Preparation method and application of micro-needle-shaped solid-phase surface-enhanced Raman substrate

A solid-phase surface and Raman substrate technology, applied in the field of analytical chemistry, can solve the problems of low sensitivity, poor qualitative analysis ability, poor stability, etc., and achieve the effects of high sensitivity, small target damage and small sample volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

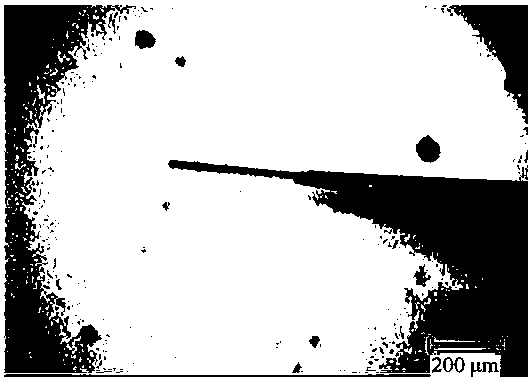

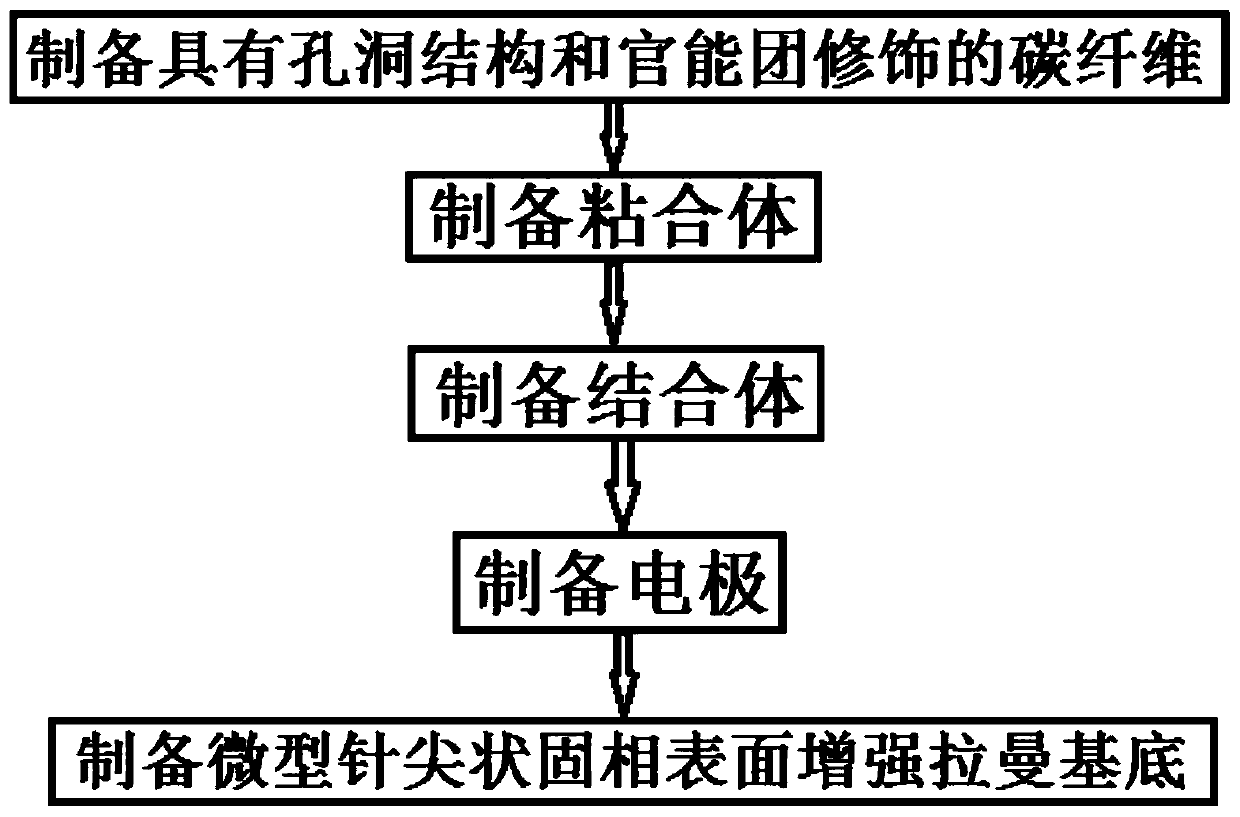

[0040]A preparation method of a microneedle-shaped solid-phase surface-enhanced Raman substrate, comprising the following steps (see figure 1 ):

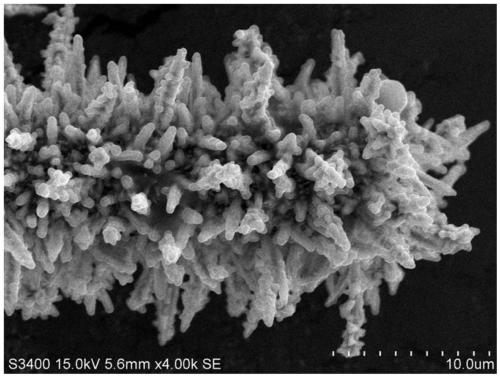

[0041] (1) Preparation of carbon fibers with pore structure and functional group modification

[0042] Select 10 carbon fibers with a length of 2 cm and a diameter of 5 μm, first ultrasonically clean them in 8M potassium hydroxide (KOH) solution for 4 hours, then ultrasonically clean them with 8M hydrochloric acid and water until neutral; Potassium oxide and water were ultrasonically cleaned to neutrality to obtain activated carbon fibers with a pore structure and functional group modification.

[0043] (2) Preparation of bonded body

[0044] Select a carbon fiber obtained in step (1) with a pore structure and functional group modification, and bond it to a silver wire with conductive glue, so that one end is a silver wire and the other end is a carbon fiber to obtain a bonded body.

[0045] (3) Preparation of conjugates

[0046...

Embodiment 2

[0058] A method for preparing a microneedle-shaped solid-phase surface-enhanced Raman substrate, comprising the following steps:

[0059] (1) Preparation of carbon fibers with pore structure and functional group modification

[0060] Select 10 carbon fibers with a length of 3 cm and a diameter of 10 μm, first ultrasonically clean them in 10M potassium hydroxide (KOH) solution for 6 hours, then ultrasonically clean them with 6M hydrochloric acid and water until neutral; Potassium oxide and water were ultrasonically cleaned to neutrality to obtain activated carbon fibers with a pore structure and functional group modification.

[0061] (2) Preparation of bonded body (same as Example 1).

[0062] (3) Preparation of conjugates

[0063] Then insert the bonded body obtained in step (2) into a glass tube with a length of 15 cm and an inner diameter of 1 mm, expose the silver wire end by 5 cm, and the carbon fiber end by 1 cm; The interface was sealed with paraffin paste in a 90°C ...

Embodiment 3

[0075] A method for preparing a microneedle-shaped solid-phase surface-enhanced Raman substrate, comprising the following steps:

[0076] (1) Preparation of carbon fibers with pore structure and functional group modification

[0077] Select 10 carbon fibers with a length of 3 cm and a diameter of 7 μm, and first ultrasonically clean them in 9M potassium hydroxide (KOH) solution for 5 hours, then ultrasonically clean them with 7M hydrochloric acid and water until neutral; Potassium oxide and water were ultrasonically cleaned to neutrality to obtain activated carbon fibers with a pore structure and functional group modification.

[0078] (2) Preparation of bonded body (same as Example 1).

[0079] (3) Preparation of conjugates

[0080] Then insert the bonded body obtained in step (2) into a glass tube with a length of 12cm and an inner diameter of 0.8mm, expose the silver wire end by 4cm, and the carbon fiber end by 8mm; The interface of the glass tube was sealed with paraffi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com