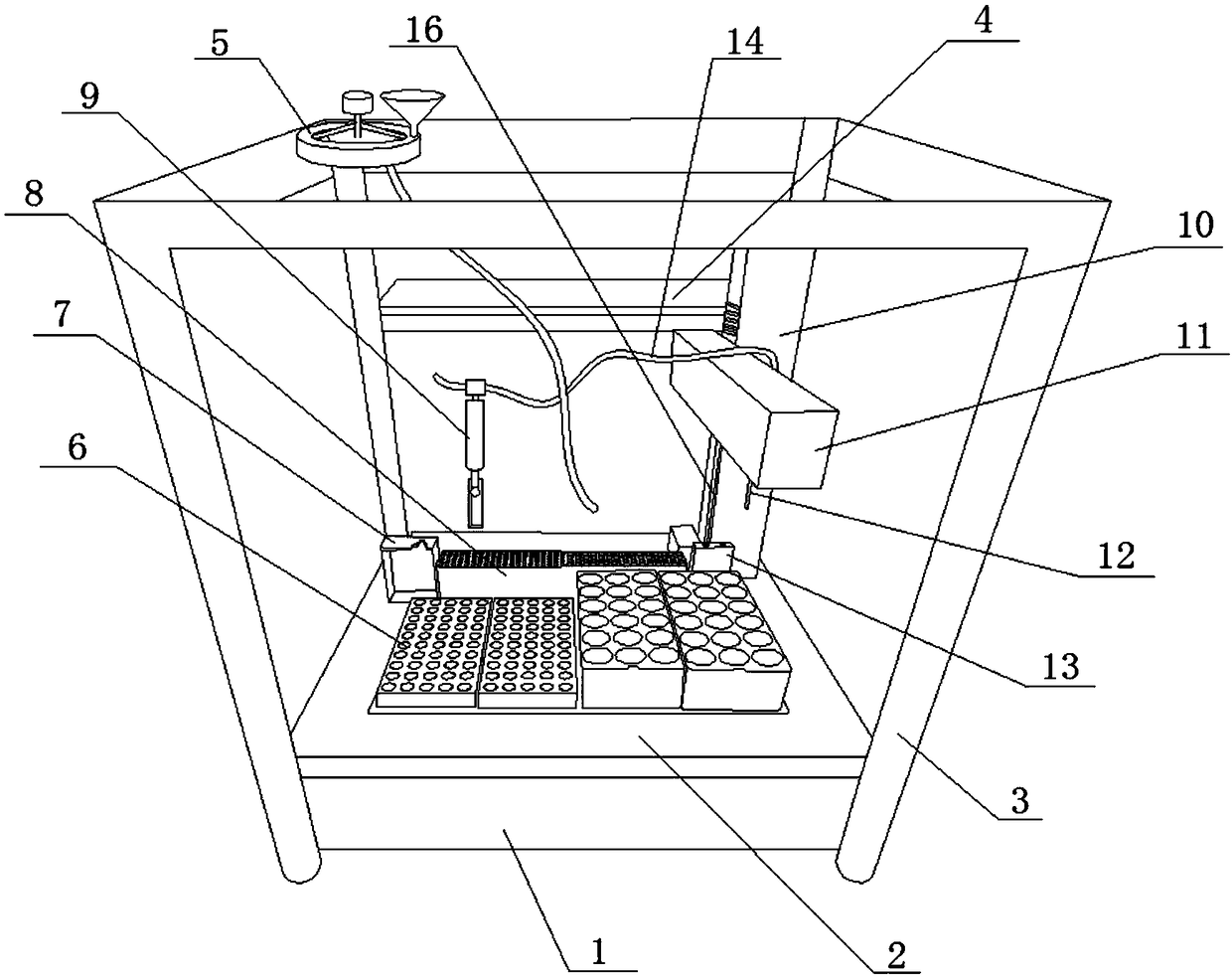

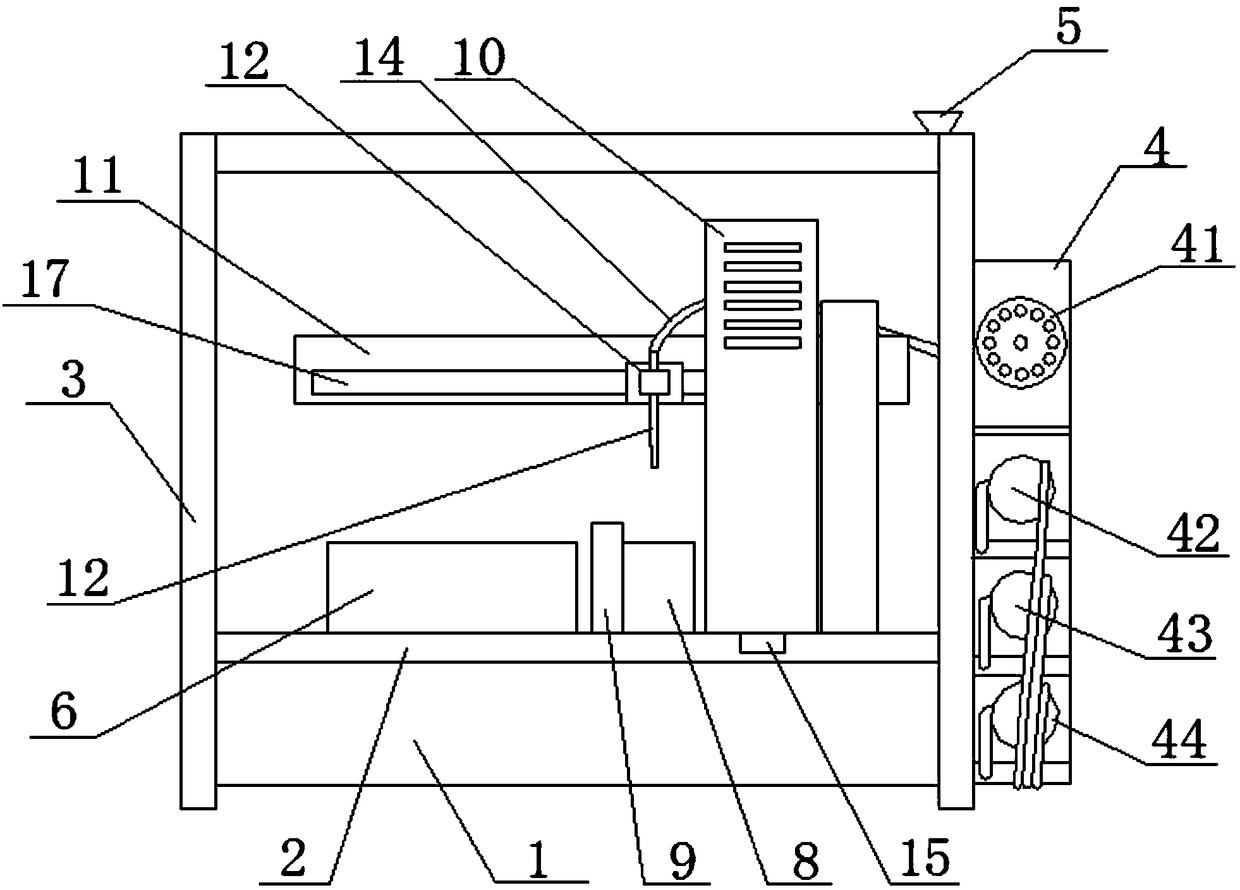

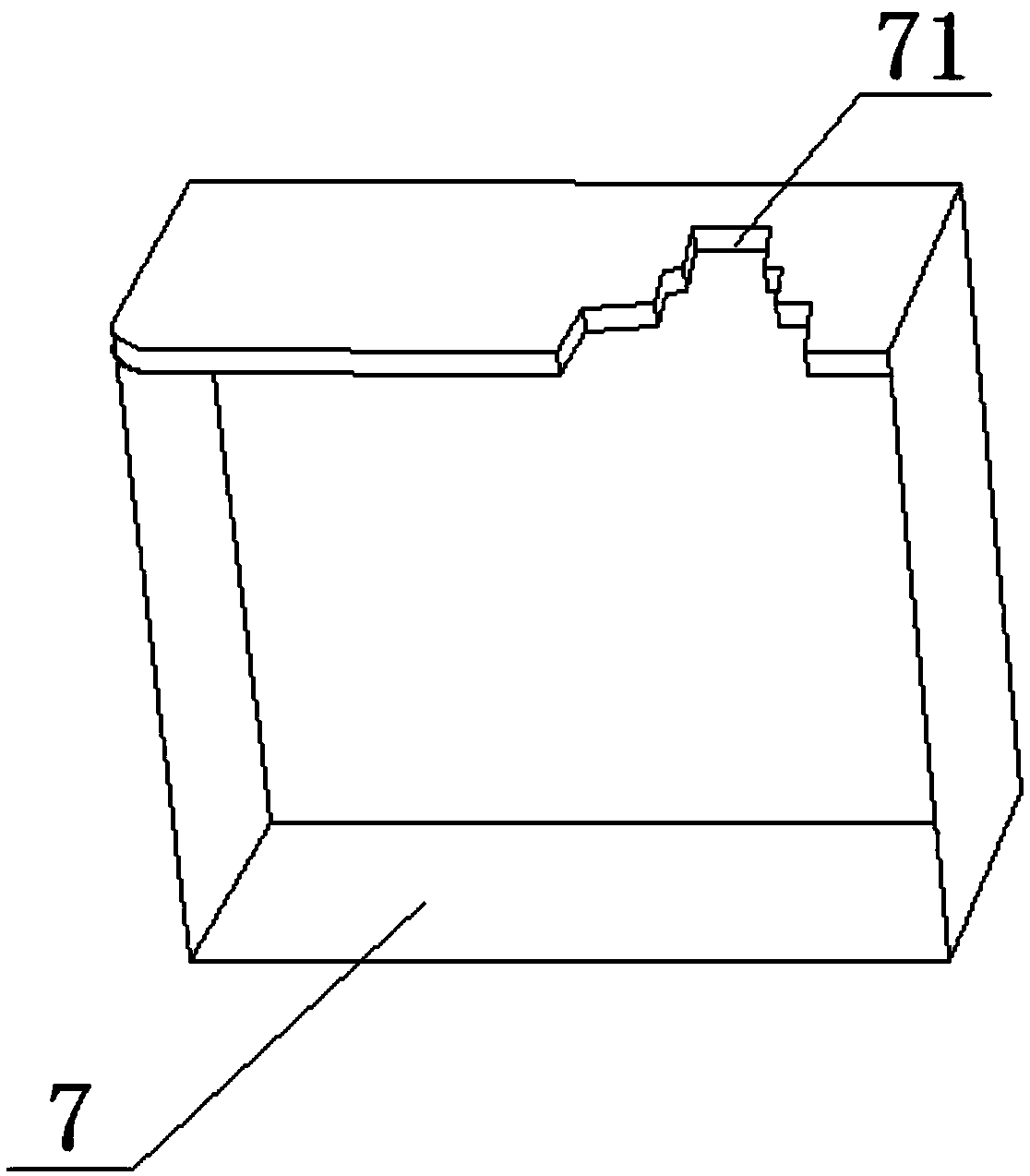

[0045] Such as figure 1 , figure 2 As shown, the automation system applied to the analysis pretreatment of nitrate nitrogen and oxygen isotope samples described in this embodiment includes a support base 1, a workbench 2, a support frame 3, a liquid filling tank 4, a feeding mechanism 5, and several shakers 6 and the three-dimensional mechanical arm, the workbench 2 is fixed on the support base 1, the shaker 6 is fixed on the workbench 2, the support frame 3 is fixed around the support base 1, and the feeding mechanism 5 is fixed on the support frame 3 , and the feeding mechanism 5 is located above the workbench 2, the liquid filling tank 4 is fixed on one side of the support base 1, the three-dimensional mechanical arm is installed on the workbench 2, and the three-dimensional mechanical arm is equipped with a needle sleeve rod 12, the described The liquid filling port of the liquid filling box 4 communicates with the liquid inlet port of the needle cover rod 12 through a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com