Photocatalyst auxiliary agent, and method and equipment for manufacturing photocatalyst cloth

A technology for manufacturing equipment and manufacturing methods, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing, etc., can solve the problems of limited fabric comfort, insufficient anti-fouling ability, and high formaldehyde content, and achieve anti-fouling ability. Strong, flexible adjustment of time, the effect of improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A photocatalyst auxiliary agent is prepared by mixing the following materials by weight: 300 parts of photocatalyst, 800 parts of water, 15 parts of binder and 8 parts of anti-emulsifier.

Embodiment 2

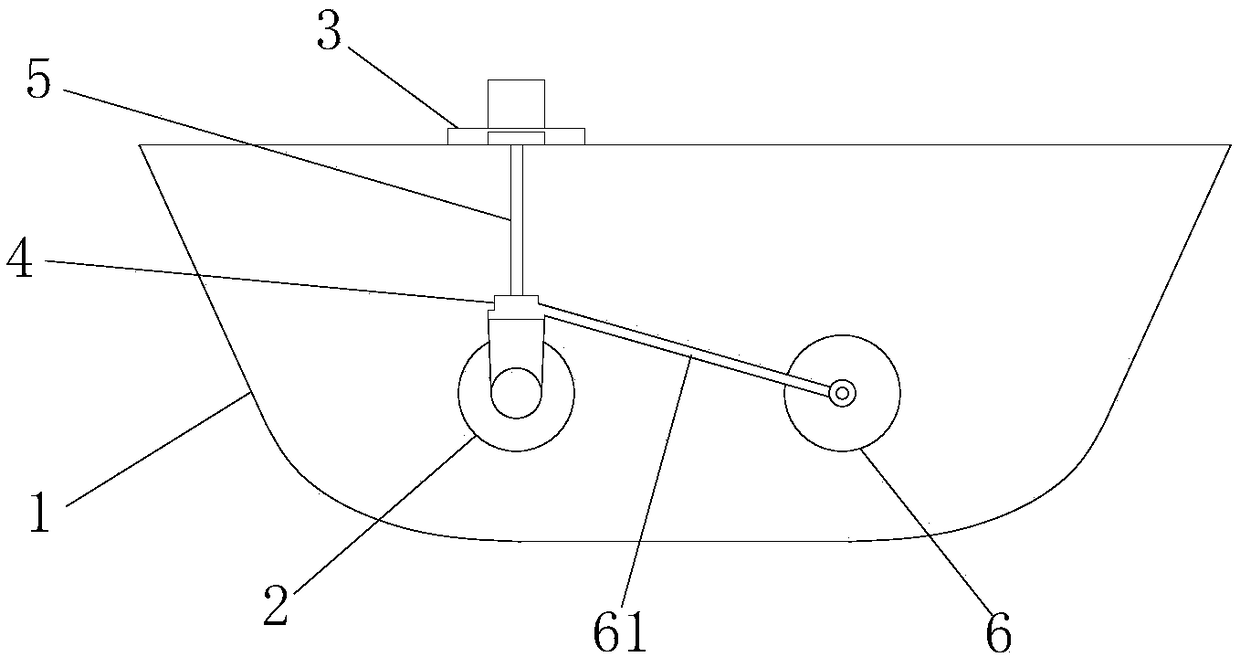

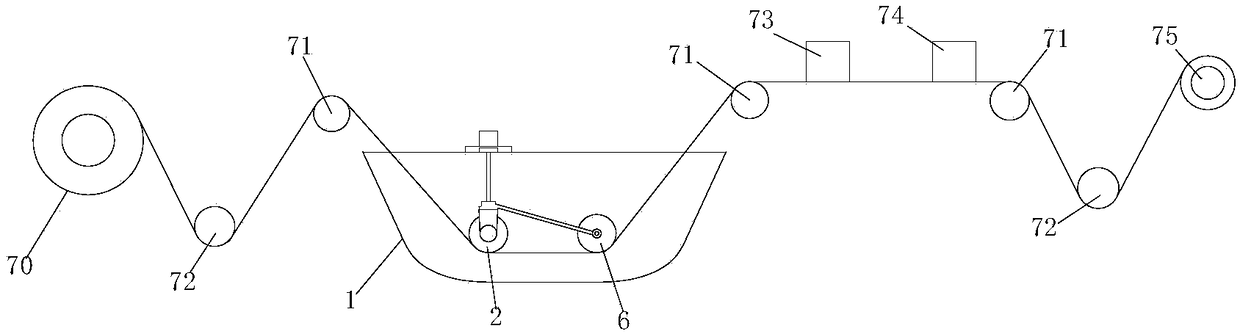

[0023] Such as figure 1 , 2 Shown is a photocatalyst auxiliary agent, which is made by mixing the following materials by weight: 50 parts of photocatalyst, 1000 parts of water, 20 parts of binder, and 5 parts of anti-emulsifier.

[0024] Experimental data

[0025] Adopt three parts of equal colored cloth fabrics, wherein adopt the photocatalyst auxiliary agent in embodiment 1 and embodiment 2 to carry out coating to two parts of colored cloth fabric outer surfaces respectively, be respectively embodiment 1 group, embodiment 2 groups, former cloth fabric As the control group; the detection structure is as follows:

[0026]

Formaldehyde (mg / kg)

temperature(℃)

Example 1 group

68

25

Example 2 group

19

25

control group

279

25

[0027] From the experimental structure, it can be concluded that the photocatalyst auxiliary agent equipped in Examples 1 and 2 can effectively reduce or even eliminate the residual pollution t...

Embodiment 3

[0031] A method for manufacturing photocatalyst cloth, comprising the following steps: 1) Stir the photocatalyst auxiliary agent prepared in any one of Examples 1-2 evenly to obtain a uniform auxiliary agent; Dip dyeing; 3) Stretch and level the cloth; 4) Dry and sterilize the cloth; 5) Treat the cloth with high temperature.

[0032] Preferably, the temperature of the high-temperature drying cloth in step 4) is 120°C-150°C.

[0033] The method has reasonable steps and high production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com