Underwater laser shock non-die incremental forming device and method

A progressive forming and underwater laser technology, applied in auxiliary devices, laser welding equipment, manufacturing tools, etc., can solve the problems of weakening of forming effect and reduction of shock wave pressure, so as to improve precision, controllability and high degree of automation , save the effect of coating the absorbing layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

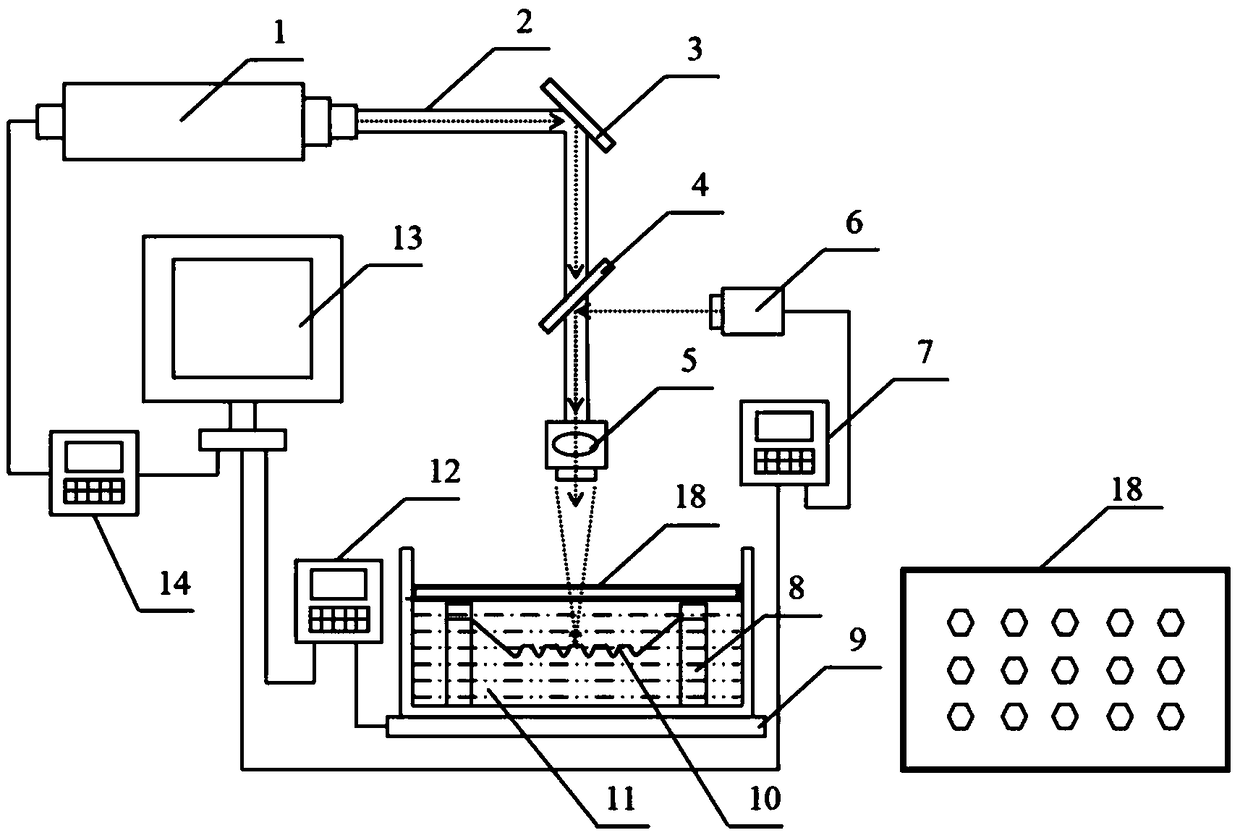

[0035] Such as figure 1 As shown, an underwater laser shock moldless progressive forming device according to the present invention includes a computer 13, a laser emitting system, a laser ranging system, and a workpiece carrying system.

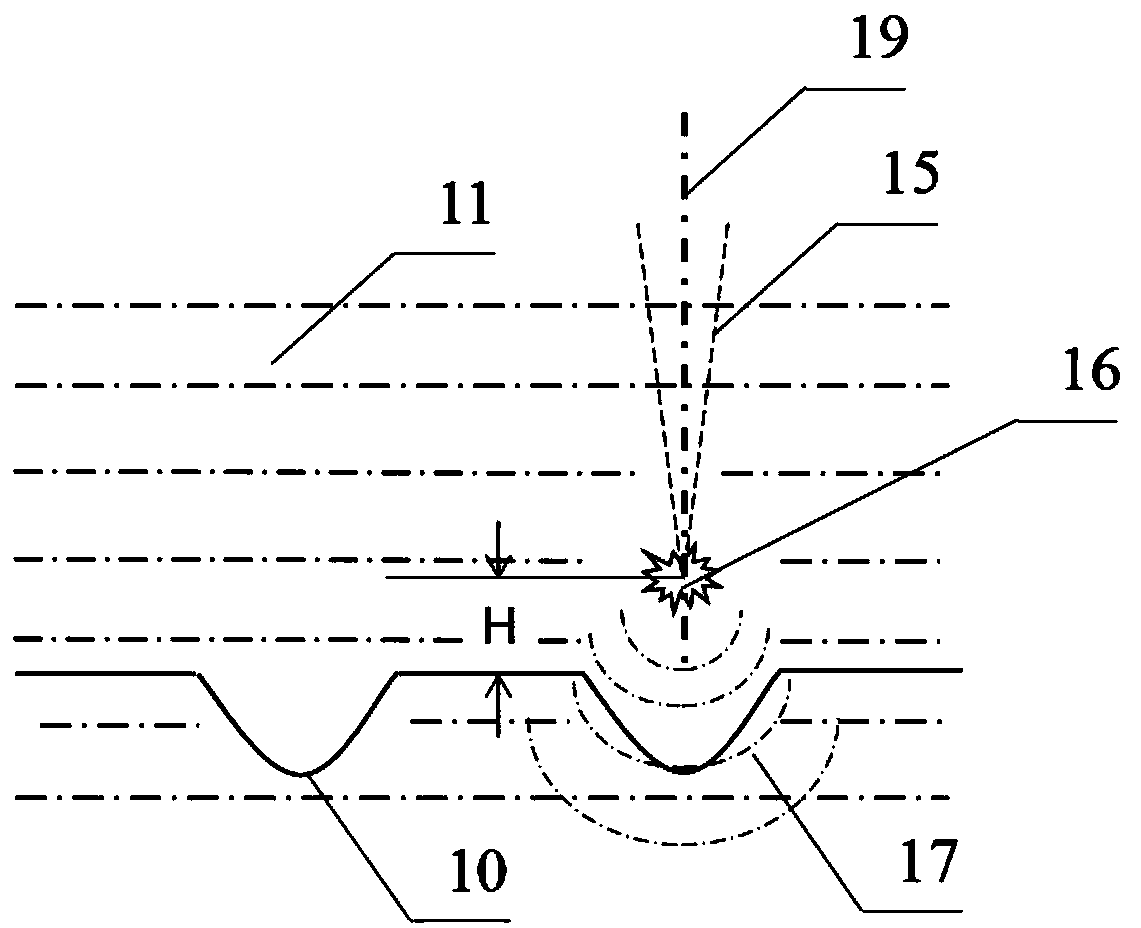

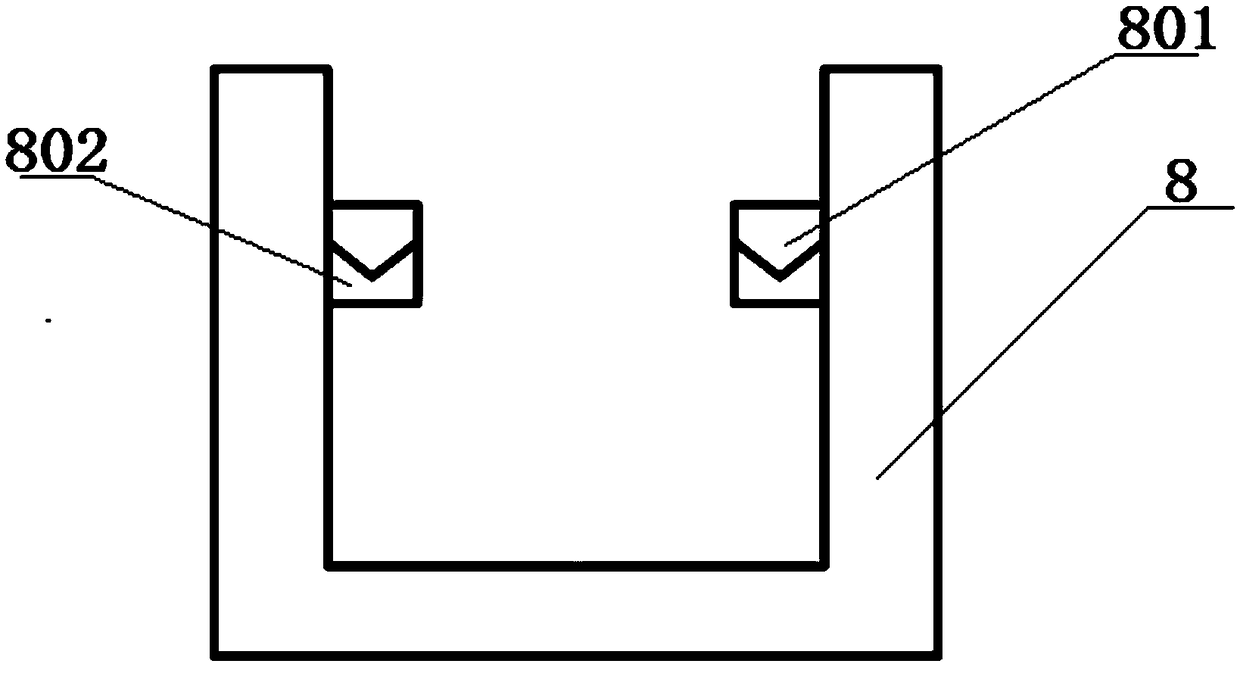

[0036] Such as figure 1 As shown, the workpiece carrying system includes a water tank 11 for holding water, a carrying fixture 8, a three-dimensional mobile platform 9, a plexiglass plate 18, and a three-dimensional mobile platform controller 12; the carrying fixture 8 is located in the water tank 11 and includes two support blocks, The two support blocks are provided with compression blocks, and the two ends of the workpiece 10 are respectively placed on the two support blocks, and are respectively pressed by the compression blocks, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com