Near-ultraviolet-excited double perovskite single-matrix white-light fluorescent material and its preparation and application

A technology of double perovskite and fluorescent materials, which is applied in the fields of luminescent materials, climate sustainability, semiconductor devices, etc., and can solve problems such as difficulty in ratio control, high correlated color temperature, and different degradation rates of phosphors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

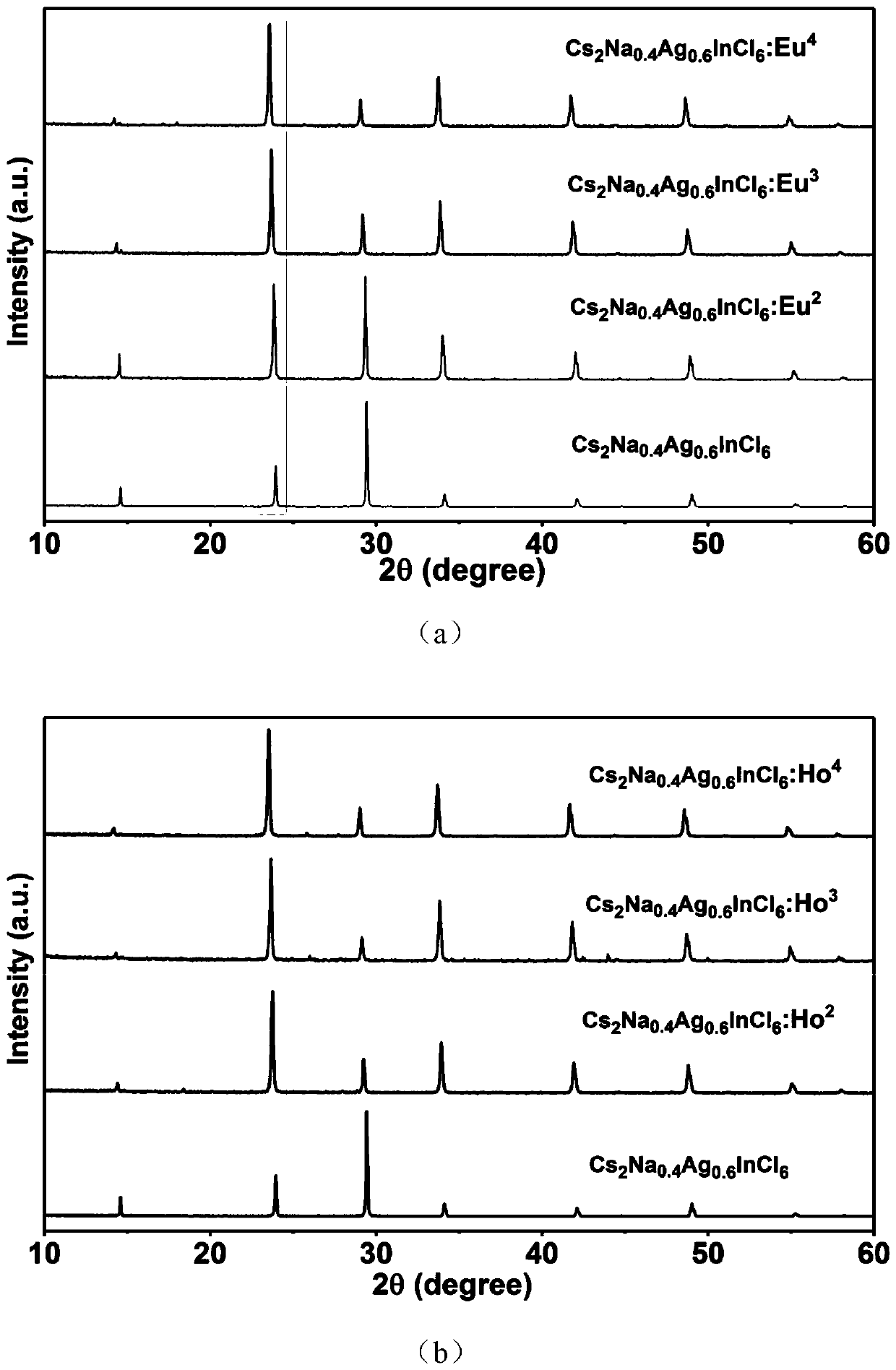

[0037] Cs 2 Na 0.4 Ag 0.6 InCl 6 Phosphor powder preparation.

[0038] The preparation method is as follows:

[0039] Weigh 2mmol of cesium chloride (CsCl), 0.6mmol of silver chloride (AgCl), 0.4mmol of sodium chloride (NaCl) and 1mmol of indium chloride (InCl) 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml hydrothermal kettle, and then 5ml of hydrochloric acid (36-38%) was added. The hydrothermal kettle was put into a muffle furnace and kept at 180°C for 10 hours, and then cooled to room temperature at a rate of 3°C / h. After cooling down to room temperature, the solid matter in the hydrothermal kettle was taken out and washed twice with ethanol. Put the rinsed solid matter into an oven and bake at 80° C. for 8 hours until completely dry. The dried solid was ground in an agate mortar.

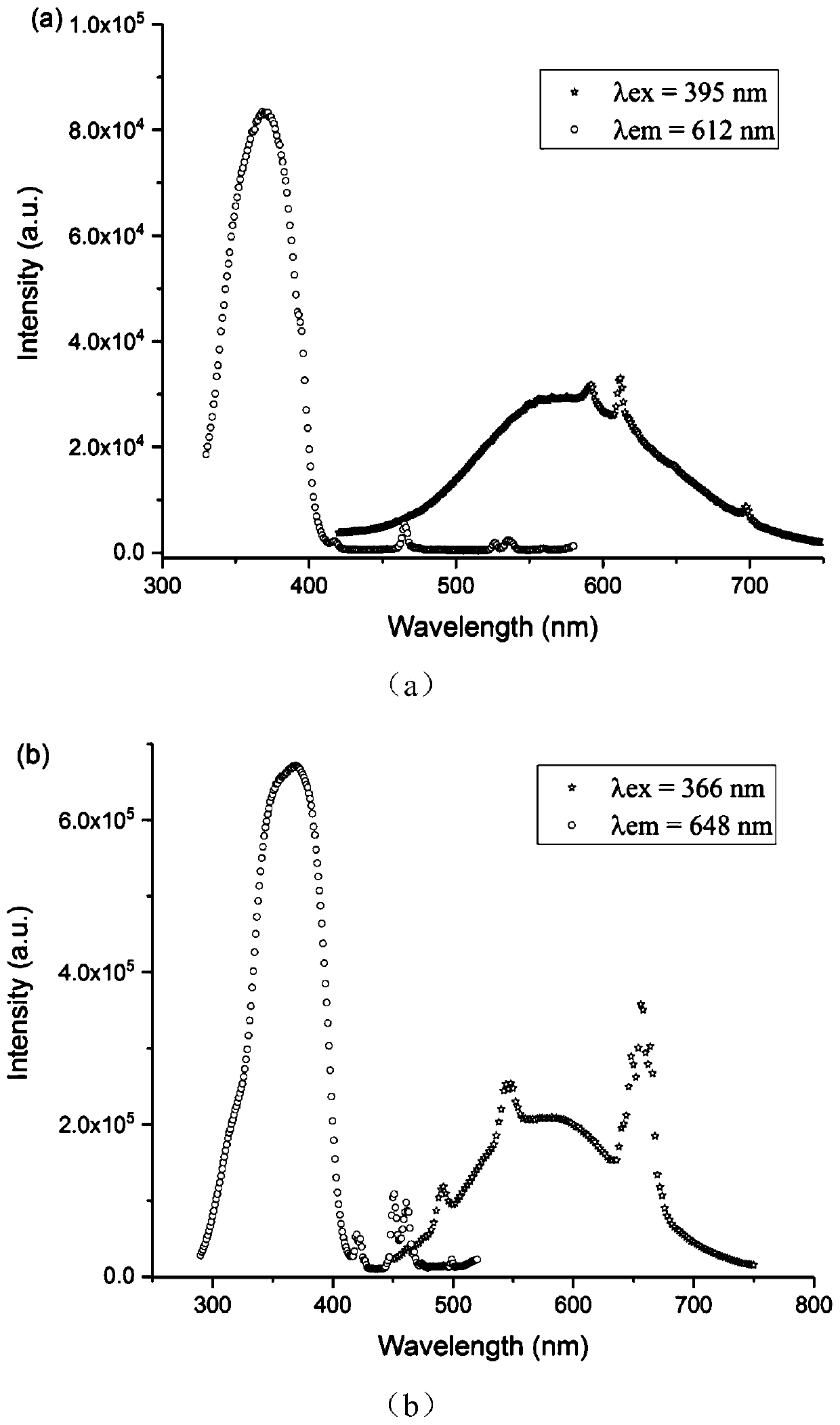

[0040] The emission wavelength of the rare earth ion-doped perovskite phosphor powder prepared in this...

Embodiment 2

[0042] Cs 2 Ag 0.6 Na 0.4 In 0.98 Eu 0.02 Cl 6 Phosphor powder preparation.

[0043] The preparation method is as follows:

[0044] Weigh respectively 2mmol cesium chloride (CsCl), 0.6mmol silver chloride (AgCl), 0.4mmol sodium chloride (NaCl), 0.98mmol indium chloride (InCl) 3 ) and 0.02mmol europium chloride (EuCl 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml hydrothermal kettle, and then 10ml of hydrochloric acid was added. The hydrothermal kettle was put into a muffle furnace and kept at 180°C for 12 hours, and then cooled to room temperature at a rate of 6°C / h. After cooling down to room temperature, the solid matter in the hydrothermal kettle was taken out and washed with ethanol for 3 times. Put the rinsed solid matter into an oven and bake at 80° C. for 10 hours until completely dry. The dried solid was ground in an agate mortar.

[0045] The emission wavelength of the rare e...

Embodiment 3

[0047] Cs 2 Ag 0.6 Na 0.4 In 0.9 Eu 0.1 Cl 6 Phosphor powder preparation.

[0048] The preparation method is as follows:

[0049] Weigh respectively 2mmol cesium chloride (CsCl), 0.6mmol silver chloride (AgCl), 0.4mmol sodium chloride (NaCl), 0.9mmol indium chloride (InCl) 3 ) and 0.1 mmol europium chloride (EuCl 3 ), the purity of the above raw materials is more than 99.9%. The weighed above-mentioned raw materials were poured into a 25ml hydrothermal kettle, and then 5ml of hydrochloric acid was added. Put the hydrothermal kettle into a muffle furnace and keep it at 170°C for 15 hours, and then lower it to room temperature at a rate of 15°C / h. After cooling down to room temperature, the solid matter in the hydrothermal kettle was taken out and washed 6 times with ethanol. Put the rinsed solid matter into an oven and bake at 80° C. for 20 hours until completely dry. The dried solid was ground in an agate mortar.

[0050] The emission wavelength of the rare earth i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com