Beer fermentation equipment convenient to clean

A beer fermentation and convenient technology, applied in beer fermentation methods, beer brewing, biochemical equipment and methods, etc., can solve the problems of insufficient contact, uneven mixing of materials, poor mixing uniformity, etc. Quality, easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

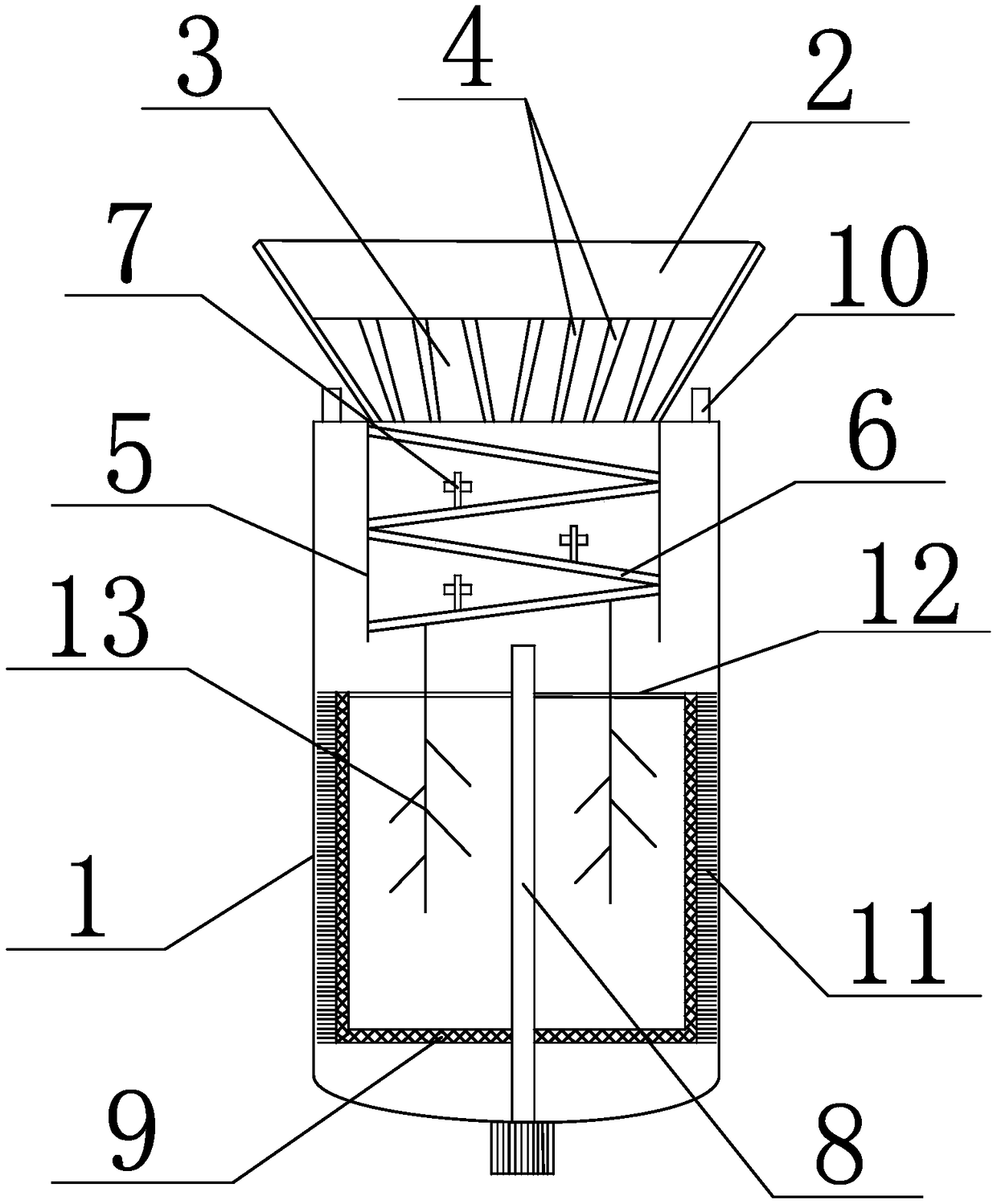

[0021] Such as figure 1 As shown, a kind of convenient cleaning beer fermentation equipment of the present invention comprises a fermenting barrel body 1, a feed inlet is provided above the top of the fermentation barrel body 1, and a liquid inlet 10 is respectively arranged on both sides of the feed inlet, and a feed inlet There is a feed hopper 2 connected to the feed hopper 2, which is provided with a diverter table 3 that fits with the inner wall of the feed hopper 2. The diverter table 3 is provided with a plurality of diverter holes 4 that run through the top and bottom surfaces of the diverter table 3. The feed port The bottom is connected with a mixing cylinder 5, and the inner wall of the mixing cylinder 5 is provided with a spiral mixing plate 6; The motor, the side wall of the stirring shaft 8 is connected with a fermented material frame 9 with a top opening, the side wall and the bottom surface of the fermented material frame 9 are grid structures, the bottom openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com