Reflecting pyramid wave-front sensor

A wavefront sensor and pyramid technology, applied in the field of adaptive optics, achieves the effects of high measurement accuracy, easy adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

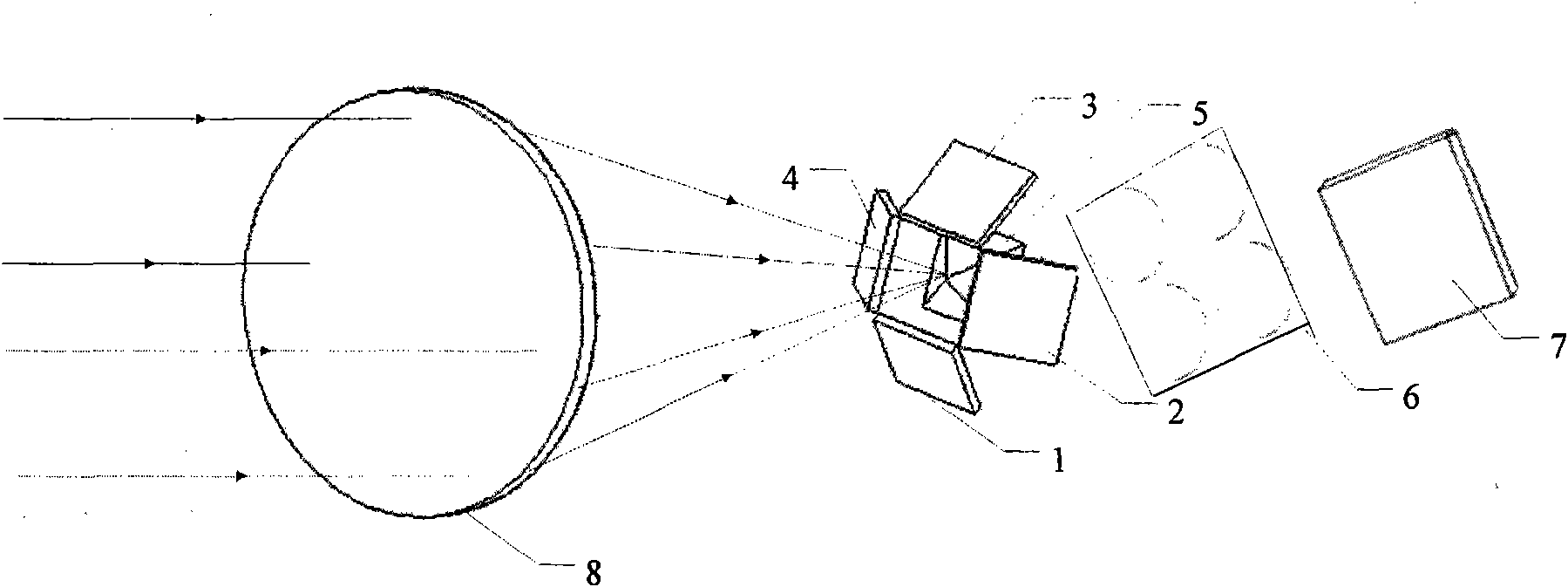

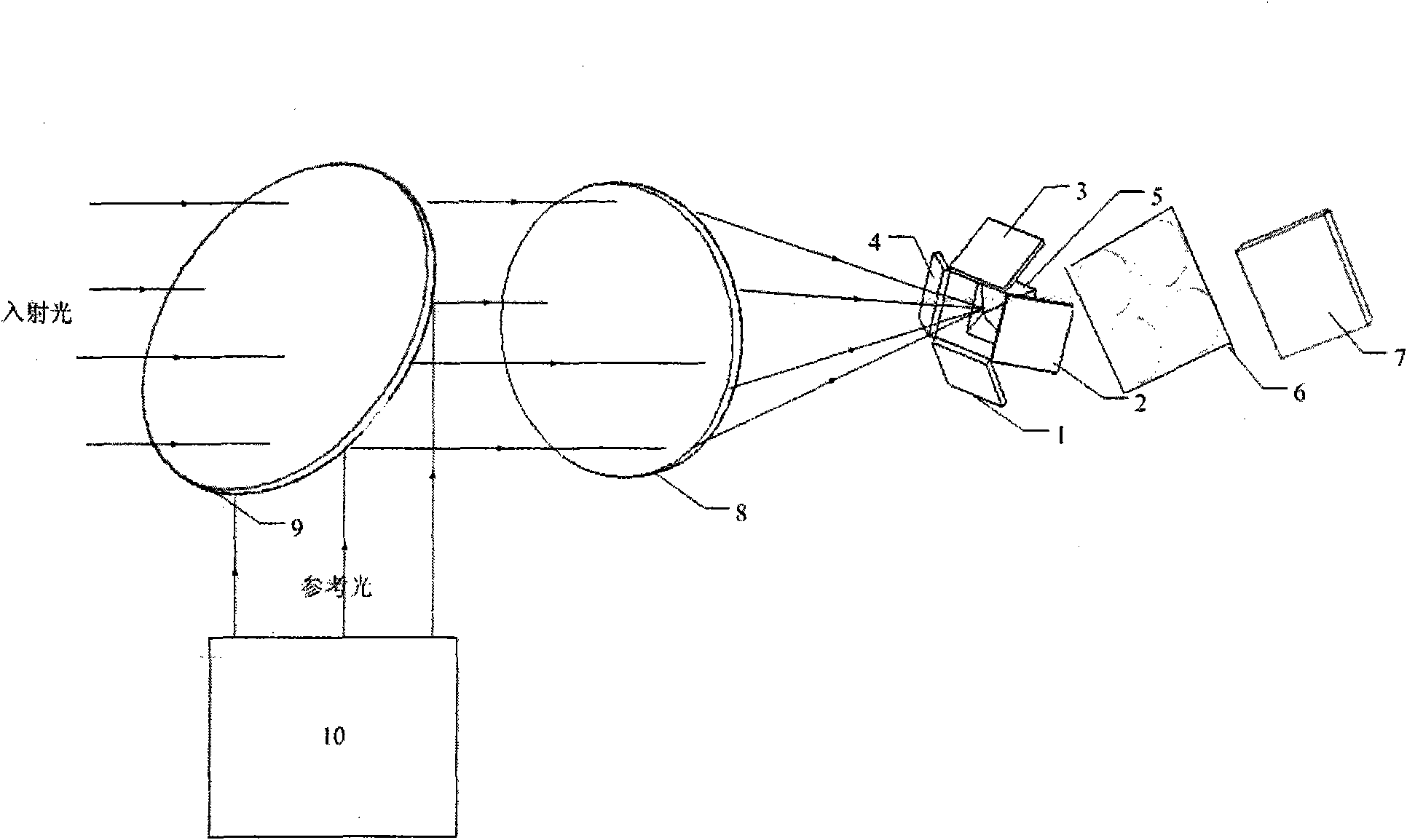

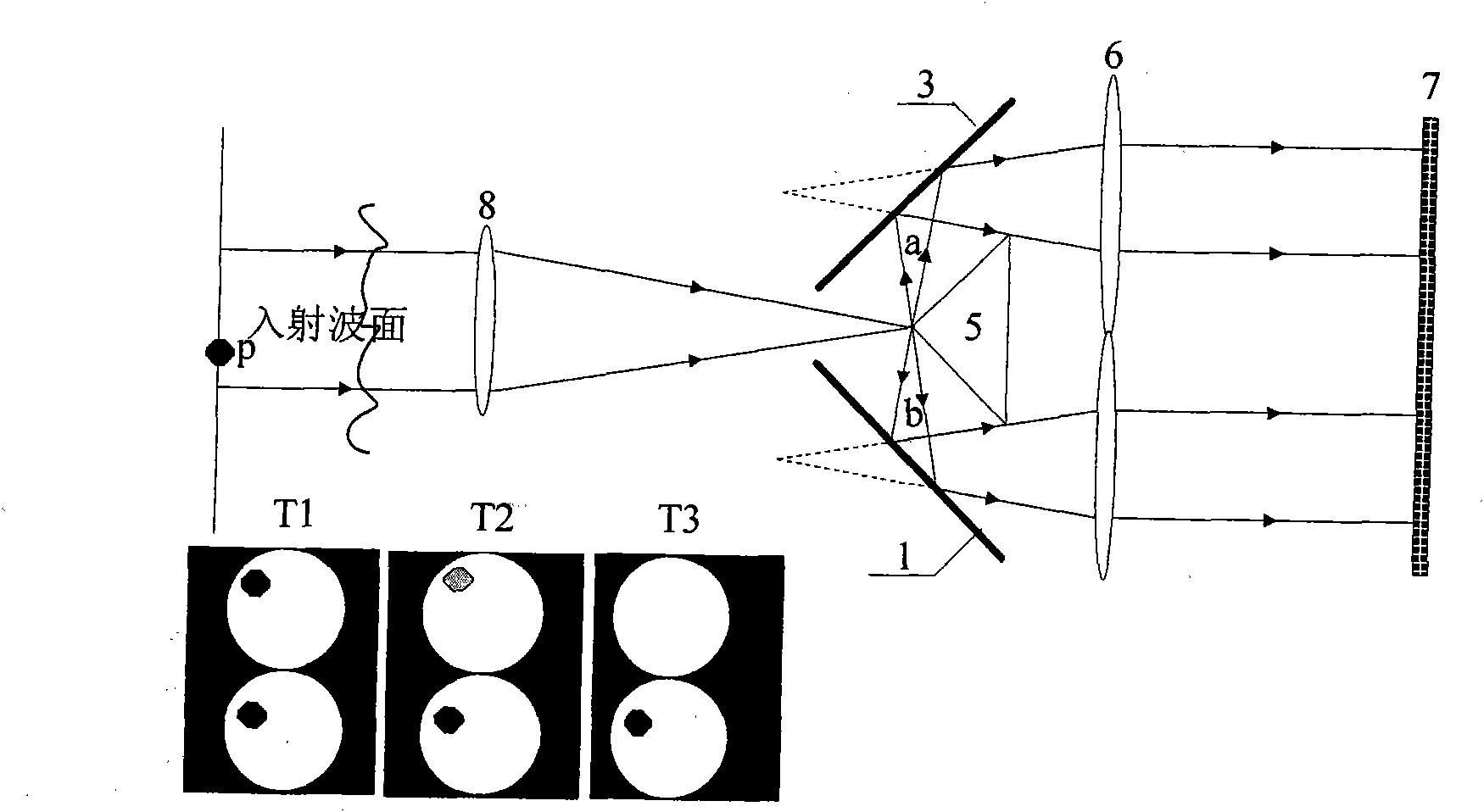

[0022] Such as figure 1 As shown, the technical solution of the present invention specifically includes a first mirror 1, a second mirror 2, a third mirror 3, a fourth mirror 4, a reflection pyramid 5, a 2×2 microlens array 6, a photodetector 7. Focusing lens 8. 2×2 microlens array 6 is placed between reflective pyramid 5 and photodetector 7; first reflector 1, second reflector 2, third reflector 3 and fourth reflector 4 respectively Be positioned at the outside of four facets of reflecting pyramid 5, the mirror surface of four reflecting mirrors and the included angle of bottom surface equal to the base included angle of reflecting pyramid 5, and four reflecting mirrors are parallel with the facing of reflecting pyramid 5; Described reflecting pyramid The pyramid apex of 5 is positioned at the focal plane position of focusing lens (8), and four facets of reflective pyramid 5 are reflective surfaces, and the light beam that passes through focusing lens 8 is focused on the apex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com