Zinc ore grade soft measurement method based on process size feature

A dimensional feature, soft measurement technology, applied in instruments, character and pattern recognition, computer parts and other directions, can solve problems such as high cost, difficulty in online detection of concentrate grade, and large delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

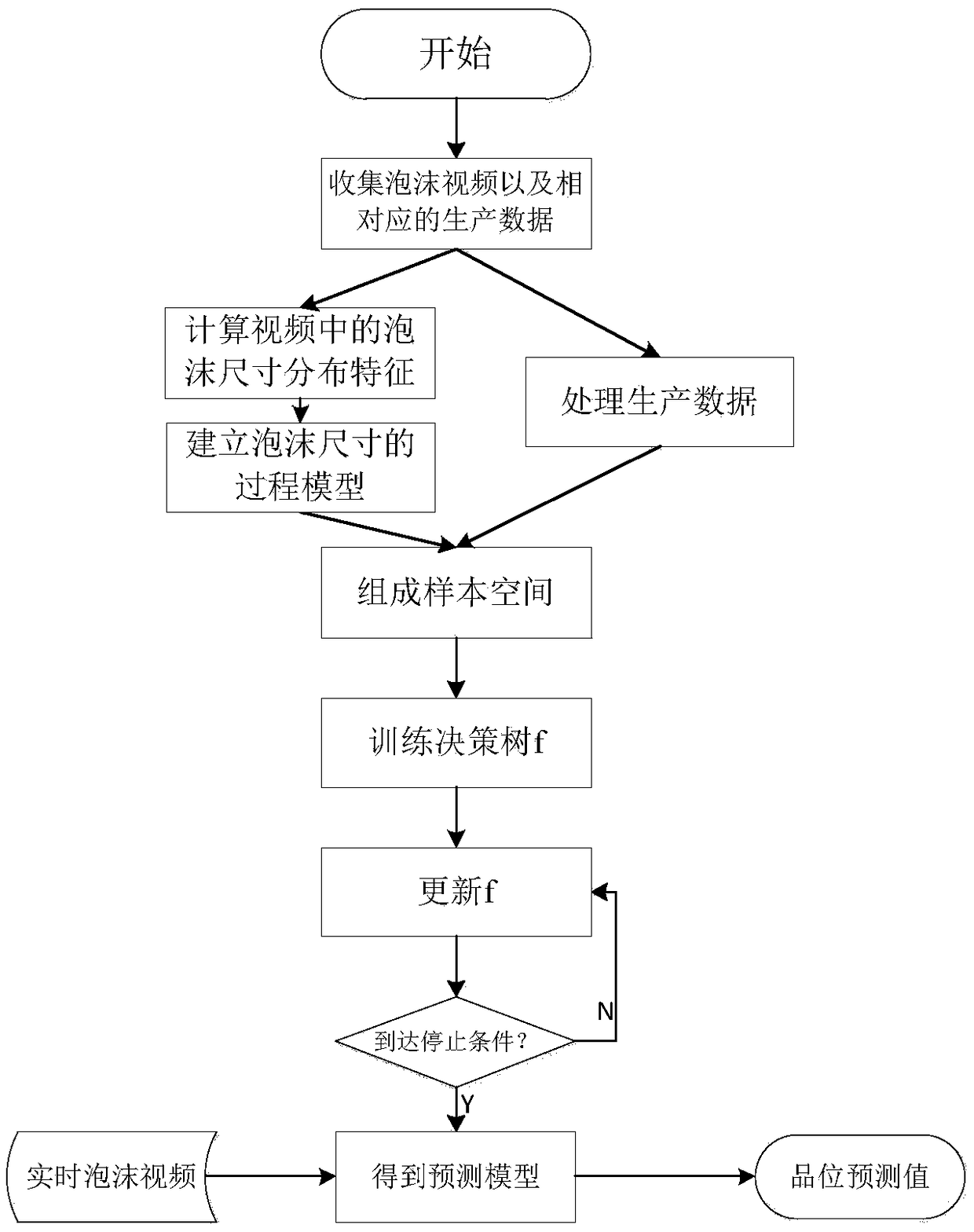

[0033] The following is a more detailed and clear description and explanation of the technical solution adopted in the present invention in conjunction with the accompanying drawings of the present invention. Aiming at the limitation that the traditional method cannot accurately reflect the foam state only by relying on a single frame picture, the invention proposes a time-related process size feature extraction method, and realizes the online detection of zinc concentrate grade by using an improved lifting decision tree model. Apparently, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those skilled in the relevant art without making creative efforts shall fall within the protection scope of the present invention.

[0034] Such as figure 1As shown, it is a flow chart of a soft-sensing method for lead-zinc ore grade based ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com