Method for supplementing and applying oil to roller bearing automatically through industrial robot

A technology for industrial robots and roll bearings, which is applied to instruments, manipulators, manufacturing tools, etc., can solve the problems of manpower consumption, missed repairs, and mixed grease repairs, and achieve the effects of reducing waste, eliminating missed repairs, and improving serious oil pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

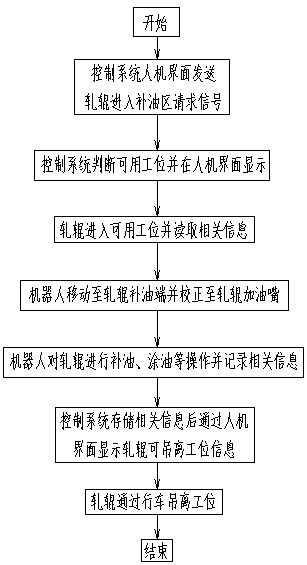

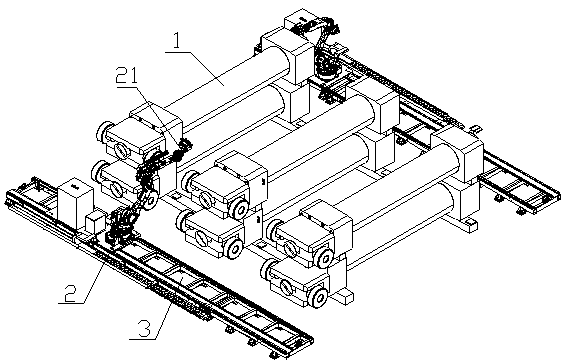

[0020] Example figure 1 , figure 2 and image 3 Shown, the present invention utilizes industrial robot to automatically replenish the oil and the method for oiling the roll bearing and comprise the steps:

[0021] Step 1. When the roll 1 enters the oil replenishment area, send an oil replenishment request signal through the man-machine interface of the control system, and the control system automatically judges the available stations and displays the available stations through the man-machine interface;

[0022] Step 2: Hoist the roll 1 into an available station by driving the crane. After the roll 1 is in place, the sensor sends the in-position information to the control system. The control system reads the RFID information of the roll through the RFID card reader, including the roll number and oil product configuration. information;

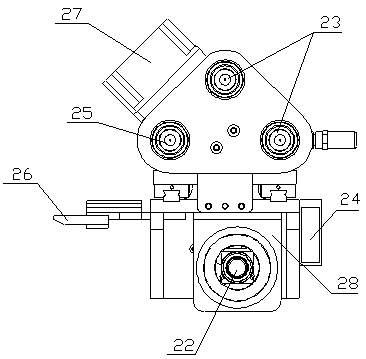

[0023] Step 3: The control system drives the robot 2 to move along the guide rail 3 to the oil supply end of the roll 1 through the servo ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com