Rotary filtration method for sewage and filter used for sewage treatment

A filtration method and filter technology, which are applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. To solve problems such as large floor space, it can reduce the size and floor space of the equipment, enhance the pollution-holding capacity, and improve the overall efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

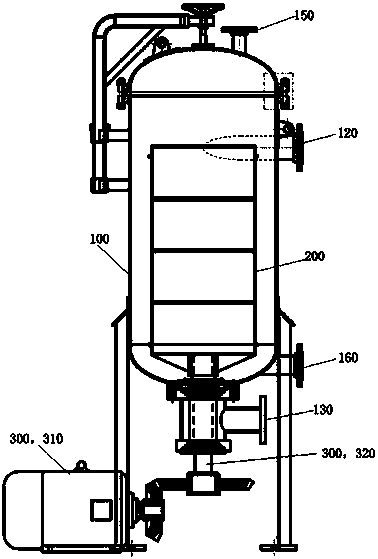

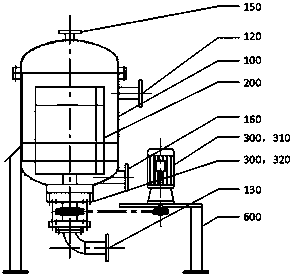

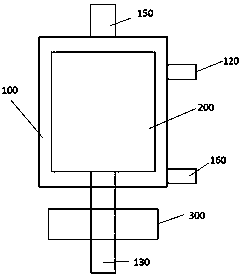

[0028] Such as Figure 1 to Figure 4 In the shown preferred embodiment of the filter for sewage treatment, it includes: a filter body 100, a rotary filter assembly 200, a rotary power unit 300, a water inlet 120 for the input of external sewage to be treated, and a water inlet for the discharge of treated sewage. the first discharge port 130; the rotary filter assembly 200 is arranged in the inner cavity of the filter body 100; the rotary power device 300 is connected with the rotary filter assembly 200 for driving the rotary filter assembly 200 Perform rotary filtration; the water inlet 120 is arranged on the side wall of the filter body 100, after the external sewage enters the filter body 100 through the water inlet 120, the sewage passes through the rotary filter assembly 200 under pressure For filtering, the dirt is blocked outside the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com