Ultrathin diffraction optical element based on ultra-structure surface

A diffractive optical element and metasurface technology, applied in the field of optics, can solve problems such as reduced precision, complex processing, and increased number of quantized steps, achieving the effects of simplified structure, great flexibility, and promotion of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

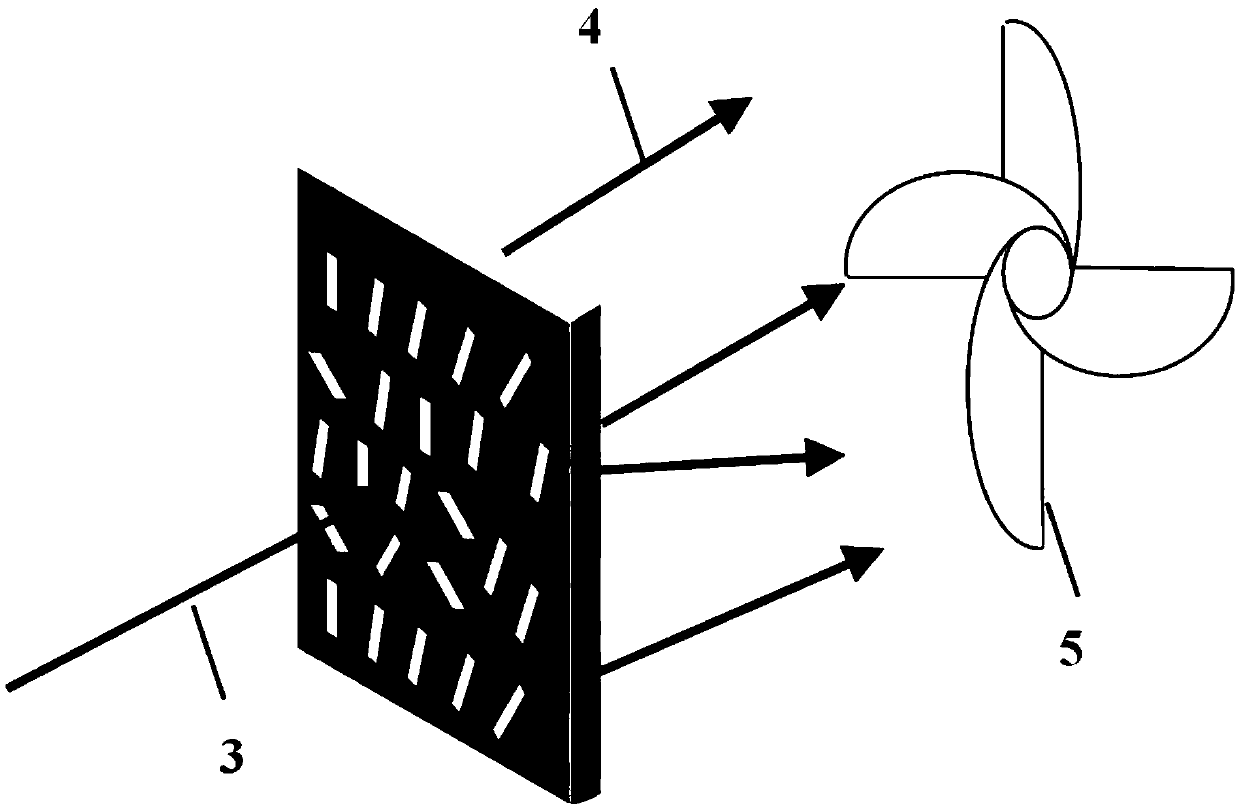

[0021] The present invention and embodiments are further described below in conjunction with the drawings:

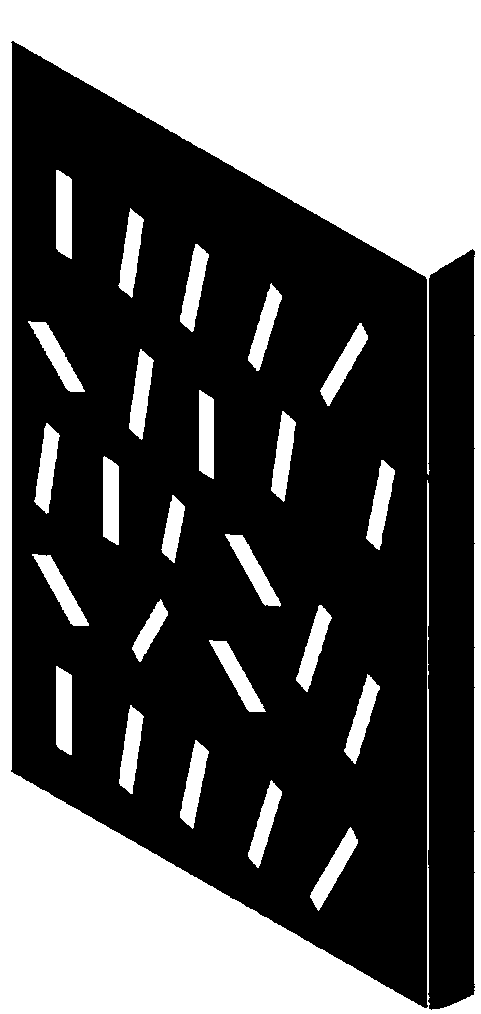

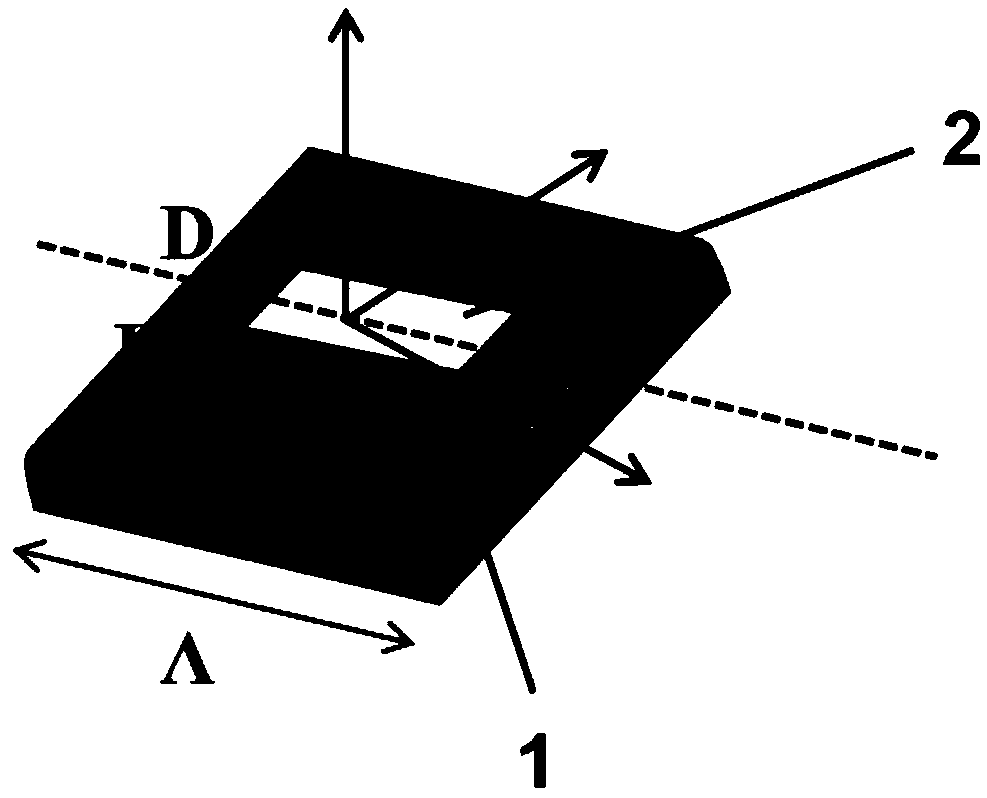

[0022] See figure 1 As shown, an ultra-thin diffractive optical element based on a meta-surface includes a diffractive optical element body. The body is a planar structure. One side of the structure is a metal nanorod structure. The orientation angle of the nanorod Different, used to adjust the phase of incident light.

[0023] The relationship between the phase modulation of the light wavefront and the direction angle of the nanorod satisfies the equation Change within 0~π. The sign of Φ is determined by the polarization of the incident light. The incident light and the outgoing light are right-handed circular polarization and left-handed circular polarization, respectively, so the phase is positive, and the incident light and outgoing light are left-handed circular polarization and right-handed circular polarization, respectively. The phase is negative.

[0024] See fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com