Application of water-soluble paper to argon arc welding of long-distance industrial pipeline intermediate joint collision port

A technology for intermediate joints and industrial pipelines, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of clogging small pipeline nozzles, excessive water-soluble paper, inconvenience, etc., to reduce engineering costs, ensure welding quality, and measure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

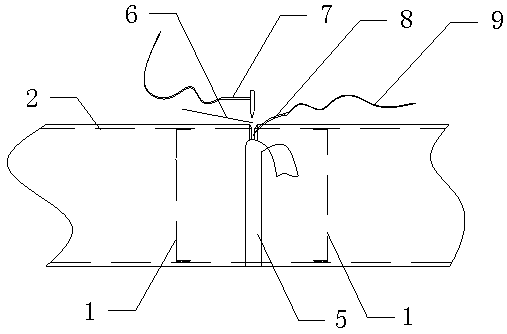

[0029] The application of the water-soluble paper of the present invention in the argon arc welding of the intermediate joints of long-distance industrial pipelines is not suitable for the welding of small-diameter pipelines of 1 inch and below. For the material of gas, after welding, flush the welded pipe with water or steam so that no water-soluble paper residue is left in the pipe, and the gas inside will disappear quickly. The specific method is as follows:

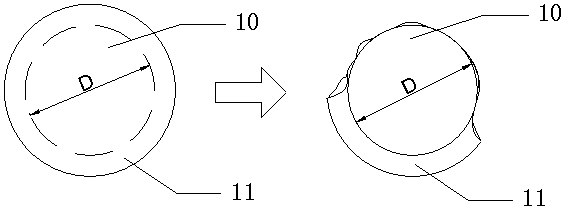

[0030] see now figure 1 , figure 1 It is a schematic diagram of the folding method of water-soluble paper. As shown in the figure, before the butt welding of the long-distance pipeline 2, prepare two pieces of water-soluble paper 1 with a diameter greater than 200 mm according to the pipe diameter, so that the water-soluble paper is folded into a water-soluble paper circle 10 and a water-soluble paper frill 11 part.

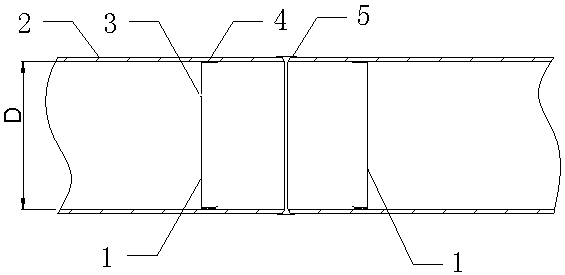

[0031] Before the pipes are aligned, use glue 4 to stick water-soluble paper 1 on the inside of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com